Metek LAND LWIR User manual

Long Wavelength Infrared Thermal Imaging Camera

i

QUALITY CUSTOMER SOLUTIONS

LWIR THERMAL IMAGER

INSTALLATION GUIDE

PUBLICATION NO814975

LANGUAGE: ENGLISH

ISSUE: 1

DATE: 07 DECEMBER 2021

Health and Safety Information

Read all of the instructions in this booklet - including all the WARNINGS and CAUTIONS

- before using this product. If there is any instruction which you do not understand, DO

NOT USE THE PRODUCT.

Safety Signs

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or

personal injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury to the user or users, or result in damage to the product or to property.

NOTE

Indicates a potentially hazardous situation which, if not avoided, could result in damage or loss of data.

Signs and Symbols used on equipment and Documentation

Caution, risk of electric shock.

Caution, attention to possibility of risk of damage to the product, process or surroundings. Refer

to instruction manual.

Caution, hot surface.

Protective Conductor Terminal.

Observe precautions for handling electrostatic discharge sensitive devices.

Equipment Operation

Use of this instrument in a manner not specied by AMETEK Land may be hazardous. Read and

understand the user documentation supplied before installing and operating the equipment.

The safety of any system incorporating this equipment is the responsibility of the assembler.

Protective Clothing, Face and Eye Protection

It is possible that this equipment is to be installed on, or near to, machinery or equipment operating at

high temperatures and high pressures. Suitable protective clothing, along with face and eye protection

must be worn. Refer to the health and safety guidelines for the machinery/equipment before installing

this product. If in doubt, contact AMETEK Land.

Wear Protective Gloves Wear Protective Clothing

Wear Eye Protection Wear Ear Protection

Wear Safety Boots Wear Face Protection

Electrical Power Supply

Before working on the electrical connections, all of the electrical power lines to the equipment must

be isolated. All the electrical cables and signal cables must be connected exactly as indicated in these

operating instructions. If in doubt, contact AMETEK Land.

IMPORTANT INFORMATION - PLEASE READ

Health and Safety Information

Read all of the instructions in this booklet - including all the WARNINGS and CAUTIONS

- before using this product. If there is any instruction which you do not understand, DO

NOT USE THE PRODUCT.

Safety Signs

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or

personal injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury to the user or users, or result in damage to the product or to property.

NOTE

Indicates a potentially hazardous situation which, if not avoided, could result in damage or loss of data.

Signs and Symbols used on equipment and Documentation

Caution, risk of electric shock.

Caution, attention to possibility of risk of damage to the product, process or surroundings. Refer

to instruction manual.

Caution, hot surface.

Protective Conductor Terminal.

Observe precautions for handling electrostatic discharge sensitive devices.

Equipment Operation

Use of this instrument in a manner not specied by AMETEK Land may be hazardous. Read and

understand the user documentation supplied before installing and operating the equipment.

The safety of any system incorporating this equipment is the responsibility of the assembler.

Protective Clothing, Face and Eye Protection

It is possible that this equipment is to be installed on, or near to, machinery or equipment operating at

high temperatures and high pressures. Suitable protective clothing, along with face and eye protection

must be worn. Refer to the health and safety guidelines for the machinery/equipment before installing

this product. If in doubt, contact AMETEK Land.

Wear Protective Gloves Wear Protective Clothing

Wear Eye Protection Wear Ear Protection

Wear Safety Boots Wear Face Protection

Electrical Power Supply

Before working on the electrical connections, all of the electrical power lines to the equipment must

be isolated. All the electrical cables and signal cables must be connected exactly as indicated in these

operating instructions. If in doubt, contact AMETEK Land.

IMPORTANT INFORMATION - PLEASE READ

Contact Us

UK - Droneld

Land Instruments International

Tel: +44 (0) 1246 417691

USA - Pittsburgh

AMETEK Land, Inc.

Tel: +1 412 826 4444

China

AMETEK Land China Service

Tel: +86 21 5868 5111 ext 122

India

AMETEK Land India Service

Tel: +91 - 80 67823240

Email: [email protected]

Web: www.ametek-land.com

For further details on all AMETEK Land oces, distributors and representatives, please visit our website.

Storage

The instrument should be stored in its packaging, in a dry sheltered area.

The maximum storage temperature is 10 °C (18 °F) higher than the maximum operating temperature.

The minimum storage temperature is 10 °C (18 °F) lower than the minimum operating temperature.

Refer to the Technical Specication for details of the operating temperature limits.

Unpacking

Check all packages for external signs of damage. Check the contents against the packing note.

Lifting Instructions

Where items are too heavy to be lifted manually, use suitably rated lifting equipment. Refer to the

Technical Specication for weights. All lifting should be carried out in accordance with local and national

regulations.

Return of Damaged Goods

IMPORTANT If any item has been damaged in transit, this should be reported to the carrier and to the

supplier immediately. Damage caused in transit is the responsibility of the carrier not the supplier.

DO NOT RETURN a damaged instrument to the sender as the carrier will not then consider a claim. Save

the packing with the damaged article for inspection by the carrier.

Return of Goods for Repair

If you need to return goods for repair please contact our Customer Service Department for details of the

correct returns procedure.

Any item returned to AMETEK Land should be adequately packaged to prevent damage during transit.

You must include a written report of the problem together with your own name and contact information,

address, telephone number, email address etc.

Design and Manufacturing Standards

The Quality Management System of Land Instruments International is approved to BS EN ISO 9001 for

the design, manufacture and on-site servicing of combustion, environmental monitoring and non-contact

temperature measuring instrumentation.

Registered ISO 9001 Management System approvals apply in the USA.

UK Calibration Laboratory: UKAS 0034.

USA Calibration Laboratory: ANAB Accredited ISO/IEC 17025.

National Accreditation Board for Testing and Calibration Laboratories approvals apply in India.

Operation of radio transmitters, telephones or other electrical/electronic devices in close proximity

to the equipment while the enclosure doors of the instrument or its peripherals are open, may cause

interference and possible failure where the radiated emissions exceed the EMC directive.

The protection provided by this product may be invalidated if alterations or additions are made to the

structural, electrical, mechanical, pneumatic, software or rmware components of this system. Such

changes may also invalidate the standard terms of warranty.

Copyright

This manual is provided as an aid to owners of AMETEK Land’s products and contains information

proprietary to AMETEK Land. This manual may not, in whole or part, be copied, or reproduced without the

expressed written consent of AMETEK Land.

Thermal Imaging CameraLWIR

Contents

1 Introduction 1-1

1.1 Points to note on installation 1-1

1.2 Using compressed air for air purging 1-1

2 Specications 2-0

2.1 Nomenclature 2-0

2.2 SpecicationTable 2-1

2.3 LED Status Indicators 2-2

3 Electrical Connections 3-1

3.1 ConnectingthemainsinputtotheTRACOPowerSupplyUnit 3-1

3.2 UsinganalternativePowerSupplyUnit 3-3

4 Installation Diagrams 4-0

5 UsingtheWebServerInterface 5-1

5.1 ConnectingtotheWebServer 5-1

5.2 AbouttheWebServerInterface 5-3

5.3 AbouttheWebServerMenu 5-4

5.4 Settings 5-4

5.5 Frame Settings 5-5

5.6 RegionsofInterest(ROI) 5-6

5.7 WorkingwithRegionsofInterest(ROI) 5-7

5.8 5.8I/O 5-9

5.9 SelectingaColourPalette 5-12

5.10AdjustingtheTemperatureSpan 5-12

5.11TimeFunctionProcessing 5-13

6 Spares&Accessories 6-0

6.1 StandardPowerSupplies 6-0

6.2 PoweroverEthernet(PoE)PowerSupplies 6-0

6.3 PowerI/OCables 6-0

6.4 Communications/PoECables 6-1

6.5 HousingsandAccessories 6-2

1-1

LWIRThermal Imaging Camera

Installation Guide

This guide gives you information on how to install the LWIR thermal

imaging camera and its installation accessories.

Theseinstructionsareprovidedasaseriesofsimpleinstallationdiagrams,

coveringtheinstallationoftheLWIRthermalcameraanditsmountings,

accessories and services.

Theequipmentmustbeused,maintainedandservicedbyproperlytrained

personnel,capableoffollowingtheproceduresgivenintheseinstructions.

Safetymaybeimpairedifthesystemisnotusedasindicated.

Itisimportanttochecktheequipmentwithwhichyouhavebeensuppliedand

thenreadtheseinstructionsthoroughlybeforeproceedingwithinstallation.

1.1 Points to note on installation

• WhenchoosingalocationtoinstalltheLWIRthermalimagingcamera,

ensurethatthecamerahasanunobstructedviewofthetargettobe

measured.

• Trytochooseamountinglocationthatpermitseasyaccesstothe

systemcomponentswhereverpossible,asthiswillspeedupanysystem

maintenance and repair.

• Ensure that the mounting locations chosen for the camera and its

accessoriesareasfreeaspossiblefromvibration,dust,steamandsmoke

etc.

• Ensure that the mounting locations chosen for the camera and its

accessoriesallowforthelengthsofinterconnectingcablesthatyouhave

ordered.Also,ensurethatallcablerunsareassecureandunobtrusiveas

possible.

1.2 Using compressed air for air purging

Ifyourapplicationrequirestheuseoftheairpurgingandyouintendtouse

compressedairtosupplyairtothepurge,thenthefollowingpointsmustbe

noted:

• Ifpossible,connectthecompressedairsupplytothepurgeviaa1m

lengthof35mmdiametersmoothboretube.Thiswillincreasetheairow

rateslightly.

• Theminimumrecommendedairpressureis20psi(1.4bar).

• Theminimumrecommendedowrateis350l/min.

• Occasionalcleaningwillberequiredtopreventthebuildupofeveryday

dirtonsitewhenthepurgeiso.

INTRODUCTION

1

Thermal Imaging CameraLWIR

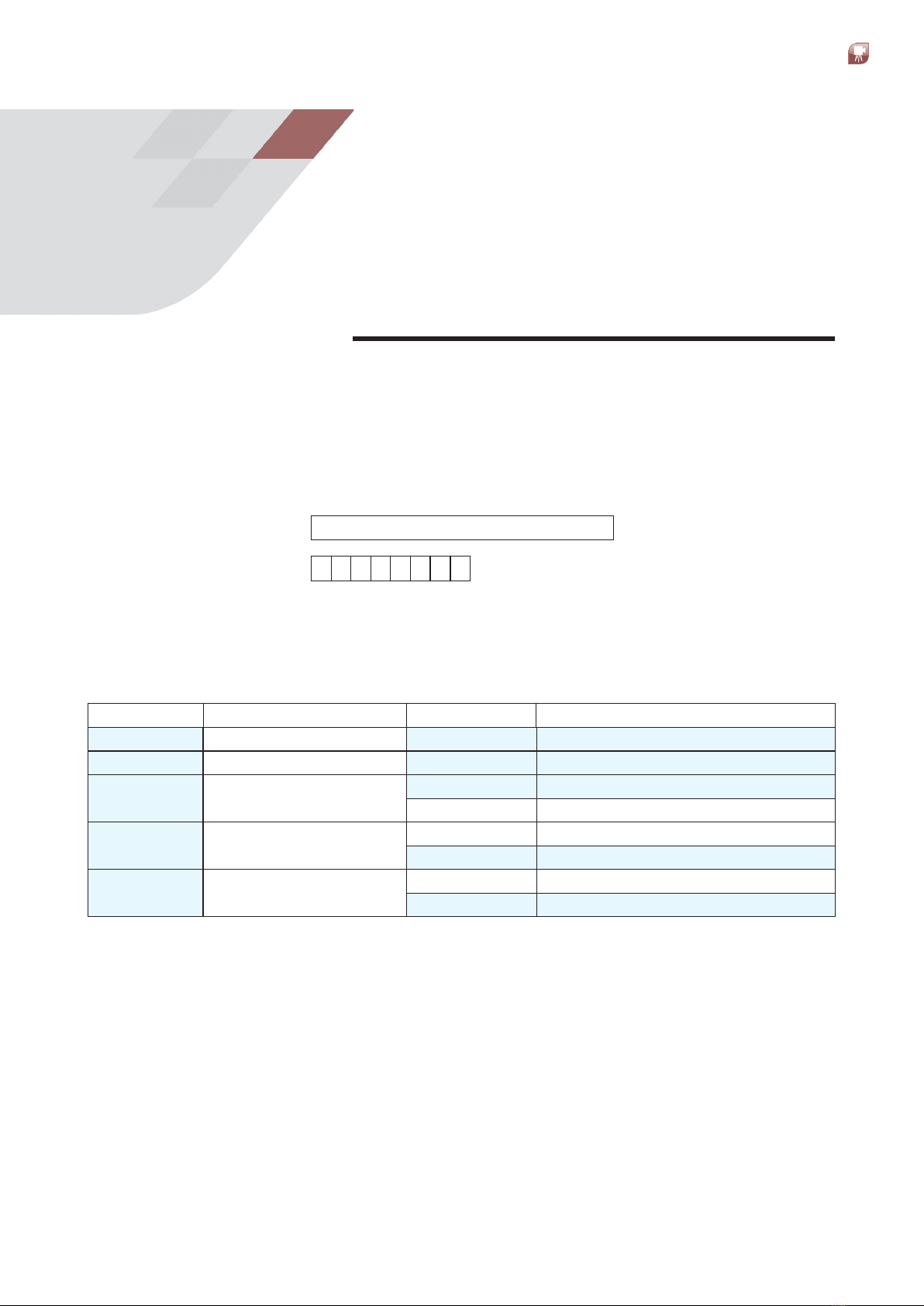

2.1 Nomenclature

Thethermalimagerdetaillabelisontherearfaceofthethermometerabove

theLANDlogolabel.

MakeanoteofyourthermometersinstrumentType and Serial Number in the

spaceprovidedbelow.

Type:

SerialNumber:

Intheexampleinthetablebelow,weexaminethenomenclatureforathermal

imagerwithaninstrumenttypelabelwhichreads:

TYPE: LWIR 640 0/500C 50 LF

Example Description Options Meaning

LWIR Series Name LWIR Longwavelengthinfrared

640 PixelResolution 640 640 x 480 pixels

0/500C TemperatureRange 0/500C 0 to 500 °C

100/1000C 100 to 1000 °C

50 HorizontalFieldofView 25 25 °

50 50 °

LF FrameRate HF 60 fps

LF 7.5 fps

Fromthetableabove,itcanbeseenthatthecamerainourexamplehasthefollowing

specication:

• Longwavelengthinfraredthermalimager

• 640 x 480 pixel resolution

• 0 to 500 °C temperature range

• 50°horizontaleldofview

• 7.5 frames per second frame rate

RefertothistablewhencheckingyourinstrumentTypelabeldetails.

SPECIFICATIONS

2

Installation Guide2-0

2-1

LWIRThermal Imaging Camera

Installation Guide

2.2 Specification Table

Camera Unit

MeasurementRange: 0to500°C/32to932°F

100 to 1000 °C / 212 to 1832 °F

PixelResolution: 640 x 480

Pixel Size/ Pitch 17μm

SpectralResponse: 8to14μm

MaxFrameRate:* 60 fps / 7.5 fps

Detector: 640x480AmorphousSilicon

Optic(HFOVxVFOV): 50 ° x 37 °

25 ° x 17 °

FocusRange: Min0.3mtoinnity(motorisedfocus)

Accuracy: 2 °C or 1 .5 % °C of reading

NETD: 40mk(@20°C)(-20to120°C)7.5Hz

Dimensions: 80x80x222mm(max)/3.14x3.14x8.7in

(includinglens)

PowerRating: 12to24VDC,+/-10%12W/IEEE802.3atPoE+

Weight: 1.6kg/3.5lb

AmbientTemperature: -20to60°C(-4to140°F)

0to95%humidity(non-condensing)

EnvironmentalRating: IP65/NEMA4

Compliance EMC(EN61326-1)

Camera Supply and I/O

Digital Connections: M12Xcoded8-wayconnector:10/100/1000Ethernet&IEEE

802.3atPoE+

AnalogConnections: 8-pinBinderConnector:2pins-12-24VDCPowerInput

6pinFunctionscanbeassignedtointernalimageprocessing

algorithms

1x4to20mAoutput

1x4to20mAoutputORrelayoutput

1x4to20mAinputORDigitalInputORrelayoutput

CameraWebBrowserforalignment&internalimage

processinganalogI/Osetup

Signal-LED: Visibleonrearofcameraonly(notwithjacket)3xLED

-Power/Status,EthernetComms&Camerainternal

temperature

Service: Water,instrumentairforoptionalcoolingenclosures

SMART Functionalities

IntegratedWebServer: RemoteaccessviaGbitEthernetinterface

IntegratedWebServerprovideslivethermalimage

AutonomousOperation: 3ROIsandcongurationofintegratedI/Osforfull

autonomous operation

Continued...

Thermal Imaging Camera

Installation Guide

LWIR

2-2

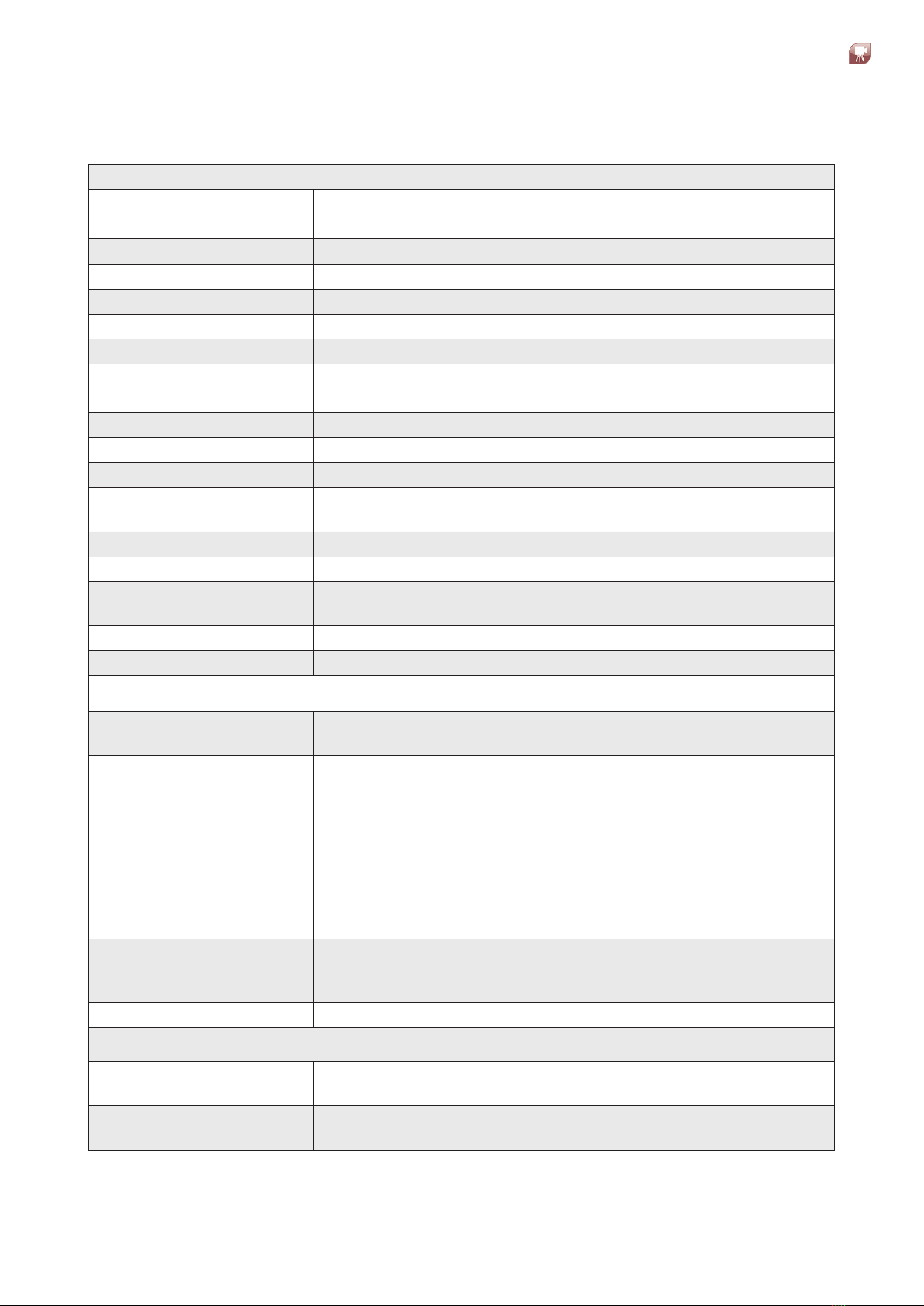

2.3 LED Status Indicators

TheLEDsontherearfaceoftheLWIRThermalImagingCamera(Fig2-11)are

used to indicate the status of the camera operation.

1 2 3

Fig.2-1LWIRThermalImagingCamerastatusLEDs

ThetablebelowgivesanexplanationoftheLEDs.

LED Function Colour Meaning

1Power/Firmwarestatus

Green PowerON

Yellow

(Flashing)

Warning.Readingsmaybe

intermittent

Yellow

(Solid)

Alarm.Cameraunabletofunction

correctly

OFF NoPower

2Ethernet Client Connection

statuse.g.IMAGEPro

Green Connected to Client

O NOClientConnected

3CameraTemperatureStatus

Green CameraTemperatureOK

Yellow

(Flashing)

CameraTemperatureWarning

Red CameraTemperatureAlarm

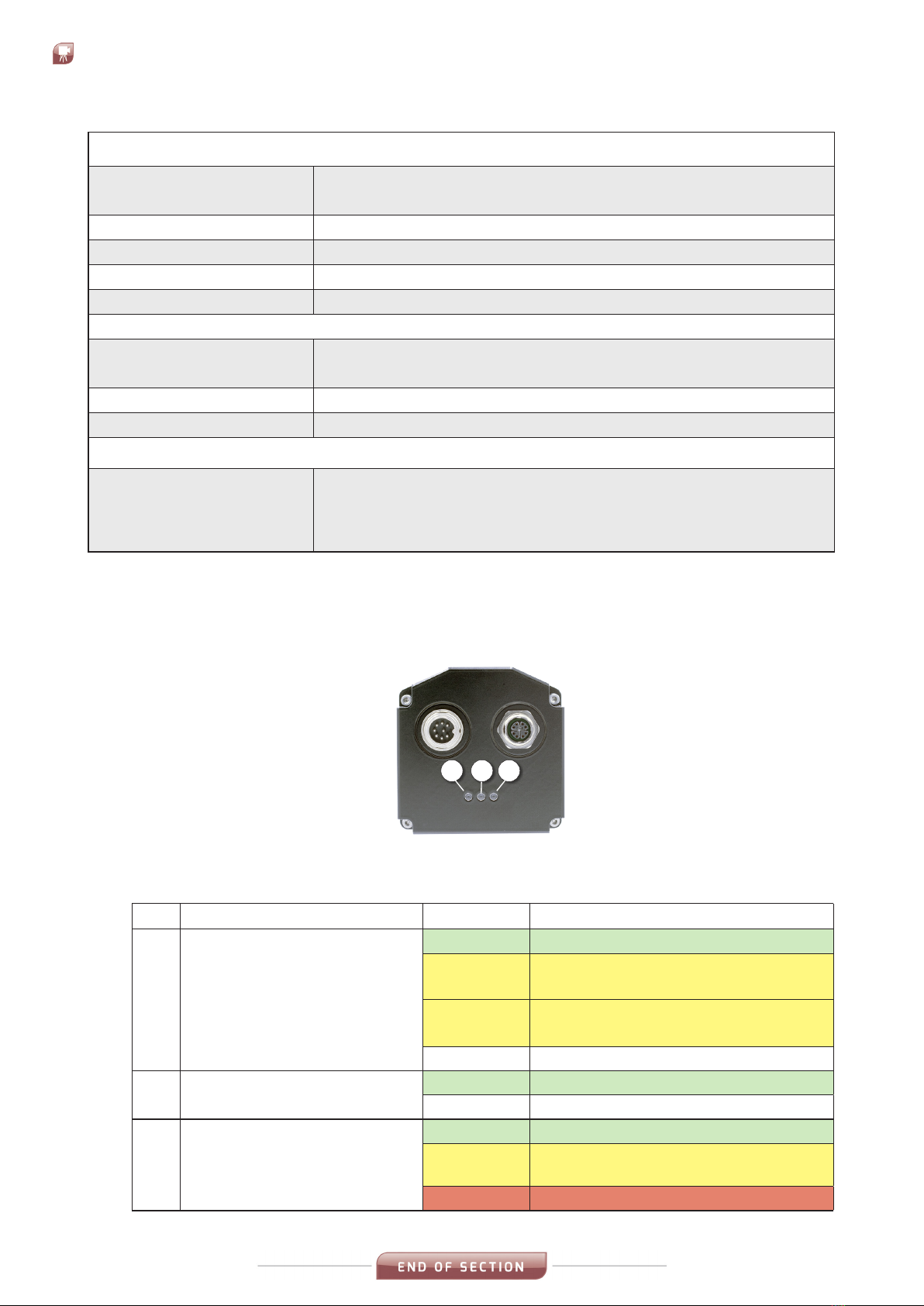

Thermal Imaging PSU Module (UL Approved)

Components &

Connections:

Powersupply,GbEthernetcommunications(switch)/PoE+

Fibreopticdataconnection(option)

EnvironmentalRating: IP65/NEMA4

Size: 380 x 380 x 211mm / 15 x 15 x 8.3 in

Weight: 15kg(33.1lbs)

ULApproval: ListedtoUL508A&CSA-C22.2No.FileNumberE499440

Image Processing

Software: IMAGEProandIMAGEViewer

IMAGEProApplication(e.gAssetMonitor)

Workstation: PC-Workstation(option)

Interfacing: OpenDataInterface,ModbusTCP,MoxaI/Ounit

Standard Accessories

Accessories(optional): ThermalImagingPSUModule(ULApproved),ProcessImager

PowerSupply,LWIR/MWIRIndustrialHousingAssemblyand

Purge,LightHousingwithPurge,cables,brackets,Blower

System,SoftwareandWorkstation

3-1

LWIRThermal Imaging Camera

Installation Guide

ELECTRICAL

CONNECTIONS

3

The basic system electrical connections are as follows:

• MainsinputtotheTRACOPowerSupplyUnit*

• 24VoutputfromTRACOPowerSupplyUnit*totheLWIRcamera

• EthernetcablefromLWIRCameratotheProcessImagingWorkstation

*TheLWIRCameracanbepoweredbyanalternativepowersupply,viacable

PartNº806032orPartNº806033(Seesection3.2).

3.1 Connecting the mains input to the TRACO Power Supply Unit

TheTRACOPowerSupplyUnitissuppliedwith

a3-pinACinputconnector(Fig.3-1).Youwill

needtodisassemblethisconnectortoinstall

thecable.

1) UnscrewthecoverfromthemainsInput

onthePowerSupplyUnit.

Fig. 3-1

Fig. 3-2

2) Theeasiestwaytodisassemblethe3-pin

ACinputconnectoristorstscrewthe

connectorassemblyontotheinputsocket

(Fig.3-2).

Thermal Imaging Camera

Installation Guide

LWIR

3-2

Fig. 3-3

3) Griptherearsectionoftheinputconnector

andunscrewitfromthePowerSupplyUnit

(Fig.3-3).

Fig. 3-4

Fig. 3-6

Theconnectionterminalsinsidetheinput

connectorwillnowberevealed(Fig.3-4).

4) Unscrewtheconnectorfrontsectionfrom

thePowerSupplyUnitanddisassemble

the remaining parts of the connector.

5) Slidetherearlockingring,gasketand

shellbodyoverthemainsinputcable.

6) Stripbackthemainscablewirestothe

appropriate lengths and connect them to

the Inputconnectorterminals(Fig.3-5)

asperthewiringschedulebelow:

Pin 1 = Live

Pin 2 = Neutral

Pin 3 = N/C

E = Earth

7) Themainsinputcableconnectorisnow

readyforre-assemblyandconnectionto

thePowerSupplyUnit(Fig.3-6).Re-

assemblethemainsinputconnector.

Fig. 3-5

3-3

LWIRThermal Imaging Camera

Installation Guide

Fig. 3-7

8) AttachthemainscabletotheInput

connectorofthePowerSupplyUnit

(Fig.3-7).

YoucannowconnecttheTRACOPowerSupply

UnittotheLWIRcameraviaInterfacePCB(Part

Nº807941).

RefertotheInstallationDiagramsinSection4.

Thermal Imaging CameraLWIR

INSTALLATION

DIAGRAMS

4

Installation Guide4-0

This section of the Installation Guide provides a series of simple

installation diagrams, covering the installation of the LWIR thermal

camera and its mountings, accessories and services.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

740.123 1

25/08/2021

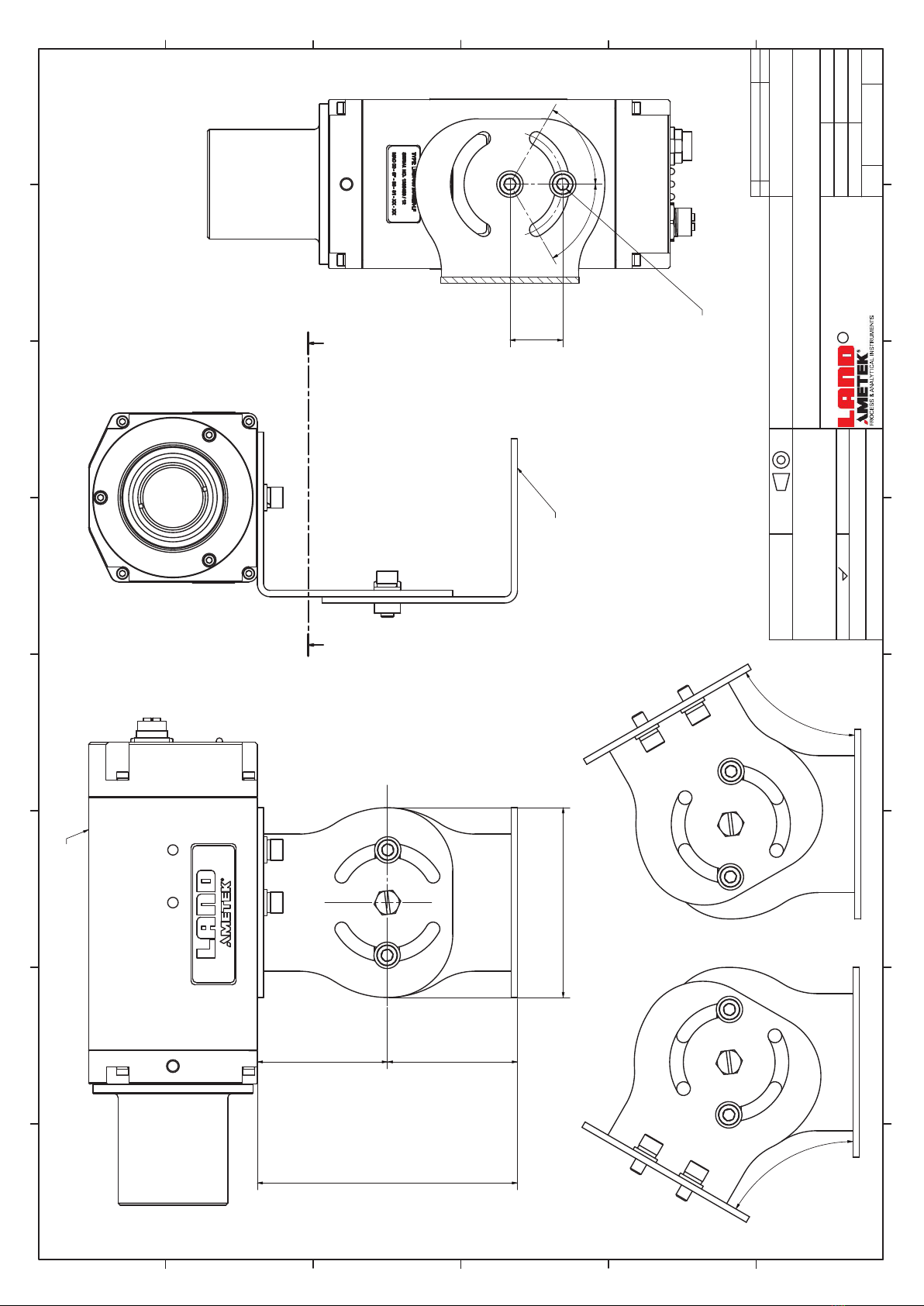

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

c L

2021

Design Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

1 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

80 [3,1]

80[3,1]

36 [1,4]

50[2,0]

18[0,7]

40[1,6]

162 [6,4]

173 [6,8]

Varies with Lens Type Overall Length

78 [3,1] 25 [1,0]9 [0,3]

9 [0,3] 78 [3,1] 25 [1,0]

1/4-20 UNC - 2B

6mm deep

1/4-20 UNC - 2B

Both Sides

0

REV DESCRIPTION DATE

LWIR/MWIR 640 Imager

M12 8 Way X-Coded PoE Ethernet Connector

M16 8 Way Connector

Power and I/O

See User Guide

for LED Functions

Approximate Overall Camera Lengths

Lens Overall Length

6 Degree 195mm [7.7"]

11 Degree 201mm [8.3"]

25 Degree 201mm [8.3"]

50 Degree 231mm [9.1"]

2 off M6x1 Tapped Holes

6mm deep

2 off M6x1 Tapped Holes

Both Sides

A-A ( 1 : 1 )

A A

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

740.123 1

25/08/2021

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

c L

2021

Desiign Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

2 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

123[4,9]

90 [3,5]

62[2,4]62[2,4]

60°

60°

60°

60°

0

REV DESCRIPTION DATE

LWIR-MWIR Imager

806761 Pan and Tilt Bracket

25[1,0]

2off M6 Cap Head Screws

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

815130 1

11/10/2021

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

c L

2021

Design Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

3 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

71 [2,8] 155 [6,1]

441 [17,4]

168[6,6]

170 [6,7]

89[3,5]

38 [1,5]Ø

106[4,2]

149 [5,8]

140[5,5]

90 [3,5]

M12 8 Way X-Coded

Ethernet PoE Connector

M16 Cable Gland Entry

Customer Power and I/O

or Power Only (Ø5 - 8 Cable)

M16 Cable Gland Entry

Customer I/O Only (Ø5 - 8 Cable)

2 off M6x1 Tapped Holes

175[6,9]

495 [19,5]

Air Inlet for Purge

90[3,5]

186[7,3]

Leave enough space

below to allow for

air purge feed pipe

This Enclosure Is NOT Cooled

65 [2,6]

Required Air Supply Conditions:

•Air supply must be clean filtered and regulated instrument air.

•MIN Flow Rate= 350 l/m for use in applications up to 1000°C

•MIN Pressure = 1.4 bar for use in applications up to 1000°C

•MAX Outlet Air temperature = 40°C

Operating temperature with

heater:

From -20°C up to +60°C.

See Videotec HEG Aluminium Camera

Housing

Manual for further details

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

815130 1

11/10/2021

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

c L

2021

Design Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

4 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

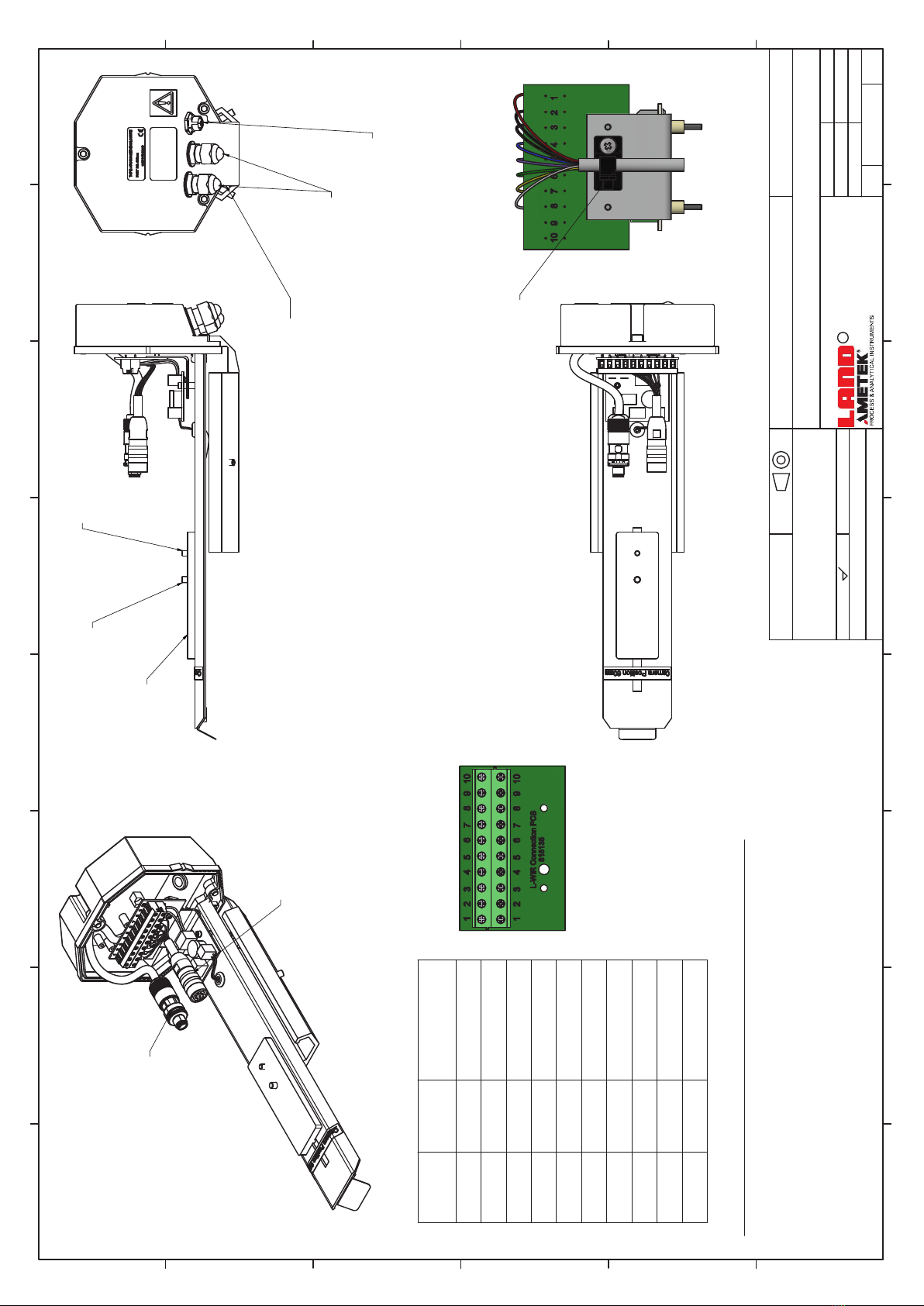

Position front face of camera Lens in to the flange on the purge.

Ensure the lens is located onto the recess face.

Fasten securely in place.

Assembly Instructions for Mounting Camera to Housing.

1,Locate the M5 countersink screw to Camera Centre Height Plate

2, Locate mounting plate into slot on mounting.

3, Fit Camera to mounting plate locating the M5 screw into the rear M6 hole.

4, Fasten Camera in position using the M6 Disc spring washer and M6 cap screw.

Ensure the washer is fitted the correct way.

Connect 2 off cable assemblies

power and Ethernet into rear

of camera.

Camera Centre

Height Plate

M12 8 Way Ethernet Cable

M16 8 Way Mains and I/O Cable Gland Entry for the Power-I/O Cable

or Power Only Cable

(High Temp 815071 25m & 815072 50m)

(STD 815155 20m & 815156 50m) Customer

Wiring

Land Supplied

M12 Ethernet X-Coded Cable Assembly

Customer Connections

Terminal Conections

Power and I/O Wire

LWIR PCB

Terminal No. Wire Colour Function

1Red +24V

2 Black 0V

3Brown +mA Out 1

4 Blue -mA Out 1

5Purple +mA Out 2/Relay 1

6 Green -mA Out 2/Relay 1

7 Yellow + Main/Digin+/Relay 2

8White - Main/Digin+/Relay 2

9N/A +24V

10 N/A 0V

Cable Clamp for Ø6 Cable

M5 Countersink Screw

M6 Cap Screw

D-D ( 1 : 2 )

E ( 1 : 2 )

D D

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

815130 1

11/10/2021

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

1.6

c L

2021

Design Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

5 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

Ensure end face of lens is located up to the

the bottom of the recess in the flange

1. Fit the Camera on to the support plate.

Position the camera forward of the camera position label

and lightly clamp in place so the camera

and can plate move up and down the slot.

Slide the assembled unit in to the main housing.

Carefully locate the lens into the flange on the back of the purge

Push the assembly in to the housing so the

rear gasket is fully engaged with the Housing.

Remove the assembly with camera carefully such that

the position of the position of the camera is not disturbed.

Tighten the screw to firmly secure the camera.

Connect connectors in to

the rear of the camera

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

815120 1

08/10/2021

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

c L

2021

Design Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

6 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

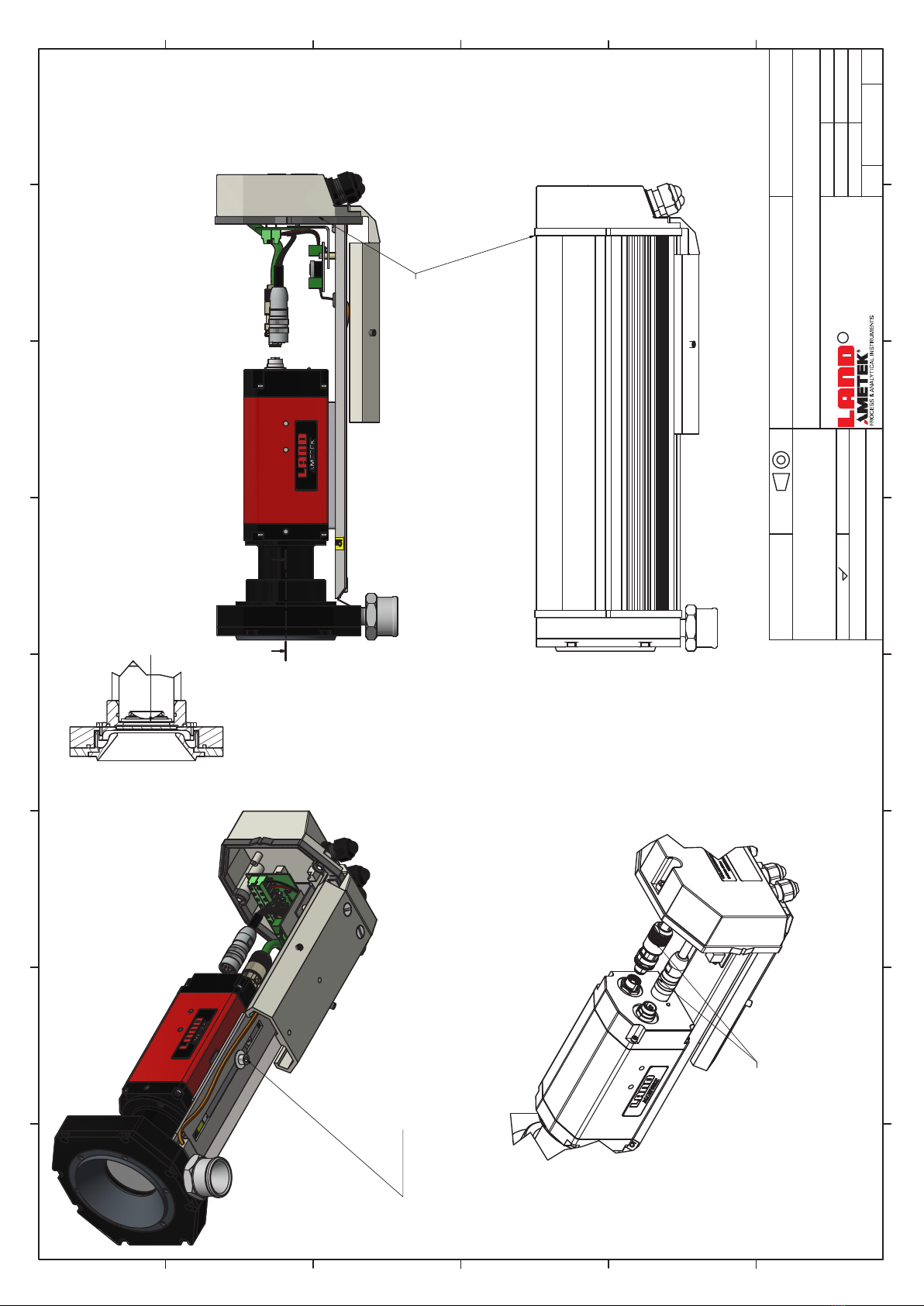

70[2,8]

101 [4,0] 265 [10,4]

124[4,9]

393 [15,5]

M6x1 - 6H

Ø9,5 [3/8"] Ø9,5 [3/8"]

99 [3,9]

145[5,7]28[1,1]

124 [4,9]

Required Water Supply Conditions:

•Water supply must be clean filtered water with a pH level between 6.5 and 8.5

•Rate of Water Hardness = <150mg/l Calcium Carbonate

•Water cooled: Flow < 1 l/min / 13Gal/hr)

•Air cooled: Flow < 450l/min / 16cfm

•Maximum working pressure: 700kN/m²/ 7 Bar (100psi)

•Plain pipe connections 3/8in /9.5mm dia.

•MAX Inlet Water temperature = 40°C

Required Air Supply Conditions:

•Air supply must be clean filtered and regulated instrument air.

•MIN Flow Rate= 350 l/m for use in applications up to 1000°C

•MIN Pressure = 1.4 bar for use in applications up to 1000°C

•MAX Outlet Air temperature = 40°C

38 [1,5]Ø

Air Inlet for Purge Leave Enough Space

BelowTo Allow For

Air Purge Feed Pipe

Water Cooling IN/OUT

2 off M32 Cable Glands

228[9,0]

55[2,2]

B-B ( 0.75 )

B B

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

815120 1

08/10/2021

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

c L

2021

Design Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

7 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

Camera Bracket Assembly

2 off M6 Cap head with spring washer

and plain washer locks camera to chassis

Ensure end face of camera lens locates up to the

lip in the holder

M4 Cap Head, Plain Washer

and Spring Washer

1. Slide camera and bracket assembly in to the housing,

carefully locate the snout of the bracket in to the end of the housing.

2. Secure the bracket in to place using the 2 off M4 screws and washers

Lens

Lens Support

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

THIS DRAWING MUST NOT BE COPIED OR USED OTHER THAN FOR THE PURPOSE OR WHICH IT

WAS ISSUED WITHOUT THE WRITTEN PERMISSION OF:-

DRG. TITLE

MATERIAL

FINISH

Created by

Approved by

DATE

DRG.No.

SURFACE FINISH ALL SHARP CORNERS REMOVED

Technical reference

SCALE

LAND INSTRUMENTS INTERNATIONAL LTD, DRONFIELD, S18 1DJ

C

SHEET

ORIGINALLY USED ON PRODUCT TYPE

Revision

S.Lonsdale

815120 1

08/10/2021

Installation Drawings for LMIR-MWIR 640 Imager System

0310 LWIR 640 Camera\Accessories

c L

2021

Design Engineering

PROJECTION

DRG.Size

Standard Assembly

DOCUMENT TYPE

A2

Not to Scale

8 of 17

All Materials and Finishes to be RoHS Compliant to Directive 2011/65/EU & (EU) 2015 / 863

Chemicals in breach of EU REACH or US TSCA limits in this product must be reported to Land Instruments

CONFORMS TO BS 8888

TOLERANCING ISO 8015

ISO 2768 -

RESPONSIBLE DEPT

D.Bramhall

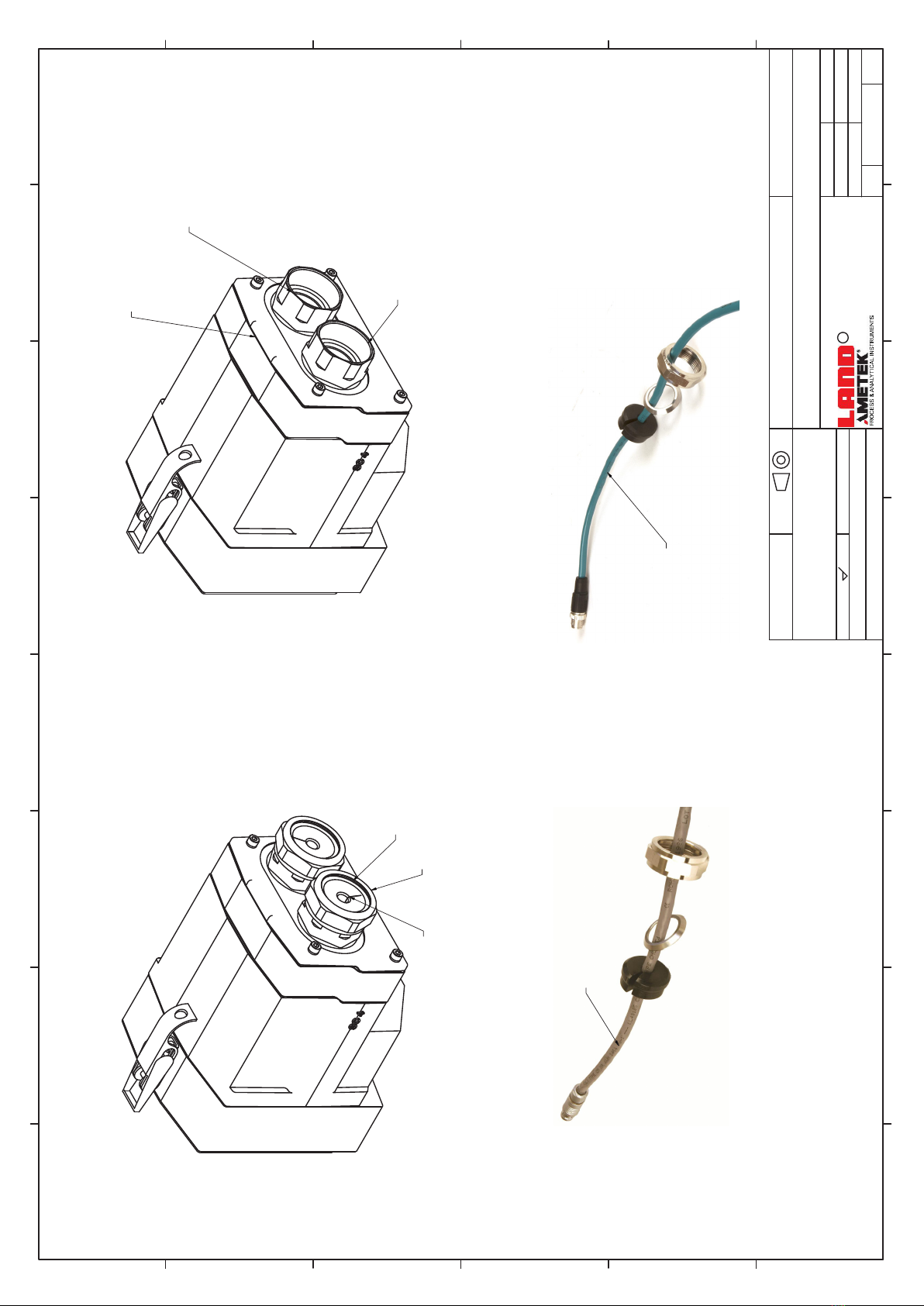

1. Remove the Gland Nut,

Sealing Washer and Cable Seal.

M12 Ethernet Cable Entry

M16 Power and I/O Cable Entry

Assembly of the Cables into the Backcap

Split Cable Seal

Seal Washer

Gland Nut

2. Slide the Gand Nut and Seal Washer over the cable connector

and place the Cable Seal around the Cable approximately 100mm from the connector. (See below)

3. Pass the connector through the gland, press the cable seal into the gland and loosely fasten the nut.

This will allow the cable to reposition when attached to the camera.

Images are for reference ONLY.

Cable types may change

Ethernet Cable

Power and I/O Cable

Table of contents