Metcom Solutions COM200 Series User manual

COM200 Series

GSM/GPRS communication module

Product Manual

Document name COM200 Manual_EN_V1.doc

Document number: Revision 1.0

Date of version: 27.02.2019

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

Page 2 of 25

COM200 module - product Manual 1.0 MetCom Solutions GmbH

COPYRIGHT NOTICE

Copyright © 2019 by MetCom Solutions GmbH. All rights are reserved.

No part of this document may be reproduced, transmitted, processed or recorded by any

means or form, electronic, mechanical, photographic or otherwise, translated to another

language, or be released to any third party without the express written consent of MetCom

Solutions GmbH.

Printed in Germany

NOTICE

The information contained in this document is subject to change without notice.

MetCom Solutions GmbH shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this

material.

For further information, see the following references:

MetCom Solutions GmbH website: http://www.metcoms-solutions.com

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

MCS301 - 3ph meter Page 3 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

Content

1 Overview............................................................................................................................4

1.1 Referenced documents...................................................................................................5

1.2 Definitions and Abbreviations..........................................................................................6

2 Safety and maintenance information...............................................................................7

2.1 Responsibilities...............................................................................................................7

2.2 Safety instructions ..........................................................................................................7

2.3 Maintenance...................................................................................................................8

2.4 Disposal..........................................................................................................................8

3 Mechanical design............................................................................................................9

3.1 Module concept..............................................................................................................9

3.2 Module housing ............................................................................................................ 10

4 Functionality.................................................................................................................... 11

4.1 Data Exchange support ................................................................................................ 11

4.2 Communication protocols .............................................................................................11

4.3 Push Support................................................................................................................ 12

4.3.1 General................................................................................................................12

4.3.2 Push Triggering ...................................................................................................13

4.3.2.1 Push Triggering by Scheduler..............................................................................13

4.3.2.2 Push Triggering by Installation.............................................................................13

4.3.2.3 Push Triggering by Alarm.....................................................................................13

4.3.2.4 Push Triggering by GPRS Connection Detection.................................................14

4.3.3 Push data format .................................................................................................14

4.3.4 Push Methods...................................................................................................... 14

4.3.4.1 Push method using UDP...................................................................................... 14

4.3.4.2 Push method using FTP.......................................................................................14

4.3.4.3 Push method using TCP......................................................................................15

4.3.4.4 Push method using SMS......................................................................................15

4.3.4.5 Push method using Email service........................................................................15

4.4 NTP synchronization..................................................................................................... 15

5 HW Variants..................................................................................................................... 16

5.1 Antenna connection......................................................................................................16

5.2 Dual/Quad Band...........................................................................................................16

5.3 Support of RS485 interface........................................................................................... 16

6 Installation....................................................................................................................... 17

6.1 Module installation........................................................................................................ 17

6.2 Signal strength & provider check ..................................................................................18

7 FW Upgrade..................................................................................................................... 19

7.1 Firmware Image transfer of the communication module................................................ 19

7.2 Firmware activation.......................................................................................................20

8 Module Configuration Tool............................................................................................. 21

8.1 Module settings ............................................................................................................21

8.2 Module status readings.................................................................................................22

8.3 Push setup Settings......................................................................................................23

9 Type key .......................................................................................................................... 24

10 Technical data............................................................................................................... 25

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

1 Overview Page 4 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

1 Overview

The MCS301 supports different communication interfaces and modules:

- On-board communication interfaces

- Communication modules

Currently following communication modules are supported

- Cellular communication

oCOM200: GSM/GPRS - 2G

oCOM205: UMTS - 3G

oCOM210: LTE - 4G

- Ethernet communication

oCOM300: TCP/IP

- Other communication

oCOM400: TLS gateway adapter with encrypted communication

oCOM410: adapter Gateway adapter without TLS

oCOM420: CL0 CL0 adapter interface module

oCOM430: RS485 RS485 adapter interface module

Figure 1: MCS301 supported communication module

More details are described in the specific user manual of the other COM Series modules.

In particular, this document describes the COM200: GSM/GPRS - 2GCellular communication

module

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

1 Overview Page 5 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

1.1 Referenced documents

Title Version Datum

Electricity metering – data exchange for meter reading, tariff and load

control – part 21 EN 62056-21 06.2002

Electricity metering – data exchange for meter reading, tariff and load

control – part 53 COSEM application layer EN 62056-53 06.2002

Electricity metering – data exchange for meter reading, tariff and load

control – part 62 Interface classes EN 62056-62 06.2002

Electricity metering – data exchange for meter reading, tariff and load

control – part 61:

Object Identification System (OBIS)

EN 62056-61 06.2002

Electricity metering equipment (AC) – general requirements, test and test

conditions – part 11 EN 62052-11 02.2003

Electricity metering equipment (AC) – general requirements, test and test

conditions – part 21:

static meters for active energy, (classes 1 and 2)

EN 62053-21 01.2003

Electricity metering equipment (AC) – general requirements, test and test

conditions – part 22:

static meters for active energy, (classes 0,2S and 0,5S)

EN 62053-22 01.2003

Electricity metering equipment (AC) – general requirements, test and test

conditions – part 23:

static meters for reactive energy, (classes 2 and 3)

EN 62053-23 01.2003

Electricity metering equipment (AC) – part 1: general requirements, test

and test conditions, – metering equipment (class indexes A, B and C) EN 50470-1 09.2005

Electricity metering equipment (AC) – part 3: particular requirements –

static meters for active energy (class indexes A, B and C) EN 50470-3 09.2005

Environmental Management System ISO14001e.pdf 10.2011

DLMS Blue Book version 1000-1 Ed. 12.1, interfaces classes, OBIS

definition Ed. 12.1

DLMS Green Book version 1000-2 Ed. 8.1, architecture and protocols Ed 8.1

DLMS Yellow Book version 1000-2 Ed. 8.1, conformance & testing Ed. 3

IDIS Standard Package 2, Edition 2.0.pdf Ed. 2.0 03.06.2014

IDIS-S02-004 - object model Pack2 Ed2.0.xls

V2.26 26.08.2016

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

1 Overview Page 6 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

1.2 Definitions and Abbreviations

Abbreviation

Explanation

HES Head-End-System for remote meter reading

HHU Hand Held Unit for local meter reading

FW Firmware

SW Software

HW Hardware

LCD Liquid Cristal Display

OBIS Object Identification System

PQ Power Quality

GSM Global System for Mobile Communications

GPRS General Packet Radio Service (2G)

UMTS Universal Mobile Telecommunications System (3G)

LTE Long Term Evolution (4G)

APN Access Point Network

IMEI International Mobile Equipment Identity

LLS Low level security, (Password)

HLS High level security, (Key exchange)

TOU Time of use

Push Send data from meter

Pull Grab data form meter

TLS Transport Layer Security

SMS Short Message Service

FTP File Transfer Protocol

TCP Transmission Control Protocol

UDP User Datagram Protocol

IP Internet Protocol

SPI Serial Peripheral Interface

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

2 Safety and maintenance information Page 7 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

2 Safety and maintenance information

2.1 Responsibilities

The owner of the communication module is responsible to assure that all authorized persons

who work with the meter read and understand the relevant sections of the User manual that

explains the installation, maintenance and safe handling with the module.

The installation personnel must possess the required electrical knowledge and skills and must

be authorized by the utility to perform the installation procedure.

The personnel must strictly follow the safety regulations and operating instructions, written in the

individual chapters of the Product Manual.

The owner of the module is responsible specially for the protection of the persons, for

prevention of material damage and for training of personnel.

2.2 Safety instructions

The following safety regulations must be observed:

• During the communication module installation, the user should be careful not to get in

contact with live parts is dangerous to life.

• Local safety regulations must be observed. Installation of the module must be performed

exclusively by technically qualified and suitably trained personnel.

• Modules which have been dropped must not be installed, even if no damage is apparent.

They must be returned for testing to the service and repair department responsible (or the

manufacturer). Internal damage can result in functional disorders or short-circuits.

• The module must on no account be cleaned with running water or with high pressure

devices. Penetrating water can cause short-circuits.

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

2 Safety and maintenance information Page 8 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

2.3 Maintenance

No maintenance is required during the communication module life-time. The implemented

communication technique, built-in components and manufacturing procedures ensure high long-

term stability.

•In case the service of the module is needed, the requirements from the module installation

procedure must be observed and followed.

•Cleaning of the module is allowed only with a soft dry cloth. Cleaning is forbidden in the

region of terminal cover, where cables are connected to the meter. Cleaning can be

performed only by the personnel responsible for maintenance.

CAUTION: Never clean soiled modules under running water or with high pressure

devices. Penetrating water can cause short circuits. A damp cleaning cloth is enough to

remove normal dirt such as dust.

•The quality of seals must be regularly checked.

DANGER: Breaking the seals and removing the terminal cover or meter cover will lead to

potential hazards because there are live electrical parts inside.

•After the end of the meter’s lifetime, the communication module should be treated

according to the Waste Electric and Electronic (WEEE) Directive!

2.4 Disposal

The components used in the COM200 series modules are largely recyclable according to the

requirements of the environmental management standard ISO14001. Specialized disposal and

recycling companies are responsible for material separation, disposal and recycling. The

following table identifies the components and their treatment at the end of the life cycle.

Components Waste collection and disposal

Circuit boards

Electronic waste disposal according to local regulations

LED’s

Special waste: Dispose of according to local regulations.

Metal parts

Recyclable material: Collect separately in metal containers.

Plastic parts To be recycle separately. If necessary, Of waste incineration.

Batteries

Prior to disposal of unused or used Li-Batteries, safety precautions must

be taken against short circuits. Batteries can leak or ignite.

Do not dispose of used or defective lithium batteries in the household

waste but observe the local waste and environmental regulations.

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

3 Mechanical design Page 9 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

3 Mechanical design

For Smart Metering or C&I applications the communication module will fit under the terminal

cover of the MCS301 meter.

3.1 Module concept

Figure 2: MCS301 with communication modules

The interface between meter and communication module provides the following feature set:

•Exchangeable communication modules

•Plug ´n´ Play Installation: The module is connected and powered from the meter.

No extra cables or actions are needed to complete the physical installation of the

module.

•SPI interface between meter and communication module for local customized

applications.

•Transparent communication, using the DLMS/COSEM protocol of the meter for

Local or Remote FW Meter or Module upgrade

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

3 Mechanical design Page 10 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

3.2 Module housing

The communication module is placed in a separate module housing. Below variant are

supported:

Figure 3: COM200 with internal antenna

Figure 4: COM200 prepared for external antenna connector SMA or FME type

Figure 5: COM200 with sealable cover (Option)

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

4 Functionality Page 11 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

4 Functionality

4.1 Data Exchange support

The COM200 module is based on IP network and SMS services. The DLMS protocol is

used for data exchange between electricity meters and HES. The HES acts as DLMS client

and the E-meter as DLMS server. The following communication services are provided:

•

GPRS

•

CSD/SMS(Wake-up)

Two operating modescanbeused:

•

Pull mode

•

Push mode

The “Pull” mode is initiated by the HES. It is used for collecting data from meters or sending

commands to meters and consumer’s interface. The “Pull” is using following DLMS services:

•

OPEN

•

RELEASE

•

GET or SET

•

Action

The “Push” mode is initiated by the meter to send critical information such as Alarms and so on

to the HES. The DATA-NOTIFICATION service of DLMS is used in this mode. Following table

shows the DLMS services in Pull and Push modes for IP-based or SMS communication.

OperatingMode

DLMSServices

IP Communication SMS Communication

Pull

GET, SET,ACTION

(Confirmed)

SET, ACTION

(Unconfirmed)

Push

DATA-NOTIFICATION

(Unconfirmed)

DATA-NOTIFICATION

(Unconfirmed)

4.2 Communication protocols

Using the COM200 module the MCS301 meter can be readout using:

•

DLMS/COSEM protocol

•

EN62056-21 protocol

Up to 3 sockets are supported. 2 sockets can be used in parallel

•

Socket 1: address: Default 4059 (for DLMS/COSEM communication) or

address: Default 4000 (for EN62056-21 communication)

•

Socket 2: address: Default 4059 (for DLMS/COSEM communication)

•

Socket 3: address: Default 4060 (for DLMS/COSEM communication)

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

4 Functionality Page 12 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

4.3 Push Support

4.3.1 General

The pushing process is done by using three main groups of COSEM objects as follows:

•Triggering Objects

•Script Table

•Push Set-up

Below figure depict the COSEM objects are involved in Pushing process and their relationship:

Figure 4: Pushing Process

As shown in above figure, the meter can be woken up by a trigger (internally or externally) to

connect to network and exchange data with Central System. This is called Triggering Process. The

following COSEM objects are considered to provide triggering:

•Push action scheduler – Interval_1

•Push action scheduler – Interval_2

•Push action scheduler – Interval_3

•Alarm Monitor 1

•Alarm Monitor 2

•Auto Answer (SMS)

A trigger calls a script in Push Script Table (0-0:10.0.108.255) and the called script invokes the

"Push" method of relevant "Push Setup" objects. At the end, the "Push" method of "Push Setup"

object sends the specified message/data to the Central System.

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

4 Functionality Page 13 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

4.3.2 Push Triggering

4.3.2.1 Push Triggering by Scheduler

3 different schedules can be used for triggering the making GPRS connection and pushing message

to the HES. They are as follows:

•Push action scheduler – Interval_1

•Push action scheduler – Interval_2

•Push action scheduler – Interval_3

The "Push action scheduler – Interval_x" is intended to trigger making connection with the CS

(Central System) at the specific time or regular fashion to activate the PDP context and establish

new GPRS session. This will be done to establish connection with the CS (Central System) at some

specific time points.

4.3.2.2 Push Triggering by Installation

The Push setup – On installation (0-7:25.9.0*255) is used to inform to the HES that meter is installed

to the system using a combination of the meter buttons activating the Meter´s LCD option

“CELL_ConnECt” under the R-button menu:

After the activation of the Push triggering by installation will be confirmed with the text “donE” in the

LCD:

4.3.2.3 Push Triggering by Alarm

If an Alarm happens, the GPRS connection can be established and the Alarm Descriptor will be sent

to the CS (Central System). The COSEM objects "Alarm Monitor 1” and “Alarm Monitor 2” are used

to handle triggering by Alarm.

If an Alarm happens, these objects call a fourth script in "Push Script Table" object (9,0-

0:10.0.108.255) and the called script invokes the "Push" method of "Push Setup-Alarm" object (40,

0-4:25.9.0.255).

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

4 Functionality Page 14 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

4.3.2.4 Push Triggering by GPRS Connection Detection

The Push on GPRS Connection Detection (Connectivity) is triggered each time a new network

connection is established. A new network connection may be caused internally (e.g. reconnection in

mode 101 -always ON mode-, starting a new connection window in mode 102 and 103) or externally

by sending a wake-up signal to the meter in mode 104 –wake-up by trigger- or 103 -CSD Call or

SMS-.

The CSD and SMS (as external triggering) is handled by “Auto Answer” COSEM object (28, 0-

0:2.2.0.255). The listening window is always active in case of external triggering mechanism is used.

The device answers (receives) only (message from) to the calling numbers that are specified in

"list_of_allowed_callers" attribute of mentioned COSEM object. The capacity of the array of attribute

of “list_of_allowed_callers” is up to 5. Each entry may contain wild cards.

4.3.3 Push data format

The data format of the pushed data is configurable:

•Using EN62056-21 data format

•Using DLMS/COSEM data format

•Up to 45 objects can be pushed with one single action

4.3.4 Push Methods

4.3.4.1 Push method using UDP

With the UDP Push method predefined data can be send without any confirmation to a

predefined Server.

Parameters for the UDP push are

•Server

•Port number

4.3.4.2 Push method using FTP

With the FTP Push method predefined data can be send to a predefined Server. Parameters for

the FTP push are

•Server

•Port number

•User name and password

•File name and path

•timeout

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

4 Functionality Page 15 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

4.3.4.3 Push method using TCP

With the TCP Push method predefined data can be send to a predefined Server using a TCP

connection. Parameters for the TCP push are

•Server

•Port number

4.3.4.4 Push method using SMS

With the SMS Push method predefined data can be send to a predefined phone number using

the SMS service. Parameters for the SMS push are

•phone number

4.3.4.5 Push method using Email service

With the Email Push method predefined data can be send to a predefined Email address using

the Email service. Parameters for the Email push are

•Server

•Port number

•Email address of transmitter

•Email address of receiver

•Reference

•User name and password

•Usage of SSL (yes/no)

4.4 NTP synchronization

With the COM200 the time & date of the meter can be synchronized by an external NTP server.

The synchronization take place:

- After power up of the meter

- At a configurable time, after the communication module is restarted

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

5 HW Variants Page 16 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

5 HW Variants

5.1 Antenna connection

The COM200 module can support 2 different antenna solutions

•Internal antenna solution

In that application the antenna is located under the module enclosure

•External antenna solution

5.2 Dual/Quad Band

The COM200 module is available for the following frequencies:

•COM200-D: Dual Band version

900 / 18000 MHz

•COM200-Q: Quad Band version

900 / 1800 MHz and

850 / 1900 MHz

5.3 Support of RS485 interface

The COM200 with external antenna provides an additional RS485 interface, which can be used

to read other meters connected to the Bus.

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

6 Installation Page 17 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

6 Installation

6.1 Module installation

The module installation can be done following these steps even when the meter is powered:

1. Remove the meter terminal cover

2. Plug out the old communication module

3. Insert the Sim card to the communication

Module

4. Connect the external antenna (If available)

5. Plug in the new communication module

6. Close the meter terminal cover

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

6 Installation Page 18 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

6.2 Signal strength & provider check

The GSM/GPRS signal strength can be checked during the installation process using s specific

icon on the meter LCD.

GSM/GPRS signal strength indication

Up to 4 signal strength symbols are used on the LCD to check a good reception:

Bar(s):

1

2 3 4

Signal strength

range: -95 … -86

dB -85 … -76

dB -75 … -65

dB >-65

dB

Icon in LCD:

Additionally, the signal strength of the communication module can be seen on the LCD under

the OBIS identifier: 131.3.0

Provider indication

Additionally, the provider of the GSM/GPRS communication can be seen on the LCD under the

OBIS identifier: 25.6.0

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

7 FW Upgrade Page 19 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

7 FW Upgrade

The COM200 provides a FW update through any of the supported interfaces of the MCS301

meter by using the configuration tool Blue2Link.

7.1 Firmware Image transfer of the communication module

Using this Plugin to download the application Firmware to the module. Below step by step

procedure:

•Load a Firmware image file and download to the module

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

7 FW Upgrade Page 20 of 25

COM200 module - Product Manual 1.0 MetCom Solutions GmbH

•Pressing “Start Image Transfer” the Image File will be transferred to the module. A

progress bar and an estimated download time in minutes and seconds (ETA) will be

shown in the lower part of the window.

7.2 Firmware activation

After the firmware download is complete 2 options will be shown for activating the firmware:

oSelect “Activate firmware NOW” and press “Activate image NOW” to activate it

immediately in the meter

oSelect “Activate firmware LATER” and select the date and time for the delayed

activation and press “Activate image LATER”

•Afterwards read current application firmware version and signature of the module

Node sayaç Çözümleri Ltd. Şti.

Metering Solutions

www.node.com.tr

This manual suits for next models

8

Table of contents

Popular Control Unit manuals by other brands

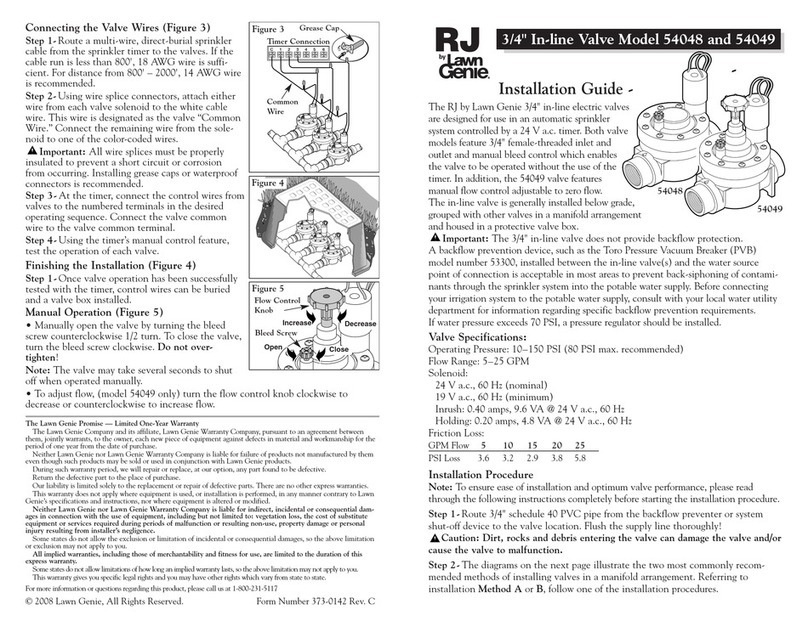

Lawn Genie

Lawn Genie RJ 54048 installation guide

ABB

ABB Welcome M2307 Online manual

Lite-Puter

Lite-Puter LPTC801 quick start guide

Sentiotec

Sentiotec Pro-C2 Instructions for installation and use

Honeywell

Honeywell CGW-MB Installation and user manual

ADCA

ADCA RP45 Series Installation and maintenance instructions