Metallkraft MBSM Series User manual

MBSM 150-200-2

Operating Instruction

MBSM 75-200-2

MBSM - SERIES

Metal-belt sander

MBSM 150-200-2

MBSM 75-200-2

2 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Imprint

Product identification

Metallkraft

Metal- belt sander

Model Item number

MBSM 75-200-2 3922075

MBSM 150-200-2 3922150

Manufacturer

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Indications regarding operating instructions

Original operating instructions

Edition: 13.09.2021

Version: 2.05

Language: English

Author: MS

Indications regarding the copyright

Copyright © 2021 St rmer Maschinen GmbH, Hall-

stadt,Germany.

The contents of these operating instructions is the sole

property of the company St rmer Maschinen GmbH.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Contents

1 Introduction ............................................. 3

1.1 Copyright ............................................................ 3

1.2 Costumer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................... 4

2.1 Symbol explanation ............................................ 4

2.2 Obligations of the operating company ................ 4

2.3 Requirements to staff.......................................... 5

2.4 Personal protective equipment ........................... 5

2.5 Safety devices .................................................... 6

2.6 Safety identifications on the Metal- belt sander.. 6

2.7 Additional safety regulations............................... 7

2.8 Residual risk ....................................................... 7

3 Intended use ............................................ 7

4 Technica Data......................................... 8

4.1 Table................................................................... 8

4.2 Noise level .......................................................... 8

4.3 Type plate........................................................... 8

5 Transport and packaging ....................... 8

5.1 Delivery and Transport ....................................... 8

5.2 Packaging........................................................... 9

6 Description of the device ....................... 9

6.1 Illustration ........................................................... 9

6.2 Optional accessory ........................................... 10

7 Settings .................................................. 10

7.1 Sanding belt change......................................... 10

7.2 Sanding belt run................................................ 10

8 Operation of the machine..................... 11

8.1 General informations ........................................ 11

8.2 Surface-grinding on the sanding belt................ 11

8.3 Grinding on the workpiece support................... 11

8.4 Connection for connecting of an extraction

system ............................................................. 11

9 Notes for the grinding process............ 11

10 C eaning, maintenance and service .. 12

10.1 Cleaning......................................................... 12

10.2 Maintenance .................................................. 12

10.3 Service........................................................... 12

10.4 Storage .......................................................... 12

11 Disturbances, possib e causes and

measures ............................................. 12

12 Disposa , recyc ing of used

devices ................................................. 13

12.1 Decommission ............................................... 13

12.2 Disposal of electrical devices......................... 13

12.3 Disposal of lubricants..................................... 14

12.4 Disposal via municipal collecting points......... 14

13 Spare parts .......................................... 14

13.1 Spare parts order........................................... 14

13.2 Spare parts drawings..................................... 15

13.3 Parts list ........................................................ 16

14 Circuit diagram ................................... 19

15 EC-Dec aration of conformity ............ 20

16 Notes .................................................... 21

Introduction

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 3

1 Introduction

With the purchase of the device of METALLKRAFT you

have made a good choice.

Thorough y read the operating instructions before

commissio-ning the machine.

It informs you about the proper commissioning, the in-

tended use as well as the safe and efficient operation

and maintenance of your device.

The operating instructions are part of the device. It must

always be stored at the place of use of the device. In ad-

dition, the local accident prevention regulations and ge-

neral safety regulations apply to the area of application

of the device.

The illustrations in these operating instructions serve the

general comprehension and may deviate from the ac-

tual type.

The term "machine" replaces the usual trade name of the

device to which these operating instructions refer.

1.1 Copyright

The contents of these instructions are copyright. Their

application is admissible in the frame the device utilisa-

tion. An application beyond the described application is

not allowed without written approval of the manufac-

turer. For the protection of our products, we shall regis-

ter trademark, patent and design rights, as this is possi-

ble in individual cases. We strongly oppose any infringe-

ment of our intellectual property.

1.2 Costumer service

Please contact your dealer if you have any questions

about your machine or technical information. There you

will be happy to help with expert advice and information.

Germany:

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair-Service:

Fax: 0049 (0) 951 96555-111

E-Mail: [email protected]

Internet: www.metallkraft.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: [email protected]

We are always interested in valuable experience and

knowledge gained from using the application-which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of iabi ity

All information and notes in these operating instructions

were summarized taking the applicable standards and

rules, the state-of-the-art and our long-term knowledge

and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use,

- Use of untrained staff,

- Unauthorized modifications,

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery conditi-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

4 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Safety

2 Safety

This paragraph will give you an overview of all important

safety packages for the protection of persons as well as

for the safe and undisturbed operation. Other taskba-sed

safety notes are included in the individual chapters.

2.1 Symbo exp anation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are intro-duced by

signal words which express the concern of the risk.

Tips and recommendations

It is necessary to observe the safety notes quoted in

these operating instructions in order to reduce the risks

for personal injuries and damages to property.

2.2 Ob igations of the operating com-

pany

The operating company is the person who operates the

machine for business or commercial reasons by herself,

or leaves it to a third party for use or application, and who

bears the legal product responsibility for the pro-tection

of the user, the staff or for third parties.

Ob igations of the operating company:

If the machine is used for commercial purposes, the op-

erating company must comply with the legal working

safety regulations. Therefore, the safety notes in this op-

erating manual, as well as the safety, accident preven-

tion and environment protection regulations applying for

the area of application of the machine must be met. The

following applies in particular:

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use the ma-

chine. She must implement these in form of oper-

ating manuals for the operation the machine.

- During the entire lifetime of the machine, the oper-

ating company must verify whether the operating

manuals prepared by her correspond to the cur-

rent status of the regulations, and must adapt

these if necessary.

- The operating company must unambiguously reg-

ulate and determine the responsibilities for instal-

lation, operation, troubleshooting, maintenance

and cleaning.

- The operating company must ensure that all per-

sons who work with the machine, have read and

understood this manual. Furthermore she must in-

struct the staff in regular intervals and inform them

about the hazards.

- The operator must provide the necessary protec-

tive equipment to the staff and order the use of the

necessary protective equipment in a binding way.

DANGER!

This combination of symbol and signal words indi-

cate an imminently dangerous situation which may

lead to death or severe injuries if they are not avoi-

ded.

WARNING!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to death or severe injuries if they are not avoided.

CAUTION!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to minor or light injuries if they are not avoided.

ATTENTION!

This combination of symbol and signal word indi-

cates a potentially hazardous situation which, if not

avoided, could result in property damage and envi-

ronmental damage.

NOTE!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

Safety

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 5

Furthermore the operating company is responsible to

keep the machine always in a technically flawless state.

Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices checked

regularly for their good working order and their in-

tegrity.

2.3 Requirements to staff

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons the

responsiveness of which is affected by e. g. drugs, alcohol

or medication, are not allowed to work with the machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator:

The operator is instructed by the operating company about

the assigned tasks and possible risks in case of improper

behavior. Any tasks which need to be per-formed beyond

the operation in the standard mode must only be per-

formed by the operator if it is indicated in these instructions

and if the operating company ex-pressively commissioned

the operator.

E ectrica y qua ified person:

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-edge

of the relevant standards and regulations, in a po-sition to

carry out work on the electrical systems and to inde-

pendently recognize and avoid possible dangers.

Qua ified personne :

Due to their professional training, knowledge and expe-ri-

ence as well as their knowledge of relevant regulations the

specialist staff is able to perform the assigned tasks and to

recognize and avoid any possible dangers them-selves.

Manufacturer:

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Persona protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while

working. The staff member has to wear personal protec-

tive equipment while performing different tasks on and

with the machine which are indicated in the individual

paragraphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

WARNING!

Danger in case of insufficient qua i-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the vacuum cleaner and expose

themselves and others to the danger of severe or

lethal injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the work-

ing area.

Eye Protection

The Eye protection protects the eyes from flying

parts and liquid splashes.

Ear protection

The Hearing protection protects ears from hearing

damage caused by noise.

Head protection

The industrial helmet protects the head against fall-

ing objects and knocking against fixed objects.

Protective g oves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fall-

ing parts and slipping over on slippery ground.

Protective c othes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

6 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Safety

2.5 Safety devices

To protect against flying sparks, a protective screen is at-

tached to the housing above the contact wheel. The on-

off switch unit is combined with an emergency stop

switch.

When the machine is running, protective covers and

guards must never be opened or removed.

EMERGENCY STOP - Button

Press the emergency stop button (Fig. 1) and the device

will stop immediately. The power supply is switched off

or the drives are mechanically disconnected. After the

emergency stop button has been pressed, it must be un-

locked by turning so that the machine can be switched

on again.

Fig. 1: EMERGENCY-STOP-Button

2.6 Safety identifications on the Meta -

be t sander

There are safety markings and instructions attached to

the metal- belt sander (Fig. 2) which must be observed

and followed.

Fig. 2: Safety lables

1 Danger high voltage | 2 Warning about rotating machine parts,

entanglement hazard | 3 Pull out the mains plug ! | 4 Wear ear

protection! |

5 wear safety glasses ! | 6 Read operating manual!

The safety markings and instructions attached to the

workshop press must not be removed. Damaged or

missing safety markings can lead to malfunctions, per-

sonal injury and material damage. They have to be re-

placed immediately.

If the safety markings are not immediately recognizable

and comprehensible, the workshop press must be taken

out of operation until new safety markings have been af-

fixed.

- Before switching on the machine, check the correct

picking up of the workpiece!

- When working with the machine, never put your

hands near rotating parts!

- Do not remove the sharp-edged chips by hand;

Use hand brushes or chip hooks!

- Use the guards and fasten them securely. Never

work without guards and get them working. Check

the functionality before starting with the work.

WARNING!

Danger to ife due to non-functioning safety

devices!

In case of dysfunctional or overridden safety devices

there is a danger of getting serious injuries or even

danger to life.

- Before starting work, check that all safety equip-

ment is in place and correctly installed.

- Never override or bypass safety devices.

- Ensure that all safety devices are always accessi-

ble.

WARNING!

Danger to ife due to unintentiona restart!

In case of unintentional restart there is a danger of

getting serious injuries or even danger to life.

- Before restarting, make sure that the cause of the

emergency stop has been remedied and all safety

devices are installed and functioning.

- Only unlock the emergency stop button when there

is no longer any danger.

NOTE!

The machines are designed to meet the general

safety requirements. Please always observe the rele-

vant accident prevention regulations. In case of

doubt, ask the supervisor.

ATTENTION!

Before starting, using, servicing or otherwise inter-

vening on the machine, read the instructions for use

and maintenance carefully. Handling and working

with the machine is only permitted for persons who

are familiar with the handling and operation of the

machine.

23

4

1

56

Intended use

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 7

- Keep the machine and its working environment al-

ways clean. Ensure adequate lighting.

- In principle, secure your workpiece when working

with suitable clamping devices. Make sure there is

sufficient support surface.

- The machine may not be modified in its design and

may not be used for purposes other than those

provided by the manufacturer.

- Never work under the influence of concentration

disorders diseases, fatigue, drugs, alcohol or

drugs.

- Remove tool wrench and other loose parts from the

machine after installation or repair before turning

on.

- Observe all safety and hazard warnings on the ma-

chine and keep them in perfect readable condition.

- Keep children and persons unfamiliar with the ma-

chine away from your work environment, machine

and tools.

- The machine may only be used, equipped and

maintained by persons who are familiar with it and

have been informed about the dangers.

- During maintenance, armament and maintenance

work, always switch off the machine! In addition,

disconnect the power plug or disconnect the ma-

chine from the power supply!

- Do not pull on the power cord to pull the plug out of

the socket. Protect the cable from heat, oil and

sharp edges.

- Make sure that the main switch is in the "OFF" po-

sition when connecting the device to the power

supply to prevent it from switching on accidentally.

- Wear tight-fitting work clothes, safety glasses,

safety shoes and a hearing protection. Tie your

long hair together. When working, do not wear

watches, straps, chains, rings or gloves (rotating

parts!).

- Eliminate disruptions that affect safety immedi-

ately.

- Never leave the machine unattended in operation

and remain with the machine until the tool is com-

pletely stopped. Then remove the mains plug to

protect against unintentional switching on.

- Protect the machine from wet (short circuit hazard).

- Never use power tools and machines near flamma-

ble liquids and gases (risk of explosion!).

- Before each use of the machine, make sure that no

parts are damaged. Damaged parts must be re-

placed immediately to avoid any danger!

- Do not overload the machine! You work better and

safer in the specified performance range. Use the

right tool! Make sure that the tools are not dull or

damaged.

- Only use original spare parts and accessories in or-

der to avoid possible danger and risks of accident.

2.7 Additiona safety regu ations

- The workpiece may only be brought into contact

with it after the grinding belt has been switched on.

- Keep your hands away from rotating parts.

- This machine is not suitable for wet grinding. Never

use water on the workpiece surface or on the sand-

ing belt.

2.8 Residua risk

Even if all safety regulations are followed and the ma-

chine is used correctly, there are still residual risks listed

below:

- Touching rotating parts or tools.

- Breakage / tear of the abrasives.

- Injuries due to flying workpieces or parts of work-

pieces.

- Fire hazard with insufficient ventilation of the en-

gine.

- Touching of live parts.

- Impairment of hearing during prolonged work with-

out hearing protection.

3 Intended use

The belt sander must be mounted according to the in-

structions. Only the parts supplied may be used. The belt

grinder is designed for grinding angular metal and metal

- like workpieces.

The machine is universally applicable for schools, handi-

craft enterprises, workshops and for the do-it-your-

selfers.

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or oth-

erwise is considered misuse.

Improper use:

The machine must not be used for grinding combustible

materials (e.g. magnesium, wood or similar).

NOTE!

It should be noted that each machine has residual

risks. When carrying out all operations (even the sim-

plest ones), great care should be taken. Safe working

depends on you!

8 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Technica Data

4 Technica Data

4.1 Tab e

4.2 Noise eve

The noise level (sound pressure level) of this machine

may exceed 87 dB (A) at the workplace.

In this case, sound and hearing protection measures are

required and have to be used by the operator.

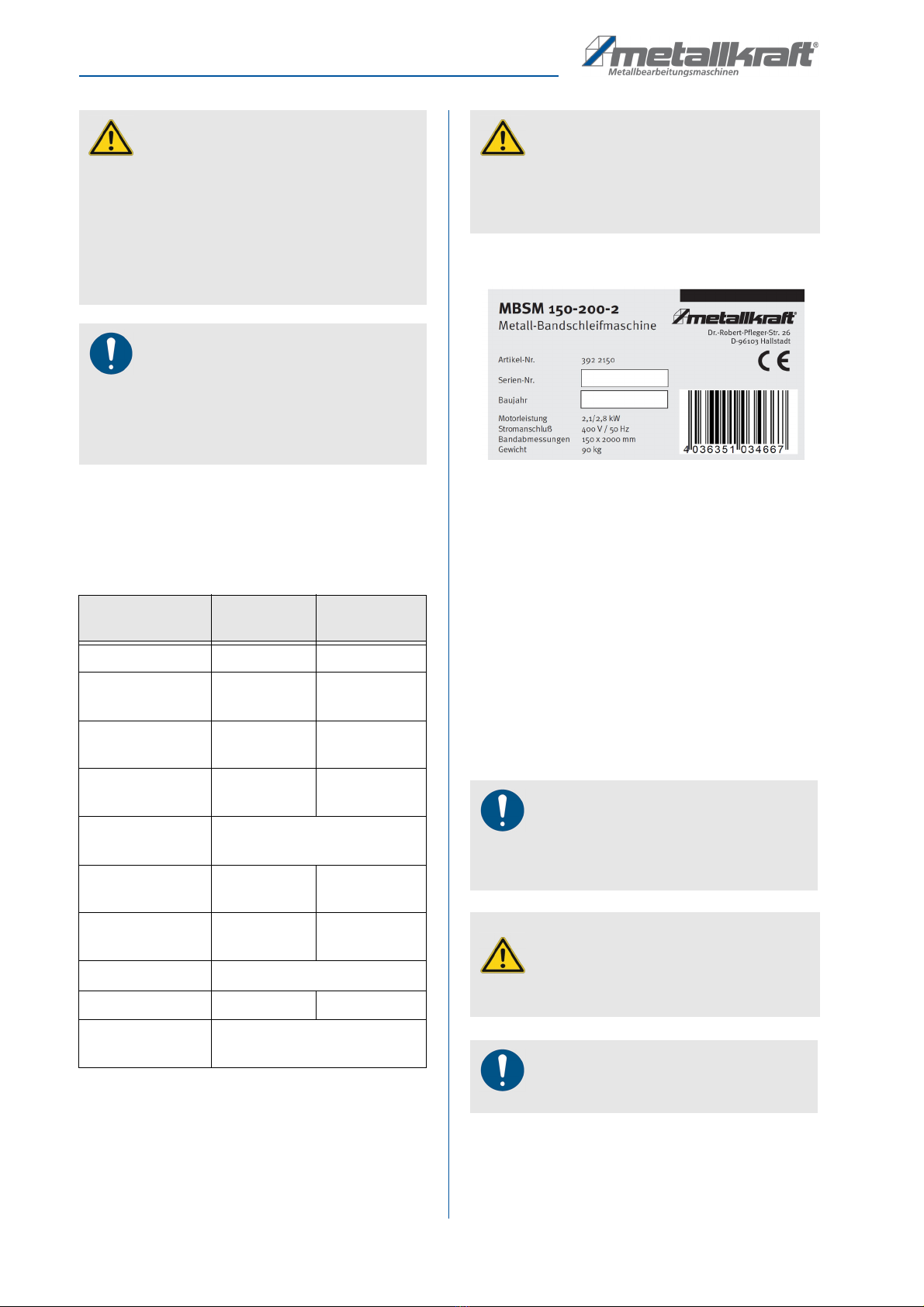

4.3 Type p ate

Fig. 3: Type plate MBSM 150-200-2

5 Transport and packaging

5.1 De ivery and Transport

Check the belt sander on delivery for any visible trans-

portation damage. If you notice any damage to the de-

vice please report this immediately to the carrier or

dealer.

Remove the machine from its packaging and remove all

protective films. Make sure that the machine is not set up

or put into operation in a damp or wet environment. The

humidity should not exceed 60% and the measured

room temperature should be between max. 0 ° C and 40

° C amount.

The machine may only be transported standing and with

the en

WARNING!

Danger in case of misuse!

Misuse of the device can lead to dangerous situa-

tions.

- Only operate the machine in the power range spec-

ified in the technical data.

- Never bypass or override the safety devices.

- Only operate the machine in a technically perfect

condition.

NOTE!

Unauthorized modifications to the machine or

improper use of the machine and disregard of safety

regulations or the operating instructions exclude lia-

bility of the manufacturer for resulting damage to per-

sons or objects and cause the warranty to lapse!

MBSM 75-

200-2

MBSM 150-

200-2

Engine power 1,5 / 2,2 kW 2,2 / 2,8 kW

Electrical

connection

400 Volt

~ 50 Hz

400 Volt

~ 50 Hz

Speed of sanding

belt

14,5 / 29 m/

sek.

14,5 / 29 m/

sek.

Dimensions 1070 x 340 x

950 mm

1070 x 415 x

950 mm

Contact wheel di-

mensions

Ø 200 mm

Sanding belt di-

mensions

2000 x 75

mm

2000 x 150

mm

Grinding width

max.

75 mm 150 mm

Suction socket 100 mm

Weight 72 kg 90 kg

sound pressure

level (dB)

87 dB(A)

WARNING!

It should be noted that the duration of the sound

exposure, the nature and condition of the work area

as well as other machines that are in operation at the

same time influence the noise level in the workplace.

NOTE!

For a safe stand, it is recommended that the machine

be fixed on a stable, flat surface (preferably con-

creted) using the holes provided in the machine base.

WARNING!

Danger to ife due to fa ing oad!

If the weight of the device is not observed during

transport, the machine may tip over or crash.

NOTE!

Protect the belt sander from moisture.

Description of the device

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 9

Transport

Improper transport is prone to accidents and can cause

damage or malfunctions to the machine, for which we do

not provide any liability or guarantee.

Transport the scope of delivery secured against shifting

or tipping with a sufficiently dimensioned industrial truck

or a crane to the installation site.

General hazards during internal transport

Machines may only be transported by authorized and

qualified persons. Act responsibly when transporting and

always consider the consequences. Refrain from daring

and risky actions.

Inclines and slopes are particularly dangerous (e.g.

driveways, ramps and the like). If it is unavoidable to

drive on such passages, special care is required.

Before starting the transport, check the transport route

for possible hazards, bumps and imperfections as well

as sufficient strength and load-bearing capacity.

Hazardous areas, bumps and imperfections must be in-

spected prior to transport. The removal of hazardous

areas, bumps and obstructions at the time of transport by

other employees leads to considerable dangers.

Careful planning of internal transport is therefore essen-

tial.

Transport with a fork ift / pa et truck:

For shipping, the device is firmly mounted on a pallet so

that it can be transported with a forklift or a pallet truck.

5.2 Packaging

All used packaging materials and packaging aids are re-

cyclable and should be taken to a materials recycling de-

pot to be disposed of.

The delivery packaging is made of cardboard, so please

dispose carefully by having it chopped up and given to

the recycling collection

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (PS). Deliver these substances to a

collection point for recyclable materials or to the compe-

tent waste disposal company.

6 Description of the device

6.1 I ustration

I ustrations in this operating manua serve the gen-

era under-standing and may deviate from the actua

design.

Fig. 4: Description of the device

WARNING!

Serious to fatal injuries from falling over and fall

down of machine parts from forklifts, pallet trucks or

transport vehicles. Observe the instructions and

information on the transport box.

Note the total weight of the machine. The weight of

the machine is given in the "Technical data" of the

machine. When the machine is unpacked, the weight

of the machine can also be read on the nameplate.

Only use means of transport and load attachment

means that can take the total weight of the machine.

WARNING!

Serious to fatal injuries due to damaged or insuffi-

ciently stable lifting equipment and load attachment

devices that tear under load. Check the lifting gear

and load attachment devices for sufficient load-bea-

ring capacity and perfect condition.

Observe the accident prevention regulations of the

professional association responsible for your com-

pany or other supervisory authorities.

Fix the loads carefully.

WARNING DANGER OF TIPPING

OVER

The machine may not be lifted more than 2cm unse-

cured.

Employees must be outside the danger zone, the

reach of the load.

Warn employees and make employees aware of the

risk.

3

2

9

8

6

7

5

1

4

10

10 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Settings

1 Machine foot

2 Interlock angle adjustment

3 Electric engine 400 V ~ 50 Hz

4 Switching box / ON-OFF-Switch

5 Cover level grinding surface hinged

6 Cover contact wheel with workpiece stop

7 Adjustment screw belt direction

8 Chips-Box with suction socket

9 Workpiece support adjustable

10 EMERGENCY-STOP-Button

6.2 Optiona accessory

We recommend only using high-quality original MET-

TALKRAFT accessories. Only with original accessories,

a flawless operation and optimal work results can be

guaranteed.

7 Settings

To achieve good machine performance and a long ser-

vice life, the site should meet the following criteria.

- The device may only be installed and operated in

dry, ventilated rooms.

- Avoid places near chips or dust generating ma-

chines.

- The place of installation must be vibration-free, i.e.

away from presses, planing machines, etc..

- Provide sufficient space for the performance of the

work of set up men, the operating personnel and

material transport.

- Also consider the accessibility for adjustment and

maintenance work.

- Ensure adequate lighting (minimum value: 300

lux).

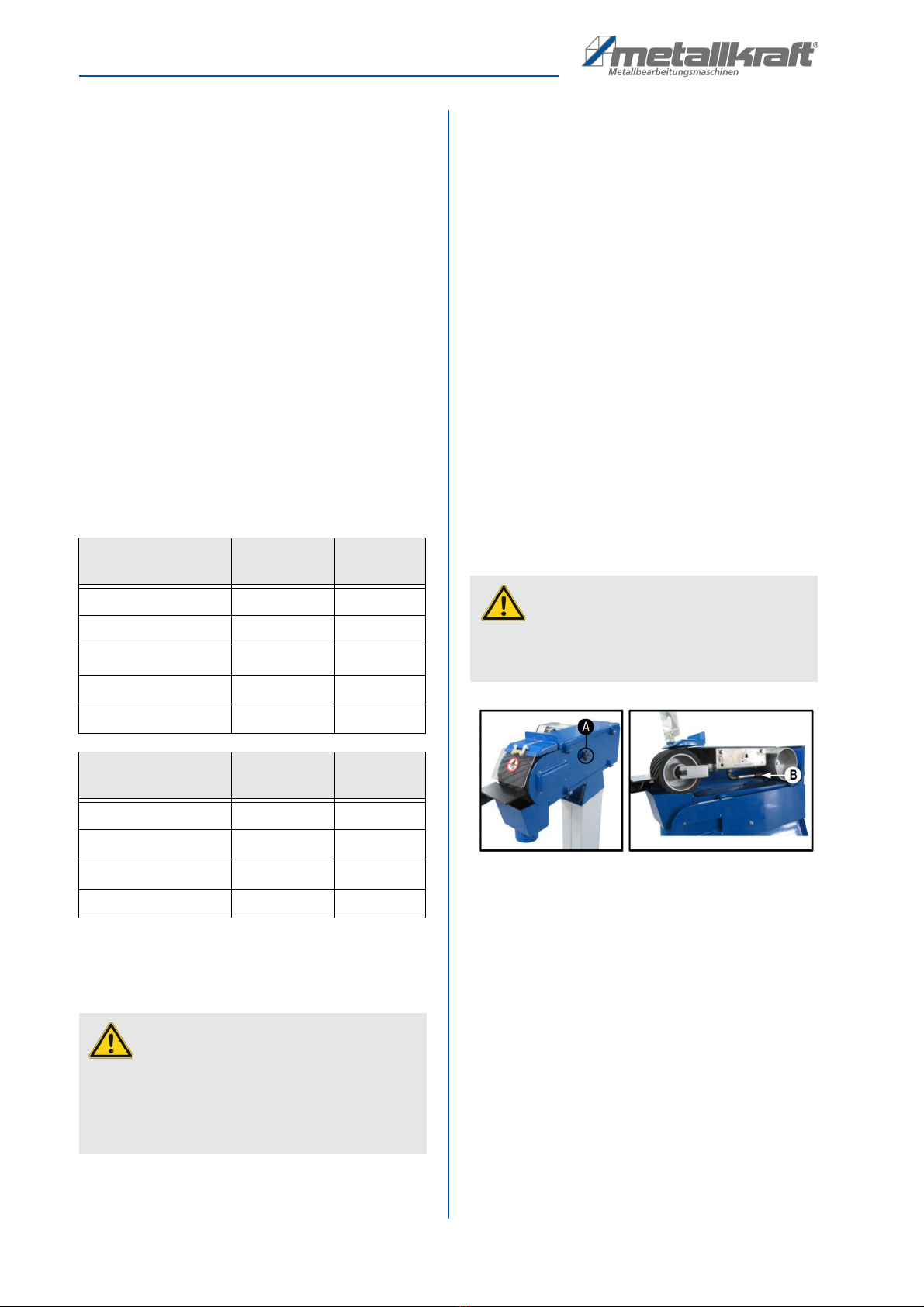

7.1 Sanding be t change

Unscrew the fastening screw (A) Fig. 5 and unfold the

side cover including the level grinding surfaces com-

pletely. Loosen the tension of the sanding belt by using

the tensioning lever (B) Fig.5. Carefully pull off the old

sanding belt. Tighten the new sanding belt and align it.

Finally, tighten the sanding belt over the tension lever

and close the side cover.

Fig. 5: Sanding belt change

7.2 Sanding be t run

The run of the sanding belt can be changed using the

sanding belt adjustment screw (Item 1, Figure 6). Check

the run of the sanding belt by gently moving it by hand.

To change the running direction of the sanding belt

loosen the hexagon head screw (item 2, Fig. 6) within

the adjusting screw (item 1). Then you can change the

tape running direction of the sanding belt by turning the

adjustment screw (item 1, Fig. 6) in a clockwise or coun-

terclockwise direction. Then move the sanding belt by

hand again and check the correct run. If necessary,

change the run again.

Sanding be ts for

extreme oad

MBSM 75-

200-2

MBSM

150-200-2

Sanding belt grain 24 3722022 3723022

Sanding belt grain 36 3722023 3723023

Sanding belt grain 40 3722024 3723024

Sanding belt grain 50 3722025 3723025

Sanding belt grain 60 3722026 3723026

Sanding be ts for

simp e use

MBSM 75-

200-2

MBSM

150-200-2

Sanding belt grain 40 3722004 3722014

Sanding belt grain 60 3722006 3722016

Sanding belt grain 80 3722008 3722018

Sanding belt grain 120

3722009 3722019

ATTENTION!

Before intervening on the machine, it must be discon-

nected from the power supply. Handling and working

with the machine is only permitted for persons who

are familiar with the handling and operation of the

machine.

ATTENTION!

When inserting the sanding belt, make sure that the

running direction of the arrow (see sanding belt inside)

matches the direction of the arrow on the housing.

Operation of the machine

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 11

Fig. 6: Belt run adjustment

8 Operation of the machine

8.1 Genera informations

Before each start of work, the fo owing tests must be

carried out:

- Check all cables and plugs.

- Check that the workpiece supports are aligned and

tightened.

- Note that there are different grit sizes for different

jobs.

- Before starting the machine, make sure that the

sanding belt is free to rotate and that it is not

braked or blocked by any workpieces.

- Lubricate regularly according to item maintenance.

- Before commissioning, the center run of the

grinding be t must a ways be checked by man-

ua feed!

8.2 Surface-grinding on the sanding

be t

Check that the workpiece stop Pos. 7 in figure 4 is cor-

rectly mounted and tightened. Open the hinged cover

Pos.4 on figure 4. Switch on the belt sander and carefully

press the workpiece with both hands against the sanding

belt and the safety stop. For better material removal and

even belt wear, the workpiece can be easily moved back

and forth.

8.3 Grinding on the workpiece support

Hold the workpiece firmly with both hands. Grind internal

curves only on the front workpiece support.

8.4 Connection for connecting of an

extraction system

On the chip box Pos. 6 (Figure 4) and the back of the belt

grinder is a 100 mm Ø connecting piece for connection

to an extraction system.

9 Notes for the grinding pro-

cess

- When grinding, pay attention to the safety instruc-

tions and use the protective devices on the ma-

chine as well as your personal protective equip-

ment (protective goggles, ear protection, safety

shoes, etc.).

ATTENTION!

The grain size of the abrasives must be selected

according to the requirements.

NOTE!

After switching the belt speed, the run of the sanding

belt must be checked and, if necessary, readjusted.

ATTENTION!

Rotating parts! Get to work with reason. Pay atten-

tion to what you do. Pay special attention to the rotat-

ing parts. Wear tight-fitting clothing. Make sure that

hair or clothing is not caught by rotating parts! Wear

a hairnet. When working with the machine no jewelry

may be worn.

ATTENTION!

Risk of injury!

Flying chips and slinging away parts! Be sure to wear

safety glasses! Protect your eyes from flying chips

and other splinters.

1

2

ATTENTION!

Do not work with too much pressure, otherwise the

sanding belt wears too fast. Do not put your fingers in

contact with the sanding belt.

ATTENTION!

The edge of the workpiece supports must be posi-

tioned so that a distance of max. 1 mm is present to

prevent jamming of workpieces or fingers between

the table and the sanding belt.

12 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

C eaning, maintenance and service

- Special reference to situations that may cause

damage to persons, the machine and / or the envi-

ronment or may lead to financial loss.

- Make sure that the gap between the work table and

the grinding wheel is not too large. Especially with

thin workpieces, there is a risk that the workpiece

will enter the gap!

- Since the machine does not have a clamping facil-

ity, it is important that your workpiece rest on the

worktable over the entire surface and be held tight!

- Make sure the abrasives are in good condition and

replace worn out abrasives in a timely manner.

Only with perfect tools you can achieve a good

grinding quality!

10 C eaning, maintenance and

service

Oil, grease and cleaning agents are hazardous to the en-

vironment and must not be disposed of in wastewater or

normal household waste.

10.1 C eaning

Basically, the machine should be cleaned after each use.

With the machine off, remove the chips and dust from

the cooling openings of the motor with a hand brush or

brush. Cleaning with compressed air is not allowed, as

the fine chips can easily fly into the eyes and cause inju-

ries.

For the disposa of the chips we refer to the oca

regu ations.

10.2 Maintenance

Empty the spark arrester regularly and check whether

the suction channel has to be cleaned. If the edges of the

contact wheel are rounded or the surface is damaged,

replace the contact wheel immediately. Replace the

graphite sanding pad on the plant table depending on

the degree of wear.

10.3 Service

As a result of wear and tear, it may happen that mainte-

nance work must be carried out on the machine.

10.4 Storage

Store the machine in a dry, clean, dust- and frost-free

environment. It must not be placed in a room with highly

oxidizing chemicals.

11 Disturbances, possib e

causes and measures

WARNING!

Always disconnect the machine from the power sup-

ply before starting any cleaning, maintenance or ser-

vicing work!

ATTENTION!

Risk of injury!

Do not remove the chips with bare hands. There is a

danger of cuts due to sharp-edged chips!

Dispose of these funds in an environmentally

friendly way. The cleaning cloths soaked in

oil, grease or detergent are easily

combustible. Collect the cleaning rags or

cleaning wool in a suitable, closed container

and dispose of them in an environmentally

friendly way - do not throw them in

household waste!

WARNING!

Repairs or maintenance work may only be carried

out by qualified and trained specialist personnel.

ATTENTION!

If one of the following errors occurs, stop working

with the machine immediately. Before you begin trou-

bleshooting, turn off the machine and unplug the

power cord. It could lead to serious injuries. All

repairs or replacement work may only be carried out

by qualified and trained specialist personnel.

NOTE!

If you can not solve the problems with your machine

yourself, then please contact your nearest

METALLKRAFT dealer. Please write down the follow-

ing information from the machine or the operating in-

structions in advance to help you with your problem in

the best possible way.

- Machine type

- Serial number of the machine

- Year of manufacture

- Error description in detail

Disposa , recyc ing of used devices

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 13

12 Disposa , recyc ing of used

devices

Please take care in your own interest and in the interest of

the environment that all component parts of the machine

are only disposed of in the intended and permitted way.

Please note that electrical appliances contain a variety of

recyclable materials as well as environmentally harmful

components. Make sure that these components are dis-

posed of separately and properly. In case of doubt,

please contact your municipal waste disposal. If neces-

sary, the help of a specialized waste disposal company

can be used for the treatment.

12.1 Decommission

Immediately decommission disused machines in order to

avoid later misuse and endangering of the environ-ment

or personal safety.

- Unplug the power plug.

- Cut the connection cable.

- Remove all environmentally hazardous operating

materials from the old appliance.

- If applicable, remove batteries and rechargeable

batteries.

- If required, disassemble the machine into easy-to-

handle and usable components and parts.

- Dispose of machine components and operating

materials by the disposal channels provided.

12.2 Disposa of e ectrica devices

Please ensure that the electrical components are prop-erly

disposed of in accordance with legal regulations.

The device contains electrical and electronic compo-nents

and must not be disposed of as household waste. Accord-

ing to European Directive 2012/19 / EC on waste electrical

and electronic equipment and its transposition into na-

tional law, used electric tools and electrical machines must

be collected separately and recycled in an environmentally

sound manner.

As a machine operator, you should obtain information

about the authorized collection or disposal system that is

valid for you.

Please ensure that the batteries and / or rechargeable bat-

teries are properly disposed of in accordance with legal

regulations. Please throw only discharged batter-ies into

the collection boxes at retailers or municipal waste dis-

posal companies.

These components must be separated and properly dis-

posed of. In case of doubt, contact municipal waste man-

agement.

If necessary, the help of a specialized waste disposal

company can be used for the treatment.

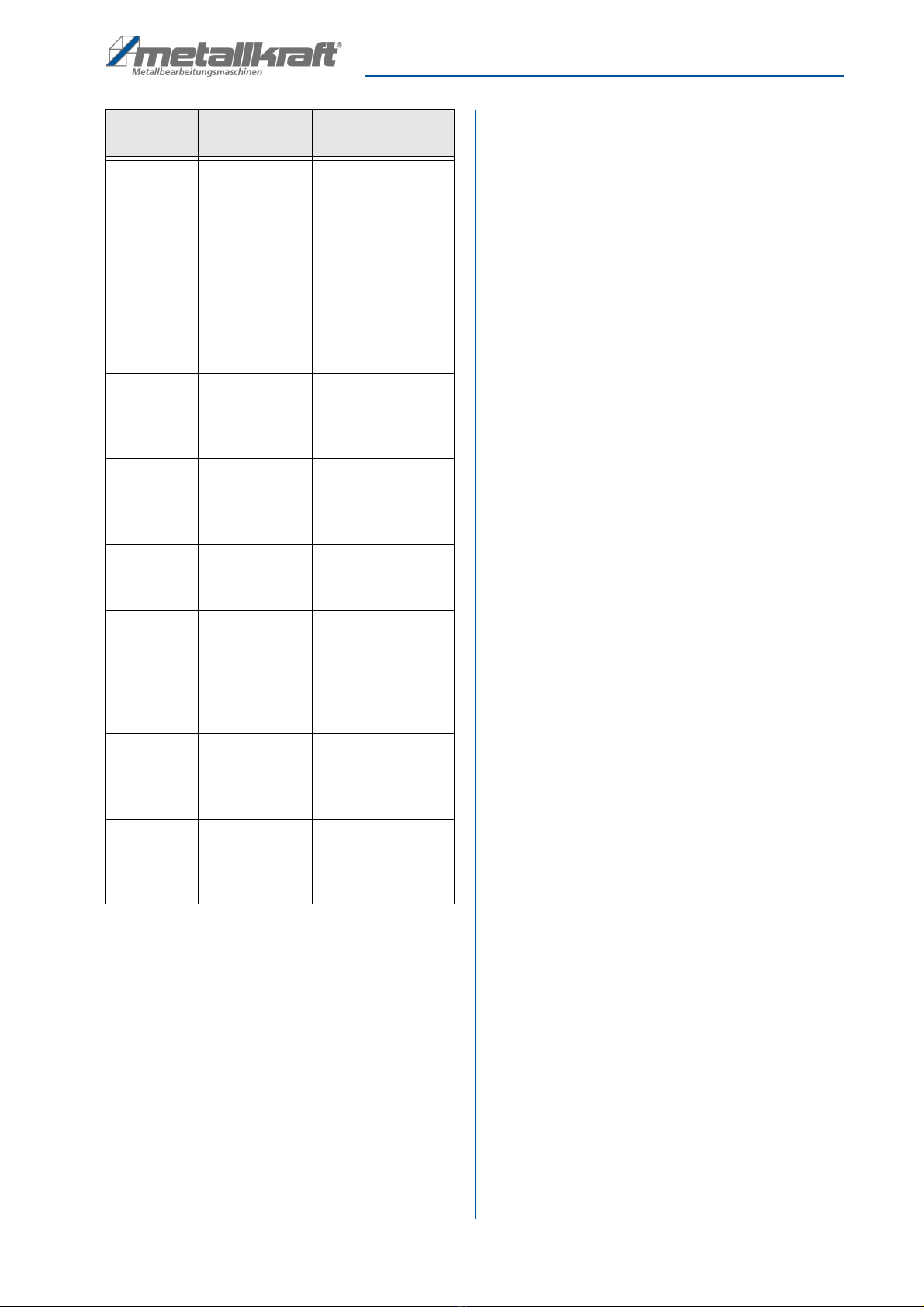

Distur-

bances

Possib e

causes

Measures

Engine

does not

start.

Damaged on /

off switch.

Damaged on /

off switch line.

Relay dam-

aged.

Engine defec-

tive.

Fuses are de-

fective.

Have the machine

checked by an elec-

trician and have re-

placed the dam-

aged parts.

Machine

slows down

while work-

ing.

It is working

with too much

pressure.

Exert less pressure

on the workpiece.

Low ser-

vice life of

the abra-

sives.

Abrasive

(sanding belt or

disk) with too

fine grain.

Use a grinding

wheel with a

coarser grain size.

Bad grind-

ing pattern

Abrasive with

too coarse

grain size

Use a grinding

wheel with finer

grain size

Grinding

angle does

not fit

Adjusted an-

gles on the

work table or

on the stop

bracket do not

fit

Check the angle

and readjust if nec-

essary.

Grinding

wheel runs

optically

non-circular

Sanding belt

not properly at-

tached

Installing the grind-

ing wheel centrally

Sanding

belt runs off

the drive

pulleys

Sanding belt

not properly in-

stalled

Readjust the track

of the sanding belt.

14 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Spare parts

12.3 Disposa of ubricants

Spent coolant emulsions and oils should not be mixed

with each other as only non-mixed waste oils are recy-

clable without pretreatment.

The disposal instructions for the lubricants used are pro-

vided by the lubricant manufacturer. If necessary, ask for

the product-specific data sheets.

12.4 Disposa via municipa co ecting

points

Disposal of used electrical and electronic

equipment (Applicable in the countries of

the European Union and other European

countries with a separate collection system

for these appliances).

The symbol on the product or its packaging indicates that

this product should not be treated as normal household

waste, but must be returned to a collection point for the

recycling of electrical and electronic equipment.

By helping to properly dispose of this product, you are

protecting the environment and the health of others. En-

vironment and health are endangered by improper dis-

posal. Material recycling helps to reduce the consump-

tion of raw materials. For more information about

recycling this product, contact your local community, mu-

nicipal waste management, or the shop where you pur-

chased the product.

13 Spare parts

13.1 Spare parts order

Spare parts are available from authorised retailers or di-

rectly from the manufacturer.

Contact detai s:

Fax: 0049 (0) 951 96555-119

email: ersatzteile@stuermer-maschinen.de

Always quote the following key data with your spare

parts orders:

- Device type

- Article number

- Position number

- Year of manufacture

- Quantity

- Desired shipping type (post, freight, sea, air, express)

- Shipping address

Spare parts orders without the aforementioned data can-

not be taken into account. The supplier shall determine

the shipping type if no relevant data was provided. Infor-

mation about the device type, article number and year of

manufacture can be found on the type plate. The

type plate is mounted on the device.

Examp e

The sanding belt for the belt sander MBSM 75-200-2

must be ordered. The sanding belt has the number 57 in

the spare parts drawing 1.

By ordering spare parts, send a copy of the spare parts

drawing (1) with the marked part (sanding belt) and

marked position number (57) to the dealer or spare parts

department and provide the following information:

Device type:

Be t sander MBSM 75-200-2

Article number:

3922075

Drawing number:

1

Position number:

57

Artic e number of your device type:

Meta - be t sander

MBSM 75-200-2 3922075

MBSM 150-200-2 3922150

ATTENTION!

Please pay attention to an environmentally friendly

disposal of the used coolants and lubricants.

Observe the disposal informations of your municipal

disposal companies.

DANGER!

Risk of injury caused by the use of

incorrect spare parts!

The use of incorrect or faulty spare parts may cause

risks for operating staff and damage as well as

malfunctions.

- Exclusively genuine spare parts made by the manu-

facturer or spare parts authorized by the manufac-

turer shall be used.

- Always contact the manufacturer if you are unsure.

NOTE!

The manufacturer warranty shall be rendered void in

the event of a use of unauthorized spare parts.

Spare parts

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 15

13.2 Spare parts drawings

In case of service, the following drawing shall help to identify the necessary spare parts. If necessary, send a copy of the

parts drawing with the marked components to your authorized dealer.

Fig. 7: Spare parts drawing 1 - MBSM 75-200-2 and MBSM 150-200-2

16 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Spare parts

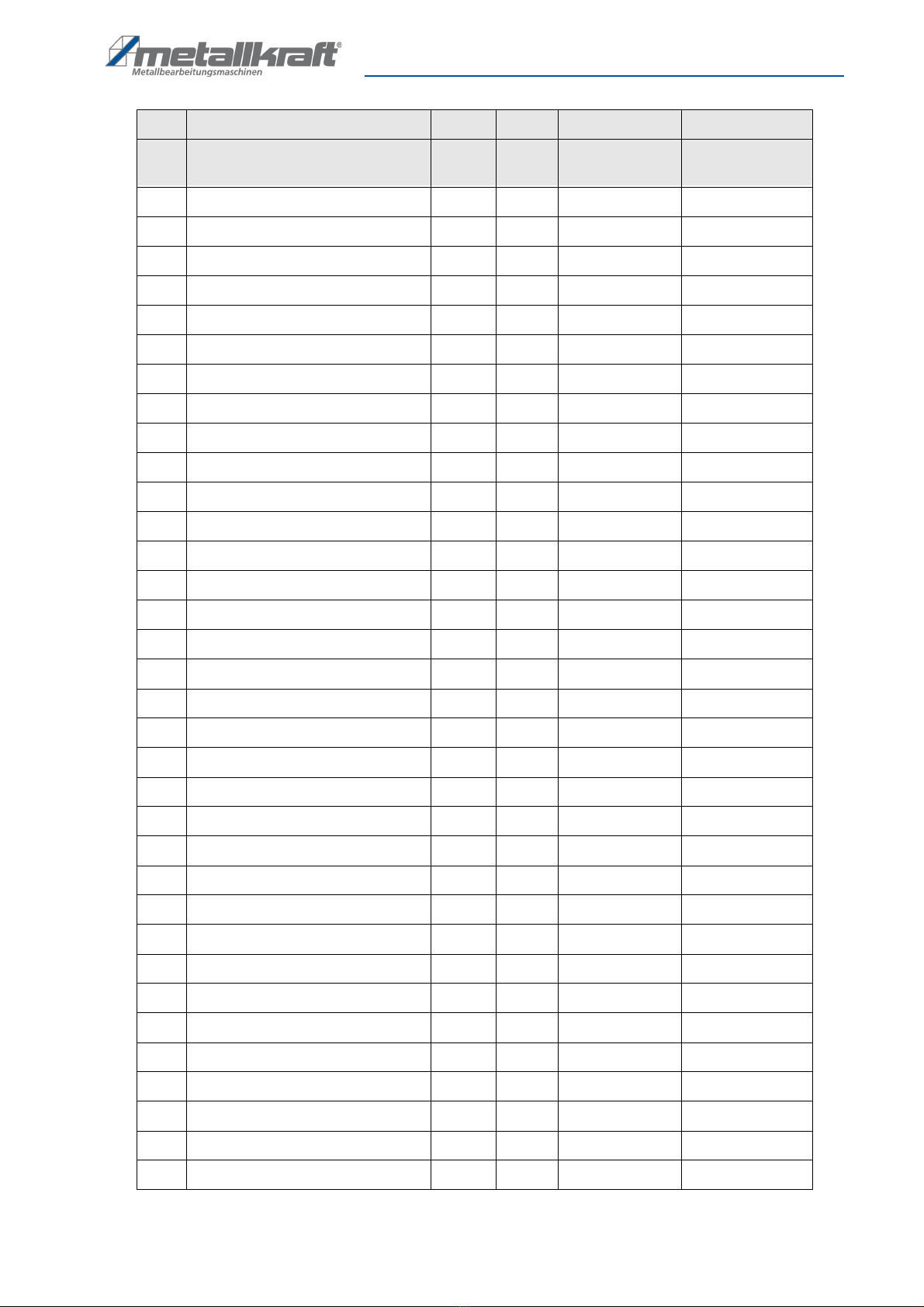

13.3 Parts ist

MBSM 75-200-2 MBSM 150-200-2

Pos. Description Quan-

tity

Size Item number Item number

1 COUNTERSUNK SCREW ISO 7047 8 M4X6 0392207501 0392215001

2 COVER BELT ADJUSTMENT 1 0392207502 0392215002

3 WORKPIECE SUPPORT 1 0392207503 0392215003

4 HOLDER WORKPIECE SUPPORT 1 0392207504 0392215004

5 WASHER 2

Φ

8 0392207505 0392215006

6 COUNTERSUNK SCREW ISO 7991 2 M8X10 0392207506 0392215006

7 COUNTERSUNK SCREW ISO 7991 4 M8X16 0392207507 0392215007

8 U-METAL SHEET 1 0392207508 0392215008

9 MAIN GIRDER 1 0392207509 0392215009

10 CHIP BOX WITH CONNECTING

PIECE

1 0392207510 0392215010

11 CONTACT WHEEL 1 0392207511 0392215011

12 STAR GRIP - SCREW 3 0392207512 0392215012

13 SPRING 2 0392207513 0392215013

14 WASHER 2

Φ

8 0392207514 0392215014

15 WASHER 6

Φ

8 0392207515 0392215015

16 HEX-NUT ISO 7040 2 M8 0392207516 0392215016

17 HEX-NUT ISO 4032 2

M8

0392207517 0392215017

18 CONTACT WHEEL GUIDE 1 0392207518 0392215018

19 CYLINDRICAL PIN 1

Φ

6X50 0392207519 0392215019

20 HEXAGON SCREW 4 M8X25 0392207520 0392215020

21 LINEAR CAM 1 0392207521 0392215021

22 ADJUSTING SCREW 1 0392207522 0392215022

23 CYLINDER SCREW ISO 4762 1 M6X30 0392207523 0392215023

24 SPRING 1 0392207524 0392215024

25 SHAFTS - CIRCLIP 2

Φ

47 0392207525 0392215025

26 BEARING 2 204 0392207526 0392215026

27 CONTACT ROLLER - AXIS 1 0392207527 0392215027

28 WASHER 5

Φ

8 0392207528 0392215028

29 HEXAGON SCREW 2 M8X25 0392207529 0392215029

30 COUNTERSUNK SCREW ISO 7047 2 M4X10 0392207530 0392215030

31 WASHER 2 0392207531 0392215031

32 PROTECTIVE SCREEN 1 0392207532 0392215032

Spare parts

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 17

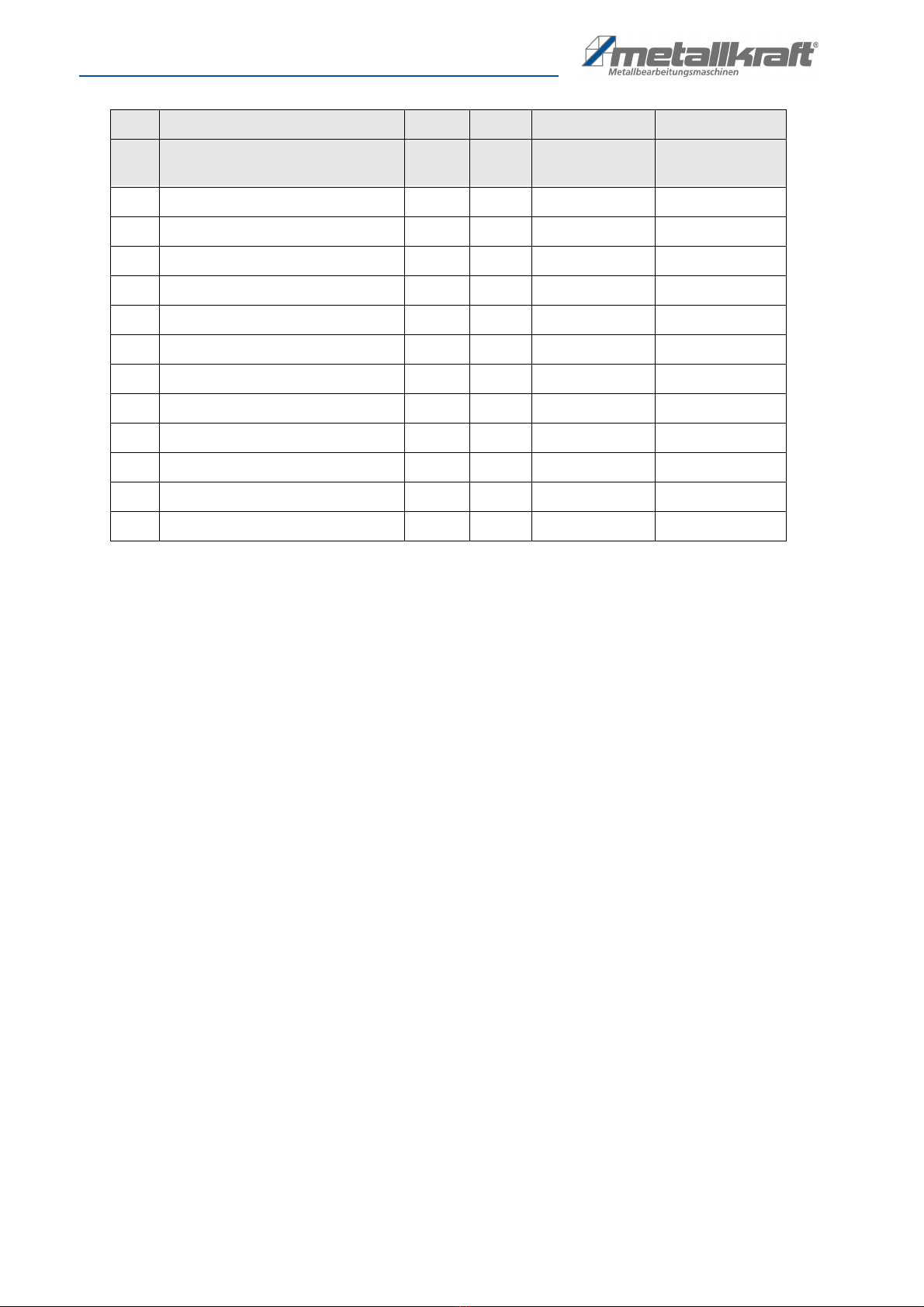

33 FIXING ELEMENT 2 0392207533 0392215033

34 COUNTERSUNK SCREW 1 M6X50 0392207534 0392215034

35 WASHER 6

Φ

6 0392207535 0392215035

36 THREADED BOLTS 3 M8X12 0392207536 0392215036

37 COVER PLATE 1 0392207537 0392215037

38 LOCKING NUT 2 M6 0392207538 0392215038

39 NUT 2 M4 0392207539 0392215039

40 MOTOR 1 0392207540 0392215040

41 SCREW 4 M8x20 0392207541 0392215041

42 LEVER 1 0392207542 0392215042

43 COVER 1 0392207543 0392215043

44 SUPPORT PLATE 1 0392207544 0392215044

45 RIGHT COVER 1 0392207545 0392215045

46 LATERAL STOP 1 0392207546 0392215046

47 HANDLE 1 0392207547 0392215047

48 PIN 1 3X20 0392207548 0392215048

49 SPRING 1 0392207549 0392215049

50 LEVER 1 0392207550 0392215050

51 BASIS 1 0392207551 0392215051

52 WASHER 1 0392207552 0392215052

53 LOCKING BUTTON 1 0392207553 0392215053

54 LOCK SHAFT 1 0392207554 0392215054

55 SCREW 1 6X16 0392207555 0392215055

56 ALLEN SCREW 1 M5X20 0392207556 0392215056

57 GRINDING BELT 1 0392207557 0392215057

58 WASHER 1

Φ

32 0392207558 0392215058

59 DRIVE WHEEL 1 0392207559 0392215059

60 COUNTERSUNK SCREW 2

M8X20

0392207560 0392215060

61 PLASTIC DISC 2

Φ

8 0392207561 0392215061

62 HEXAGON SCREW 2 M8X12 0392207562 0392215062

63 CONNECTOR 1 0392207563 0392215063

64 HANDLE 1 0392207564 0392215064

65 GRAPHITE SUPPORT 1 0392207565 0392215065

66 HINGE 4 0392207566 0392225066

MBSM 75-200-2 MBSM 150-200-2

Pos. Description Quan-

tity

Size Item number Item number

18 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

Spare parts

67 COUNTERSUNK SCREW ISO 7047 16 M4X6 0392207567 0392215067

68 CUP SPRING 1 0392207568 0392215068

69 HEXAGON SCREW 1 6X12 0392207569 0392215069

70 REMOVABLE SHEET 1 0392207570 0392215070

71 ADJUSTABLE HANDLE 1 0392207571 0392215071

72 MONTING PLATE 1 0392207572 0392215072

73 SCREW 1 8X120 0392207573 0392215073

74 SWITCH 1 0392207574 0392215074

75 SCREW 4 6X12 0392207575 0392215075

76 WASHER 4

Φ

6 0392207576 0392215076

77 EMERGENCY STOP 1 0392207577 0392215077

78 SCREW 4 4x12 0392207578 0392215078

MBSM 75-200-2 MBSM 150-200-2

Pos. Description Quan-

tity

Size Item number Item number

Circuit diagram

MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05 19

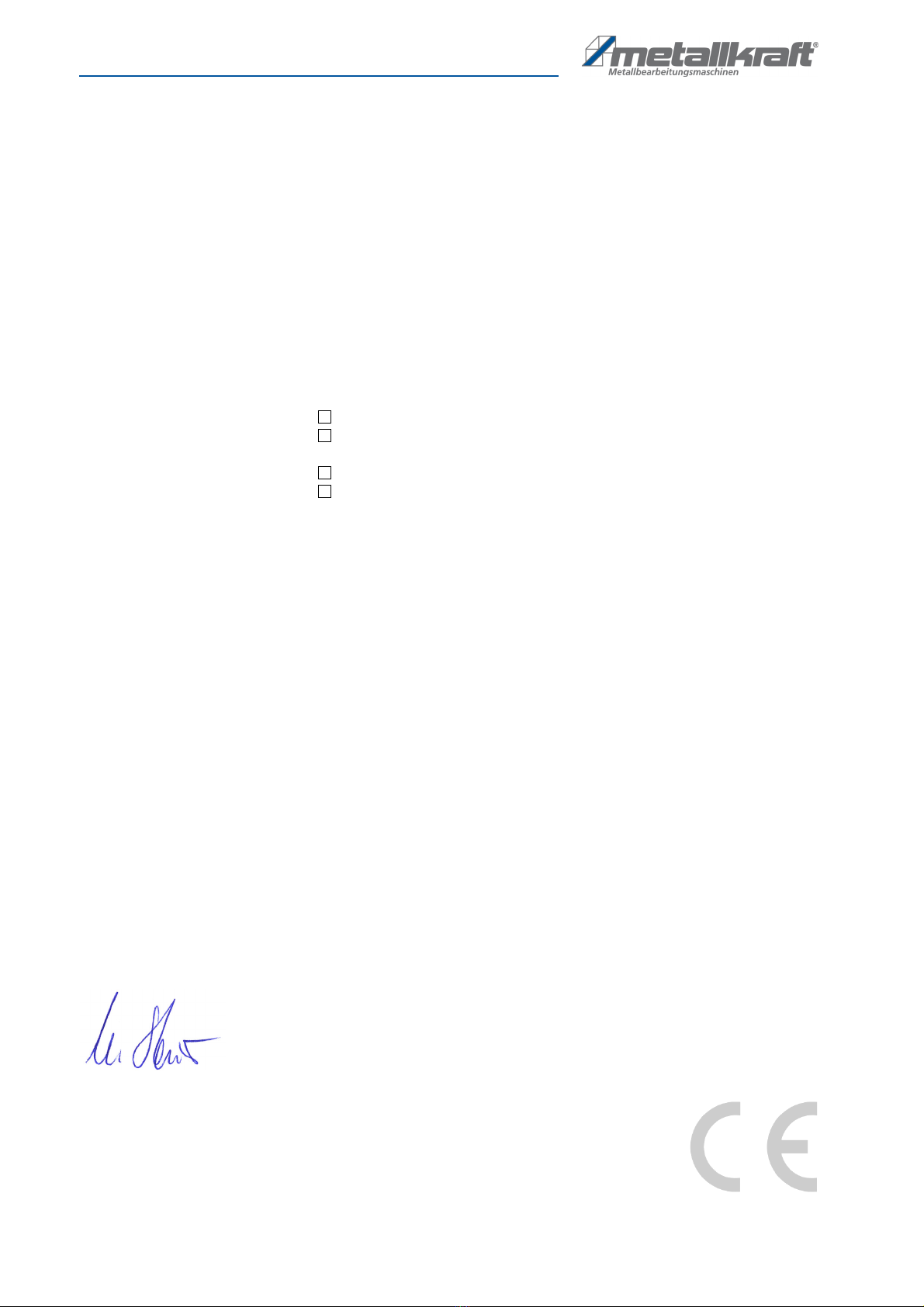

14 Circuit diagram

Fig.5: Circuit diagram MBSM 75-200-2 and MBSM 150-200-2

20 MBSM 75-200-2 | MBSM 150-200-2 | Version 2.05

EC-Dec aration of conformity

According to Machinery Directive 2006/42/EC Annex II 1.A

Manufacturer / distributor:

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Straße 26

D-96103 Hallstadt

hereby declares that the following product

Product Group:

Metallkraft® Metallbearbeitungsmaschinen

Machine type:

Metal- belt sander

Description of the machine*:

MBSM 75-200-2

MBSM 150-200-2

Item number*:

3922075

3922150

Seria number*:

____________________

Year of manufacture*:

20____

* fill in these fields using the information on the nameplate

corresponds to all the relevant provisions of the abovementioned Directive and other Directives applied (below) - includ-

ing their amendments valid at the time of the declaration.

Re evant EU Directives:

2014/30/EU EMC Directive

The fo owing harmonized standards have been app ied:

DIN EN ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

reduction (ISO 12100:2010)

DIN EN 60204-1:2007-06 Safety of machinery - Electrical equipment of machines - Part 1: General

requirements

Responsib e for documentation:

Kilian St rmer, St rmer Maschinen GmbH,

Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, den 15/04/2016

______________________

Kilian St rmer

Manager

15 EC-Dec aration of conformity

This manual suits for next models

3

Table of contents

Popular Sander manuals by other brands

Sparky Group

Sparky Group PMB 1200CE Original instructions

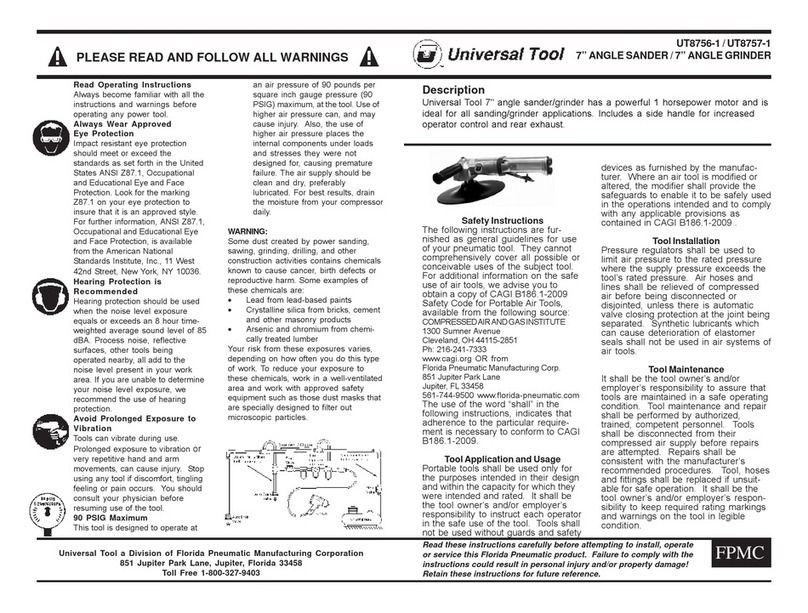

Florida Pneumatic

Florida Pneumatic Universal Tool UT8756-1 quick start guide

Oliver

Oliver 5370 owner's manual

Scheppach

Scheppach DS200 Translation of the original manual

Rupes

Rupes LH75P Operating and maintenance instructions

Fein

Fein CG13-150 instruction manual