MetalMaster EWM-75 User manual

OPERATION MANUAL

Edition No : EWM-75-1

Date of Issue : 02/2021

Model. EWM-75

Order Code S225

English Wheels

2

OPERATION MANUAL

NOTE:

In order to see the type and model of the machine, please see the

specication plate. Usually found on the back of the machine. See

example (Fig.1)

Fig.1

ENGLISH WHEEL

MACHINE

EWM-75

MODEL NO.

SERIAL NO.

DATE OF MANF.

Note:

This manual is only for your reference. Owing to the continuous improvement of the

Metalmaster machine, changes may be made at any time without obligation or notice.

Please ensure the local voltage is the same as listed on the specication plate before

operating any electric machine.

Distributed by

www.machineryhouse.co.nz

MACHINE DETAILS

3

OPERATION MANUAL

C O N T E N T S:

1. GENERAL MACHINE INFORMATION

1.1 Specications.............................................................. 4

1.2 Accessories Included................................................ 4

1.3 Identication............................................................... 5

2. IMPORTANT INFORMATION

2.1 General Metalworking Machine Safety............. 6

2.2 Specic Safety For English Wheels...................... 8

3. SETUP

3.1 Unpacking.................................................................... 9

3.2 Assembly...................................................................... 9

4. OPERATION

4.1 Operation Overview................................................. 10

4.2 Tracking Patterns....................................................... 11

5. MAINTENANCE

5.1 Cleaning And Oiling................................................. 11

Spare Parts............................................................................ 12

Risk Assessment Sheets.................................................... 15

4

OPERATION MANUAL

1.1 SPECIFICATION

Order Code S225

MODEL EWM-75

Operation (Type) Hand Operated

Mild Steel - Capacity (mm/gauge) 1.6 / 16

Copper - Capacity (mm/gauge) 2.0

Throat Depth (mm) 711

Top Anvil Size (mm) Ø203 x 50

Radius Dies (mm) 50, 73, 101, 152, 203, 305

Working Height (mm) 1200

Dimensions (L x W x H) (mm) 350 x 90 x 350

Packing Dimensions (L x W x H) (mm) 89 x 77.5 x 18.5

Weight (kg) 73

1.2 ACCESSORIES INCLUDED

Includes 50.8, 76.2, 101.6, 152.4, 203.2, 304.8mm

radius dies & 1 x at die

Instruction Manual

Fig. 2

5

OPERATION MANUAL

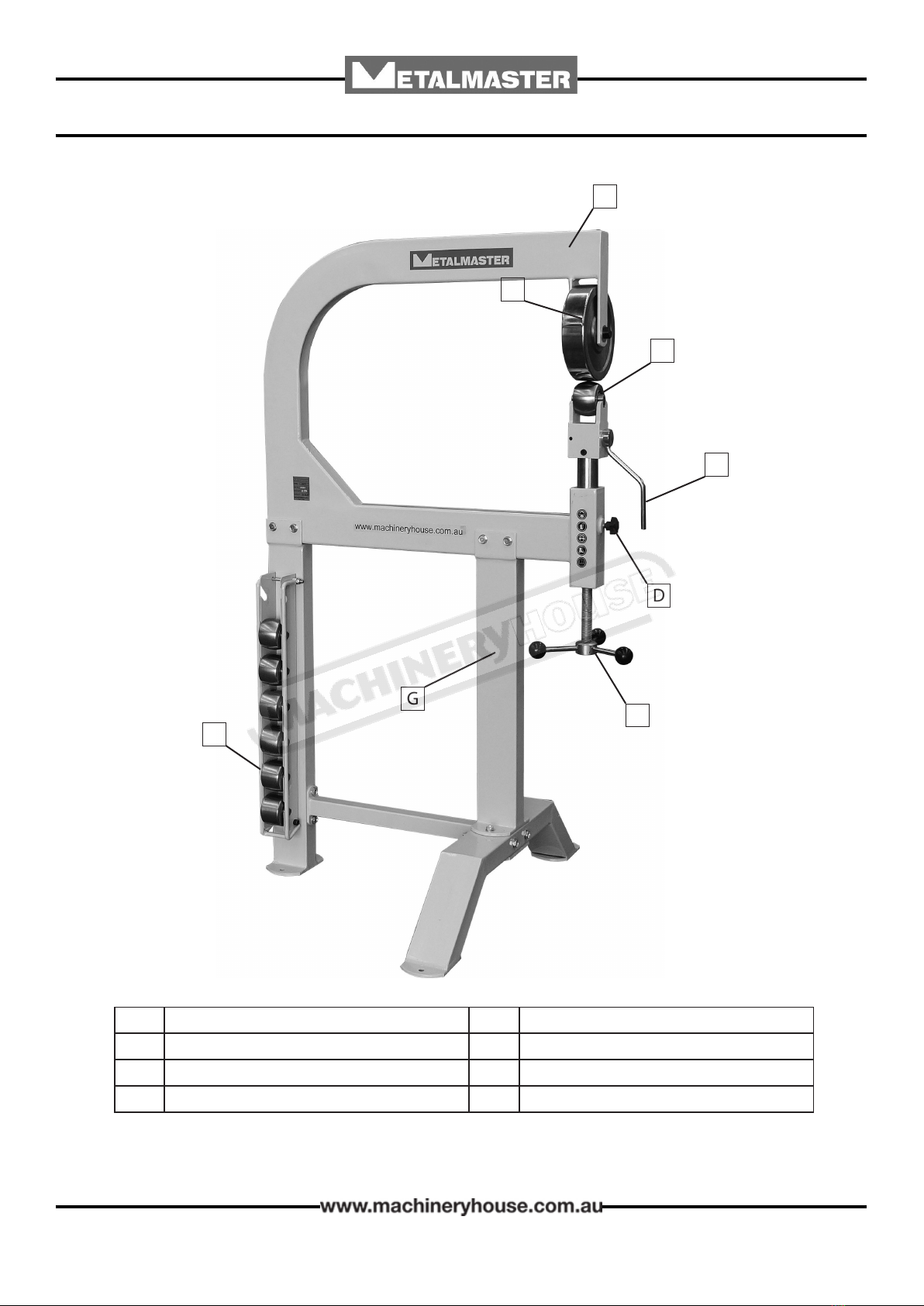

AMain Frame EAdjusting Handle

BBottom Die FTop Die

CHandle GStand

DLocking Knob HBottom Die Rack

A

B

H

D

F

1.3 IDENTIFICATION

C

E

G

6

OPERATION MANUAL

: When using any tool, basic safety precautions should always be followed

to reduce the risk of personal injury and damage. Read the instruction manual before using any

tool or machine!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep the work area well lit. Do not use electric power tools

or machinery in the presence of ammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let them

handle machinery, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool capacity.

6. Use the right tool for the job. Do not attempt to force any machine, tool or attachment to

do the work of a larger industrial tool. Do not modify, and do not use any tool for a

purpose for which it was not intended.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Protective, electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved impact safety goggles. Wear

a full face shield if you are producing metal lings or wood chips. Wear an ANSI approved

dust mask or respirator when working around metal, wood, and chemical dusts and mists.

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines. Keep hands and ngers clear of moving parts.

10. Maintain tools with care. Keep tools clean for better and safer performance. Follow the

instructions for lubricating and changing accessories. Handles must be kept clean, dry,

and free from oil and grease at all times.

11. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches are

removed from the tool or machine work surface before plugging it in.

12. Stay alert. Be attentive and use common sense. Do not operate any machine or tool when

you are tired.

13. Check for damaged parts. Before using any machine or tool, parts that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function safely. Check for alignment and binding of moving parts. Any broken

parts or mounting xtures, or any other condition that may aect proper operation. Any

part that is damaged should be properly repaired or replaced by a qualied technician. Do

not use the machine or tool if any switch does not turn on and o properly.

2.1 GENERAL METALWORKING MACHINE SAFETY

7

OPERATION MANUAL

2.1 GENERAL METALWORKING MACHINE SAFETY

14. Replacement parts and accessories. When servicing, use only identical replacement parts.

The use of any other parts will void the warranty. Only use accessories intended for use

with the machine or tool.

15. Do not operate machinery if under the inuence of alcohol or drugs. Read warning labels

if taking prescription medicine to determine if your judgment or reexes are impaired

while taking drugs. If there is any doubt, do not operate the machinery or tools.

16. Maintenance. For your safety, service and maintenance should be performed regularly by a

qualied technician.

17. Workpiece may be sharp. After bending or cutting workpieces use caution. Be aware of

sharp edges or metal debris of metal that may be created. Use heavy duty gloves when

handling the workpiece.

18. Health and re hazards. Understand that the health and re hazards can vary from

material to material. Make sure all appropriate precautions are taken.

19.Clean-up when nished. Clean machines and the surrounding area when the operation is

nished.

20.Use proper lock out procedures. When servicing or cleaning machines, make sure that the

machine cannot be started by accident.

DO NOT

×Do not distract an operator. Horseplay can lead to injuries and should be strictly prohibited.

×Do not wear loose clothing, gloves, necktie’s, rings, bracelets or other jewellery that can be

come entangled in moving parts. Conne long hair.

×Do not handle cuttings by hand because they are very sharp. Do not free a stalled cutter

without turning the power o rst. Do not clean hands with cutting uids.

×Do not use rags or wear gloves near moving parts of machines.

×Do not use compressed air to blow debris from machines or to clean dirt from clothes.

×Do not force the machine. It will do the job safer and better at the rate for which it was

designed.

BEFORE OPERATING ANY MACHINE, TAKE TIME TO READ AND UNDERSTAND

ALL SAFETY SIGNS AND SYMBOLS. IF NOT UNDERSTOOD SEEK EXPLANATION

FROM YOUR SUPERVISOR.

MACHINES ARE SAFEGUARDED TO PROTECT THE OPERATOR FROM INJURY

OR DEATH WITH THE PLACEMENT OF GUARDS. MACHINES MUST NOT BE

OPERATED WITH THE GUARDS REMOVED OR DAMAGED.

8

OPERATION MANUAL

2.2 SPECIFIC SAFETY FOR ENGLISH WHEELS

DO NOT use this machine unless you have been instructed in its safe use

and operation and have read and understood this manual.

Safety glasses must be worn at

all times in work areas.

Close tting protective clothing or

overalls are encouraged

Appropriate protective footwear

with substantial uppers must be

worn.

Rings and jewelery must NOT be

worn in the workshop

PRE-OPERATIONAL SAFETY CHECKS

1. Ensure you are familiar with the operation of the English Wheel

2. Check for any damage or parts missing

3. The area around the machine must be clean and free of trip hazards.

4. Any forming die must be inspected for safe use i.e. no cracks.

5. Ensure safety glasses or goggles are available and are worn by all persons in the vicinity.

6. Any test piece, project or material (work piece) to be worked must be of an appropriate

thickness and safe to use on this equipment.

7. Faulty equipment must not be used. Immediately check suspect machinery.

OPERATIONAL SAFETY CHECKS

1. Place your test piece, project or material (work piece) securely between the top and bottom

dies

2. Do not over reach. Maintain a balanced stance at all times, so that you do not fall or lean

against the machine.

3. Use the English Wheel by moving the workpiece is a forward and back action, to slowly

work the material.

4. Keep hands and ngers away from the dies.

5. Wear leather gloves when handling the work piece.

6. Use the right tool. Do not force a die set to do a job that it was not designed to do.

7. Give your work undivided attention. Looking around, carrying on a conversation and

“horseplay” are careless acts that can result in serious injury

8. DO NOT apply excessive force to the English Wheel.

AFTER OPERATION COMPLETED

1. Clean the machine and place any tools and equipment in the appropriate storage area.

2. Place all scrap or waste in the appropriate bin.

POTENTIAL HAZARDS

Beware of high forces applied Eye injuries – ying or shattering objects

Pinch and squash Laceration injuries

Gloves should be worn when

handling the work piece

Ear protection should be used in

loud and noisy conditions

9

OPERATION MANUAL

3. SETUP

3.1 UNPACKING

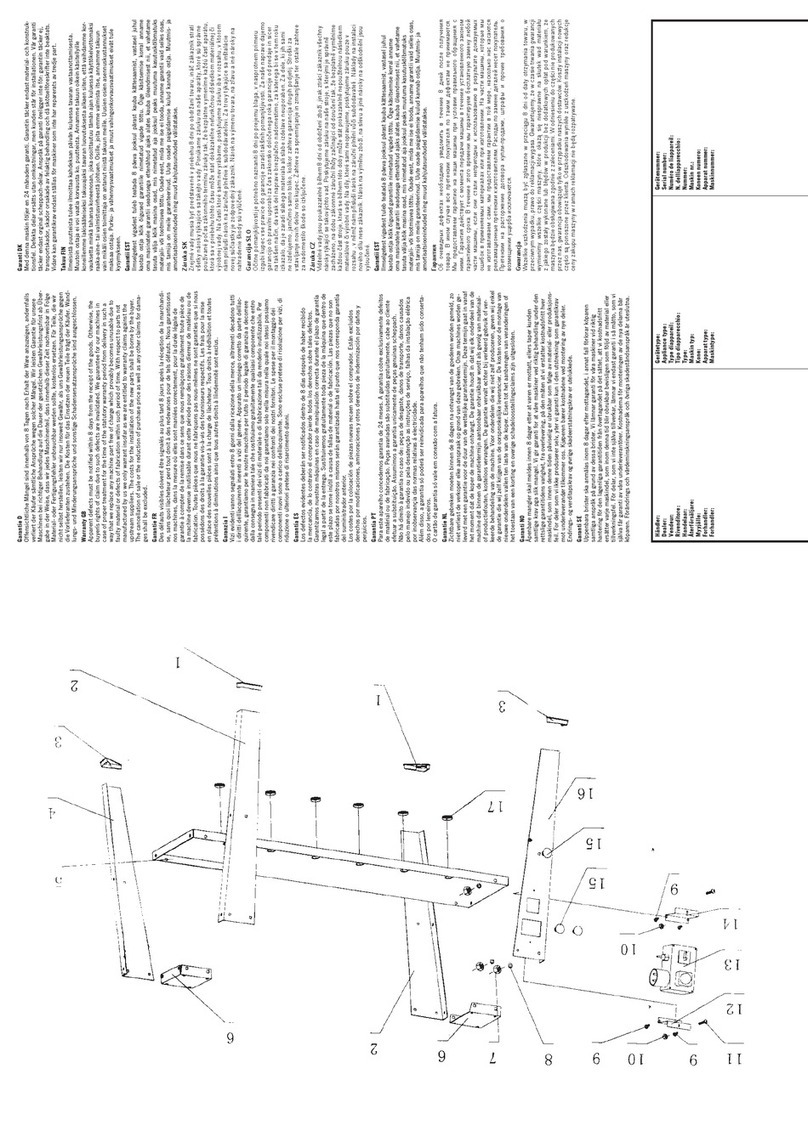

When unpacking, check to make sure that all parts shown in the Parts Diagram are included. If

any parts are missing or broken, please contact the distributer

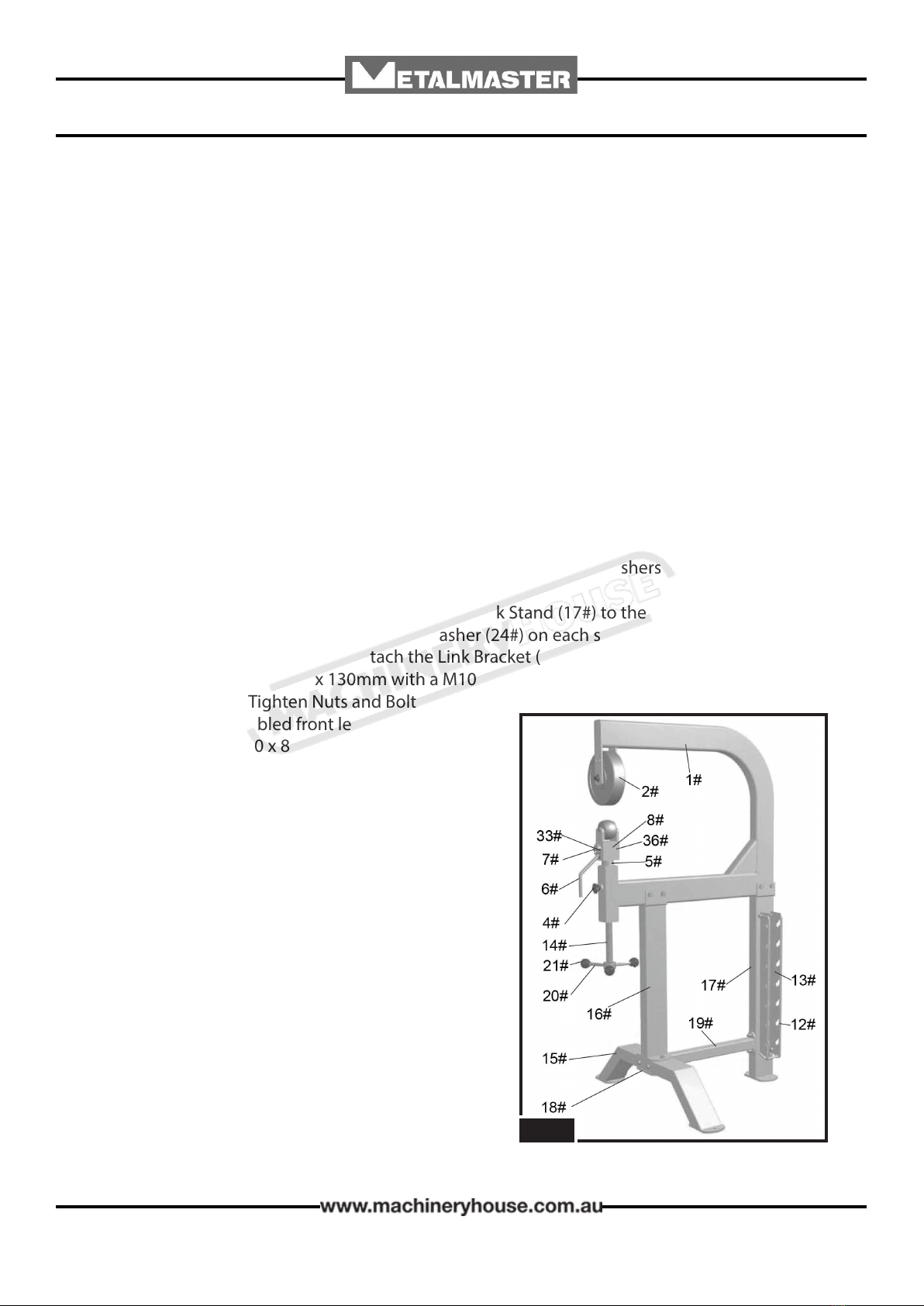

3.2 ASSEMBLY

THE METALMASTER English Wheel will require minor assembly prior to operation. It is import-

ant that the entire manual is read to become familiar with the unit BEFORE you

assemble and use the Machine. Before assembling the English Wheel, be sure that you have all

parts described in the Parts List. (Fig.3.1)

To assemble the machine:

1. Layout the English Wheel components on the oor where the unit will be located and

mounted. The oor must be able to support the weight of the English Wheel and the

workpieces.

2. Attach the Front Stand (15#) under the Front Tube (16#) so that the mounting holes align.

Insert the two Bolts M10 x 85mm (25#) with a M10 washer (24#) from the top. Once the

bolts are ready, place the plate (18) over the bolts with a M10 Washers (24#), and then a

M10 nut (26#)

3. With the parts laying on the oor, attach the Back Stand (17#) to the main frame (1#) using

the two M10 x 80mm bolts with a M10 Washer (24#) on each side of the main frame and

secure with a M10 Nut ((26#). Attach the Link Bracket (19#) to the Back Stand (17#) using

the two Bolts (35#), M10 x 130mm with a M10 Washers (24#) both sides of the frame, and

M10 Nuts (26#). Tighten Nuts and Bolts securely.

4. Attach the assembled front leg (16#, 15#) using

the two Bolts M10 x 80mm (23#), with a M10

Washers (24#),on each side of the frame, then

M10 nut (26#).

5. Attach the link bracket (19#) to the front leg

assembly (16#, 15#) with the two bolts M10 x

85mm (25#) with a M10 washer (24#) both sides

of the frame and secured with a M10 nut (26#0

6. With the help of at least two other people, lift the

assembled Frame so that it is upright.

7. Securely tighten all assembled frame

components.

8. Insert Steel Tube (5#) into the Bottom Die Yoke

(8#). Secure with two Screws M8 x 12mm (32#).

Place Assembly into the mounting hole in Frame

(1#).

9. Screw Knob (4#) into the threaded hole on Frame

(1#). Lift and turn Steel Tube (5#) so that the Knob

(4#) seats into the slot of Steel Tube (5#). Tighten

Knob (4#).

Fig. 3.1

10

OPERATION MANUAL

3. SETUP

10. Insert the Eccentric Shaft (7#), with the Handle (6#), into the hole of Bottom Die Yoke

(8#).

11. Thread each Handle Lever (20#) into the Thread Rod (14#). and securely tighten. Thread on

to the Handle the Balls (21#).

12. Screw Thread Rod (14#) into the bottom of Frame (1#). and into Steel Tube (5#) already

installed in Frame (1#).

13. Place the Top Die (2#) with Bearings (9#) on each side, into the top of the Frame (1#). Secure

in place with Shaft (3#), Washers M20, and M16mm(22# & 37#),and M16 Nut (31#). Securely

tighten.

14. Mount the Bottom Die Rack (13#) to the Back Stand (17#) using two Bolts M8 x 65mm(28#),

M8 Washers both sides (29#), and M8 Nuts (30#). Securely tighten.

15. Mount the Lock Bracket (12#) onto the Bottom Die Rack (13#) using M8 x 95mm Bolt (34#),

M8 Washer (29#), and M8 Nut (30#). Securely tighten.

16. Install Shafts (10#) in each Bottom Die (11#-01 to 11#-06) with Bearings (9#).

17. Open the Lock Bracket (12#) and place each Bottom Die (11#-01 to 11#-06) on the

Bottom Die Rack (13#). Each Bottom Die has its size stamped on it. Place in order of size on

the Bottom Die Rack (13#).

18. With the help of two other people, move the assembled English Wheel to the location

where it will be mounted to the oor. Measure the size of the mounting holes in the Front

Stand (15#) and Back Stand (17#), then drill appropriate size holes in the oor to

accommodate the mounting hardware(not supplied).

4. OPERATION

4.1 OPERATIONAL OVERVIEW

The instructions in this section are written with the understanding that the operator has the

necessary knowledge and skills to operate this machine.

1. Select the Bottom Die from the Bottom Die Rack (13#), and place on the Bottom Die in

the Yoke(8#). When selecting the Bottom Die, consider the type and hardness of the metal

being formed as well as the desired curvature of the metal.

2. Insert the workpiece in between the Top Die (2#) and the Bottom Die.

3. Turn the hand wheel (Thread Rod 14#) to raise or lower the Bottom Die Yoke (8#) for an

appropriate clearance (or pinching) of the metal between the two dies. It is better to have

a loose pinch than a tight one. A tight pinch will make it harder to push the metal through

the dies and may cause unwanted creasing. A loose pinch makes it easier to push the metal

through the dies, and with more accuracy. It may take more passes to form the

metal, however.

4. Turn Knob (4#) clockwise until tight.

5. Begin forming the metal by pushing and pulling it over the dies.

6. If a small adjustment is required between the dies, loosen Knob (4#) and turn the handle

(6#). This causes the Eccentric Shaft (7#) to slightly raise or lower the Bottom Die. Tighten

Knob (4#) again before proceeding.

11

OPERATION MANUAL

5. MAINTENANCE

5.1 CLEANING AND OILING

When nished with the machine always clean down the machine and oil with a light oil all

moving parts and machined surfaces. Inspect the general condition of the tool. Check for loose

screws,misalignment or binding of moving parts,cracked or broken parts, and any other condi-

tion that may aect its safe operation. If abnormal noise or vibration occurs, have the problem

corrected before further use. Do not use damaged equipment.

5.2 MAINTENANCE SCHEDULE

Maintenance Chart

Maintenance Type Before

Use

After

Use Weekly Monthly Every 6

Months Yearly

Inspect Tools for damage x

Wipe o with clean cloth x x x x x

Oil moving parts with light oil x

When metal passes between the upper and lower

dies, a “track” or shiny line is pressed into the metal.

Various tracking patterns can be used to shape work-

pieces depending upon their shape or size.

Bellow are a list of patterns and their use.

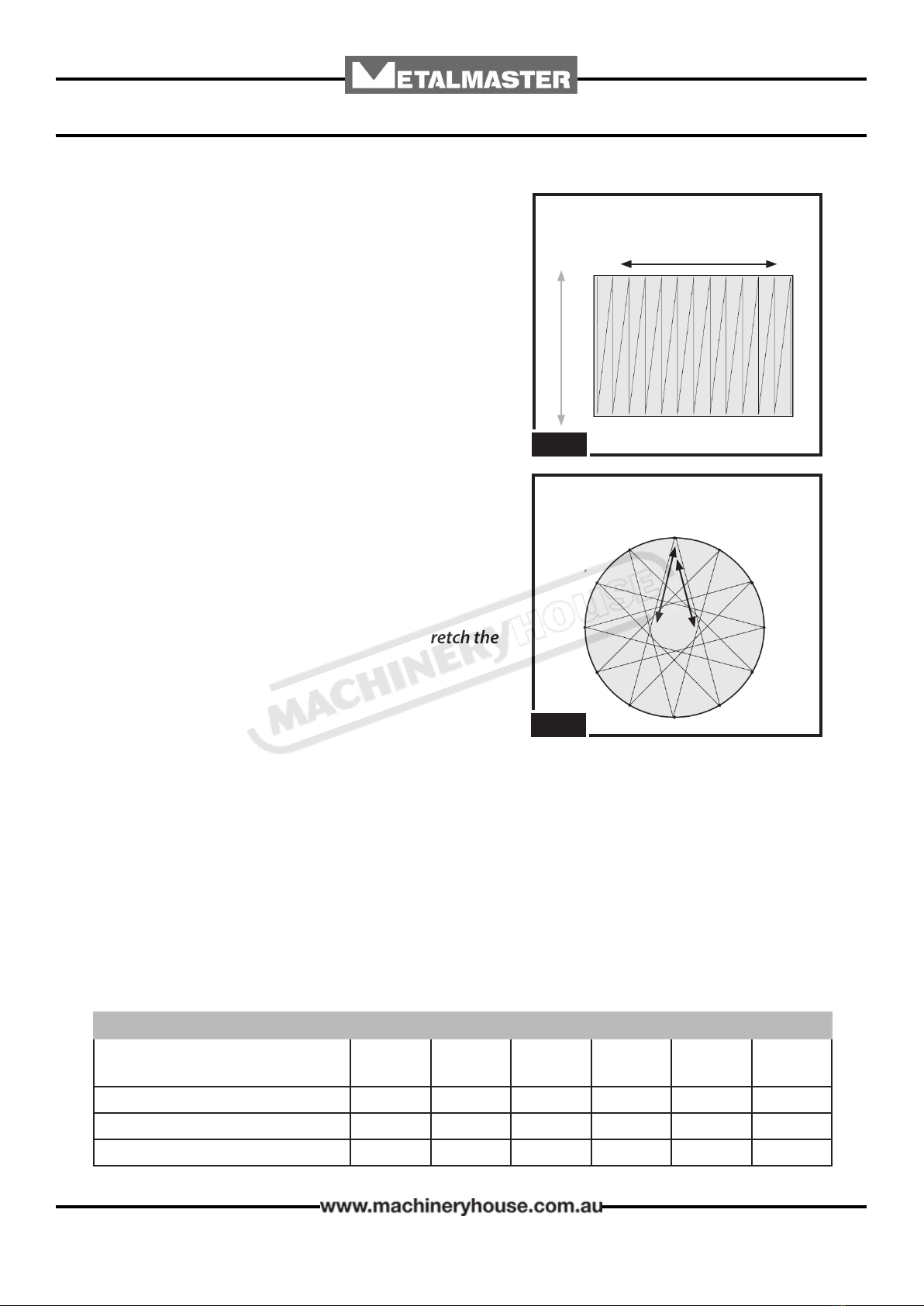

Zigzag Pattern

This pattern can be used for a series of forms.(Fig. 4.1)

Note: Try keeping the tracks close to each other

in a consistent pattern

Star Pattern

The star pattern is useful for shaping round

workpieces. (Fig. 4.2)

Note: Avoid rolling directly over center of

workpiece, as too many passes could overstretch the

metal.

4.2 TRACKING PATTERNS Move

Between

the dies Feed Following the

Pattern

Feed Following the

Pattern

Fig. 4.1

Fig. 4.2

12

OPERATION MANUAL

SPARE PARTS SECTION

Spare Parts Diagram................................................. 13

Spare Parts List........................................................... 14

The following section covers the spare parts diagrams and lists that were current at the time

this manual was originally printed. Due to continuous improvements of the machine, changes

may be made at any time without notication.

HOW TO ORDER SPARE PARTS

1. Have your machines model number, serial number & date of manufacture

on hand, these can be found on the specication plate mounted on the machine

2. A scanned copy of your parts list/diagram with required spare part/s

identied.

NOTE: SOME PARTS MAY ONLY BE AVAILABLE AS AN ASSEMBLY

3. Go to www.machineryhouse.com.au/contactus and ll out the inquiry form attaching a

copy of scanned parts list.

CONTENTS

Edition No : EWM-75-1

Date of Issue : 02/2021

Model. EWM-75

Order Code S225

English Wheels

13

OPERATION MANUAL

SPARE PARTS DIAGRAM

14

OPERATION MANUAL

SPARE PARTS LIST

ITEM DESCRIPTION QT Y. ITEM DESCRIPTION QT Y.

1

2

3

4

5

6

7

8

9

10

1101

1102

1103

1104

1105

1106

1107

12

13

14

15

16

FRAME

TOP DIE

SHAFT

KNOB

STEEL TUBE

HANDLE

ECCENTRIC SHAFT

BOTTOM DIE YOKE

BEARING

SHAFT

BOTTOM DIE 50.8MM/2″

BOTTOM DIE 76.2MM/3″

BOTTOM DIE 101.6MM/4″

BOTTOM DIE 152.4MM/6″

BOTTOM DIE 203.2MM/8″

BOTTOM DIE 304.8MM/12″

FLAT DIE

LOCK BRACKET

BOTTOM DIE RACK

THREAD ROD

FRONT STAND

FRONT TUBE

1

1

1

1

1

1

1

1

16

7

1

1

1

1

1

1

1

1

1

1

1

1

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

BACK STAND

PLATE

LINK BRACKET

HANDLE LEVER

HANDLE BALL

WASHER 20MM

BOLT M10X80

WASHER 10MM

BOLT M10X85

NUT M10

SCREW M10X15

BOLT M8X65

WASHER 8MM

NUT M8

NUT M16

SCREW M8X12

SCREW M10X16

BOLT M8X95

BOLT M10X130

SCREW M4X12

WASHER 16MM

HEX KEY WRENCH 3MM

1

1

1

3

3

1

4

20

2

11

1

2

6

3

1

2

1

1

4

1

1

1

NOTE: SOME INDIVIDUAL PARTS MAY ONLY BE AVAILABLE AS AN ASSEMBLY

General Machinery Safety Instructions

1. Read the entire Manual before starting

machinery. Machinery may cause serious injury if

not correctly used.

2. Always use correct hearing protection when

operating machinery. Machinery noise may cause

permanent hearing damage.

3. Machinery must never be used when tired, or

under the influence of drugs or alcohol. When

running machinery you must be alert at all times.

4. Wear correct Clothing. At all times remove all loose

clothing, necklaces, rings, jewelry, etc. Long hair

must be contained in a hair net. Non-slip protective

footwear must be worn.

5. Always wear correct respirators around fumes

or dust when operating machinery. Machinery

fumes & dust can cause serious respiratory illness.

Dust extractors must be used where applicable.

6. Always wear correct safety glasses. When

machining you must use the correct eye protection

to prevent injuring your eyes.

7. Keep work clean and make sure you have good

lighting. Cluttered and dark shadows may cause

accidents.

8. Personnel must be properly trained or well

supervised when operating machinery. Make

sure you have clear and safe understanding of the

machine you are operating.

9. Keep children and visitors away. Make sure

children and visitors are at a safe distance for you

work area.

10. Keep your workshop childproof. Use padlocks,

Turn off master power switches and remove start

switch keys.

11. Never leave machine unattended. Turn power off

and wait till machine has come to a complete stop

before leaving the machine unattended.

12. Make a safe working environment. Do not use

machine in a damp, wet area, or where flammable

or noxious fumes may exist.

13. Disconnect main power before service

machine. Make sure power switch is in the off

position before re-connecting.

14. Use correct amperage extension cords.

Undersized extension cords overheat and lose

power. Replace extension cords if they become

damaged.

15. Keep machine well maintained. Keep blades

sharp and clean for best and safest performance.

Follow instructions when lubricating and changing

accessories.

16. Keep machine well guarded. Make sure guards

on machine are in place and are all working

correctly.

17. Do not overreach. Keep proper footing and

balance at all times.

18. Secure workpiece. Use clamps or a vice to

hold the workpiece where practical. Keeping the

workpiece secure will free up your hand to operate

the machine and will protect hand from injury.

19. Check machine over before operating. Check

machine for damaged parts, loose bolts, Keys and

wrenches left on machine and any other conditions

that may effect the machines operation. Repair and

replace damaged parts.

20. Use recommended accessories. Refer to

instruction manual or ask correct service officer

when using accessories. The use of improper

accessories may cause the risk of injury.

21. Do not force machinery. Work at the speed and

capacity at which the machine or accessory was

designed.

22. Use correct lifting practice. Always use the

correct lifting methods when using machinery.

Incorrect lifting methods can cause serious injury.

23. Lock mobile bases. Make sure any mobile bases

are locked before using machine.

24. Allergic reactions. Certain metal shavings and

cutting fluids may cause an ellergic reaction in

people and animals, especially when cutting as the

fumes can be inhaled. Make sure you know what

type of metal and cutting fluid you will be exposed

to and how to avoid contamination.

25. Call for help. If at any time you experience

difficulties, stop the machine and call you nearest

branch service department for help.

Machinery House

requires you to read this entire Manual before using this machine.

English Wheel Safety Instructions

1. Maintenance. Make sure all moving parts are

locked down before any inspection, adjustment or

maintenance is carried out.

2. English Wheel Condition. English Wheel machine

must be maintained for a proper working condition.

Never operate a English Wheel machine that

has damaged or worn parts. Scheduled routine

maintenance should performed on a scheduled

basis.

3. Roll Condition. Never operate a English Wheel

machine with damaged or badly worn Rolls. Replace

if required. Rolls should never be greased or

lubricated as rolls will slip the material and will not

bend.

4. Hand Hazard. Keep hands and fingers clear from

moving parts. Serious injury can occur if hand or

finger tips get pinched by rolls and can be dragged

into machine.

5. Gloves & Glasses. Always wear leather gloves and

approved safety glasses when using this machine.

6. Avoiding Entanglement. Tie up long hair and use

the correct hair nets to avoid any entanglement with

the English Wheel machine moving parts.

7. Understand the machines controls. Make sure you

understand the use and operation of all controls.

8. Work area hazards. Keep the area around the

English Wheel machine clean from oil, tools, chips.

Pay attention to other persons in the area and

know what is going on around the area to ensure

unintended accidents.

9. Guards. Do not operate this machine without the

correct guards in place. Necessary guards protect

you from injuries by rolls and moving gears and

parts.

10. Material condition. Material must be clean out of

oil and dry. Oily material can slip and will not bend.

11. Material hardness. Make sure your hardness is

the same throughout the material, we recommend

that you use certified material. Never bend hard

steel, glass or fragile material on this machine.

12. Level machine. Level the machine on a flat

concrete surface by using a spirit level.

13. Feeding material. Making a tight bend in one pass

is not possible. So you need several passes before

you can achieve a certain radius. Tighter curves

and full radius always need more passes.

14. Call for help. If at any time you experience

difficulties, stop the machine and call you nearest

branch service department for help.

Machinery House

requires you to read this entire Manual before using this machine.

Manager:

English Wheel

D

SHEARING

Developed in Co-operation Between A.W.I.S.A and Australia Chamber of Manufactures

This program is based upon the Safe Work Australia, Code of Practice - Managing Risks of Plant in the Workplace ( WHSA 2011 No10 )

Authorised and signed by:

NEW MACHINERY HAZARD IDENTIFICATION, ASSESSMENT & CONTROL

PLANT SAFETY PROGRAM

No.

Hazard

Identification

Item

Hazard

PUNCTURING

MEDIUM

Assessment

Wear gloves to prevent cuts from sharp material.

B

C

LOW

Risk Control Strategies

(Recommended for Purchase / Buyer / User)

Ensure machine is bolted down.

Secure & support work material.

CRUSHING

CUTTING, STABBING,

Keep hands clear from moving parts on rolls.

MEDIUM

Revised Date:

www.machineryhouse.com.au

www.machineryhouse.co.nz

12th March 2012

Plant Safety Program to be read in conjunction with manufactures instructions

Safety officer:

This manual suits for next models

1

Table of contents

Other MetalMaster Lathe manuals

Popular Lathe manuals by other brands

Jet

Jet JWL-1840DVR Operating instructions and parts manual

EINHELL

EINHELL TC-WW 1000/1 operating instructions

Jet

Jet JWL-1442VS owner's manual

Van Norman

Van Norman 204 Instruction manual and parts list

Master Quality Power

Master Quality Power MW40018 instruction manual

Scheppach

Scheppach Lata 5.0 Translation from the original instruction manual

Wadkin

Wadkin BZL operating instructions

Precision matthews

Precision matthews PM-1236T manual

Optimum

Optimum OPTI turn TU 3008G operating manual

Record Power

Record Power MAXI-1 Original instruction manual

Jet

Jet JWL-1640VS operating instructions

Arc Euro Trade

Arc Euro Trade SC3 Dismantling and reassembly guide