MetalMaster HP-63T User manual

www.machineryhouse.com.au

www.machineryhouse.co.nz

Electrohydraulic Press

OPERATION MANUAL

HP-63T, HP-100T, HP-150T

HP-200T, HP-300T

www.machineryhouse.com.au

www.machineryhouse.co.nz

Please read the OPERATING INSTRUCTION before using.

INDEX

1. Performance characteristics and application

2. Technical parameters

3. Application

4. Checking & Filling Hydraulic Oil

4. Operation & Controls

5. Spindle Nose

6. Raising & Lowering the Beam

7. Sliding Head Type

8. Troubleshooting & Specications

9. Care and Maintenance

8. Risk Assessment & Test Certicate

www.machineryhouse.com.au

www.machineryhouse.co.nz

Electric Hydraulic Press

1 Performance characteristics and application

Metalmaster Electric hydraulic press are a developed product based on the experi-

ences found in the manufacture of press brakes and other hydraulic machines. They

are formed with a frame, bench beam, bolt, table plates, high pressure hose, oil tanks,

electrical boxes, and pumping stations, etc. (See gure 1).

.Performance Characteristics

1. Metalmaster electric hydraulic presses utilizes a single acting cylinder and operate

through a manual selector valve to control the up and down stroke.

2. The main column is equipped with a table and beam that can be moved up and down

by using the stroke of the cylinder to set the distance between the sizing block and cylin-

der spindle nose. The special lifting chains can be used to adjust the table up and down

by using the cylinder. The table beam is them secured at the height with the 2 pins.

3. The pins are tted with safety clips to insure that the pins can not be withdrawn dur-

ing operation.

4. The electrical control system is equipped with an emergency stop button, which is

convenient located to allow for a quick response if an emergency occurs.

5. Metalmaster Hydraulic presses are designed to meet the safety standards. Modica-

tions to the machines should not be made and may void your warranty. Please read the

“Risk Assessment” sheet supplied with the machine before operating

www.machineryhouse.com.au

www.machineryhouse.co.nz

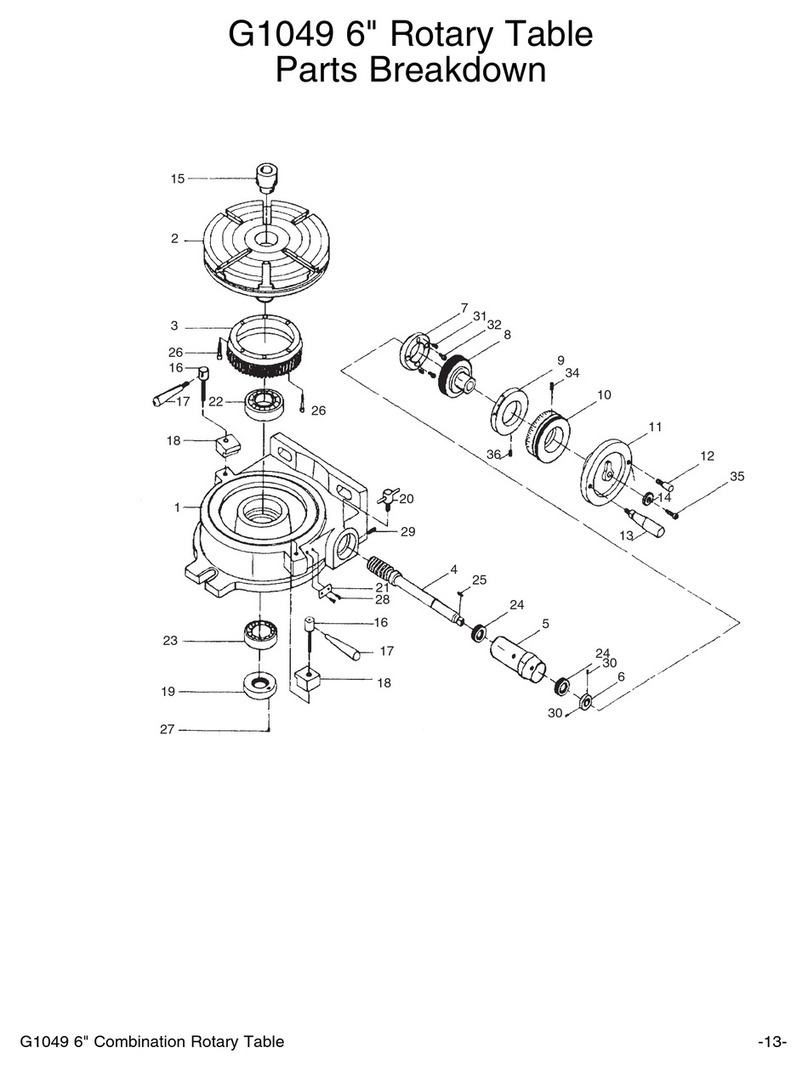

1. Main frame 2. Table Plate

3. Bench Beam 4. Pins

5. Pump 6. Lifting Tool

7. Control box 8. High Pressure Hose

9. Cylinder

Fig.1

1

2

3

4

67

8

9

5

www.machineryhouse.com.au

www.machineryhouse.co.nz

Application

1. Service Conditions:

Do not exceeding indoor ambient temperature higher than +40 ℃, or less than -10 ℃.

Voltage 415V ± 10%, frequency 50Hz.

2. Service Scope:

The machine is suitable for the machinery industry where processes such as a press-t, or demoli-

tion, correction and forming operations are required.

Variable hydraulic pump station allows for rapid descending, slow proceeding and rapid return, which

promotes efciency and energy savings.

3. Checking The Oil

Before operating the press remove the plastic seal under the oil ller cap

(Fig.3) so the tank can breathe.

Check the oil level by viewing the site glass (Fig.2)

4. Filling The Press With Oil

It is extremely important that new, clean, light hydraulic oil be used in this

press, Superdraulic 46 or an equivalent. It is strongly recommended that the

oil be ltered to remove any possible dirt. The piston should be in its maxi-

mum upper position when lling the reservoir. Fill the reservoir to the upper

level on the site glass. UNDER NO CIRCUMSTANCES USE OLD DIRTY OIL.

Fig.2

Fig.3

www.machineryhouse.com.au

www.machineryhouse.co.nz

Operations And Controls

The operator should acquaint themselves with the use of the following

controls:

1. Main isolating switch is situated on the back of the machine and must be

turned “ON”

2. On/Off control panel contains the start and stop buttons and emergency

stop. To operate the press the ON button is presses to start the pump.

Under an emergency or if the pump needs to be stopped the large red stop

button can be pressed. To unlock the emergency stop twist the red knob.

3. The handle attached to the operating valve is used to move the ram up

and down. The handle is spring loaded and returns to the neutral position

when released

The ram is a single speed ram but does reduce in speed under load

SPINDLE NOSE

1. The threaded spindle nose cap is designed for use with the chain retain-

ing plate used to raise and lower the beam.

X

2. The threaded nose cap must not be used as a ne adjuster and when

pressing and must at all times be adjusted so that there is no gap between

the cap and the spindle

www.machineryhouse.com.au

www.machineryhouse.co.nz

RAISING AND LOWERING THE BEAM

The operator should acquaint themselves with the method of lowering and

raising the beam before any attempt is made.

1. Loosen the spindle cap so that the chain retaining plate can be tted be-

tween the spindle and the spindle cap.

2. Mount the chain retaining plate between the spindle and spindle cap

and tighten the spindle cap making sure that the plate is mounted rm and

securely

3. The ends of the chain are then secured to the anchor points on the beam

making sure that the chain lengths are the same so that the beam will be

level when it is listed

4. With the ends of the chain are secured to the anchor points on the beam

slowly take the weight of the beam until the locating pins are loose.

5. With the pins now loose, remove the pins and raise or lower the beam

using the cylinder. When the beam is at the desired height locate place the

pins in the nearest pin hole.

Note! Never use ngers to locate or line up the holes

www.machineryhouse.com.au

www.machineryhouse.co.nz

SLIDING HEAD TYPE

METALMASTER also supply a range of hydraulic presses with a Sliding Work Head. These presses

allow for an expansion of many workshop applications. Once unlocked the head slides easily to the

left and to the right.

To move the head rst unlock the two clamps on the head, one

on the R/H side and one on the left. If there is no hand wheel the

head will slide very smoothly from side to side with no pressure on

the cylinder. (Fig 1.)

Fig. 1

Some larger models use a rack and pinion driven by a hand wheel

to move the head.(Fig.2)

Note! The head should always be secured before it is used

Fig. 2

www.machineryhouse.com.au

www.machineryhouse.co.nz

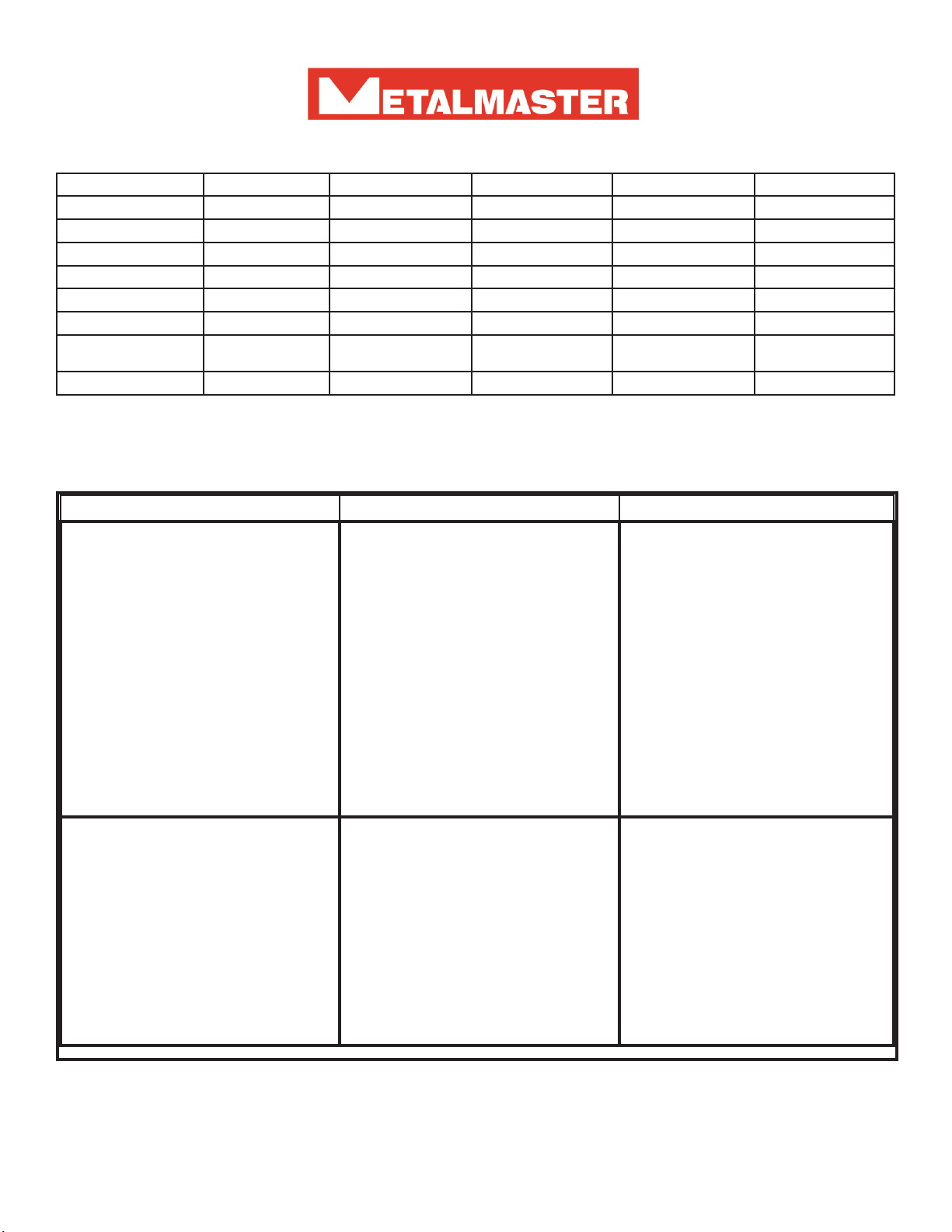

TROUBLE SHOOTING

FAULTS POSSIBLE REASON ACTION

Insufcient

Pressure

1. Gauge Failure

2. Blocked hole in either the

safety relieve valve, or poppet

valve

3. Loose or leaking joint or

damaged seal.

4. Blocked oil lter

1. Check pressure gauge and

repair or replace.

2. Check the seats on the

safety and poppet valve for

blockage

3. Tighten lacking joints and

replace damaged seals

4. Clean lter

Slow Flowing Tank

1. Low oil temperature

2. Low oil level causing oil

pump suction to be interrupted

3 Oil leaks restriking the ow.

1. Control the oil temperature

to 20 - 40 C

2. Top up oil level to operating

level

3. Check for leaks and tighten

joints and replace damaged

seals

For all other problems please contact the service department of the dealer you purchased the unit from or

Specications

Model HP-63/HPM-63 HP-100T/HPM-100T HP-150T/HPM-150T HP-200T/HPM-200T HP-300T/HPM-300T

Capacity 60 Tonne 100 Tonne 150 Tonne 200 Tonne 300 Tonne

Piston Travel 325mm 363MM 390mm 420mm 380mm

Between Posts 895mm 1050mm 1100mm 1050mm 1200mm

Max Ram-Table 1000mm 1010mm 900mm 700mm 900mm

Voltage 415 415 415 415 415

Motor Power 4Kw 7.5Kw 7.5Kw 7.5Kw 22Kw

Dimensions LxWxH

(mm)

1900x930x2030 1970x1050s2230 2020x1120x2160 2280x1130x2530 2360x1220x2470

Weight (Kgs) 1060 1650 1950 2680 3700

www.machineryhouse.com.au

www.machineryhouse.co.nz

CARE AND MAINTENANCE

1. Before any maintenance is commenced switch the isolating switch to “OFF” If the power is sup-

plied through a switch and plug if possible remove the plug from the power point

2. Periodically check the joints and seals for leaks which could cause the machines performance to

be restricted.

Note ! Before examining the machine for leaks move the cylinder rod to the lowest position (except

when examine the cylinder)

3. Remove and wash the oil lter every six months

4. Used hydraulic oil must be ltered before. Replacement hydraulic oil with the same specication

every one to two years to insure normal running.

5. Keep the press surfaces clean an free of dirt and maintain the press regularly to insure the press

remains in good working order.

6. If the machine is not to be used for a long period of time, it should be cleaned and machine parts

should be coated with rust preventing oil. Remove the oil from the oil tank. Raise the cylinder rod to

the top position and place a piece of wood between the cylinder rod and the table to avoid the cylinder

rod dropping due to the dead weight of the cylinder..

7. The machine should be stored in a dry place with a temperature not lower than -15 C

8. Before any maintenance is commenced switch the isolating switch to “OFF” If the power is sup-

plied through a switch and plug if possible remove the plug from the power point

9. The pressure should never be adjusted unless under the supervision of the manufacturers staff

or service persons.

10. Always use the press and its hydraulic system as designed to be used by the manufacturer.

.

General Machinery Safety Instructions

1. Read the entire Manual before starting

machinery. Machinery may cause serious injury if

not correctly used.

2. Always use correct hearing protection when

operating machinery. Machinery noise may cause

permanent hearing damage.

3. Machinery must never be used when tired, or

under the influence of drugs or alcohol. When

running machinery you must be alert at all times.

4. Wear correct Clothing. At all times remove all loose

clothing, necklaces, rings, jewelry, etc. Long hair

must be contained in a hair net. Non-slip protective

footwear must be worn.

5. Always wear correct respirators around fumes

or dust when operating machinery. Machinery

fumes & dust can cause serious respiratory illness.

Dust extractors must be used where applicable.

6. Always wear correct safety glasses. When

machining you must use the correct eye protection

to prevent injuring your eyes.

7. Keep work clean and make sure you have good

lighting. Cluttered and dark shadows may cause

accidents.

8. Personnel must be properly trained or well

supervised when operating machinery. Make

sure you have clear and safe understanding of the

machine you are operating.

9. Keep children and visitors away. Make sure

children and visitors are at a safe distance for you

work area.

10. Keep your workshop childproof. Use padlocks,

Turn off master power switches and remove start

switch keys.

11. Never leave machine unattended. Turn power off

and wait till machine has come to a complete stop

before leaving the machine unattended.

12. Make a safe working environment. Do not use

machine in a damp, wet area, or where flammable

or noxious fumes may exist.

13. Disconnect main power before service

machine. Make sure power switch is in the off

position before re-connecting.

14. Use correct amperage extension cords.

Undersized extension cords overheat and lose

power. Replace extension cords if they become

damaged.

15. Keep machine well maintained. Keep blades

sharp and clean for best and safest performance.

Follow instructions when lubricating and changing

accessories.

16. Keep machine well guarded. Make sure guards

on machine are in place and are all working

correctly.

17. Do not overreach. Keep proper footing and

balance at all times.

18. Secure workpiece. Use clamps or a vice to

hold the workpiece where practical. Keeping the

workpiece secure will free up your hand to operate

the machine and will protect hand from injury.

19. Check machine over before operating. Check

machine for damaged parts, loose bolts, Keys and

wrenches left on machine and any other conditions

that may effect the machines operation. Repair and

replace damaged parts.

20. Use recommended accessories. Refer to

instruction manual or ask correct service officer

when using accessories. The use of improper

accessories may cause the risk of injury.

21. Do not force machinery. Work at the speed and

capacity at which the machine or accessory was

designed.

22. Use correct lifting practice. Always use the

correct lifting methods when using machinery.

Incorrect lifting methods can cause serious injury.

23. Lock mobile bases. Make sure any mobile bases

are locked before using machine.

24. Allergic reactions. Certain metal shavings and

cutting fluids may cause an ellergic reaction in

people and animals, especially when cutting as the

fumes can be inhaled. Make sure you know what

type of metal and cutting fluid you will be exposed

to and how to avoid contamination.

25. Call for help. If at any time you experience

difficulties, stop the machine and call you nearest

branch service department for help.

Machinery House

requires you to read this entire Manual before using this machine.

www.machineryhouse.com.au

www.machineryhouse.co.nz

TEST REPORT

Model Number .........................................

Serial Number .........................................

Date of Manufacturing ............/......./..................

Electrics qElectric Motor q

Hydraulics Pump qHydraulics q

The product has been checked and is manufactured in accordance with the code of stan-

dard for Hydraulic Presses

Examiner: .......................................................

Date: ........../............../..................

This manual suits for next models

4

Table of contents

Other MetalMaster Power Tools manuals

Popular Power Tools manuals by other brands

KRESS

KRESS 1-2+FIX instruction manual

Parkside

Parkside PSTK 800 A1 translation of original operation manual

Bosch

Bosch GNA 2,0 Professional Original instructions

Silverline

Silverline 633629 owner's manual

Powermate

Powermate Px P024-0098 instruction manual

Porter-Cable

Porter-Cable PCC650 instruction manual