MetalMaster HG3208VR User manual

19/3/08

HG3208VR

HYDRAULIC GUILLOTINE

MANUAL

(S960)

S960% % % %%%%%%%% HG3208VR%%%%%%%%%%%%18/3/08

QC11Y-8X3200

Hydraulic Guillotine shears

Operation Manual

Serial No.:Q709103

QC11Y% Hydraulic% Guillotine% Shear%

1

Contents

1、Application of the Machine ―――――――――――――――――2

2、Performance Parameters of Machine. ―――――――――――――――3

3、Structures of the Machine. ―――――――――――――――――― 4

4、Hoisting and Installation――――――――――――――――― ――― 6

5、Adjustment and Operation of Machine ――――――――――――――8

5.1 Preparation before operation ―――――― 8

5.2 Run trial ―――――――――― 8

5.3 Single cut ―――――――――― 9

5.4 Continuous cut ―――――――――― 9

5.5 Adjustment of cutting angle ――――――― 9

5.6 Reset of cutting angle ―――――――――― 40

5.7 Fill oil ―――――――――― 10

6、Hydraulic Driven System ―――――――――――――――――――11

6.1 Cutting principle ―――――――――― 11

6.2 Valve position print ―――――――――― 11

6.3 Valve action print ―――――――――― 12

7、Electric System of Machine ―――――――――――――――――13

7.1 General introduction ―――――――――― 13

7.2 Caution ―――――――――― 13

7.3 Electric principle chart―――――――――― 14

7.4 Electic components list ―――――――――― 15

8、Maintenance &Trouble Shooting ――――――― ―――17

8.1 Blades ―――――――――― 17

8.2 Lubrication of the machine――――――――― 18

8.3 Air pressure inspection of accumulator ―― 19

8.4 Maintenance of hydraulic system ―――― 19

8.5 Maintenance of the machine ―――――――― 20

9、Packing List ―――――――――――――――――――――― 22

QC11Y% Hydraulic% Guillotine% Shear%

2

1

.

A

p

p

l

i

c

a

t

i

o

n

o

f

t

h

e

M

a

c

h

i

T

h

i

s

m

a

c

h

i

n

e

s

u

i

t

s

t

h

e

f

i

QC11Y% Hydraulic% Guillotine% Shear%

3

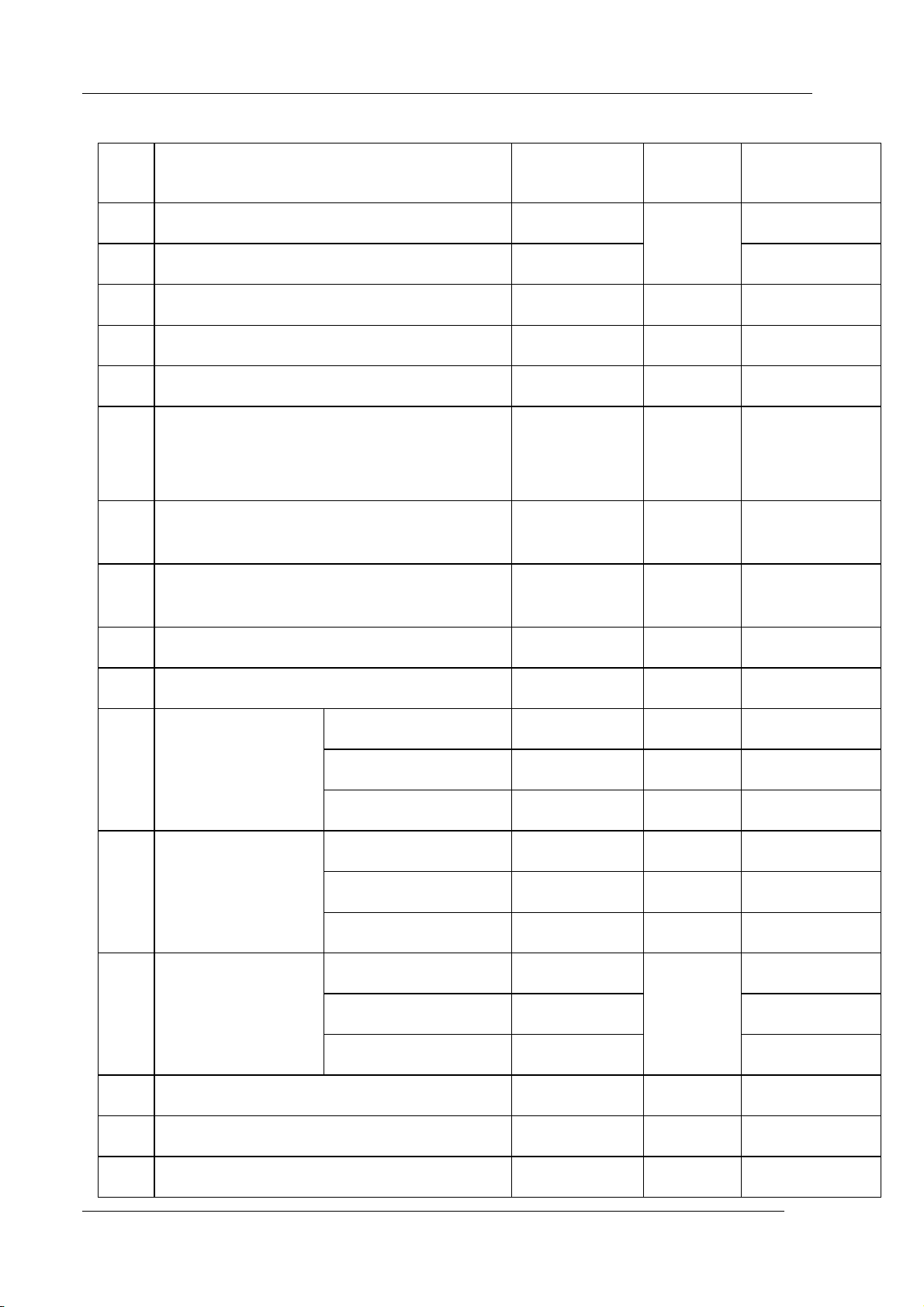

2、Performance Parameters of Machine ( table 1 )

No.

Item

Data

Unit

Notes

1

Max. Cutting Thickness

8

2

Max. Cutting Width

3200

mm

3

Shear angle

2

Degree

4

Stroke times without load

7

Min-1

5

Upper knife Holder Maximum Travel

140

Mm

6

Maximum Cutting Force

280

KN

Including the

return

pressure

7

Maximum Clamping Pressure

280

KN

Vary as per

the load

8

Maximum Working Pressure of

Hydraulic System

18

MPa

9

Adjustment Range of Back-gauge

10-1000

mm

10

Table Height Above Floor

800

mm

Model

Y132M-4B5

Power

7.5

kw

11

Main Motor

Speed

1440

R/min

Model

NT3-G25F

Flow

25

ml/r

12

Oil Pump

Pressure

31.5

Mpa

Length

3850%

Width

2200%

13

Overall

Dimensions

Height

1980%

mm

14

Machine Gross Weight

6800

kg

QC11Y% Hydraulic% Guillotine% Shear%

4

3

、

S

t

r

u

c

t

u

r

e

o

f

t

h

e

M

a

c

h

i

n

e

3

.

1

F

r

a

m

e

:

W

e

l

d

e

d

s

t

e

e

l

c

o

3

.

2

U

p

p

e

r

k

n

i

f

e

b

e

a

m

:

3

.

3

C

y

l

i

n

d

e

r

s

d

e

v

i

3

.

4

H

y

d

r

a

u

l

i

c

s

y

3

.

5

C

l

a

m

p

i

n

g

d

3

.

6

B

l

a

d

e

I

t

c

o

n

s

i

3

.

7

E

l

I

t

c

o

QC11Y% Hydraulic% Guillotine% Shear%

5

3.7.1 Panel fig of switchboard (chart 1)

NO.

Function explanation

1

Power indicator

2

Power switch

3

Cutting angle increase

4

Back gauge distance decrease

5

Back gauge distance increase

6

emergency stop

7

Oil filling button

8

Main motor stop

9

Main motor start

10

cutting stroke adjustment

11

Adjusting\single cutting\continuous cutting switch

12

Cutting angle decrease

13

Back gauge value displayer (E10)

14

Cutting angle position indicator

QC11Y% Hydraulic% Guillotine% Shear%

6

4、Hoisting and Installation

4.1.Hoisting

4.1.1The machine has lift holes at the top for hoisting . Pls choose proper steel ropes and hoisting equipment as per the machine weight. Accidents will occur if the hoisting is not effected properly.

4.1.2 The basis of the machine

The earth around the basis should be solid , and the depth depends on the specific condition.

4.1.2.1 Basis draw(chart2)

QC11Y% Hydraulic% Guillotine% Shear%

7

4.2 Installation of the machine

4.2.1 When installation , remove the balling cover on the worktable , and put the

same height pad at the processing side. And put the IM ruler on the pad. And then

use the lever meter to adjust vertically and horizontally , the allowance is less than

0.2mm every 1000mm length, the left and right direction should be same. The base

depth for machine installation depends on the earth situation (but not less than

500mm.) The earth pouring work is done by twice( pls see the chart). After 15 days

from the date of first pouring, put the machine on the base and adjust horizontally

and then set the foot screws and adjust the pad iron and then make the second

pouring. After 48 hours of that, adjust horizontally and tighten the foot screws.

4.2.2 Before the machine delivery, put the knife beam to bottom dead point and

fix up with pad to prohibit accidents; after installation, pls backout the

twice fixed pads at the inner-bottom between left and right

boards, or else it will cause mechanism troubles.

QC11Y% Hydraulic% Guillotine% Shear%

8

5、Adjustment and Operation of the Machine

5.1 Preparation before the operation

A、Must backout the twice fixed pads at the inner-bottom between left and right

boards, or else it will cause mechanism troubles.

B、Clean the oil stains of the machine surface,inspect all bolts are tighten.

C、Fill the lubrication grease .

D、Clean and fill the Model L-HL 46 ordinary hydraulic oil into the oil tank。

E、The machine should be grounded , connect the power supply , the machine uses

415V/50HZ power.

F、Tighten all hydraulic pipe connecting nut.

G、before the delivery of the machine, the various valves have been locked

properly and tightly. Pls do not adjust the handwheel freely to avoid abnormal

action of the machine and avoid loss.

H、the air pressure of accumulator has been setted to 5~6 MPa before delivery,

need not to adjust unless you have special situation

5.2 Run Trial

A、Power on and turn the power switch to “1 ”.

B、Push the motor button , and start the main motor. Inspect the motor(use the

same axis with oil pump) and make sure that the motor rotation direction should

conform to the oil pump marked direction. If not conformed, pls change the input

phase . But do not change the inner connection. When conformed, start main

motor.

C、Because the knife beam is on the bottom dead point, pls reset it.

1)Turn the switch on the penal to adjust function

QC11Y% Hydraulic% Guillotine% Shear%

9

2)Press oil filling button and angle increase button meantime, adjust the

filling pressure to 14~16 MPa and keep 2~3 seconds.

3)Loose the angle increase button first, then loose oil filling button, knife

beam return.

4)Turn the switch on the penal to cutting function

D、Turn the hand wheel according to the plate thickness and adjust the blade

clearance

E、Adjust the back gauge distance according to the plate length.

F、After above action is finished, then Stamp the foot switch and start the cutting.

G、Push the red button “EMERGENCY STOP” when machine is abnormal or

when you want to stop the machine.

H、After the machine is tested fine under both no load operation and load operation,

then you can make the machine into formal production. If find the machine is

abnormal, you will have to correct the problems and then put into production.

5.3 Single cutting

Turn the switch on the penal to single cutting mode, then stamp the foot switch, the

knife beam moves down and starts to cut. The cutting is finished when moves to

the lower limit SQ3 or when you release the foot switch. After complete the cutting

stroke, the machine will automatically moves up until it is up to the upper limit

SQ4 . If the plate is not cut off completely, pls do not release the foot switch to

avoid the hurt of plate.

5.4 Continuous cutting

Turn the switch on the penal to Continuous cutting mode, stamp the foot switch

and press the pump start button at the same time, then loose them, The knife beam

QC11Y% Hydraulic% Guillotine% Shear%

10

will automatically repeat the action of single mode until that times are up or switch

is turned off . Anyway we do not encourage customers to use this mode as the

machine runs quickly and sometimes may hurt the plate or accident occurs.

5.5 Adjustment of cutting angle

Turn the switch to adjust mode, press the angle decrease or increase button to

decrease or increase cutting angle; after adjustment, turn the switch to cutting

mode.

5.6 Reset of cutting angle(oil compensation of the series oil circuit )

The cutting angle is set up to be 2 degree originally. After many times angle

adjustment, 2 degree maybe not obtainable, and in this situation the angle can be

recovered back to 2 degree. (This item also suits the oil compensation of the series

oil circuit). The procedure is as below: turn the switch to adjust mode, stamp the

foot switch , then push the angle increase button. When the knife beam moves

down to the dead point, hold on the button for a few seconds and then release the

angle increase button , then release the foot switch . After adjustment is finished,

turn the switch to cutting mode.

5.7 Oil filling

When the machine have been operated for a period of time, the return pressure may

be consumed a lot, in this situation the knife beam can not return to the dead point,

so we will have to fill the oil in this case. Oil filling procedures as below: turn the

button on the panel to adjust mode, push the oil filling button, the knife beam

moves down to the dead point, , adjust the overflow valve up to pressure around

14~16Mpa, the pressure will be displayed by pressure meter(17). When filling is

finished, turn the button on the panel to cutting mode.

QC11Y% Hydraulic% Guillotine% Shear%

11

6

、

H

y

d

r

a

u

l

i

c

D

r

i

v

e

n

S

y

s

t

e

m

6

.

1

C

u

t

t

i

n

g

p

r

i

n

c

i

p

l

e

:

W

h

e

n

s

t

a

m

p

t

h

e

f

o

o

t

s

w

i

t

c

h

,

Y

V

1

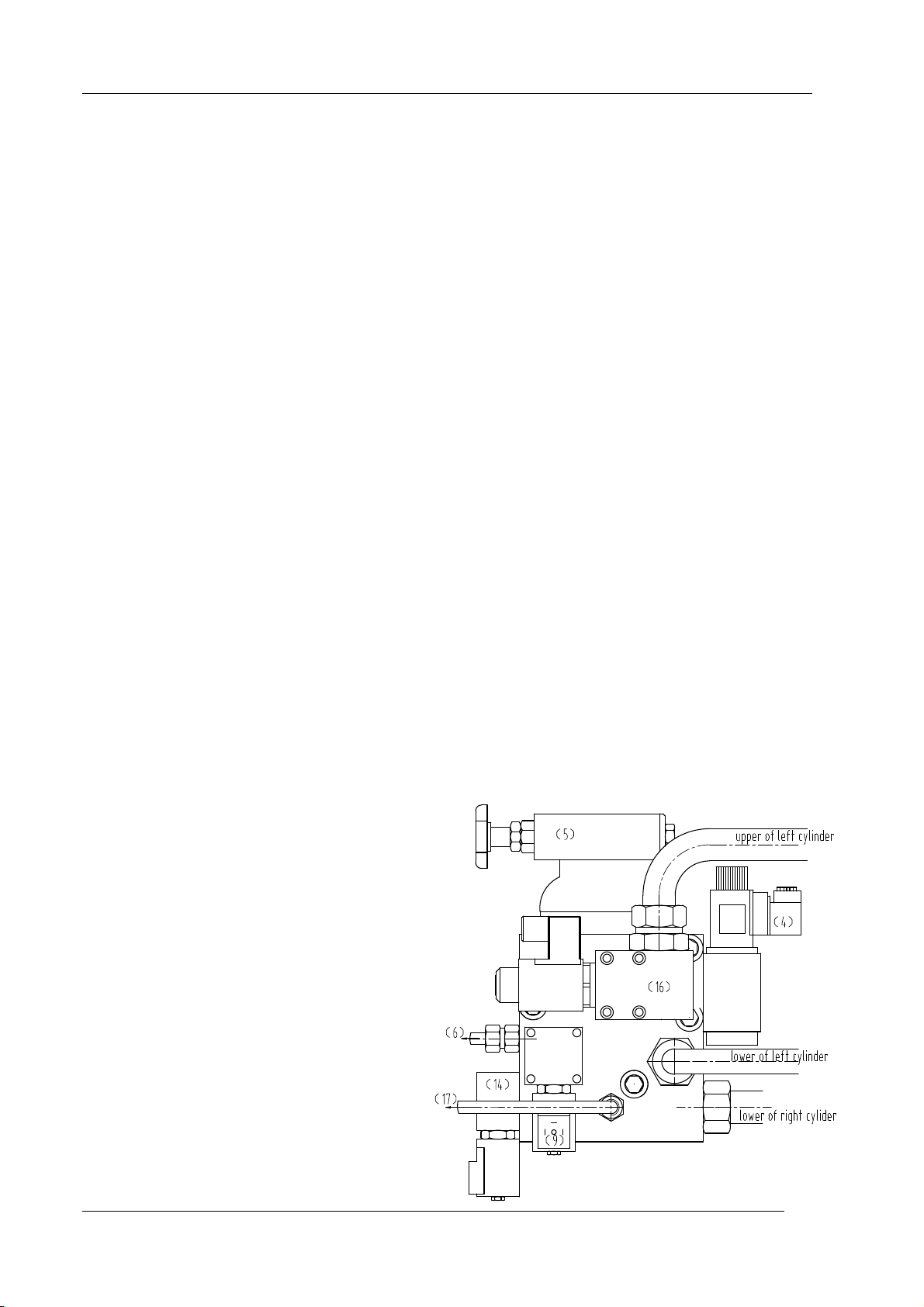

6.2 、

v

a

l

v

e

p

o

s

i

t

overflow valve(5)

m

a

i

n

p

r

e

s

s

u

r

e

e

l

e

c

t

r

o

m

a

g

n

e

e

l

e

c

t

r

o

m

a

g

n

p

r

e

s

s

u

r

e

m

e

l

e

c

t

r

o

m

a

a

n

g

l

e

a

d

e

l

e

c

t

r

o

QC11Y% Hydraulic% Guillotine% Shear%

12

6.3 Hydraulic principle print(chart 4)

QC11Y% Hydraulic% Guillotine% Shear%

13

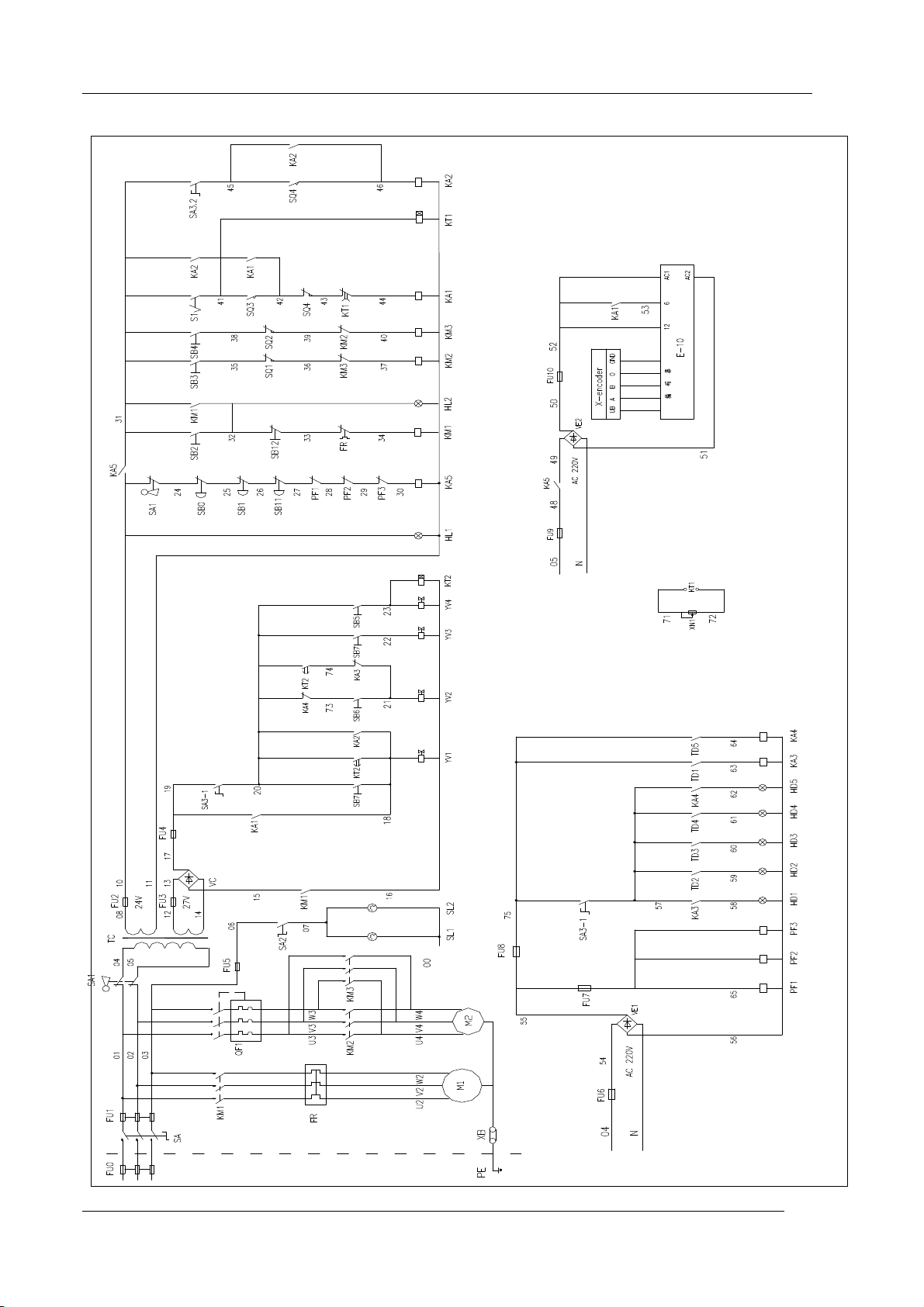

7、Electric System of Machine

7.1

General introduction

:

The machine adopts the three-phase 415V power supply. 24V to A.C. control circuit; 27V and then 24V to D.C. Light power is AC 220V; output of the transformer is supplied to control circuit.The machine connects the ground safely. The electric components of the machine

are maily installed inside the electric box and control panel. Pls refer to our electric components list for introduction of these components.

7.2 Caution:

7.2.1 This machine is special tool, so users should arrange special operators.

The operators should read this operation manual very carefully and receive

training by our plant. Operators can run this machine only under approval of

our technicians by training. People without training can not run this machine

to avoid loss and hurt.

7.2.2 Operator should lock the SA1 key button and turn off the power switch

at the electric box when leaves . Make sure the machine is power off when

no operator.The machine should be grounded properly.

7.3 Electric principle print(refer to chart 5)

7.4 Electric components list (refer to table 2)

QC11Y% Hydraulic% Guillotine% Shear%

14

Electric principle print(chart 5)

QC11Y% Hydraulic% Guillotine% Shear%

15

Electric components list(table 2)

Code

Item

Model

Specs

Usage

KM1

AC connector

LC1-D2510B7

4《0》+1《C》

Oil pump motor control

KM2

AC connector

LC1-D0901B7

3《0》+1《C》

Backgauge motor control

KM3

AC connector

LC1-D0901B7

3《0》+1《C》

Backgauge motor control

KA5

AC connector

LC1-D0901B7

3《0》+1《C》

Backgauge motor control

KA1

Middle relay

LC1-D0901B7

3《0》+1《C》

process control

KA2

Middle relay

LC1-D0901B7

3《0》+1《C》

process control

KA3

Middle relay

process control

KA4

Middle relay

RXM-AAB2B

D+ MY4NJ

3《0》+1《C》

3《0》+1《C》

process control

FR

Heat relay

LR2-D1322

Heat protection of oil pump motor

QF

Air switch

NS80H-MA

32A

Power control of whole machine

QF1

Breaker switch

C65N 3PC3A

3P 4A

Back gauge motor circuit overload

protection

SQ1

Limit switch

TZ-9208

1《0》+1《C》

Back gauge front limit

SQ2

Limit switch

TZ-9208

1《0》+1《C》

Back gauge back limit

SQ3

Limit switch

TZ-9208

1《0》+1《C》

Knife beam upper limit

SQ4

Limit switch

TZ-9208

1《0》+1《C》

Knife beam lower limit

SA1

Key switch

ZB2-BG21

2《0》

power of control

SA2

change switch

ZB2-BD21

1《0》

Alignment Light switch

SA3

Change switch

ZB2-BD33

2《0》+《C》

Selection of adjust/single

SB0

Emergency stop

ZB2-BS542

1《C》

Emergency stop

SB1

Emergency stop

ZB2-BS542

1《C》

Emergency stop

SB11

Emergency stop

ZB2-BS542

1《C》

Emergency stop

SB2

Start button

ZB2-BW3361

1《0》

Oil pump start button

SB12

Control button

ZB2-BA42

1《C》

Oil pump stop

SB3

Control button

ZB2-BA51

1《0》

Control the positive rotating of back

gauge motor.

SB4

Control button

ZB2-BA51

1《0》

Control the reverse rotoation of the

back gauge motor

SB5

Control button

ZB2-BA31

1《0》

reduce the cutting angle

QC11Y% Hydraulic% Guillotine% Shear%

16

SB6

Control button

ZB2-BA31

1《0》

Enlarge the cutting angle

SB7

Control button

ZB2-BA31

1《0》

Oil filling

HL1

Indicator

XB7-EV61

AC 24V

Indicator of power on or off

HL2

Indicator

DL1-CEO024

AC 24V

Start Indicator of oil pump motor

Indicator

TPN-082

DC 24V

HD1-

HD5

Indicator

TPN-082

DC 24V

Limit switch

TZ-1308

1《0》

TD1-

TD5

Limit switch

TZ-1308

1《0》

KT1

Time relay

ST3PA-Y

AC 24V

Motor start delay

KT2

Time relay

JSS21-A

DC 24V

Cutting angle decrease delay

KT3

Time relay

JSS21-A

AC 24V

Cutting angle decrease delay

VE1

Switch power

S-145-24

145W

Supply direct current power

VE2

Switch power

S-35-24

35W

Supply direct current power

TC

Transformer

JBK5-500VA

415V/220V 24V

Supply control circuit power

S1

Foot switch

JWL1-11

1《0》

Control of knife moving down

FU1

Fuse box

C65N 3PC32A

3P 32A

System short circuit protection

FU2

Fuse box

C65N 1PC6A

1P 6A

System short circuit protection

FU3

Fuse box

C65N 1PC6A

1P 6A

System short circuit protection

FU4

Fuse box

C65N 1PC6A

1P 6A

System short circuit protection

FU5

Fuse box

C65N 1PC1A

1P 1A

System short circuit protection

FU6

Fuse box

C65N 1PC6A

1P 6A

System short circuit protection

FU7

Fuse box

C65N 1PC1A

1P 1A

System short circuit protection

FU8

Fuse box

C65N 1PC6A

1P 6A

System short circuit protection

FU9

Fuse box

C65N 1PC1A

1P 1A

System short circuit protection

FU10

Fuse box

C65N 1PC1A

1P 1A

System short circuit protection

PF

Photoelectric

switch

BEN

10M-TFR2

DC 24V

Back protection

Position

Indication

E-10

DC 24V

Encoder

ENC-100-A

QC11Y% Hydraulic% Guillotine% Shear%

17

8、

Maintenance &Trouble Shooting

8.1 Blades

8.1.1 T

he blade clearance (blade gap) adjustment:

It is a very important factor to adjust the blade clearance which relates the cutting quality and knife life. Pls follow below procedures: the clearance data is 0.07~0.1 times of the plate thickness, the plate thickness =0.07~0.1t. The above is for Ob=450-500N/mm2.For more

than450-500N/mm2, it is suggested to use smaller clearance. And for less than 450-500N/mm2, pls use larger clearance. Turn the handwheel in the front of the plane board to adjust the clearance data. That means adjust the clearance according to the plate thickness. The data will

be displayed on the handwheel

8.1.2

measuring of blade clearance and adjustment of the proportional clearance

the proportional clearance relates the cutting quality directly. It is set up by the manufacturing and unnecessary to modify normally. After the machine has been used for a period of time and if the knife side is changed, then it is a must to adjust the blade clearance again . The

adjustment procedure is as below: turn the switch to adjust mode, adjust knife beam to balance( cutting angle is 0

,

Turn the clearance adjust hand wheel anticlockwise to the “smallest clearance”, turn off main motor(power on), press oil filling button, move knife beam down until

distance between upper and bottom blades is 3~5mm, adjust the bolts and nut which support bottom blade on work table, use the plug gauge to inspect the clearance. After the adjustment is finished, repeat reset course of knife beam(5.2.C).

8.1.3

The installation of the blade

After the machine has been used for a period of time, must turn over the blade sides

or change the blade. The installation of the upper blade is as below: make the upper

knife beam flat( the cutting angle is 0 ). Then turn off the screw at the lower knife to

change the blade or turn over the blade. (be careful of the sharp blade to avoid hurt.)

it is easier to change the lower blade.Just take off the upper blade cover at the

working table and turn off the screw to change the blade or turn over the blade.

8.1.4

The grinding and change of the blades

QC11Y% Hydraulic% Guillotine% Shear%

18

The blades need to be ground timely. And It is costly if do not grind the blades

timely. If the blade is not sharp enough, the blade will be hurt due to too much

pressure in cutting and the cutting quality will be affected. So pls make up a

complete blade grinding timeline according to the production status. It is

recommended to have some spare blades for replacement at any time.

Our recommended blade grinding timeline:

(1) For operation 80-100hours, pls turn over the blade sides. The upper blades and

the lower blades can be turned over three times.

(2) For operation 320-400 hours, pls grind the blade. For most severe damaged

blade, pls change the blade. After the blade grinding or when new blade is used, the

blade clearance needs to be reinspected and readjusted.

8.2

Lubrication of the machine

Good lubrication is a must for the proper machine operation and long machine life.

Pls make good lubrication as per our provided procedures.

The main areas for lubrication:

A、The guiding rod and thread rod of the back gauge. Lubricate it once a week.

( clean the thread rod off the dirt and oil stains.)

B、3 rolled guiding rails. Lubricate it every day for the initial stage of machine

running.

C、For the spare parts outside and the rolled bearings, pls lubricate it twice a week.

And pls inspect and clean the lubrication system freaquently and take good care

of them.

8.3

The air pressure inspection of accumulator(the air pressure has been setted

to 5~6 MPa before delivery, need not to adjust unless you have special situation)

When the upper knife beam returns slowly( the oil pressure is proper), pls inspect

the air pressure of accumulator. The inspection way is as below: Make the machine

power on, and do not start the main motor, turn the switch to adjust mode and push

the oil filling button, discharge the return oil pressure and then the upper knife

This manual suits for next models

1

Table of contents

Other MetalMaster Lathe manuals

Popular Lathe manuals by other brands

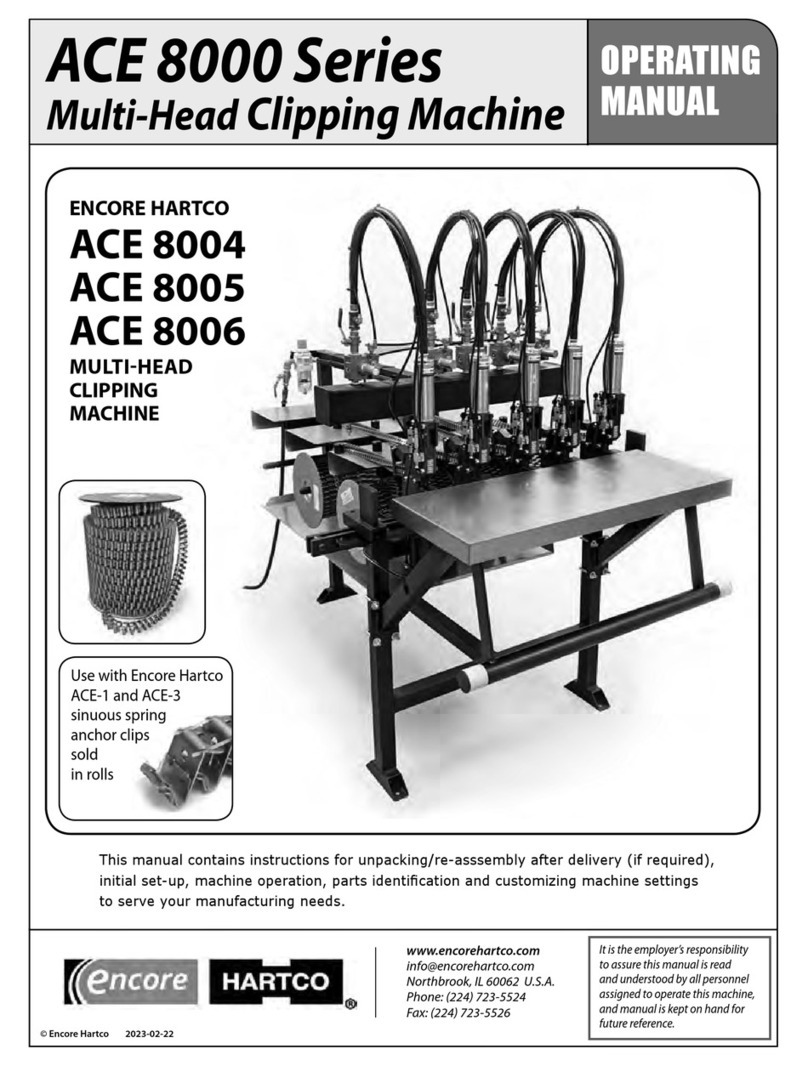

Encore Hartco

Encore Hartco ACE 8000 Series operating manual

Woodstock

Woodstock M1109 owner's manual

Grizzly

Grizzly G0766 owner's manual

Record Power

Record Power CL3-CAM Original instruction manual

Master Quality Power

Master Quality Power MW40018 instruction manual

Precision matthews

Precision matthews PM-1127VF-LB manual