MetalMaster S924A User manual

MECHANICAL GUILLOTINE

OPERATION MANUAL

Edition No : MGG-2

Date of Issue : 06/2018

Models.

MG-440, MG-840

Order Code S924A Order Code S926A

2

OPERATION MANUAL

NOTE:

In order to see the type and model of the machine, please see the

specication plate. Usually found on the back of the machine. See

example (Fig.1)

Fig.1

MECHANICAL GUILLOTINE

MACHINE

MODEL NO.

SERIAL NO.

DATE OF MANF.

Note:

This manual is only for your reference. Owing to the continuous improvement of the

Metalmaster machines, changes may be made at any time without obligation or notice.

Please ensure the local voltage is the same as listed on the specication plate before

operating this electric machine.

Distributed by

www.machineryhouse.co.nz

MACHINE DETAILS

3

OPERATION MANUAL

C O N T E N T S:

1. GENERAL MACHINE INFORMATION

1.1 Specications................................................................. 4

1.2 Standard Equipment................................................... 4

1.3 Overall Drawings.......................................................... 5

2. IMPORTANT INFORMATION

2.1 Safety Requirements................................................... 6

2.2 Features of the Machine............................................ 8

2.3 Lifting Instructions...................................................... 9

3. INSTALLATION

3.1 Base Foundation and Securing Points.................. 10

3.2 Machine Leveling......................................................... 11

3.3 Checking the Power Supply..................................... 11

3.4 Attaching The Accessories........................................ 12

4. COMMISSIONING

4.1 Preparation of the Machine...................................... 13

4.2 Omrom E3Z Safety Sensor Alignment.................. 13

4.3 Manual Back Gauge..................................................... 16

4.4 Commissioning Check List........................................ 16

5. OPERATION INSTRUCTION

5.1 Pre-Operational Safety Check.................................. 17

5.2 Start Up............................................................................ 18

5.3 Adjusting Of The Blade Gap..................................... 19

6. MAINTAINANCE

6.1 Type And Frequency Of Inspections................... 21

6.2 Lubrication Points........................................................ 22

6.3 Brake Adjustment........................................................ 23

6.4 Calibrate Rapid Blade Adjustment Dial................ 24

6.5 Top Position Cam Adjustment................................. 26

APPENDIX

A. Electrical Diagram........................................................ 27

Risk Assessment Sheets...................................................... 28

4

OPERATION MANUAL

Machine Type MG-440 MG-840

Shearing Length (mm) 1300 2500

Material Capacity Mild Steel (mm) 4 4

Material Capacity Stainless Steel (mm) 2.5 2.5

Shear Angle (degree) 2 2

Back Gauge Range (mm) 750 750

Back Gauge Type Rack & Pinion Rack & Pinion

Strokes per Minute 22 28

Dimensions Width (mm)

Depth (mm)

Height (mm)

1860

2210

1180

3124

2398

1290

Weight (kgs) 1440 2500

Main Motor 3 Phase 415 Volt 50Hz (kW) 4 7.5

Back Gauge Manual Manual

1.1 SPECIFICATIONS:

1.2. Standard Equipment:

Instruction Manual

Back-gauge assembly

Front guarding

Foot switch and control panel

5

OPERATION MANUAL

1.3 OVERALL DRAWING

6

OPERATION MANUAL

DO NOT use this machine unless a Qualied person has instructed you in its safe use and

operation of the machine.

The most common metal guillotine injuries are crushed or amputated ngers.

Most of these accidents are not caused by the blade of the guillotine, but by the clamps that

hold the sheet metal being cut. Other injuries are from ngers jamming under the sheet that is

to be cut, and strain injuries while handling large and awkward sheets of metal.

By law, guillotines must be guarded, and operators must be trained. Safe working procedures

must be developed to prevent injuries.

2.1 SAFETY REQUIREMENTS

The following topics can be used as a guide to identify workplace hazards and to reduce the

risks of operating metal guillotines.

It is an unsafe practice for two people to work at a guillotine unless both operators are provided

with interlocked actuating devices (usually a foot control). However in some guillotine

operations, for example cutting large sheets, two operators may be required to maneuver

sheets into position before cutting. For such operations safe work procedures should be

developed to control any hazards.

Safety glasses must be worn at

all times in work areas. Earmus

should be worn if the work area is

noisy.

Sturdy footwear must be worn

at all times in work areas.

Gloves should be worn when

handling the material used on this

machine.

Long and loose hair must be

contained with a net or under a

hat

2. IMPORTANT INFORMATION

7

OPERATION MANUAL

SAFETY CHECKS BEFORE OPERATING

qEnsure xed guards are in place to prevent hands or other parts of the body from entering

the trapping space.

qGuards or safety devices must never be removed or adjusted, except by an authorized

person for maintenance purposes.

qWorking parts should be well lubricated and free of rust and dirt.

qThe area around the machine must be adequately lit and kept free of materials, which

might cause slips or trips.

qBe aware of other personnel in the immediate vicinity and ensure the area is clear before

using equipment.

qFamiliarize yourself with and check all machine operations and controls.

qEnsure cutting table is clear of scrap and tools.

qFaulty equipment must not be used. Immediately report suspect machinery

SAFETY CHECKS WHEN OPERATING

qDo not attempt to cut material beyond the capacity of the machine.

qNever attempt to cut rod, strap or wire with this machine.

qUse correct lifting procedures when handling large sheets of material.

qTake extreme care during the initial feeding of the workpiece into the machine.

qThe workpiece should always be held suciently far back from the edge being fed into the

guillotine.

qEnsure ngers and limbs are clear before actuating the guillotine.

qHold material rmly to prevent inaccurate cutting due to creep.

qWhen cutting ensure feet are positioned to avoid contact with the foot operated lever.

SAFETY CHECKS AFTER OPERATION

qRemove all o cuts and place them in either the storage rack or waste bin.

qLeave the work area in a safe, clean and tidy state.

POTENTIAL HAZARDS

qCuts from the sharp edges and burrs on the sheets before and after cutting

qParts of the body being caught in crush and pinch points.

qInjuries caused when handling metal sheets

8

OPERATION MANUAL

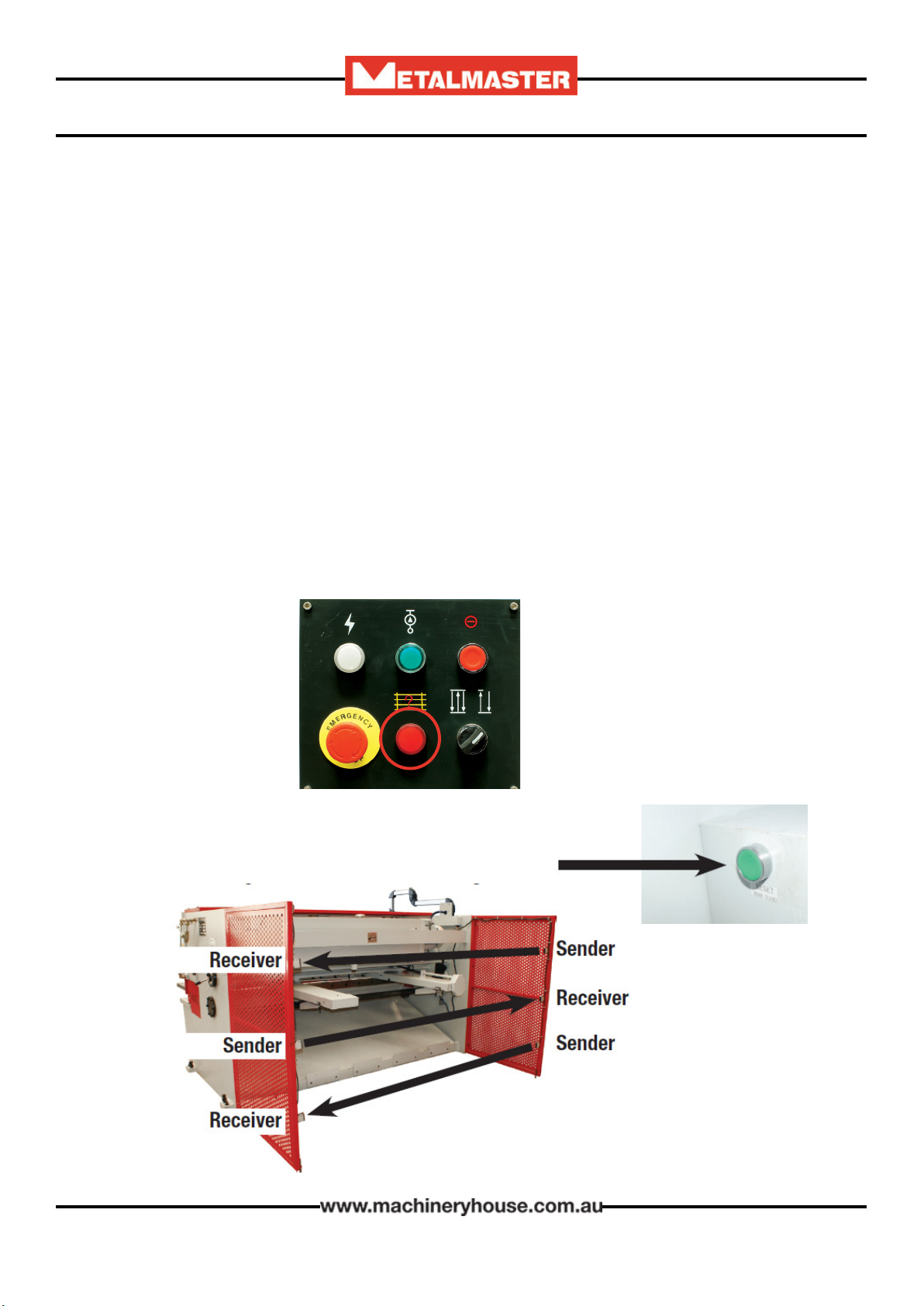

The electrical circuits of your machine are designed to allow operation

with maximum safety. The following precautions are available on the

machine for enhanced safety.

There are three Emergency stop buttons (engaging type). They are

found on the foot switch, control unit, and on the front of the machine.

Once the buttons has been pressed to reset the emergency stop, the

red button must be rotated.

2.2. FEATURES OF THE MACHINE:

Foot pedal control

The foot pedal when pressed activates the beam and must be held in the

depressed position until the machine has completed its cut.

Release the foot pedal during the cutting operation and the blade will stop

and stay in that position. To make it return to the top of the stroke the foot

pedal must be pressed again and held until the cycle has been completed.

Main Controls

The main machine operating controls are located on the front of the

machine.

12

3

4

56

1 Power ON Light

2 Illuminated Start Button

3 Electrics OFF

4 Continuous or Single cut

5 Emergency Stop

6 Rear Safety Guard

9

OPERATION MANUAL

2.3 LIFTING INSTRUCTIONS

On the day that the machine arrives, make sure that a crane with sucient capacity is available

to unload the machine from the vehicle. Ensure access to the chosen site is clear and that doors

and ceilings are suciently high and wide enough to receive the machine.

To handle the Guillotine, use only the two sling lifting points located on the top of the end

plates. (Fig. 2.3) The slings should be positioned so the machine is level when lifted.

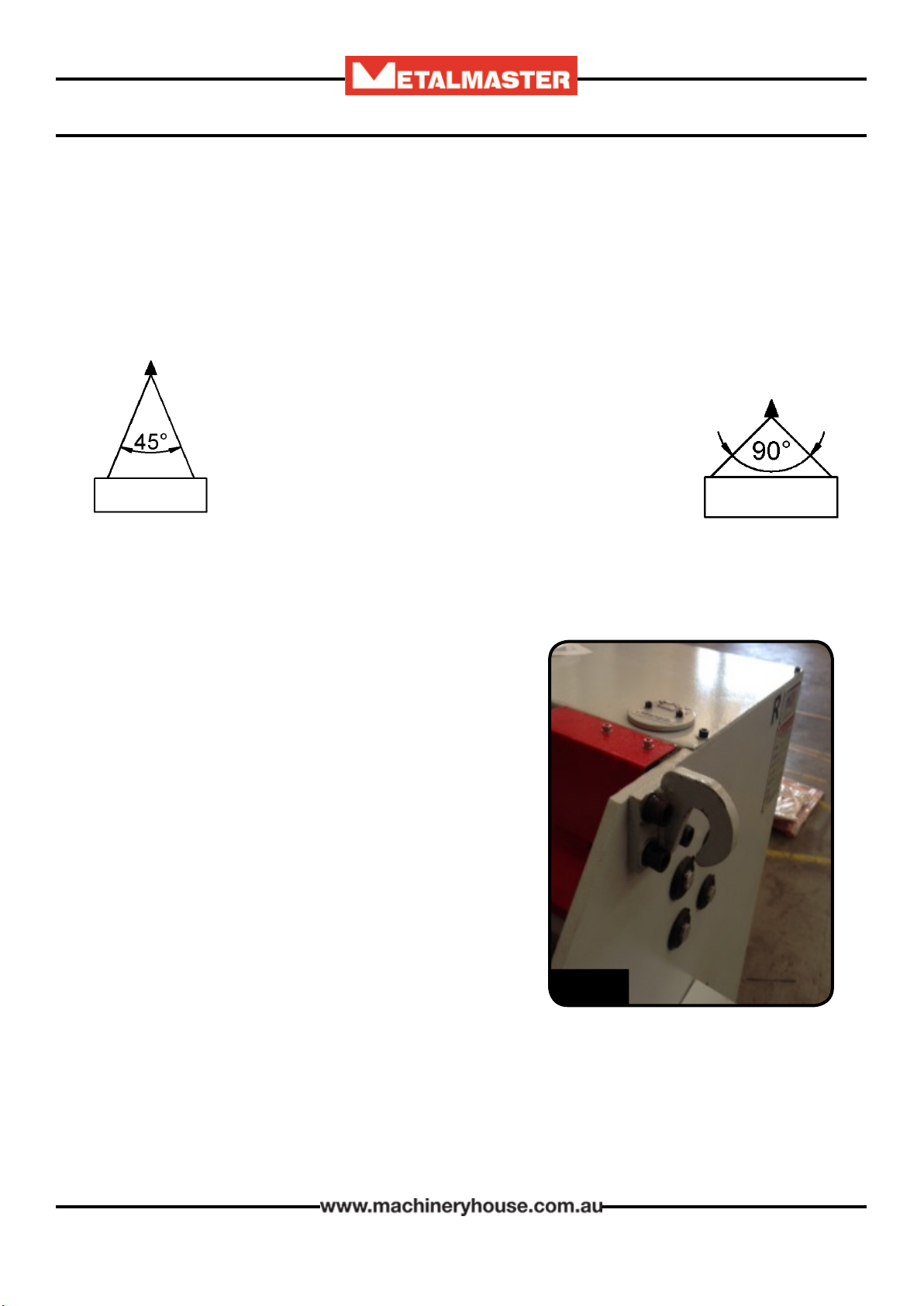

When using slings please take note of the sling angle and the loads that apply

When the slings are at a 45° angle then each sling is carry-

ing the equivalent of 50% of the load weight. (Fig.2.1).

When the slings are at a 90° angle then each sling will

have a weight equal to 75% of the load on each sling.

(Fig 2.2)

Note! Metalmaster recommend not to exceed 90° angle

Fig 2.2

Fig 2.1.

When lifting the machine use only certied lifting slings

Ensure that when lifting, the machine does not tip over.

Check that the lifting slings do not interfere with the

hydraulic pipes or electrical conduits.

Failure to follow these instructions could cause damage

to the machine

Lifting Points

Fig. 2.3

10

OPERATION MANUAL

The machine is delivered in a complete assembled execution. It must be leveled and rmly

stationed on the oor where it is to be used, according to the Installation Diagram attached.

Indoor installation and a dry working environment without danger of re and explosion is

necessary. The oor load, where the machine is to be installed, must be suitable for the weight

of the machine.

3. INSTALLATION

3.1 BASE FOUNDATION AND SECURING POINTS

Before securing the machine a solid concrete base must be prepared to the specication of the

machine. The sizes for the bolt holes position are listed as A-B.

Size A B

1300 1640 500

2500 2504 500

11

OPERATION MANUAL

3.3 Checking The Power Supply

METALMASTER machines are supplied wired ready to run. Check the specication plate on the

machine to conrm the correct voltage of the power supply.

Check the rotation of the motor is correct.

The machine must be connected to the power only by a qualied and licensed electrician.

Warranty may be voided if it is found that the connection was not carried out by a qualied

electrician.

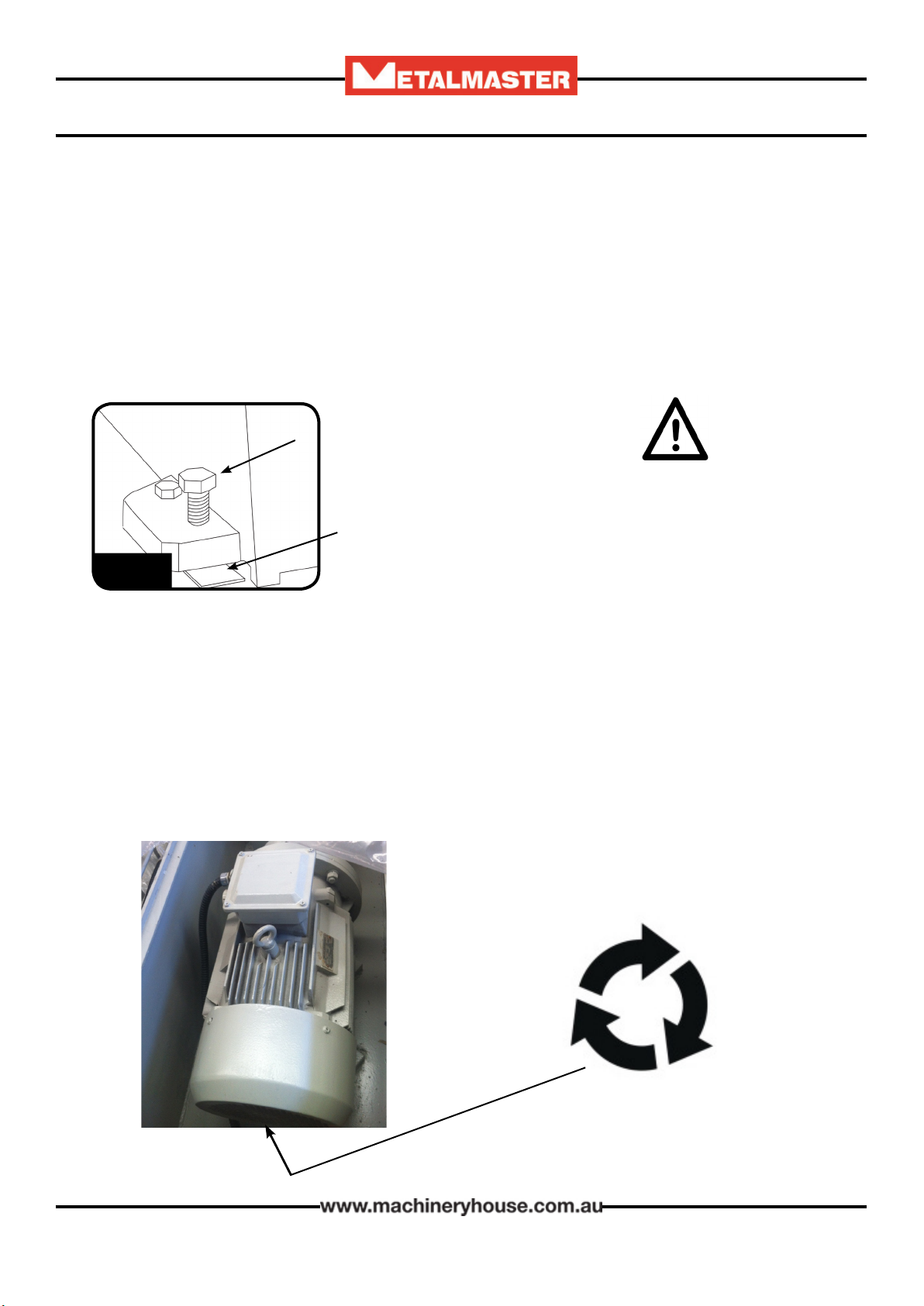

3.2 MACHINE LEVELING

To set your machine up so that it operates to optimum performance, apply the following

procedure

After your guillotine has been anchored to a concrete slab oor, it then needs to be leveled. The

leveling is performed using each of the screws on each pad.(Fig. 3.1). Loosen the hold down

bolts and place a level on the surface of the working table. Tolerances: 1000:0.30mm, for both

longitudinal and transverse.

Metal plates need to be placed under each jacking screw to distribute the load. Once level then

tighten the hold down bolts.

Metal Plate

Jacking Screw

The machine must not rest on supports

other than those dened in Fig. 3.1

Fig. 3.1

12

OPERATION MANUAL

1. Place the squaring stops Fig 3.3 into position on the table

top, securing into place with the bolts supplied.

2. Check that the square stops are square to the blade.

3. Adjust by loosening the bolts and moving by the amount

allowed by the clearance of the holes.

4. Re tighten the screws.

3.4 ATTACHING THE ACCESSORIES.

Bolt the support arms onto the feed table. Ensure they are level and square to the table. (Fig 3.2)

Unpack and attach the rear fence to the back of the machine. Ensure that the sensors have been

connected and set up. (Fig.3.4)

Unpack the mobile foot control and plug the into the socket provided on the machine. (Fig.3.5)

Fig. 3.4

Fig. 3.2

Fig. 3.3

Fig. 3.5

13

OPERATION MANUAL

4. COMMISSIONING

4.1. PREPARATION OF THE MACHINE.

qRemove all wrapping and packing grease from the machine.

qCheck the machine for loose bolts. Tighten as required.

qCheck the top return position is correct.

qClean the blades and tighten the securing bolts as required. Examine the cutting edges of

both blades for damage.

qInform your service provider of any damage or faults with the machine.

Warning- Follow all setup instructions before starting the machine

The safety circuit consists of a reset switch and two rear side guards, each having 3 sensors.

Your machine will have a RED warning light on the main control panel. When the main power

is switched on or the rear sensors have been tripped the safety circuit must be reset before the

motor can be started.

Warning Indication: The safety circuit has not been Reset.

4.2 OMROM E3Z SAFETY SENSOR ALIGNMENT

Red Warning Light

Reset Switch

Press the “Reset Rear Guard” button on the back of

the electrical cabinet to reset the safety circuit

14

OPERATION MANUAL

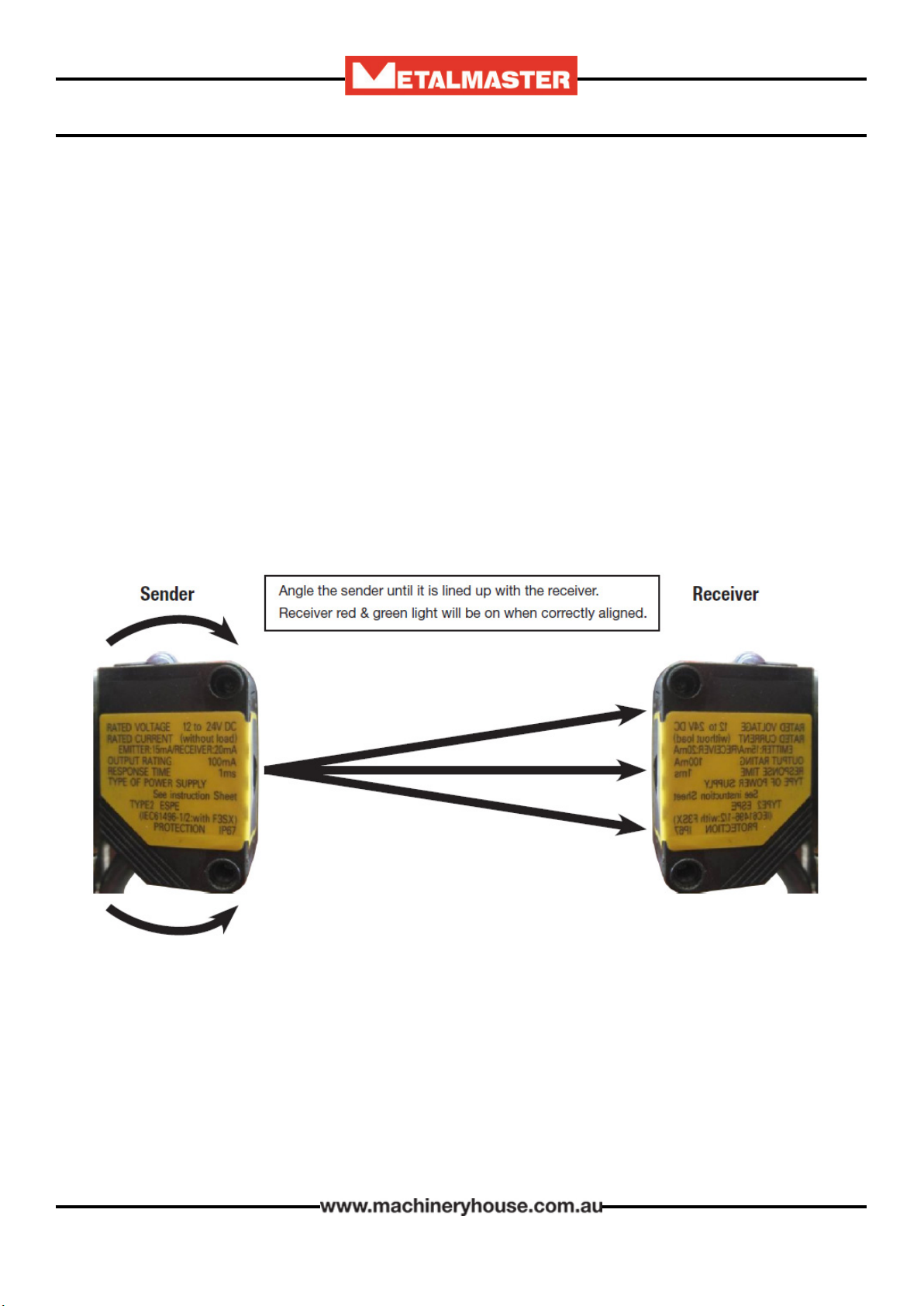

4.2 OMROM E3Z SAFETY SENSOR ALIGNMENT Cont.

Identifying Sensors

Sender

The sender has one red light on top of the unit and one red

light at the front. These two lights will be on at all the times

while the machine has power.

Receiver

The receiver has two lights on top of the unit. The receiver should have one green light on or a

red and green light on when all the sensors have been aligned correctly.

NOTE: No.1 receiver could be mounted top, middle or bottom on the guard.

The receivers are wired in series so No.1 receiver will have a green light on, indicating it has

power. When it is correctly aligned with its sender the red & green light will be on and it will

send power to No.2 receiver.

No.2 receiver will have a green light on and when that receiver has been correctly aligned with

its sender the red & green light will be on and it will send power to the No.3 receiver.

No.3 receiver is aligned using the same technique.

So when all 3 receivers are aligned correctly with their corresponding senders they should all

have red and green lights on top of each unit.

15

OPERATION MANUAL

Alignment of Senders & Receivers

4.2 OMROM E3Z SAFETY SENSOR ALIGNMENT Cont.

Ensure that the machine is level and all four leveling jacking bolts are correctly adjusted. Check

the rear guards are bolted tight and adjust the stabilizing feet to ground level to support the

guards.

The sensors are sensitive to alignment so try to align as accurately as possible. If the sender is

only just aligned with the receiver, any vibration when cutting will stop the motor and the safety

circuit will have to be reset again.

Loosen the sender screws and angle the sender up until the receiver loses alignment.

Angle sender down until the receiver re-aligns and then loses alignment again.

Half way between these two positions is the most accurate alignment.

The sensors may also have to be angled sideways as well to get the best possible alignment. This

may involve packing individual brackets or sensors.

You can now reset the safety circuit & press the reset button

After a successful reset the light on the control panel will not be illuminated and the machine

is ready to operate.

16

OPERATION MANUAL

4.3 MANUAL BACK GAUGE. (Fig. 4.1)

The back gauge consists of a left and right hand shafts

tted with a rack and pinion. Mounted on each shaft is a

sliding block that slides along the rack shaft carrying the

back gauge. The racks are connected by a shaft and hand-

wheel. When turning the hand wheel the back gauge is

moved in and out. The shaft can also be used for adjusting

the synchronizing of the two ends of the back gauge to

keep them parallel.

The right rack shaft is tted with a scale with graduations

of 0.5mm. When installing the machine for the rst time

or after grinding the blade, you should carefully adjust the

“zero” position,

The two sliding blocks are tted with clamping handles.

After the adjustment of the gauge distance, re-clamp the

handles.

Digital Readout (Fig. 4.2)

Some machines are tted with a digital readout on the

back gauge. The adjustment can be set using the display.

The display unit can be changed between inch or metric

and allows for “Zero” to be selected in any position.

It also has a button (ABS) which allows a switch between

absolute and incremental measurement.

E.G. First cut is at 100mm, and the second cut is at 400mm

when ABS is pressed then the total of the two is displayed

as “500”mm.

The digital display is attached to the right hand shaft and

does not need to be reset as the scale can be“Zero” in any

position.

4.4 COMMISSIONING CHECK LIST.

Before starting the machine the following checks must be carried out.

qInstallation and machine preparation has been performed according to the manuals

instructions.

qAll grease nipple points have been lubricated.

qElectrical earth tted and power circuits, switches, and foot-pedal checked for any damage

qSetup rear sensors

qCheck motor rotation.

qTest safety operation, E stop, rear sensors, stop button etc.

qTest all mechanical operation on the machine including blade and back gauge travel and limit

switch operation.

qTest cut material and check quality of cut

qTools, equipment and personnel are clear of the machine.

qOperation Manual on how to operate the machine has been read.

Fig. 4.1

Fig. 4.2

Fig. 4.3

17

OPERATION MANUAL

5. OPERATION INSTRUCTIONS

5.1 PRE-OPERATIONAL SAFETY CHECK PRIOR TO OPERATING

Before operating the machine the rear safety beam guard

needs to be checked. Below are the steps that need to be fol-

lowed.

1. Start machine as per instruction procedures

2. Stand outside rear safety gate & obstruct sensor (1)

3. Ensure machine has stopped and is disabled

4. Check your control: Warning light (A)

5. Press green reset button at the rear of electrical box image

(C)

A: Basic Control - Light on

Emergency Stop Check,

B: Rear Guarding Sensors

C: Guard Reset Button

1. Start machine as per instruction procedures

2. Press the emergency stop buttons on the control panel and front of the machine. (E)

3. Ensure the machine has stopped and is disabled

4. Reset emergency stop button by twisting the red dial. (D)

(Some models need guard to also be reset)

5. Repeat steps 1 to 4 for each emergency stop on your machine

E: Emergency Stop D: Guard Reset Button

(1)

(2)

(3)

18

OPERATION MANUAL

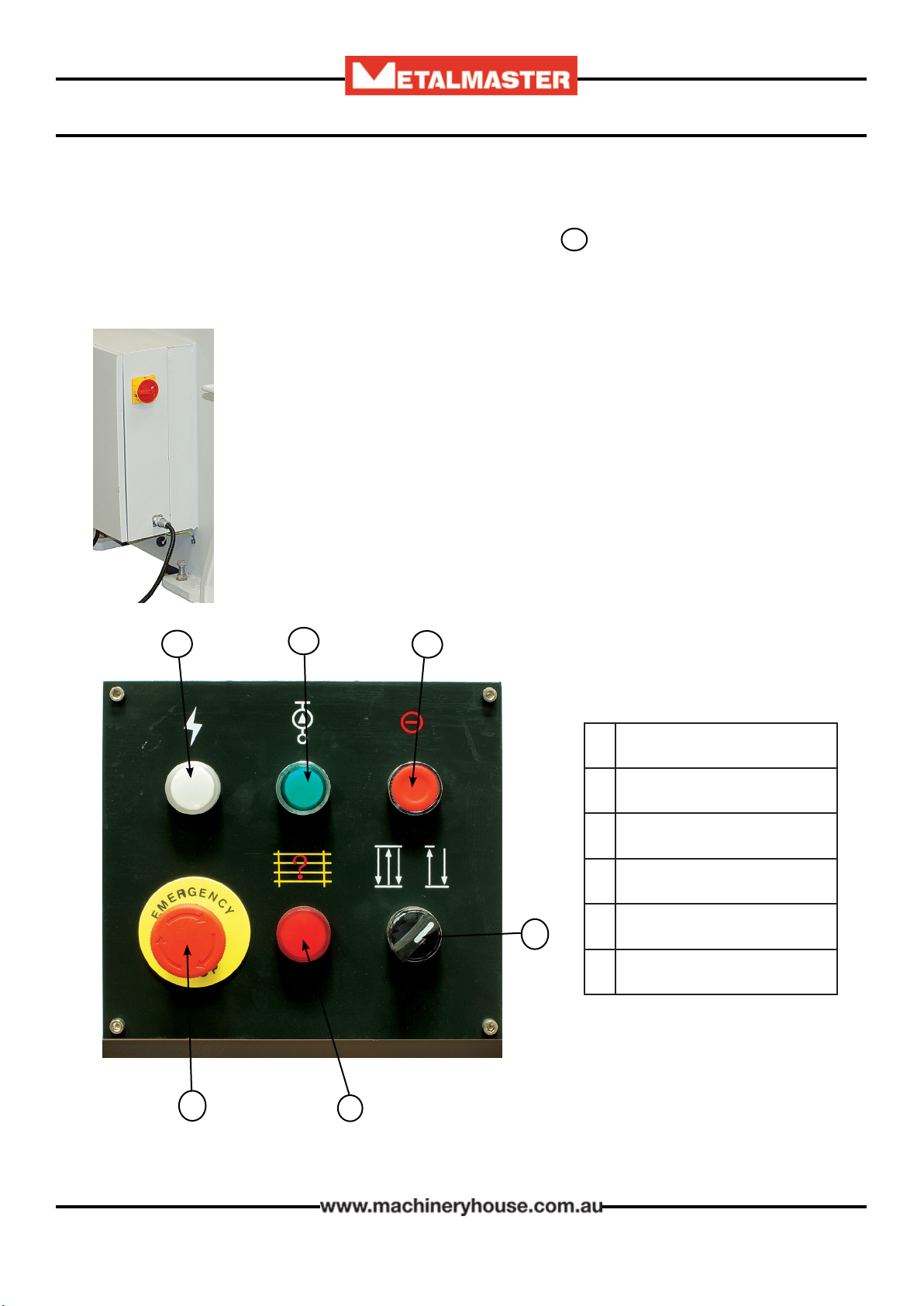

5.2 STARTUP

Before starting the machine ensure that the manual has been read and understood.

1. Switch the isolating switch on (Fig 1.) The “Power On Light” (Fig.2) will be illuminated.

Fig 1.

12

3

4

56

1 Power ON Light

2 Illuminated Start Button

3 Electrics OFF

4 Continuous or Single cut

5 Emergency Stop

6 Rear Safety Guard

2. If all the safety checks have been done then press the

“Start” button to energize the electrics. (Fig 2.)

Now the pedal can be depressed to start the cut

NOTE! The “Start Button” must be illuminated for the

pedal to operate.

Fig 2.

1

19

OPERATION MANUAL

5.3 ADJUSTING OF THE BLADE GAP

Check the maximum cutting capacity of the guillotine..

This can be found on the specication plate on the ma-

chine. The capacity listed is for Mild Steel. Stainless steel

capacity can be found in the specication table in this

manual. (Page 4)

Check The Blade Gap Setting

The machine is supplied from the factory with the blade

gap set to the capacity of the machine.

NOTE! It is extremely important that the blade gap must

be reset to suit the thickness of the material every time

the size of the materials changes. Failure to do this could

cause damaged to the machine

The blade gap should be approximately 10% of the thick-

ness of the material.

E.G. 1mm material = 0.1mm Blade Gap

2mm material = 0.2mm Blade Gap

Adjusting the Blade Gap

Step 1. Isolate the machine from the power supply and

place a maintenance tag on the electrical

cabinet.

Step 2. The 4 head bolts at both ends of the machine

should not be tightened up too tight. The gap

should be able to be adjusted with out undoing

the bolts. If they need to be loosened to adjust

the blade gap, be sure they are tightened only

slightly. (Fig.5.3)

Step 3. Set the rapid blade adjustment to the correct

gap. Repeat the operation at the opposite end

of the machine to ensure that the blade is

parallel. (Fig. 5.4)

Step 4. Re-tighten the head bolts at both ends of the

machine. Do not over tighten the bolts as this

can reduce the set blade gap

There are two types of blade adjustment supplied on

these machines. Your machine will be tted with one of

these methods for adjustment.

Fig. 5.3

Fig. 5.4

Type 1

20

OPERATION MANUAL

Adjusting the Blade Gap Cont.

Type 2

Step 1. Isolate the machine from the power supply and

place a maintenance tag on the electrical

cabinet.

Step 2. The 4 head bolts at both ends of the machine

should not be tightened up too tight. The gap

should be able to be adjusted with out

undoing the bolts. If they need to be loosened

to adjust the blade gap, be sure they are

tighten only slightly. (Fig.5.5)

Step 3. Move the rapid blade adjustment lever (Fig. 5.6)

up or down to the correct blade gap required

displayed on the blade gap scale. (Fig.5.7)

Repeat the operation at the opposite end

of the machine to ensure that the blade is

parallel.

Step 4. Re-tighten the head bolts at both ends of the

machine. Do not over tighten the bolts as this

can reduce the set blade gap

Fig. 5.5

Fig. 5.6

Fig. 5.7

This manual suits for next models

3

Table of contents

Other MetalMaster Power Tools manuals