© Arc Euro Trade Ltd, England 2012

- 2 -

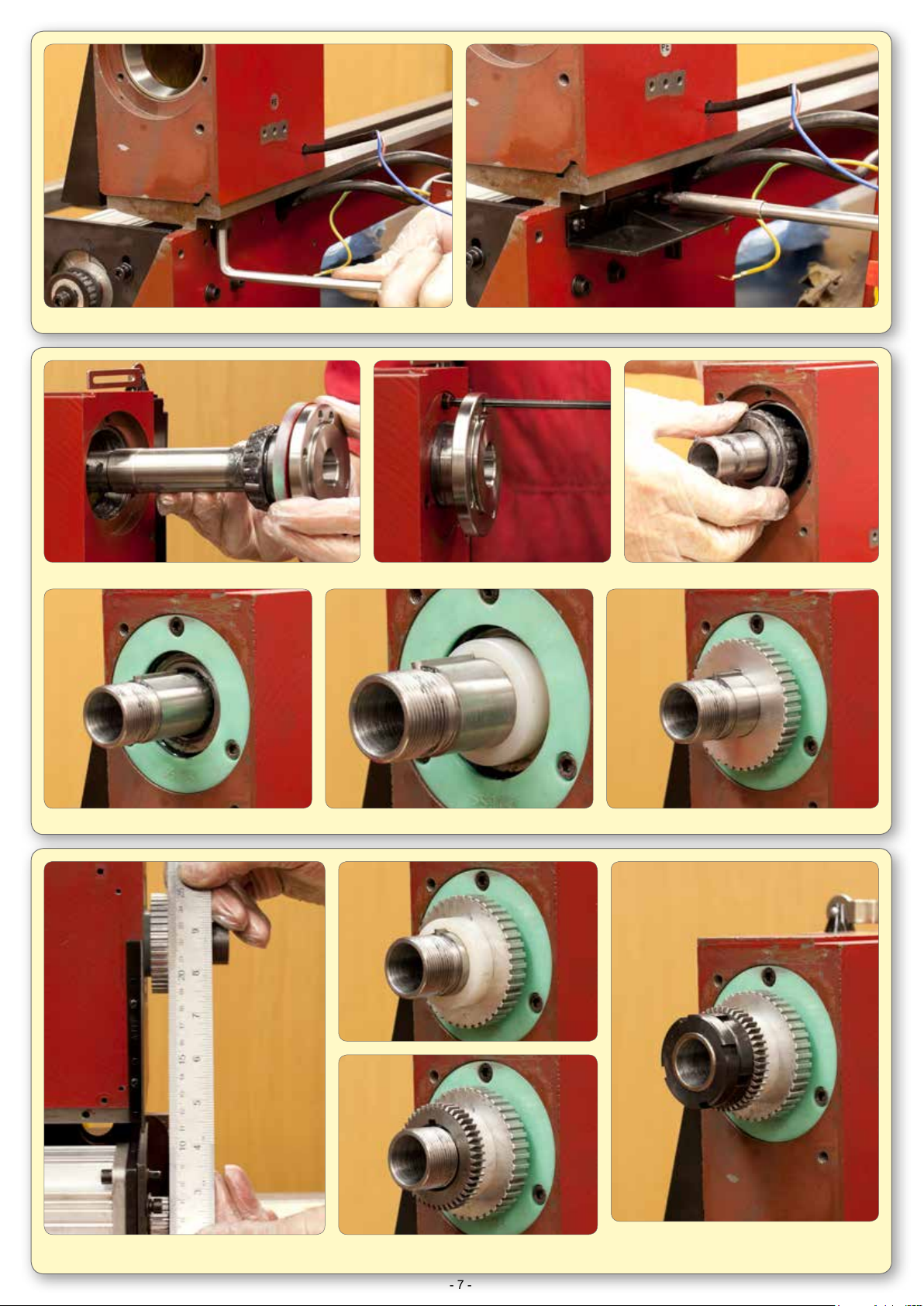

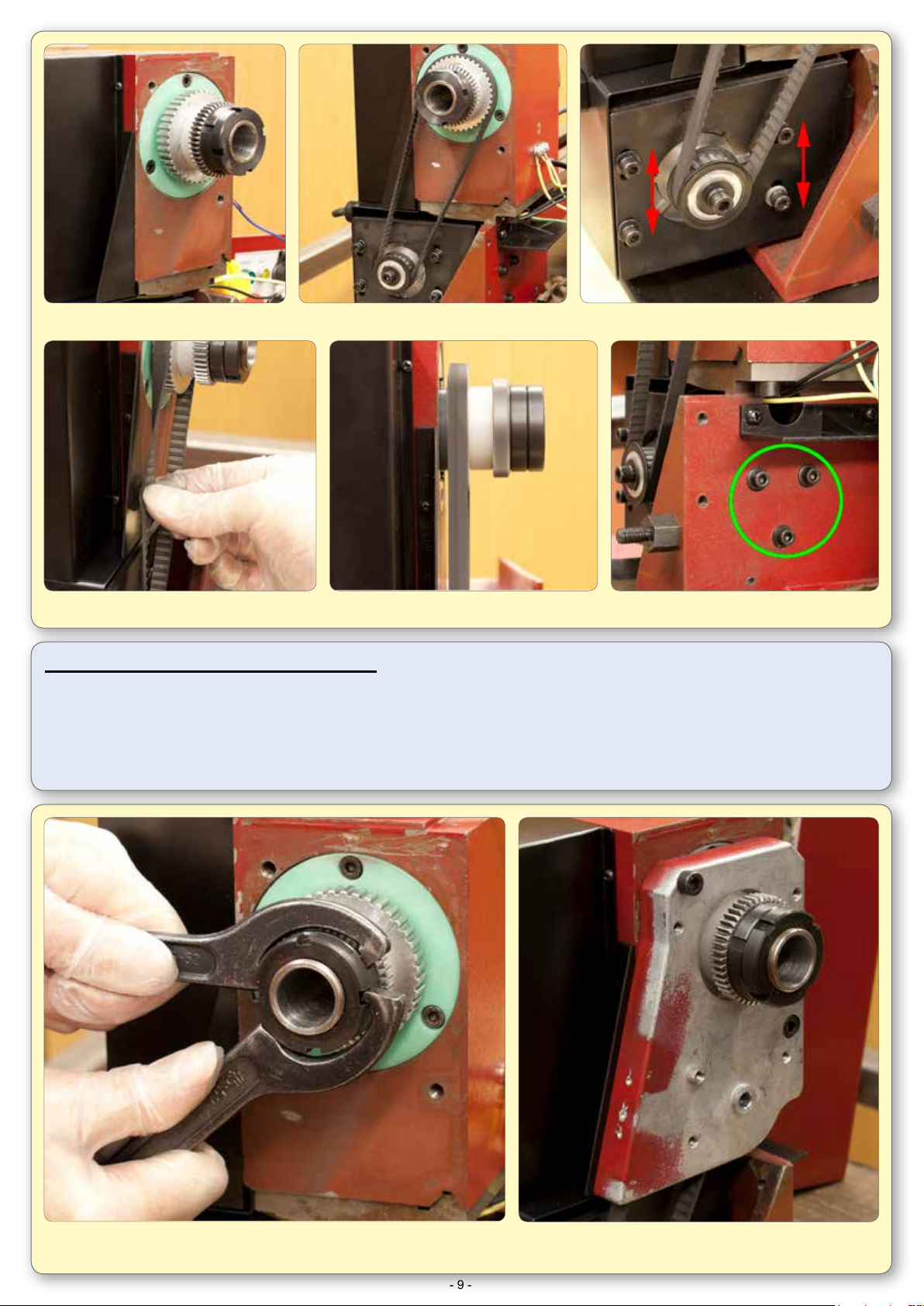

6. Remove the leadscrew gear. 7. Remove the quadrant.

The Sieg C3 Mini Lathe is currently one of the most popular small

lathes available to model engineers today. The new Sieg SC3 takes

the Mini Lathe to a higher level by employing a powerful 500W

brushless motor and eliminating the 2 speed spindle gearbox.

The SC3 has a swing of 180mm (90mm centre height) and is 400mm

between centres. The spindle has a through bore of 20mm and an

MT3 taper whilst the camlock tailstock taper is MT2. The standard

80mm 3 jaw self centring chuck is mounted directly to the spindle

ange which will also accommodate an 80mm 4 jaw independent

chuck, an ER25 collet chuck or an ER32 collet chuck directly on it’s

ø55mm register. A larger 100mm chuck may be tted using one of

our C3 (adaptor) backplates, but we do not recommend the use of a

chuck larger than 100mm.

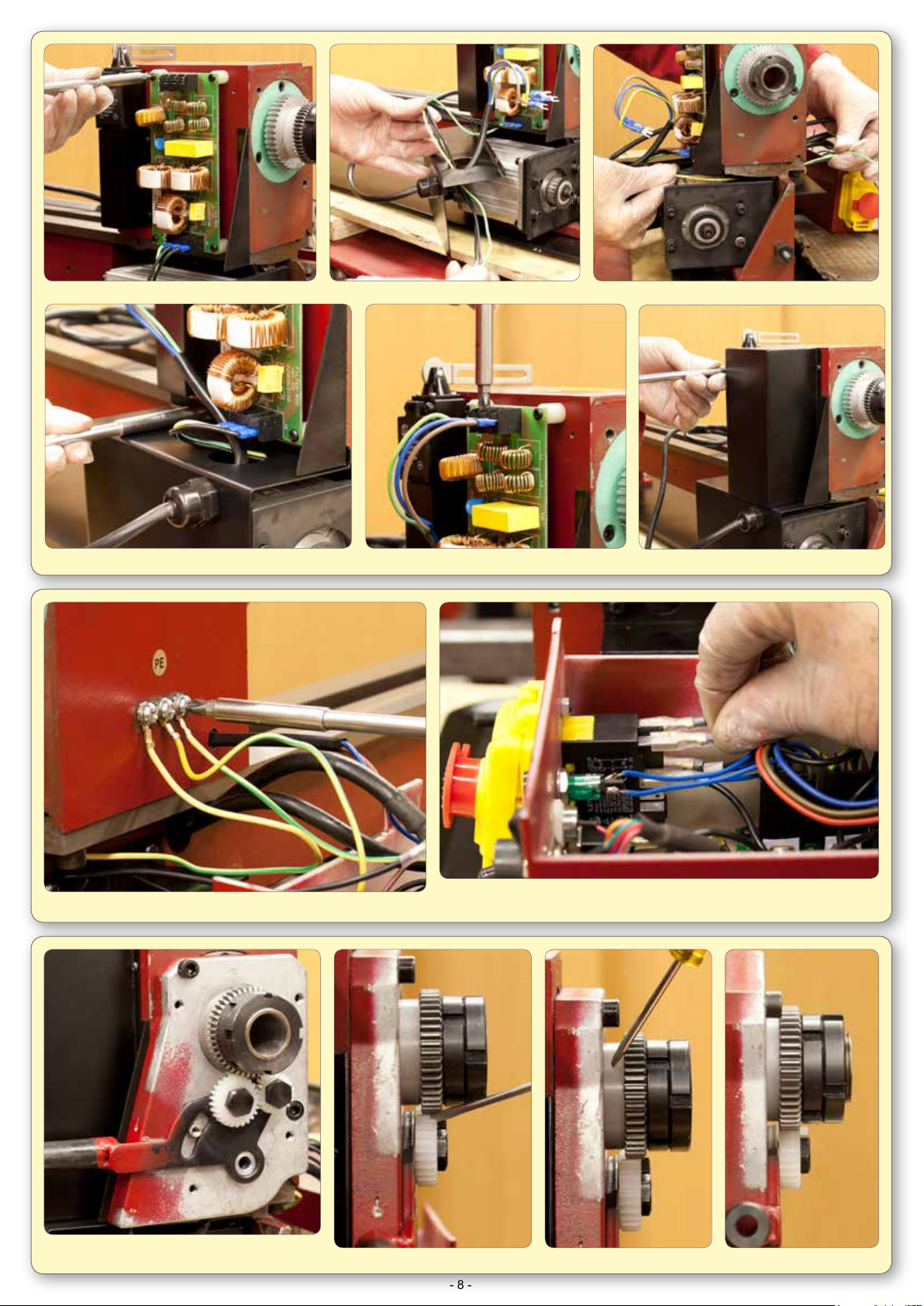

As mentioned earlier, power is provided by a 500w brushless DC

motor which drives the spindle directly via a toothed timing belt and

is electronically controlled to give a speed range of 100-2500 rpm.

The Sieg SC3 is available in both metric and imperial options and

Standard indexable dials are tted as standard to the cross slide and

top slide. The machine is tted with a socket for an optional spindle

speed display and digital readouts are also an extra option.

This picture story guide is designed to help you dismantle,

reassemble, lubricate and make the proper adjustments to your

lathe.

Before dismantling your SC3 mini lathe, you should read through the

entire guide and assess that you have the required equipment and

skills to complete the task. For instance, some operations require the

use of a lathe and you can’t use your lathe if its all in bits!

Although not expressly stated at each stage in this guide, every part

is thoroughly cleaned in a paran type solvent before reassembly.

For lubrication, we recommend Molyslip HSB grease (ARC code:

170-100-10300), and a good quality lubricating oil such as Rock

Oil HLP 32 Hydraulic Oil (ARC code: 170-150-00400). We do not

recommend using automotive engine oil or 3-in-1 oil.

Please note that Sieg also manufacture the C2, C2A, SC2 and C3

mini lathes which are all smaller variations of the SC3 and will have

some construction dierences. There are also other factories in

China making mini lathes similar to the C3 so these will be dierent

again.

[Updated: 4/12/2017]

1. The lathe out of the box and we are ready to start work. 2. Remove the chuck guard.

3. Remove the end cover. 4. Remove the rear splash guard..

5. Remove the tailstock.

PLEASE READ THIS FIRST