MetalMaster HP-20PP User manual

OPERATION MANUAL

Edition No : HP-20PP-3

Date of Issue : 05/2020

Model. HP-20PP

Order Code P142

HYDRAULIC PRESS

2

OPERATION MANUAL

NOTE:

In order to see the type and model of the machine, please see

the specication plate. Usually found on the side or back of

the machine. See example (Fig.1)

Fig.1

HYDRAULIC PRESS

MACHINE

HP-20PP

MODEL NO.

SERIAL NO.

DATE OF MANF.

Note:

This manual is only for your reference. Owing to the continuous improvement of the

Metalmaster machine, changes may be made at any time without obligation or notice.

Please ensure the local voltage is the same as listed on the specication plate before

operating any electric machine.

Distributed by

www.machineryhouse.co.nz

MACHINE DETAILS

3

OPERATION MANUAL

C O N T E N T S:

1. GENERAL MACHINE INFORMATION

1.1 Specications................................................................ 4

1.2 Identication................................................................. 5

2. IMPORTANT INFORMATION

2.1 General Workshop Safety......................................... 6

2.2 Safe Operating Procedure for Hydraulic press.. 8

2.3 Lifting Instructions...................................................... 9

3. INSTALLATION

3.1 Assembly......................................................................... 10

3.2 Bleeding The Hydraulic System.............................. 13

3.3 Site Preparation............................................................ 13

3.4 Options For Mounting................................................ 13

4. OPERATION

4.1 Positioning the Bed..................................................... 14

4.2 Positioning the Ram.................................................... 14

4.3 Pressing Process........................................................... 15

5. MAINTENANCE

5.1 Inspection Schedule.................................................... 16

5.2 Troubleshooting........................................................... 16

5.3 Filling The Hydraulic Oil............................................. 17

Spare Parts.............................................................................. 18

Risk Assessment Sheets..................................................... 25

4

OPERATION MANUAL

Order Code P142

Model HP-20PP

Pressing Capacity (Tonne) 20

Hydraulic Ram Operation (Type) Manual-Hydraulic

Sliding Ram (left-right) (Yes/No) Yes

Width Between Front Posts (mm) 542

Width Between Side Posts (mm) 85

Table Top Opening - (Front to Back) (mm) 105

Ram To Table (Max.) (mm) 980

Piston Ram Stroke (mm) 185

Ram Diameter (mm) Ø48

Operating Pressure (p.s.i) 110 -120

Dimensions (W x D x H) (mm) 738 x 700 x 1790

Shipping Dimensions (W x D x H) (mm) Carton 1 1560 x 195 x 135 (80kg)

Shipping Dimensions (W x D x H) (mm) Carton 2 730 x 270 x 170 (35kg)

Nett Weight (kg) 112

1.1 SPECIFICATIONS

5

OPERATION MANUAL

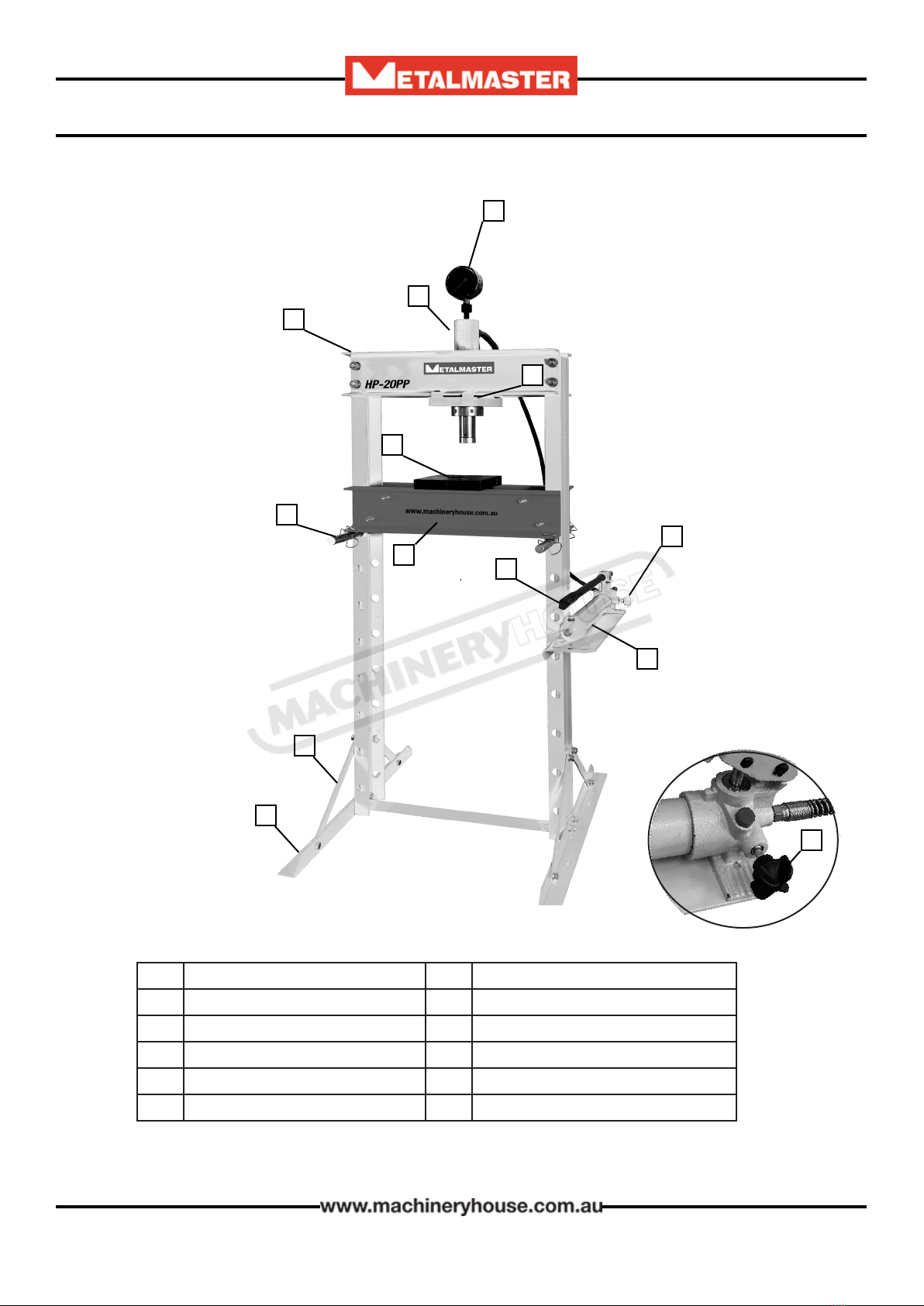

1.2 IDENTIFICATION

A

K

B

C

D

E

F

G

E

H

J

AMain Frame GHydraulic Pump Handle

BCylinder HPress Feet

CPressure Gauge IPress Feet Support Bars

DRam Baseplate JBed or Working Table

EPump Release Valve KSafety Pins with Retaining Clips

FHydraulic Pump LPressing Plates

I

L

6

OPERATION MANUAL

2.1 GENERAL SAFETY REQUIREMENTS

DO NOT use any machine unless you have read the manual or have been instructed in the use of

the machine in its safe use and operation

Safety glasses must be worn at

all times in work areas. Earmus

should be worn if the work area is

noisy.

Sturdy footwear must be worn

at all times in work areas.

Gloves should NOT be worn when

operating this machine

Long and loose hair must be

contained with a net or under a

hat

This manual provides safety instructions on the proper setup, operation, maintenance, and

service of this machine. Save this manual, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual may result in serious

personal injury—including amputation, or death.

The owner of this machine is solely responsible for its safe use. This responsibility includes, but

is not limited to proper installation in a safe environment, personnel training and authorization

to use, proper inspection and maintenance, manual availability and comprehension, of the

application of the safety devices, integrity, and the use of personal protective equipment.

The manufacturer will not be held liable for injury or property damage from negligence,

improper training, machine modications or misuse.

WARNING

CHECK DAMAGED PARTS. Regularly inspect

the machine for any condition that may aect

the safe operation. Immediately repair or re-

place damaged or parts that are incorrectly

tted before operating.

OWNER’S MANUAL. Read and understand this

owner’s manual before using the machine.

TRAINED OPERATORS ONLY. Operators that

have not been trained have a higher risk of

being seriously injured. Only allow trained or

supervised people to use this machine. When

the machine is not being used, disconnect the

power, to the machine to prevent unautho-

rized use—especially around children. Make

the workshop safe.

7

OPERATION MANUAL

WEARING PROPER APPAREL Do not wear

clothing, apparel or jewelry that can become

entangled in moving parts. Always tie back

or cover long hair. Wear non-slip footwear to

avoid accidental slips, which could cause loss of

operating control.

HEARING PROTECTION. Always wear hearing

protection when operating or observing loud

machinery. Extended exposure to this noise

without hearing protection can cause perma-

nent hearing loss.

USE CORRECT TOOL FOR THE JOB. Only use

this tool for its intended purpose. Do not force

the machine or its attachments to do a job for

which they were not designed. Never make

unapproved modications. Modifying the ma-

chine or using it dierently than intended may

result in malfunction or mechanical failure that

can lead to personal injury or death!

AWKWARD POSITIONS. Keep proper footing

and balance at all times when operating the

machine. Do not overreach! Avoid awkward

hand positions that make operating control

dicult. This could increase the risk of acciden-

tal injury.

FORCING MACHINERY. Do not force the ma-

chine. It will do the job safer and better at the

rate for which it was designed.

NEVER STAND ON MACHINE. Serious injury

may occur if the machine is tipped or if crush

points are unintentionally contacted

STABLE MACHINE. Unexpected movement

during operation greatly increases risk of injury

or loss of control. Before using the machine ,

verify that it is stable

UNATTENDED OPERATION. To reduce the risk

of accidental injury, never leave the machine in

use while unattended.

MAINTAIN WITH CARE. Follow all maintenance

instructions and lubrication schedules to keep

the machine in good working condition. A

machine that is improperly maintained could

malfunction, leading to serious personal injury

or death.

CHILDREN & BYSTANDERS. Keep children and

bystanders at a safe distance from the work

area. Stop using machine if they become a

distraction.

2.1 GENERAL WORKSHOP SAFETY Cont.

Warning: Crush Points can occur

between the Ram and the workpiece

or between the workpiece and the

table.

8

OPERATION MANUAL

2.2 SAFE OPERATING PROCEDURE FOR HYDRAULIC PRESS

DO NOT use this machine unless you have been instructed in its safe use

and operation and have read and understood this manual.

Safety glasses must be worn at

all times in work areas.

Close tting protective clothing or

overalls are encouraged

Appropriate protective footwear

with substantial uppers must be

worn.

Rings and jewelery must NOT be

worn in the workshop

PRE-OPERATIONAL SAFETY CHECKS

1. Ensure you are familiar with the operation of the hydraulic press.

2. Check for any hydraulic uid leaks.

3. The press table must be clean and steel weights are at and secure on press table.

4. Any forming die or cutting die must be inspected for safe use i.e. no cracks.

5. Ensure safety glasses or goggles are available and are worn by all persons in the vicinity.

6. Any test piece, project or material (work piece) to be pressed must be of an appropriate

thickness and safe to use on this equipment.

7. Faulty equipment must not be used. Immediately check suspect machinery.

OPERATIONAL SAFETY CHECKS

1. Place your test piece, project or material (work piece) securely on the press table.

2. Ensure the pressure valve is closed before operation.

3. Use the press handle, in a pumping action, to slowly lower the press hammer.

4. Use your shoulder muscles when operating – NOT your lower back.

5. Keep hands and ngers away from all clamping and moving parts.

6. Carefully and accurate alignment the press hammer face with the work piece for even force

to be applied.

7. Once the press hammer makes contact with the work piece, closely watch the PSI gauge

and note the pressure applied.

8. Once the work piece is pressed suciently, release the hammer pressure at the release

valve.

9. DO NOT apply excessive force with the press.

AFTER OPERATION COMPLETED

1. After use, clean the press down and place any tools and equipment in the appropriate

storage area – including the press handle.

2. Place all scrap or waste in the appropriate bin.

POTENTIAL HAZARDS

Beware of high forces applied Eye injuries – ying or shattering objects

Pinch and squash Laceration injuries

Potentially uneven forces being applied to the work piece

9

OPERATION MANUAL

2.3 LIFTING INSTRUCTIONS

Make sure that a crane or forklift with sucient capacity is available to unload the machine from

the vehicle. Ensure access to the chosen site is clear and that doors and ceilings are suciently

high and wide enough to receive the machine.

The machine is heavy and will require two or more to lift and assemble.

When lifting the machine only certied lifting slings

should be used. (Fig.2.1)

Ensure that when lifting, the machine does not tip over.

Check that the lifting slings do not interfere with the

hydraulic pipes.

Failure to follow these instructions could cause damage

to the machine

LIFTING POINTS

Fig. 2.1

10

OPERATION MANUAL

The position where your machine is operated is important for safe operation and the longevity

of its components. For best results, operate this machine in a dry environment that is free from

excessive moisture, hazardous chemicals, airborne abrasives, or extreme conditions.

Extreme conditions for this type of machinery are generally those where the environment is

subject to vibration, shocks, or bumps.

Children or untrained people may be seriously injured by this machine. Only install in an

access restricted location.

Lighting around the machine must be adequate enough that operations can be performed

safely.

Consider the largest size of workpiece that will be processed through this machine and provide

enough space around the machine for adequate operator material handling or the installation

of auxiliary equipment.

3. INSTALLATION

3.1 ASSEMBLY

Ensure the press and its components suered no damage during transit and that all the parts

are present. Should any loss or damage become apparent, please contact your local dealer

immediately.

IMPORTANT: Due to the weight of the press components, we recommend that you get

assistance during assembly.

IMPORTANT: Do not locate your press where it will be open to the elements, as severe weather

conditions will damage the hydraulic parts.

Use the spare part exploded drawing on page 23 as your guide to assemble.

Lay all parts and assemblies out in front of you before beginning.

Loosely attach all frame parts rst then once the frame is all assembled tighten all the fasteners.

The following procedure is recommended:

1. Attach one base section (21) to a main

post (20) and lower cross member (26)

using bolts M12 x 35mm (25), washers

M12 (22), spring washers M12 (23) and

nuts M12 (24), then attach the other

post to the opposite side of the lower

cross member, using the same fasteners

as above. (Fig.3.1)

2. Attach the 4 x Support bars (34) to the

base section (21) and the main posts (20)

using bolts M10 x 25mm (33), washers

M10 (14), spring washer M10 (15) and

nuts M10(16). (Fig.3.1) Fig.3.1

11

OPERATION MANUAL

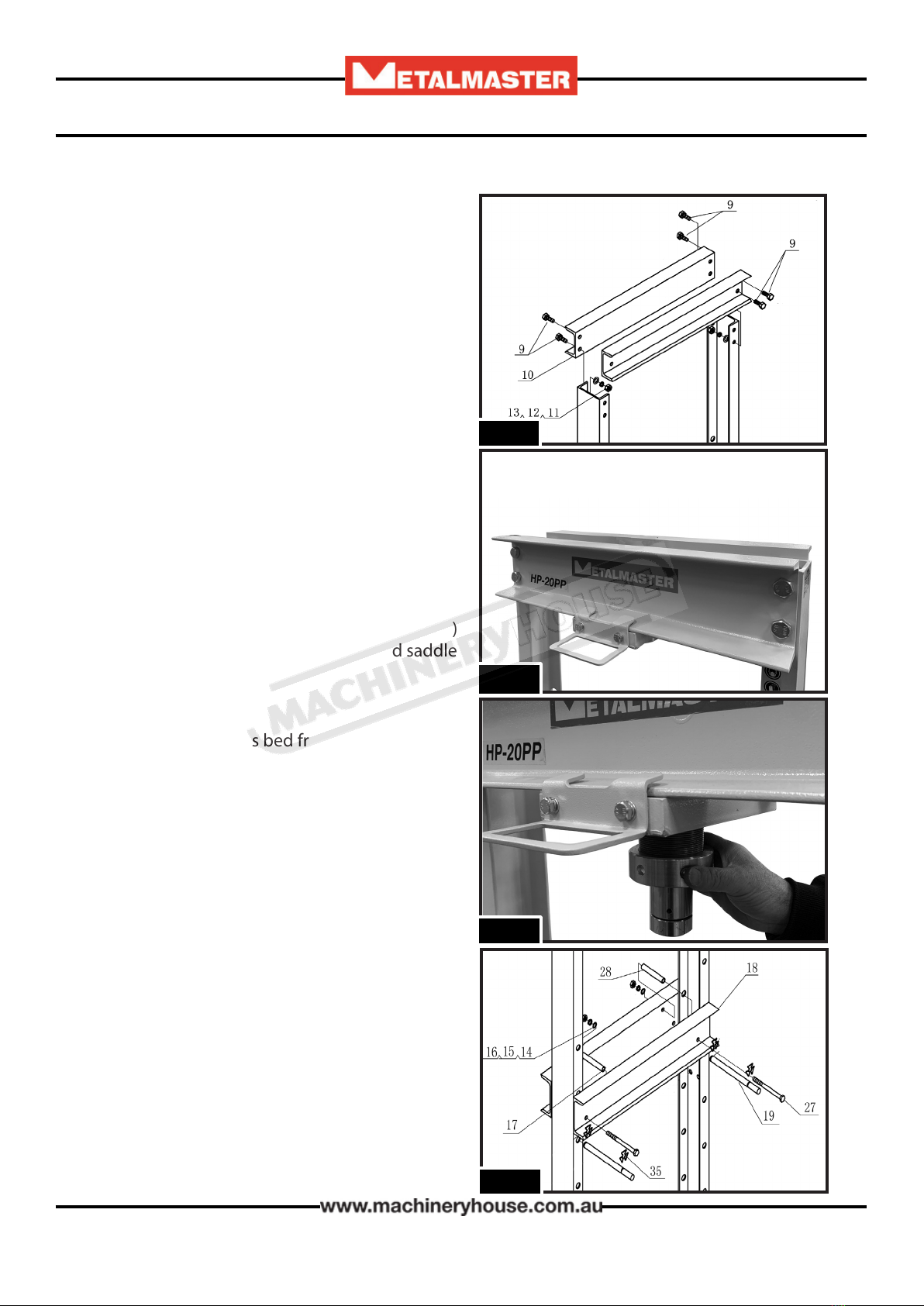

Fig.3.2

3. Put the press frame in an upright position,

attach the 2 x upper cross beams (10) to left

and right main posts (20) using bolts M16 x

35 (9), M16 washers (13), M16 spring

washers (12) and M16 nuts (11). The upper

cross beam with the Metalmaster logo is to

be facing the front of the press. (Fig.3.2)

4. Tighten all frame bolts

5. Attach the sliding plate (7) to the upper

cross beams, with the handle hook side

facing the front of the press. Using the 4 x

M8 x 20 bolts, at and spring washers.

(Fig.3.3)

6. Screw the upper round nut (6) onto the ram

(3), insert the ram into the hole in the under

plate (7), then screw the under round nut (8)

onto the ram and attach the serrated saddle

(5) to the ram. (Fig.3.4)

7. Join the two press bed frame (18) together

by inserting the four bolts M10 x 140 (27)

through the bushings (28) and the holes in

the bed frames, then secure the four bolts

by tighten the M10 washer (14), M10 lock

washer (15) and M10 nut (16) on it. (Fig.3.5)

8. Insert bed frame pin (19) into the holes in

the posts, then insert the joined press bed

frame (18) into press frame and onto bed

frame pin. Use the retaining clip (35) to

secure the pins in place.

Fig.3.5

Fig.3.3

Fig.3.4

12

OPERATION MANUAL

Fig.3.6

8. Attach the setting plate (31) to the right

hand post using bolts M12 x 30 (36), M12

washers (22), M12 lock washers (23) and

M12 nuts (24), then secure the pump

assembly using the M8 x 16 screws (30) and

M8 washers (29), and then insert the handle

to the handle bracket (Fig.3.6)

9. Assemble the pressure gauge to the

pressure gauge connection nut (R13) and

nylon ring (2) which are on the top of ram

(3). Use PTFE sealing tape to seal the threads

(Fig.3.7)

10. Unfasten the protective hose caps and

screw the hose onto the threaded

connection of the hydraulic ram.

11. With the ram in the fully retracted position,

unscrew the ller plug on top of the

cylinder and check that the pump is lled

with oil up to the bottom of the thread.

(Fig.3.6)

Fig.3.7

Fig.3.8

Filler Cap

R13

13

OPERATION MANUAL

3.4 OPTIONS FOR MOUNTING

The machine is best mounted on a concrete slab.

Masonry anchors with bolts are the best way to anchor the

machinery, because the anchors sit ush with the oor sur-

face, making it easy to unbolt and move the machine later, if

needed. (Fig. 3-8)

3.3 SITE PREPARATION

When selecting the site for the machine, consider the largest size of workpiece that will be

processed through the machine and provide enough space around the machine for operating

the machine safely. Consideration should be given to the installation of auxiliary equipment.

Leave enough space around the machine to open or remove doors/covers as required for the

maintenance and service as described in this manual.

It is recommended that the machine is anchored to the oor to prevent tipping or shifting. It

also reduces vibration that may occur during operation.

3.2 BLEEDING THE HYDRAULIC SYSTEM

Before using the press, any air needs to be

removed from the system.

To Bleed the system:

1. Opening the release valve by turning it

anticlockwise

2. Pump the handle of the pump around ten

full strokes to eliminate any air bubbles.

(Fig.3.9)

3. Close the release valve by turning it clock

wise and start to pump. If the pressing

seems spongy then repeat the process.

• The press is now ready for use.

Fig. 3.10

Fig.3.9

Release

Valve

14

OPERATION MANUAL

4. OPERATION

IMPORTANT: Due to the weight of the bed, we recommend that you get assistance from

another person when adjusting the bed height.

1. Position the bed at the desired height, so that it will be as close as possible to the ram when

the workpiece is mounted on it.

2. Raise one side of the bed and insert a supporting pin into the next locating hole.

3. Repeat at the other end to level the bed.

4. Repeat until the bed is at the desired height, with the supporting pins fully ‘home’.

5. Replace the safety clips on both end of the supporting pins.

The bed height should only be raised or lowered one hole at a time,

working alternately from one side and then the other, failure to work in this way may cause the

bed to fall and cause injury to the operator

4.1 POSITIONING THE BED

Fig.4.1

4.2 POSITIONING THE RAM

The press is designed with a quick action

method when moving the ram. It can be

quickly positioned in either direction as re-

quired by sliding the ram baseplate along the

cross-beam using the handle.

The head is secured when pressure is applied

to the ram.

Always position the ram

directly above the workpiece.

NOTE:

Always make sure you are pressing with the whole ram.

Center the ram over the work, do not press with only the

edge of the nose piece. This can cause injury by ejecting

the part, or damage to the ram.

Incorrect Correct

15

OPERATION MANUAL

4.3 PRESSING PROCESS

1. Place the workpiece on the bed. It must be

completely stable and supported by packing

or shims where required. Steel pressing plates

are supplied, (Fig.4.2) which locate on the

bed in either at or vertical position. Place the

workpiece on a combination of these to give

it stability.

NOTE: Any packing pieces or shims used MUST

be capable of withstanding the pressure that will

be brought to bear, and MUST be of sucient

size with sucient surface area, so as to avoid the

possibility of slipping or springing out. Mating

surfaces MUST be horizontal so that the force

being exerted will NOT be at an angle.

2. Close the release valve by turning it clockwise

until tightly closed. (Fig. 4.3)

3. Pump the handle to bring the ram very lightly

into contact with the workpiece.

4. Position the workpiece or slide the ram to

one side so that the desired point of contact

is directly beneath the centre of the ram

Fig.4.2

5. When satised that the workpiece is correctly aligned and is completely stable in that

position, slowly pump the handle so that the ram begins to exert pressure on the work

piece. Continue to pump the handle whilst standing to the side. Do NOT stand directly

in front of the work, and constantly monitor the process, ensuring the ram and work

remain completely in line and there is no risk of slipping.

6. When the process is complete, turn the release valve anticlockwise in small increments to

release ram pressure and allow removal of the workpiece.

Do not exceed the rated capacity of the press. Do not allow any

person who is inexperienced in the use of hydraulic presses, to use the press unless they are

under direct supervision

Fig.4.3

Release

Valve

16

OPERATION MANUAL

5. MAINTENANCE

• A visual inspection must be made before each use of the press, checking for leaking

hydraulic uid and damaged, loose, or missing parts.

• Owners and/or users should be aware that repair of this equipment requires specialized

knowledge and facilities. It is recommended that a thorough annual inspection of the press

be made and that any defective parts be replaced with genuine Metalmaster parts.

• Any press which appears to be damaged in any way, is found to be badly worn, or operates

abnormally SHOULD BE REMOVED FROM SERVICE until the necessary repairs are made.

• If the press is not to be used for any length of time, store it with the ram retracted and the

operating handle in the lowered position to protect the moving parts.

5.1 INSPECTION SCHEDULE

• Check the press frame to make sure all bolts are tight and inspect for cracked welds, bent,

loose or missing parts.

• Check the hydraulic connections for leaks. Replace or properly repair any damaged or

leaking hydraulic components before using. In the event of leaking seals, oil can be topped

up via the plug on the end of the pump. Oil should be level with the bottom of the hole. If

necessary top up with hydraulic oil, This task is carried out with the ram fully retracted.

• If any rust is apparent it must be removed completely and the paint restored

Problem Probable Cause Remedy

Pump unit will not work Dirt on the valve seat/worn

seals

Bleed pump unit or have unit

overhauled with new seals

Pump will not produce

pressure. Pump feels hesitant

under load. Pump will not

lower completely

Air-lock

Open the release valve and

remove the oil ller plug.

Pump the handle a couple

of full strokes and close the

release valve.

Replace the ller plug.

Pump will not deliver

pressure

Reservoir could be overlled

or have low oil level

Check oil level by removing

the ller plug and topping up

to the correct level.

Pump feels hesitant under

load

Pump cup seal could be worn

out Have the cup seal replaced.

Pump will not lower

completely Air-lock Release air by removing the

ller plug

5.2 TROUBLESHOOTING

17

OPERATION MANUAL

5.3 FILLING THE HYDRAULIC OIL

When lling the oil the ram must be in the FULLY UP POSITION

before any lling of the oil takes place. Failure to do so will cause overowing of the oil, creating

a slip hazard.

Checking the hydraulic oil:

The hose must not be remove when checking

the oil. To check or ll the pump, open the oil

ller cap on the top of the reservoir. (Fig.5.1).

The oil should be lled to the bottom of the

thread. If the oil is not adequate, ll with 32#

hydraulic oil as necessary. Once lled, then

replace the ller cap, and bleed the air from the

hydraulic system as described on page 13.

Metalmaster have technical support engineers

available for service. Fig.5.1

Filler Cap

18

OPERATION MANUAL

CONTENTS

Pump Spare Parts Diagram.................................... 19

Pump Spare Parts List.............................................. 20

Ram Spare Parts Diagram...................................... 21

Ram Spare Parts List................................................. 22

Press Spare Parts Diagram..................................... 23

Press Spare Parts List................................................ 24

SPARE PARTS SECTION

The following section covers the spare parts diagrams and lists that were current at the time

this manual was originally printed. Due to continuous improvements of the machine, changes

may be made at any time without notication.

HOW TO ORDER SPARE PARTS

1. Have your machines model number, serial number & date of manufacture

on hand, these can be found on the specication plate mounted on the machine

2. A scanned copy of your parts list/diagram with required spare part/s

identied

3. Go to www.machineryhouse.com.au/contactus and ll out the enquiry form attaching a

copy of scanned parts list.

Edition No : HP-20PP-3

Date of Issue :05/2020

Model. HP-20PP

Order Code P142

HYDRAULIC PRESS

19

OPERATION MANUAL

HP-20PP PUMP SPARE PARTS DIAGRAM

20

OPERATION MANUAL

No. Description Qty No. Description Qty

P01

P02

P03

P04

P05

P06

P07

P08

P09

P10

P11

P12

P13

P14

P15

P16

P17

P18

P19

P20

Pump

Filter

O-ring

Reservoir

Tie rod

Screw

Screw

O-ring

Pump foot

Steel ball

O-ring

Release valve

Hydraulic hose

Coupler

Dust cap

Steel ball

Base of steel ball

Spring

Screw

O-ring

1

1

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

2

P21

P22

P23

P24

P25

P26

P27

P28

P29

P30

P31

P32

P33

P34

P35

P36

P37

P38

P39

P40

Screw

Cap

Steel ball

Nylon ring

Sealing ring

O-ring

Nylon ring

Base of pump core

O-ring

Nylon ring

Pump core

Pin

Retaining ring

Pin

Base of handle

Handle

Handle sleeve

Screw

Nylon ring

Spring

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

HP-20PP PUMP SPARE PARTS LIST

This manual suits for next models

1

Table of contents

Other MetalMaster Power Tools manuals