Metal Samples MS1000 User manual

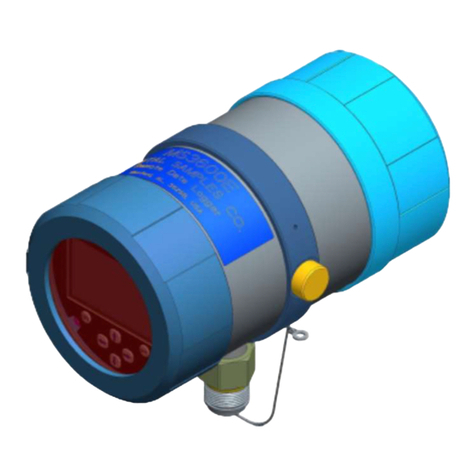

MS1000

Corrosion Meter

Owner’s Manual

Metal Samples

A Division of Alabama Specialty Products, Inc.

152 Metal Samples Rd., Munford, AL 36268

Phone: (256) 358-4202 Fax: (256) 358-4515

Table of Contents

I. Introduction .....................................................................1

A. Background ...................................................................1

B. InstrumentCapabilities ...................................................2

C. ApplicationsfortheMS1000 .........................................6

II. MS1000Specifications and Features ..............................7

III. MS1000Operation ...........................................................9

A. Test Readings ................................................................9

B. DataAcquisition .............................................................9

1. InstantaneousCorrosionRateMeasurements ............9

2. ZRAandEPRMeasurements .................................10

C. Electrode Installation, ReplacementandCare ...............10

D. CorrectingforLowSolutionConductivity Effects.......... 11

IV. UNSConstantTable.......................................................14

V. Maintenance ...................................................................16

VI. Troubleshooting ..............................................................16

VII. ReplacementParts .........................................................18

VIII.Warranty ........................................................................20

IX. References......................................................................21

MS1000 manual - rev. 15.12

I. Introduction

A. Background

TheMS1000isaportable,hand-held,battery-poweredcorrosion

meter. Thisversatileinstrumentmeasurestheinstantaneouscorrosion

ratewiththe LinearPolarizationResistance(LPR) technique. Italso

measuresthecurrentflowingbetweenelectrodes intheshort-circuited

conditionwithahighprecisionzeroresistanceammeter(ZRA). The

MS1000cananalyze two-electrodelinearpolarizationresistanceor

galvanictypeprobes.

Theprincipleuse ofthisinstrument istomeasurecorrosion ratesunder

variousconditionsintheplant,field,orlab.Inadditiontousingthis

instrumenttomonitor corrosionrates,corrosionengineers canalsouse

theMS1000to monitorinhibitoreffectiveness, identityprocessupsets,

identifylocalizedcorrosionevents,andevaluatecorrectiveactionsin

realtime. Thesemeasurements areveryimportantsince achangeinthe

processconditionscanleadto dramatic changes intheobserved

corrosionrate.

1

B. Instrument Capabilities

Instantaneous Corrosion Rate Measurements

Instantaneouscorrosionrate measurementsaremade withthelinear

polarizationresistance(LPR)technique. Thistechnique isareliable

electrochemicalprocedurebased onprinciplesoutlinedinASTMG59

StandardPracticeforConductingPotentiodynamicPolarizationResis-

tanceMeasurements.1Anexcellenttechnicalreviewofthistechniqueis

givenelsewherebyMansfeld.2,3

Thedeterminationof a corrosionratefromthe parameters measured

withcorrosionprobesdependsonFaraday’slaw. Themassloss,

current,potential,andchanges inthesevariablesareconverted intoa

corrosionrate. ASTMG102StandardPractice for Calculation of

CorrosionRatesandRelatedInformationfrom ElectrochemicalMea-

surementsprovides allnecessaryinformationforthe directcalculationof

thecorrosionrate.4

ThemethodusedbytheMS1000 for calculating the corrosionrateisas

follows. Alow amplitudedcvoltageisapplied across theelectrodes

andthenthe resultingcurrent,normalized tocurrentdensity, ismea-

sured. Thevoltageis heldconstantforthirty secondsbeforemeasuring

thecurrent sothat anycapacitanceinthe oxidelayerwillbe fully

charged. Thepolarityofthe applied voltage isthenchangedandthe

measurementcycleis repeated. Polarityisreversedto minimizepoten-

tialerrorsdue topossibleelectrodedissimilaritiesorchangesin the

opencircuitpotentialoftheelectrodesduringthemeasurement.

Thepolarizationresistance,Rp, ofthecorrodingelectrodes is calcu-

latedfromtheslope of thepotential-currentdensityplot. Rpisdefined

as:

Rp=E

i

2

where Eis thepolarizationfrom theopencircuitpotential ofthe

electrodesandiisthemeasuredcurrentdensityat E.Sternand

Gearyshowedthat thereisalinear relationship betweenpotentialand

appliedcurrentatpotentialsonlyslightlyremovedfromthecorrosion

potential.1Basedonthe kineticsofelectrochemicalreactions and

conceptsofmixedpotentialtheory,asdiscussed byWagnerandTraud,

anequationwas derivedwhichrelatedthe polarizationresistancetothe

corrosioncurrentdensity,icorr.6Thecorrosion currentdensityiscalcu-

latedas:

whereßaandßc aretheanodicandcathodicTafelconstants (ie., the

slopesofthe anodicandcathodicpolarization curvesintheTafel

region).

The instantaneouscorrosionrate inmilsperyear (mpy)isdetermined

fromicorr withthefollowingequation:

icorr =2.303Rp(ßa+ ßc)

ßaßc

whereEWis theequivalentweight, Kisaconstant forunitsconversion,

and isthedensity. Theequivalentweightdepends upon the composi-

tionofthealloy. Guidelinesfordeterminingtheequivalentweightare

giveninASTMG102.4

Notethatthis instrument hasbeendesignedto calculatethecorrosion

rateofcarbonsteel and commongradesofstainlesssteel in milsper

year. Inother words, the programmedvaluesoftheTafelslopes,

equivalentweight,anddensityaretypical forcarbonsteelandcommon

gradesofstainlesssteel. Multiplicationfactorsfor copper,admiralty

brass,andleadare includedonthefrontpanel of theinstrument.

COR(mpy) =icorr • EW • K

3

Theinstrumentisprogrammedforelectrodeswithsurfaceareas offive

cm2. Multiplicationfactorsarealsoincludedforflushmountelectrodes

withsurfaceareasof0.5cm2.

Zero Resistance Ammeter (ZRA) and Equivalent Pitting Rate

Ahighprecisionzeroresistanceammeterisusedformonitoring the

short-circuitcurrentbetweenelectrodes. Thistotalcurrent flowing

betweentheelectrodes intheshort-circuitedcondition ismonitored.

Thecurrentis displayedinmicroamps. Thezero resistanceammeter

(ZRA)functionmayalsobeusedtomonitorthe galvaniccurrent

betweenelectrodesof differentalloysorthe areaeffectofgalvanic

corrosion.

Generally,ifthemagnitudeoftheZRAreading dividedby2islessthan

thecorrosionrate, then pittingmaybeoccurring but thepitswillprob-

ablybeshallow andwide;however,pittingmaybe aseriousconcernif

theZRA/2 isgreaterthanthecorrosionrate.

Faraday’slaw may be used tocalculatethemassofmateriallostasa

resultof thelocalizedcorrosionasfollows:

W=[( ZRA)/n] • t • EW

F

whereWisthemassofthecorrodedmetal in grams, ( ZRA)/nis the

time-integratedZRAdivided by n,thenumber ofdaysofexposure,tis

thetime thecurrentisflowingin seconds,EWistheequivalentweight

aspreviouslydefined,andF istheFaraday constant, 96480Coulombs/

mol. Themassofthecorrodedmaterialmaybeusedto calculate a

4

corrosionrate,designatedasthe equivalent pitting rate, basedonthe

ZRA. Thisequivalentpittingrateisdefinedas:

whereEPRisthe equivalentpittingrateinmpy,K’isa constantfor

unitsconversion,Aisthe surface areaincm2, Wis the masslossin

grams, tisthetimeofexposureinseconds,and isthedensity of the

alloyingrams/cm3.

Additionaltechnicalinformationonthisinstrumenthasbeenpublishedin

theProceedingsofthe1994 InternationalWaterConference.7

EPR =K’ • W

A • t •

5

C. ApplicationsfortheMS1000

• Measuretheinstantaneous corrosionrateinaqueous solutions.

Forexample,thecontent anddosageofinhibitorsin water

treatmentfacilitiesandchemicalprocessplantscanbemonitored

andoptimized.

• Monitorthe actuallifetimeofplantequipment.Corrosion

monitoringprovidesdatathatmaybe combinedwithother forms

ofdatatoestimatethelifetimeofequipmentintheplant.

• Detectionoflocalizedcorrosion due toprocessconditionsor

upsets.

• Evaluatealternatematerials foraspecificpurpose. Optionfor

otheralloys,heat treatments,orfinishesmay beevaluatedand

comparedtotheperformance ofthespecificalloyconsidered.

• Analyzegalvanic probesandmeasurethegalvaniccurrent

betweenelectrodes. Areaeffects ingalvaniccorrosioncanalso

beinvestigated.

6

Model

MS1000 - LPR Corrosion Meter (Ordering # IN1000)

PhysicalData

InstrumentWeight: 0.84 lb. (0.38 Kg)

TotalWeight w/CarryingCase

andAccessories: 5.20lb.(2.36Kg)Instrument

Dimensions: 7.63"H x 4.15"W x 1.3"D

(19.38cmx10.54cm x 3.30cm)

CarryingCaseDimensions: 10"H x 11.75"W x 5.4"D

(25.40cmx 29.85cm x 13.72cm)

OperatingTemperature: 32° to 122°F (0° to 50°C)

StorageTemperature: -4° to 158°F (-20° to 70°C)

PerformanceData

MeasurementType: 2-ElectrodeLPR,Galvanic

Range: 2-Electrode: 0-40mpy

Galvanic: 0-80µA

Resolution: 2-Electrode: 0.02mpy

Galvanic: 0.04µA

CycleTime: CorrosionRate: 60sec

ZRA: 30 sec

ElectricalData

PowerRequirements: One 9V RechargeableBattery

MaximumProbe CableDistance: 2000 ft (609.6 m)

C. MS1000 Specifications and Features

7

Special Features

• Microprocessor-basedelectronics

•Functionkeyinterface using4-keykeypadand4-line LCDdisplay

• Low-batterydetection

• Portable

Accessory Items

CarryingCase, 10' ProbeCable, Battery Charger, Lightweight

Protective Case, Meter Prover, Operation Manual

8

III. MS1000Operation

A. Test Readings

TheMS1000issuppliedwitha test probe to checkproperfunctioning

ofthecableandinstrument. Inorder to guarantee the accuracy ofyour

data,checktheinstrument readings atroomtemperaturewiththe test

probepriorto taking measurements.

Thetestprobe is usedtoverifycorrect instrumentoperationasfollows:

1. Insert test probe into cable.

2. Press ON.

3. Press COR tomeasuretheinstantaneouscorrosionrate.After

60secondsthedisplay should read:

CORROSION RATE = 5.00 ± 0.05 mpy

4. PressZRAto measure the current imbalance. After 30seconds

thedisplayshouldread:

ZRA = 0.00 ± 0.12 µA

B. Data Acquisition

1. Instantaneous Corrosion Rate Measurements

Corrosionratemeasurements maybecollectedas follows:

a. Connecttheinstrumentcabletothedesiredprobe.

b. Press ON to turn the MS1000 on.

c. Press CORtomeasuretheinstantaneouscorrosionrate.

d. A short beep willsoundafter60secondstoindicatethat the

measurementiscompleteandthemeasured corrosionratewill

bedisplayedonthescreen.

e. The measuredrateiscalculatedforcarbon steel. If another

9

electrodematerialwasused,theresult shouldbemultipliedby

theappropriatealloymultiplier. Fourcommonalloysarelisted

ontheMS1000keypad.Amorecomprehensive list is

providedon page 14.

2. ZRAand EPRMeasurements

Electrochemicalcurrentnoiseandequivalentpittingratemeasurements

maybecollectedasfollows:

a. Connect theinstrumentcabletothedesiredprobe.

b. Press ON to turn the MS1000 on.

c. Press ZRAtomeasurethecurrent imbalancebetweenthe

electrodes.

d. A short beep willsoundafter30secondstoindicatethat the

measurementiscompleteandthemeasuredZRAandEPR will

bedisplayedonthescreen.

C. Electrode Installation, Replacement, and Care

Theelectrodessuppliedfrom MetalSampleshavea600grit (ground)

surfacefinish. Theelectrodes are alsodegreasedandshipped in volatile

corrosioninhibitor(vci)bagsfor protection. Additionalcleaningofthe

elementspriortouseis not required. However,itisrecommendedthat

theelectrodesbepretreatedinthetestsolution of interest in order to

bringtheelectrode surfacestoequilibrium. Pretreatmentmaybe

conductedin afullstrengthmixtureofthesolutioninthesystem. Typical

pretreatmenttimesareatleast24 hours.

Theresultingdata generatedfromthe pretreatedelectrodeswillindicate

thecorrosiontrendsofthesystemmuchmore rapidly,usuallywithina

day, as opposed to as much as a week for untreated electrodes.

10

Newelectrodesare1.250"(31.75mm)inlengthand0.188"(4.76mm)

indiameter. Ascorrosionoccurs,theelectrodediameterdecreases. As

aresult,theelectrodesurfaceareadecreasesandthedistancebetween

theelectrodesincreases. These two factors are sources of error and

maydiminishthe accuracyofthemeasuredcorrosion rate. Therefore,it

isrecommendedthatthe electrodes bereplacedwhentheirdiameter

has decreased by 17%. In other words, the electrodes should be

replacedwhentheirdiameterhasdecreasedto0.156"(3.97mm).

Ifthe probe and electrodes are tobemoved,or if the electrodes

becomefouledwith corrosionproductsorsystemcontaminants,

removetheelectrodesfrom the probeandpolishthemto a dullshine

withwet600grit abrasive paper. Afterpolishing, rinse anddegrease

theelectrodespriortoreinstallation.

Note:Whenhandling electrodes, usecleanlatexgloves and paper

towels. Thiswillkeeptheelectrodesclean andfreefromcontaminating

oilydeposits.

D. Correcting for Low Solution Conductivity Effects

Lowsolution conductivityeffectsincreasetheapparentpolarization

resistance,thusyieldinganunderestimationof thecorrosionrate. The

effectofsolutionresistance isafunctionof thecellgeometry. Sincethe

cellgeometry(inthiscase,the electrodeconfigurationof thecorrosion

probe)remainsconstant, analyticalcorrectionmaybeperformed to

compensateforthis apparentincreaseinthepolarizationresistance.

Thefollowingequationmaybe usedtoapproximate themagnitudeof

thiseffect.

Rp= Ra-

whereRpis thetruepolarizationresistance,Rais theapparentpolariza-

tionresistanceasmeasured by theinstrument,listhe distance between

l

11

thetwoelectrodes incm,and isthesolutionconductivityinohms-1/

cm. Specificguidelinesforthiscorrectiontechniquearedetailedin

ASTM G102.4

Theaboveequation has beenusedtoanalyticallyderive acorrection

curveforlow solutionconductivityeffects. Thecurve is plottedasa

functionofthe corrosion rate,asmeasuredby the instrument,andthe

solutionconductivity. Thiscorrectioncurveisgivenin Figure3.

CorrosionRate(mpy) /SolutionConductivity (µmhos/cm)

Figure3-Multipliers for IRcorrection.

12

Anexampleofhow tousethecorrectioncurveis givenbelow.

Ifthe

Corrosion Rate (Instrument Reading) = 1.00 mpy

Solution Conductivity = 100 µmhos/cm

andthe

thenthevalueon the x-axis ofthegraphmaybecalculated as

10 -2

=

Corrosion Rate (mpy)

Solution Conductivity (µmhos/cm)

Referringtofigure3,avalueof10-2 onthex-axiscorrespondstoa

multiplierof1.3.

Therefore,thecorrosionrate, as corrected for IR drop in the electro-

lyte,istheproductof 1.3 and the measured corrosion rate. In other

words,

Corrected Corrosion Rate = 1.3 • 1.00 = 1.30 mpy

13

IV.UNSConstantTable

Thefollowinglistsmanyofthecommonconstructionalmetals/alloys

withtheirappropriatealloyconstants.

Alloy Alternate Major Constituents

UNS# Const. Designation (or common names)

F12101 1.0 - Gray Cast Iron

F13502 1.0 - Gray Cast Iron

G10100 1.0 AISI 1010 0.1% Carbon Steel

G10180 1.0 AISI 1018 0.18%Carbon Steel

G10200 1.0 AISI 1020 0.20%Carbon Steel

K03504 1.0 ASTMA105 0.35% Carbon Steel

K03006 1.0 ASTMA106 0.3% Carbon Steel

K02504 1.0 ASTMA53 0.25% Carbon Steel

K03011 1.0 ASTMA350LF2 0.3% Carbon Steel

K01800 1.0 ASTMA516 0.18% Carbon Steel

G41300 1.0 AISI 4130 1% Cr 0.2% Mo Steel

K41545 1.0 ASTMA199 5% Cr 0.5%Mo.Steel

S50400 1.0 ASTMA199 (T9) 9% Cr 1.0%Mo.Steel

S30400 1.0 AISI304 18%Cr 8%NiS.S.

S30403 1.0 AISI304L 18%Cr8% Ni (Low Carbon) S.S.

S31600 1.0 AISI316 18/Cr10/Ni/3/MoS.S.

S31603 1.0 AISI316L (LowCarbon)S.S.

S32100 1.0 AISI 321 Ti Stabilized 18/8 S.S.

S41000 1.0 AISI410 12%Cr.S.S.

S43000 1.0 AISI430 17%Cr.S.S.

S31200 1.0 ASTMA182 26Cr6NiDuplexSS

S31803 1.0 ASTMA276 22Cr5Ni3Mo.DuplexS.S.

C11000 2.0 AMS4500 99.90Copper

C26000 1.8 AMS4505 70-30Brass

C28000 1.8 ASMESB111 Muntz Metal (60% Cu)

14

Alloy Alternate Major Constituents

UNS# Const. Designation (or common names)

C23000 1.9 ASMEB16.22 85-15Brass

C63000 1.9 AMS4640 AluminumBronze

C68700 1.9 ASMESB111 Aluminum Brass (Arsenical)

C44300 1.8 ASMEB111 Admiralty Brass

C70690 1.9 ASTMF96 90-10CopperNickel

C71590 1.6 ASTMF96 70-30CopperNickel

N04400 1.2 AMS4544 Monel 400

N08825 1.0 ASMEB163 Incoloy 825

N06600 1.0 AMS5540 Inconel 600

N06625 1.0 AMS5401 Inconel 625

N10001 1.0 AMS5396 Hastelloy B

N10002 1.0 AMS5388 Hastelloy C

N10276 1.0 ASMEB366 HastelloyC-276

N02201 0.9 AMS5553 Nickel201

N08904 1.0 ASMEB625 23-1-4-25Cr-Cu-Mo-Ni

Z13001 1.3 ASTMB6 99.990 Zinc

R05200 0.6 ASTMB364/365 Tantalum

R50250 0.7 ASTMF67 Titanium

R60701 1.0 ASTMB493 Zirconium

A96061 0.9 AA6061 Aluminum

15

V. Maintenance

Theonlymaintenance itemintheMS1000 isthe9volt rechargeable

battery. Abatterychargerisincludedwiththeinstrumenttofacilitate

recharging. Thebatterywillrechargetofull capacityinafewhours.

TheLEDindicator onthebatterycharger willturnredwhile thebattery

ischarging,andwillturn greenwhenthe batteryisfully charged.Over

timetherechargeable batterymayrequirereplacement.It shouldbe

replacedwitharechargeablebatteryofthesame type.Alternately, a

standardalkalinebatterycan beinstalled,butyoushouldNOT attempt

torechargeit.Attempting to rechargeanalkaline batterymaycauseitto

leakandcausedamage totheinstrument.

VI. Troubleshooting

If the corrosion rate 5.00 ± 0.05 mpy when the calibration probe

is connected

Checkthefollowingitems:

1. Isthecalibrationprobecompletelypluggedintothe

cableassembly?

2. Is thecableassemblypluggedintothe “Probe”port

ontheinstrument?

If the above methods do not cause the corrosion rate to be 5.00 ± 0.05

mpy,itispossiblethatthe cable assembly hasbeendamaged. Youmay

checkthecableassembly for properoperationasfollows:

1. Unplug theinstrumentfromthe poweroutletand turnthepower

switchontheinsidefrontpaneltothe“off”position.

2. Unplug thecableassemblyfrom the“probe”connection onthe

instrument.

3. Place a 1000 Ohm resistor across thebottomtwopins of the

probeconnectorontheinstrument OR use jumper wires and

16

Table of contents

Other Metal Samples Measuring Instrument manuals