ORGAPACK OR-T 50

16 12.06/WE

ORGAPACK

Original

jklsfjklsdjš

lksdfjkl

jkljsdllkjjkljsd

fkljjklkjkljsdafj

asdfjklkjjkljklj

ksldafkjkljklš

jkljklkljsdafjlkj

jkljjkljklkljljlk

Original ORGAPACK spare

parts must be used exclusi-

vely!

Not using original spare parts

will dissolve the warranty and

the liability.

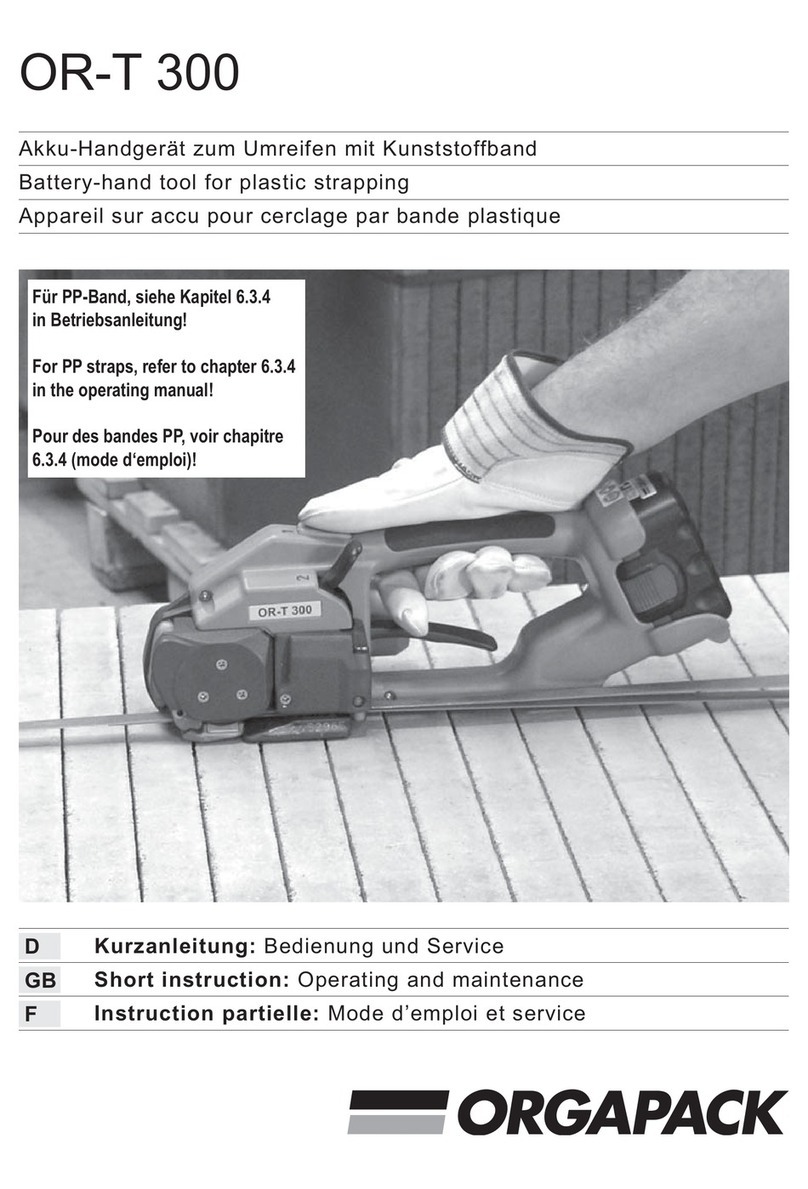

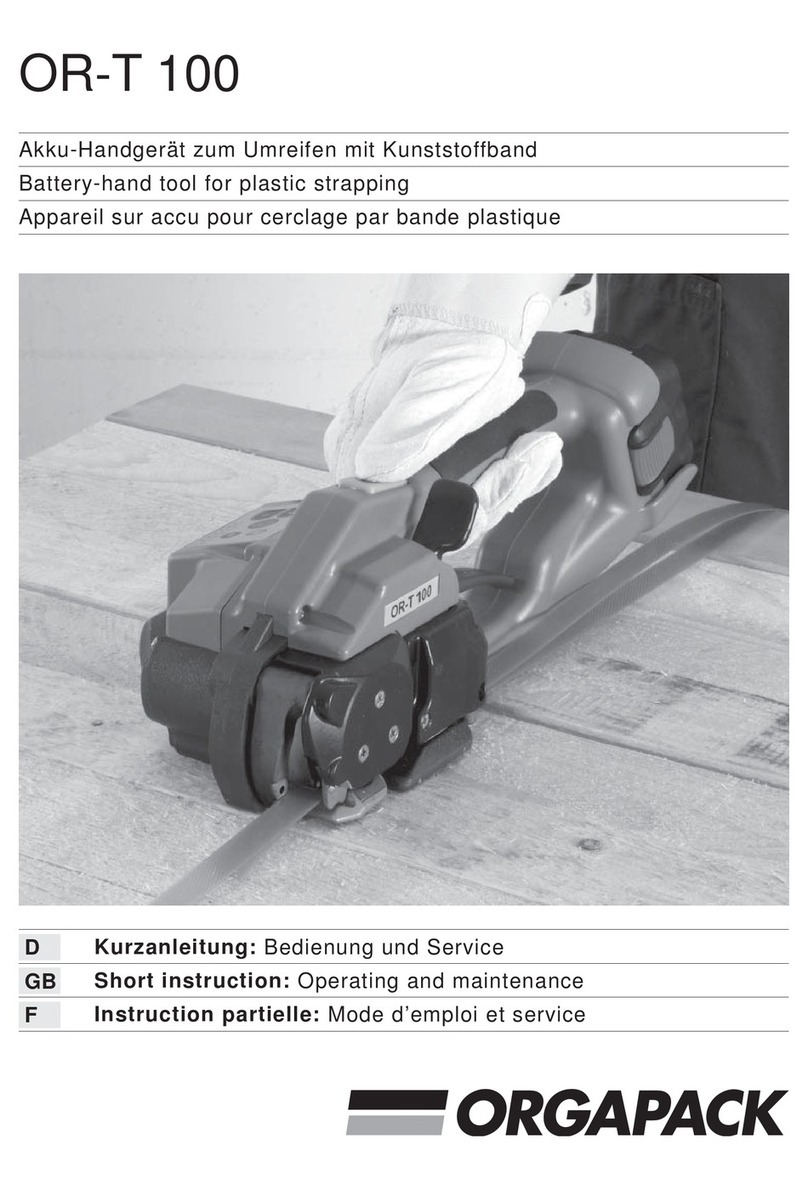

Use for the intended purpose

This tool is designed for strapping packages, pallet

loads and the like.

The tool was designed and manufactured to provide

safe handling during the strapping operation.

The tool is designed for use with plastic straps (poly-

propylene and polyester).

Possible misuse

The use of steel straps is not possible.

3.1 SAFETY INSTRUCTIONS FOR BATTERY

CHARGER AND BATTERY

Always inspect the electrical

plug and cable before use. If

damaged, they must be

replaced by qualified personnel.

• Do not charge other types of batteries (see chapter

5.1) and use original accessories only.

• Keep the battery charger slot free of foreign objects

and protect against dirt.

• Protect the battery charger against humidity and

use it in dry areas only.

• Do not open the battery. Protect the battery against

impact, heat and fire. Risk of explosion!

• When the battery is outside the battery charger,

cover its battery terminals to avoid short circuits

with metal objects. Risk of fire and explosion!

• Keep battery dry and protected against frost. Do

not store it at temperatures over 50°C or below

10°C.

• Damaged batteries should not be used longer.

3SAFETY INSTRUCTIONS

Inform yourself!

Read the operating instructions

carefully.

Preventive and corrective main-

tenance on the tool may only

be carried out by trained per-

sonnel.

Protect yourself!

When operating the tool, wear

eye, face and hand protection

(cut-proof gloves).

Power source!

Before starting preventive or

corrective maintenance, remo-

ve battery from the tool.

Warning:

Strap will snap forward!

When cutting the strap, hold

the upper portion and stand

safely away from the strap.

Caution:

The lower strap will snap

forward.

Warning:

Strap could break!

Do not stand in line with the

strap while it is tensioned. The

strap could break!

Caution:

Only strap packed goods!

Do not put hands or other parts

of the body between the strap

and the package during the

strapping process.

Caution:

Danger of squeezing!

Do not put your fingers into the

tension wheel area.

Do not use water!

Do not use water or steam to

clean the tool.