Meto mn-4 User manual

Copyright Information:

Firmware (Software) Agreement

The enclosed Firmware (Software) resident in the Printer is owned by Licensor or its

suppliers and is licensed for used only on a single printer in the user’s Trade or Business.

The User agrees not to, and not to authorize or permit any other person or party to,

duplicate or copy the Firmware or the information contained in the non-volatile or

programmable memory. The firmware (Software) is protected by applicable copyright

laws and Licensor retains all rights not expressly granted. In no event will Licensor or its

suppliers be liable for any damages or loss, including direct, incidental, economic,

special, or consequential damages, arising out of the use or inability to use the Firmware

(Software).

Information in this document is subject to change without notice and does not represent a

commitment on the part of Meto International GmbH. No part of this manual may be

reproduced or transmitted in any form or by any means, for any purpose other than the

purchaser's personal use, without the expressed written permission of Meto International

GmbH.

All rights reserved. Printed in the United States of America.

© Copyright 2000 by Meto International GmbH

Part Number: 88-2256-11

Revision: A

Agency Compliance and Approvals:

C US

Listed

UL1950 Information Technology Equipment

C22.2 No. 950-M93

EN60950

For 230 Volt Operation (Europe): Use a cord set, marked "HAR," consisting

of a min H05VV-F cord which has a minimum 0.75 square mm diameter

conductors, provided with an IEC 320 receptacle and a male plug for the

country of installation rated 6A, 250V

Für 230 Volt (Europa): Benützen Sie ein Kabel, das mit "HAR" markiert ist,

bestehend mindestens aus einem H05VV-F Kabel, das mindestens 0,75

Quadratmillimeter Drahtdurchmesser hat; sowie eine IEC320 Steckdose und

einen für das Land geeigneten Stecker, 6A, 250 Volt.

As an Energy Star Partner, the manufacturer has determined that this product

meets the Energy Star guidelines for energy efficiency.

The manufacturer declares under sole responsibility that this product conforms

to the following standards or other normative documents:

EMC: EN 55022 (1993) Class A

EN 50024 (1998)

Safety: This product complies with the requirements of EN 60950 (1992),

A1 (1993), A2 (1993), & A3 (1995)

Gost-R

FCC: This device complies with FCC CFR 47 Part 15 Class A.

;Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if not installed

and used in accordance with the instructions in this manual, it may cause

harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Important Safety Instructions

This printer has been carefully designed to give you many years of

safe, reliable performance. As with all electrical equipment, there are a

few basic precautions you should take to avoid hurting yourself or

damaging the printer:

•Carefully read the installation and operating instructions

provided with your printer.

•Read and follow all warning instruction labels on the printer.

•Place the printer on a flat, firm, solid surface.

•To protect your printer from overheating, make sure all openings

on the printer are not blocked.

•Do not place the printer on or near a heat source.

•Do not use your printer near water, or spill liquid into it.

•Be certain that your power source matches the rating listed on

your printer. If you are unsure, check with your dealer or with

your local power company.

•Do not place the power cord where it will be walked on. If the

power cord becomes damaged or frayed replace it immediately.

•Do not insert anything into the ventilation slots or openings on

the printer.

•Only qualified, trained service technicians should attempt to

repair your printer.

i

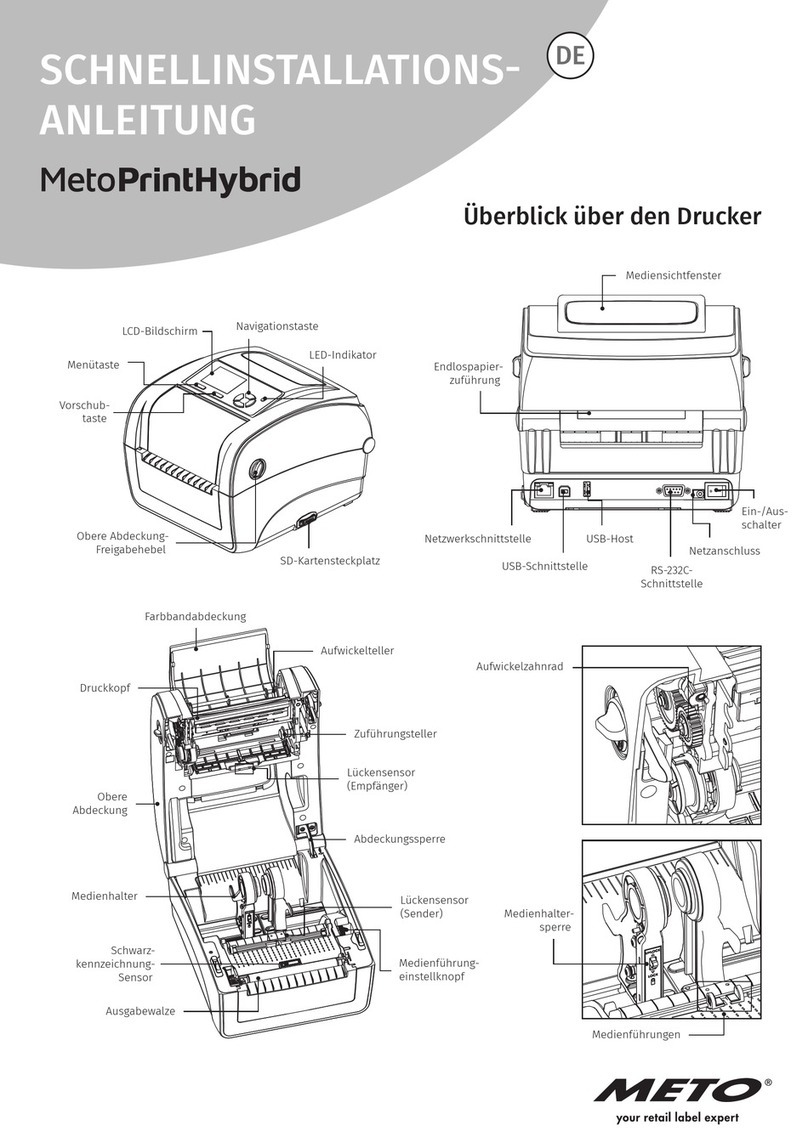

Printer Overview

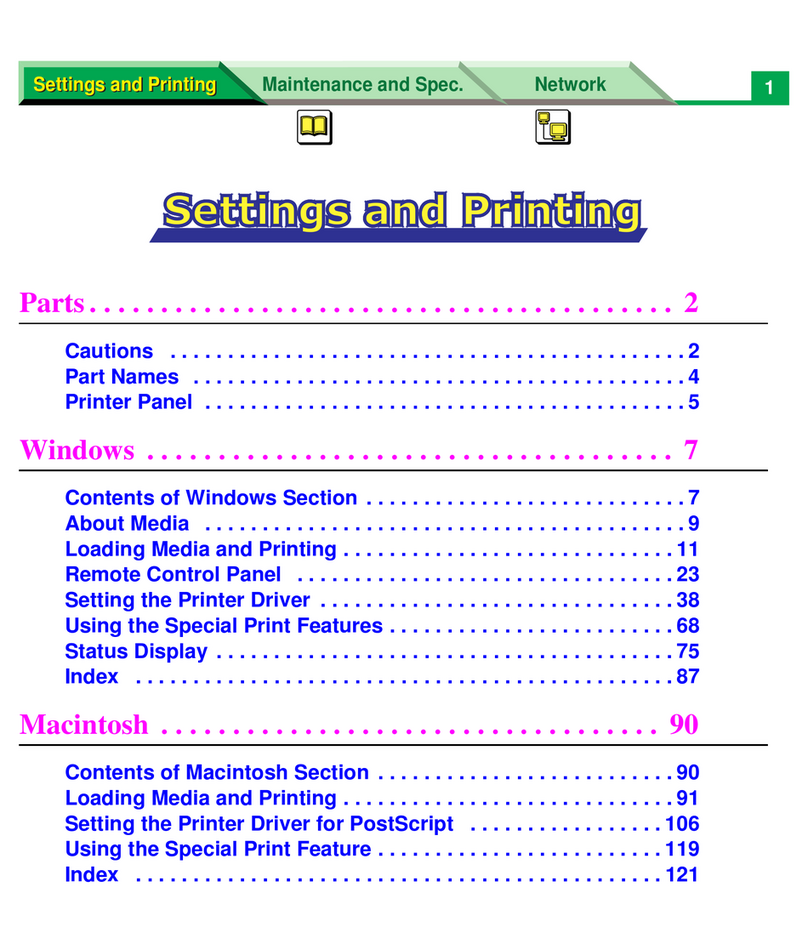

1.0 Introduction........................................................................... 1

1.1 About this Printer.................................................................. 2

1.1.1 Standard Features....................................................... 2

1.1.2 Optional Features....................................................... 3

Getting Started

2.0 Before using the Printer ........................................................ 5

Setting Up the Printer

3.0 Introduction........................................................................... 7

3.1 Connecting the Printer .......................................................... 7

3.1.1 Power Connection...................................................... 7

3.1.2 Interface Connection.................................................. 8

3.1.3 Interface Cables ......................................................... 8

3.2 Loading Media ...................................................................... 10

3.2.1 Loading Media for Peel Configuration...................... 12

3.3 Loading Ribbon (Thermal Transfer)..................................... 14

Using the Front Panel

4.0 Front Panel Operation ........................................................... 16

4.1 Lights..................................................................................... 16

4.2 Buttons .................................................................................. 17

4.3 Normal Mode - Button Functions ......................................... 17

4.4 Printer Setup Mode - Button Functions ................................ 18

4.4.1 Printer Setup Menu List............................................. 20

4.4.2 Menu Items and Values ............................................. 21

4.4.3 Example of Changing Baud Rate............................... 23

ii

4.5 Calibration Mode .................................................................. 26

4.5.1 Media Sensor Calibration Procedure......................... 27

4.5.2 Auto Media Calibration Procedure............................ 29

4.6 Internal Labels....................................................................... 30

4.6.1 Database Configuration and Dot Check Label .......... 30

4.6.2 Test Label .................................................................. 32

Maintenance and Adjustments

5.0 Introduction........................................................................... 34

5.1 Cleaning the Printhead.......................................................... 35

5.2 Fine Printhead Adjustment.................................................... 36

5.3 Ribbon Width Adjustment .................................................... 37

5.4 Media Width Adjustment...................................................... 38

5.5 Printhead Replacement.......................................................... 39

5.6 Darkness Adjustment ............................................................ 40

5.7 Resetting to the Factory Defaults.......................................... 40

5.8 Downloading Firmware and Fonts........................................ 41

Troubleshooting

6.0 Introduction ............................................................................ 42

Specifications

7.0 Printer Specifications ............................................................ 46

Appendix A

ASCII Control Code Chart ............................................................ A-1

Appendix B

Embedded Fonts and Barcodes ..................................................... B-1

Appendix C

Limitation of Liability................................................................... C-1

mn-4203

1

1

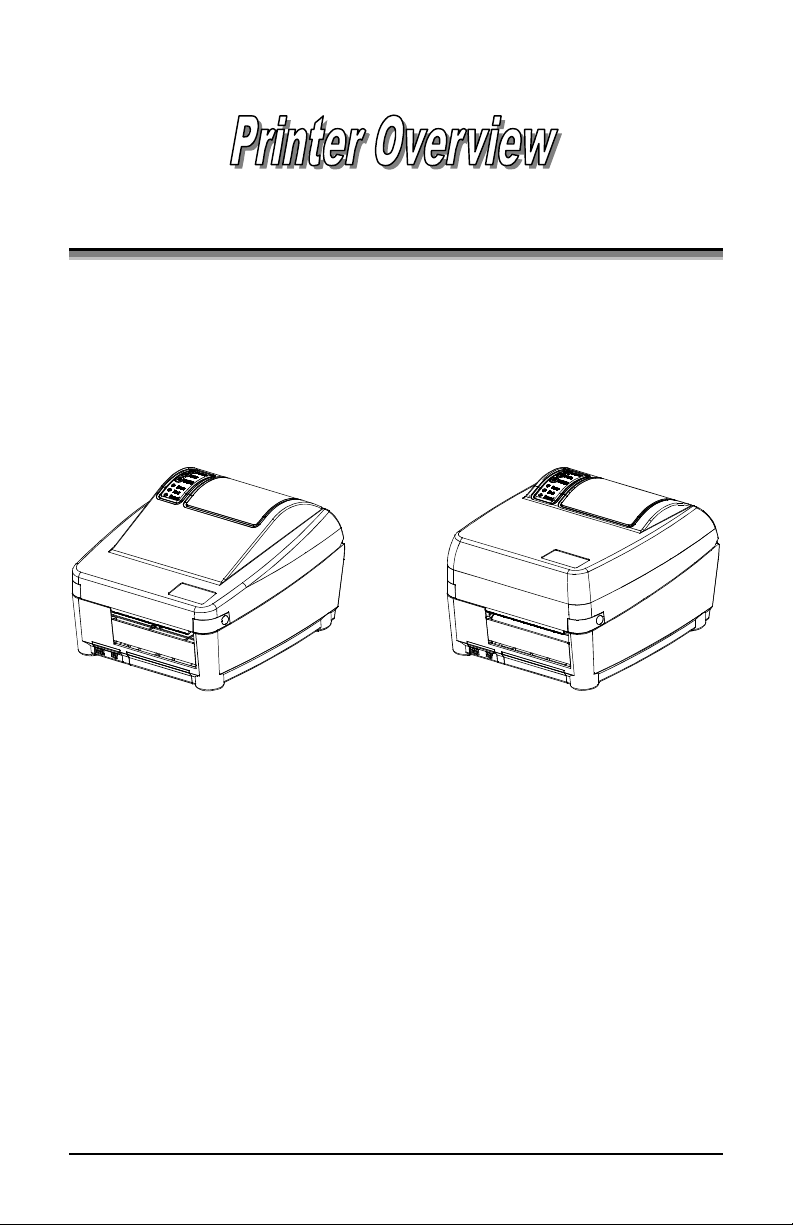

1.0 Introduction

The

mn-4203

hereafter referred to as ‘the printer’, is a user-friendly

printer that blends quality and durability at an affordable price. The front

panel was designed to make operation of the printer a simple task. The

printer offers direct thermal and optional thermal transfer printing as

well as RS232 serial and parallel interfaces for ease of connection to

your host system.

Direct Thermal Model Thermal Transfer Model

This manual provides all the information necessary to operate the

printer.

To print labels or tags simply refer to the instructions included with the

software you have chosen to create the labels. A Windowsprinter

driver can be found on our website or on the Accessories CD.

If you wish to write a custom program, a copy of the

mn-4

Series

Programmer’s Manual (88-2265-11) is included on the Accessories CD.

2

mn-4203

1.1 About this Printer

This printer offers the following standard and optional features:

1.1.1 Standard Features

Printing

¾Direct Thermal Printing

¾On Demand and Batch Printing

¾203 DPI Printhead

¾AGFA Scalable Font Engine

Memory

¾1 MB FLASH memory

¾2 MB DRAM Memory

Interfaces

¾This printer is equipped with an RS-232 serial interface and a

Centronics parallel interface.

Operational

¾Simple Media Loading

¾Media Tearbar

¾Fan-fold media compatible from rear of printer

¾1” (25mm) internal media supply core

mn-4203

3

1.1.2 Optional Features

Thermal Transfer

Thermal transfer printing requires the use of a ribbon. The ink/wax

from the ribbon transfers to the media by the printer to create an

image. Thermal transfer printing provides exceptional clarity and

scanability.

External Cutter

The external cutter provides ease of automatic cutting for tags and

labels after a label is printed. This feature attaches to the front of the

printer.

Present Sensor

The present sensor allows the printer to be configured for "one up"

printing. With the sensor installed, the printer will not print the next

label until the previous printed label has been removed from the

printer.

FLASH Memory Expansion

FLASH Expansion cartridges are used for permanent storage of

custom fonts, formats and graphics. The FLASH memory cartridges

cannot be used in conjunction with the ILPC option

External Media Supply Stand

The external media supply option allows the use of large media

supply rolls, up to 8-inches in diameter, on 1−3″cores.

ILPC

International Print Capability consisting of one of the following:

¾CG-Times (western European) Scalable font

¾Kanji Gothic B Scalable font

¾Simplified Chinese GB Scalable font

4

mn-4203

mn-4203

5

2

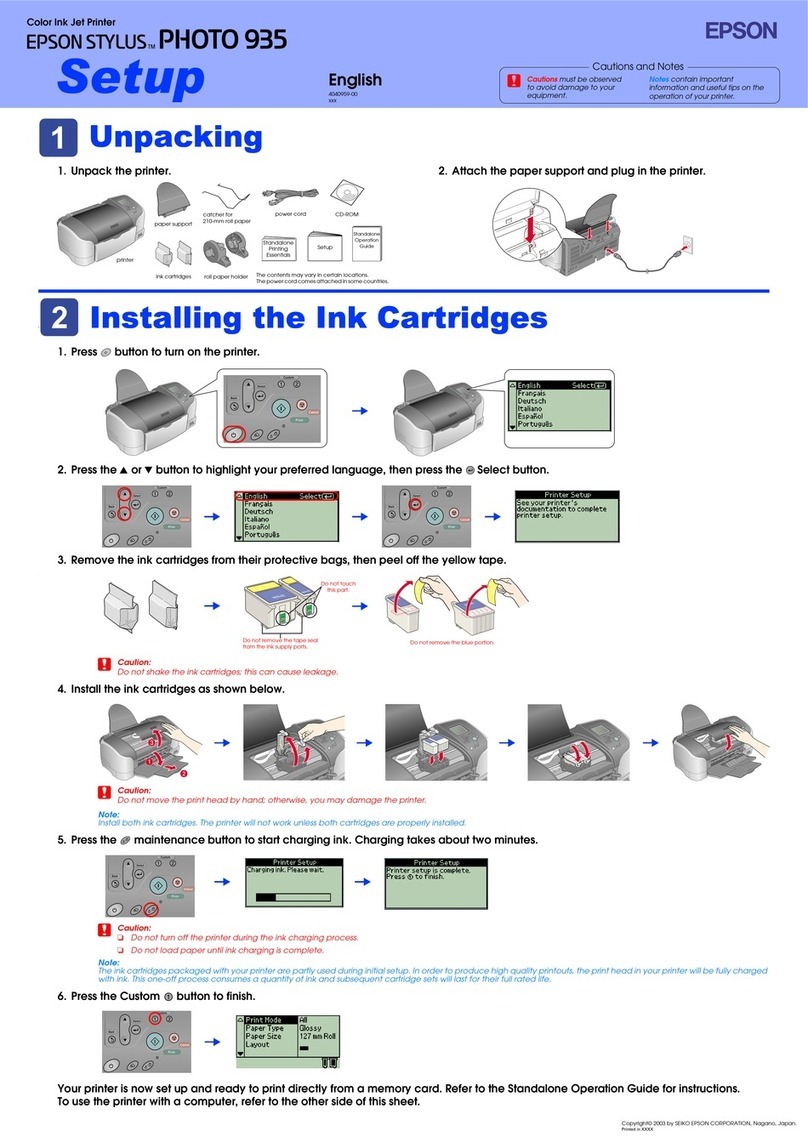

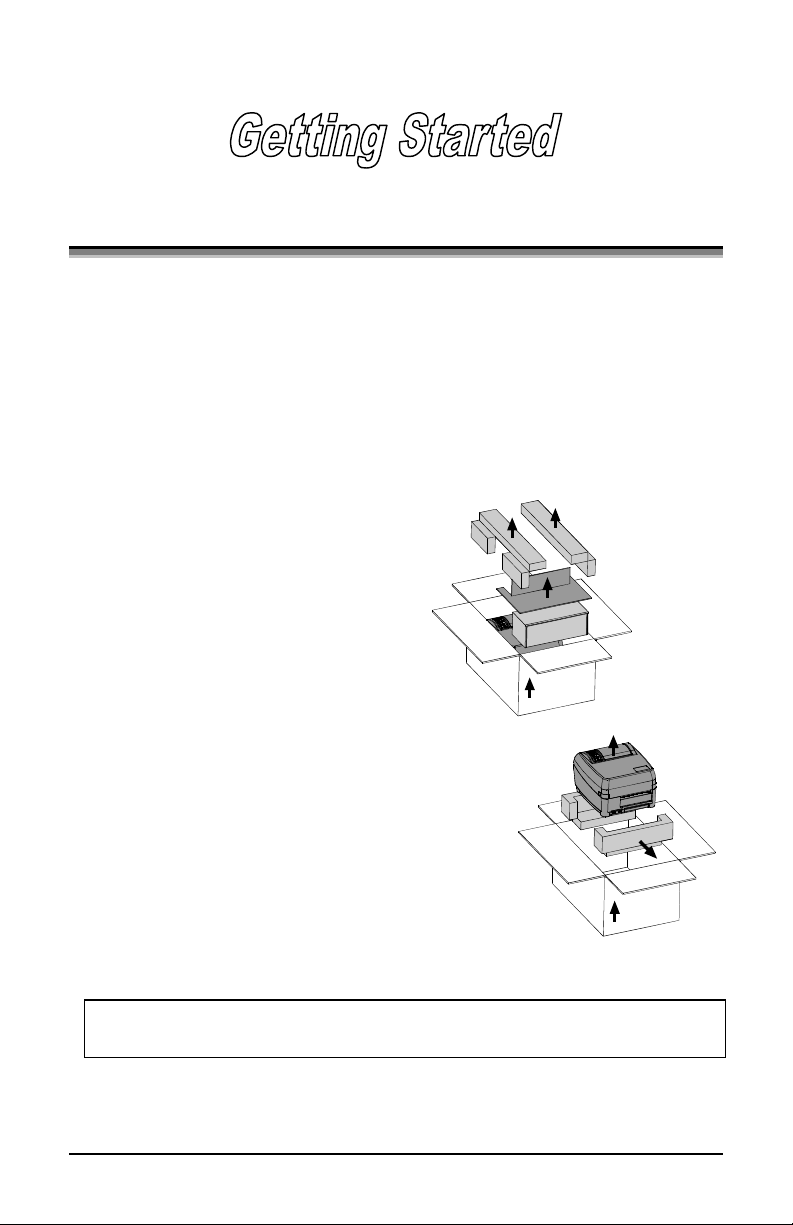

2.0 Before using the Printer

Removing the Packaging

Inspect the shipping container(s) for damage, if damage is evident notify

the shipping company to report the nature and extent of the damage.

The printer is carefully packaged to avoid any damage during transit. In

order to operate the printer you will need to remove the packaging

materials, (i.e., tape and foam) that were placed in the printer for

shipment. Complete the following steps prior to connecting power or

attempting to load media.

¾Open the box, (make sure the arrow

on the box is pointing up).

¾Remove packing foam, cardboard

divider, and power supply box.

¾Lift the printer from its box and remove the

packing foam.

¾Remove the plastic bag from the printer.

;Note: It is a good idea to save the carton and packaging materials

in the event shipping the printer is ever required.

6

mn-4203

Inspecting the Printer

After removing the printer from the packaging material, check the

contents of the package. The following items should be included:

¾Printer

¾External power supply

¾Accessories CD

¾Special or additional items

purchased.

Additional Requirements

The following items are necessary for generating labels from your

printer. Contact your customer support representative for advice on

which media and software is best suited for your needs.

¾Serial or parallel cable

¾Applicable media

¾Applicable software

mn-4203

7

3

3.0 Introduction

This chapter explains how to connect your printer, load media and

ribbon (optional), and print a configuration label.

3.1 Connecting the Printer

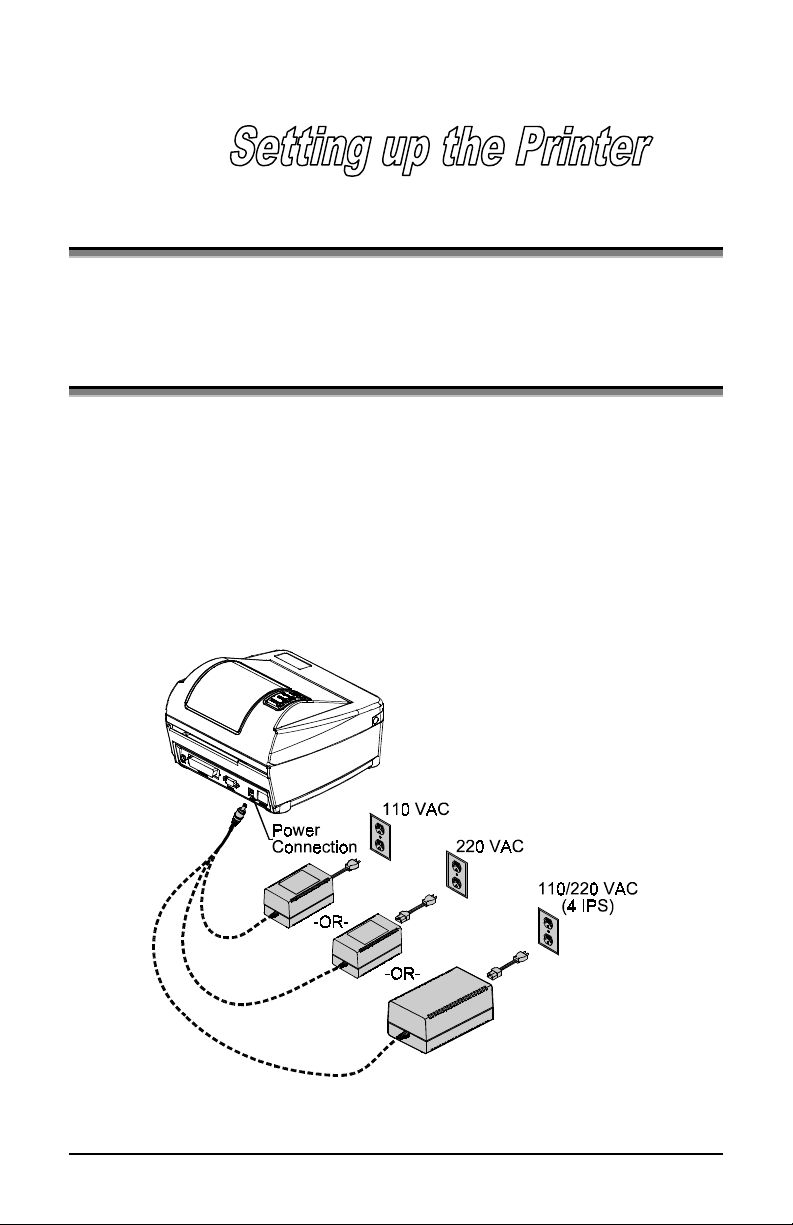

3.1.1 Power Connection

The printer is powered from an external power supply that connects to

the printer as shown below. Power supplies are available in both 110

and 220 AC voltages as well as an auto-ranging (110V/220V) power

supply for the printer’s 4 IPS (inches per second) print speed option.

Ensure that the power supply shipped with your printer matches your

electrical service.

8

mn-4203

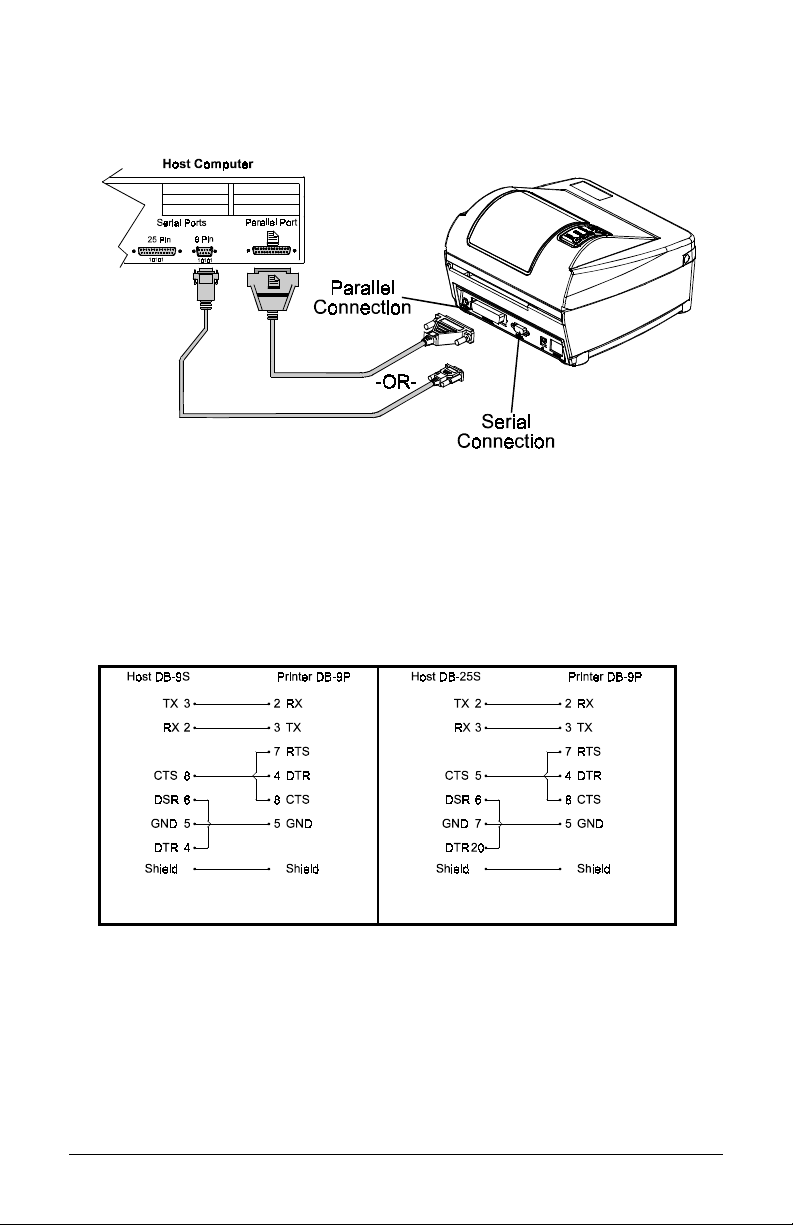

3.1.2 Interface Connection

The printer can be connected to the host via a serial or parallel cable.

3.1.3 Interface Cables

An interface cable is necessary to connect the printer to the host. The

interface between the printer and the host will be either a serial RS-232C

or parallel cable. Cable configurations for serial (RS-232C) interfaces

are shown below, (contact your reseller for part numbers and ordering

information).

Part# 425 063

Part# 425 064

The printer can also be connected to the host with a parallel connection.

In addition, the printer has a unique feature where if you connect both

the serial and parallel cables to the printer at the same time, the printer

will automatically interface to the first connection, (serial or parallel)

that transmits valid data. After a connection has been made, the printer

must be turned off and then back on again to change the interface

connection.

10

mn-4203

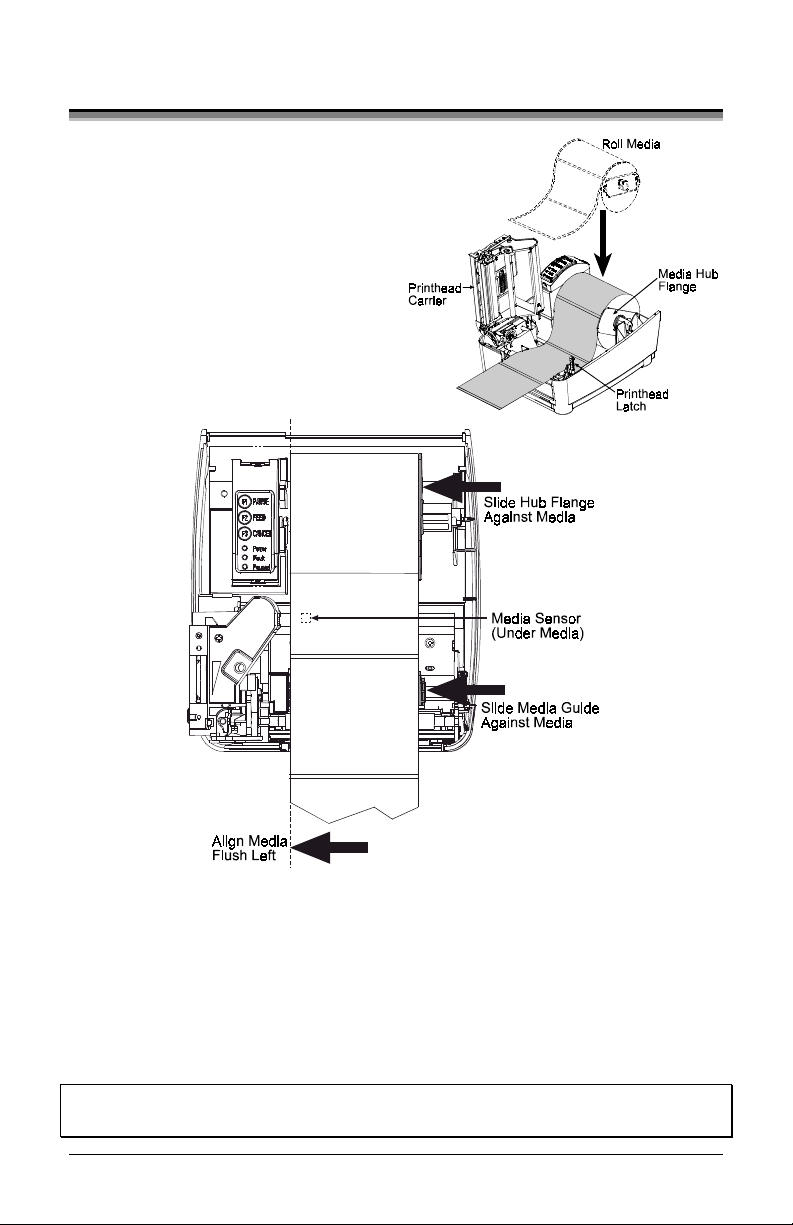

3.2 Loading Media

1. Open the cover.

2. Push the Printhead Latch toward

the back of the printer and raise

the Printhead Carrier Assembly.

3. Place a roll of media (labels

facing up) on the media hub and

insert them into the printer. Slide

the Media Hub Flange against the

roll of media.

4. Route the media as shown below.

5. Slide the Media Guide to the edge of the media.

6. Close the Printhead Carrier Assembly and press down until it locks into

place.

7. Close the cover and press the ‘Feed’ button several times to feed the media

and ensure proper tracking. If the printer does not correctly sense the top of

each label it may be necessary to perform the Calibration Procedure, Section

4.5.

Note: The printer is factory set for 4-inch media and ribbon, when using

different width media/ribbon please refer to Chapter 5.

12

mn-4203

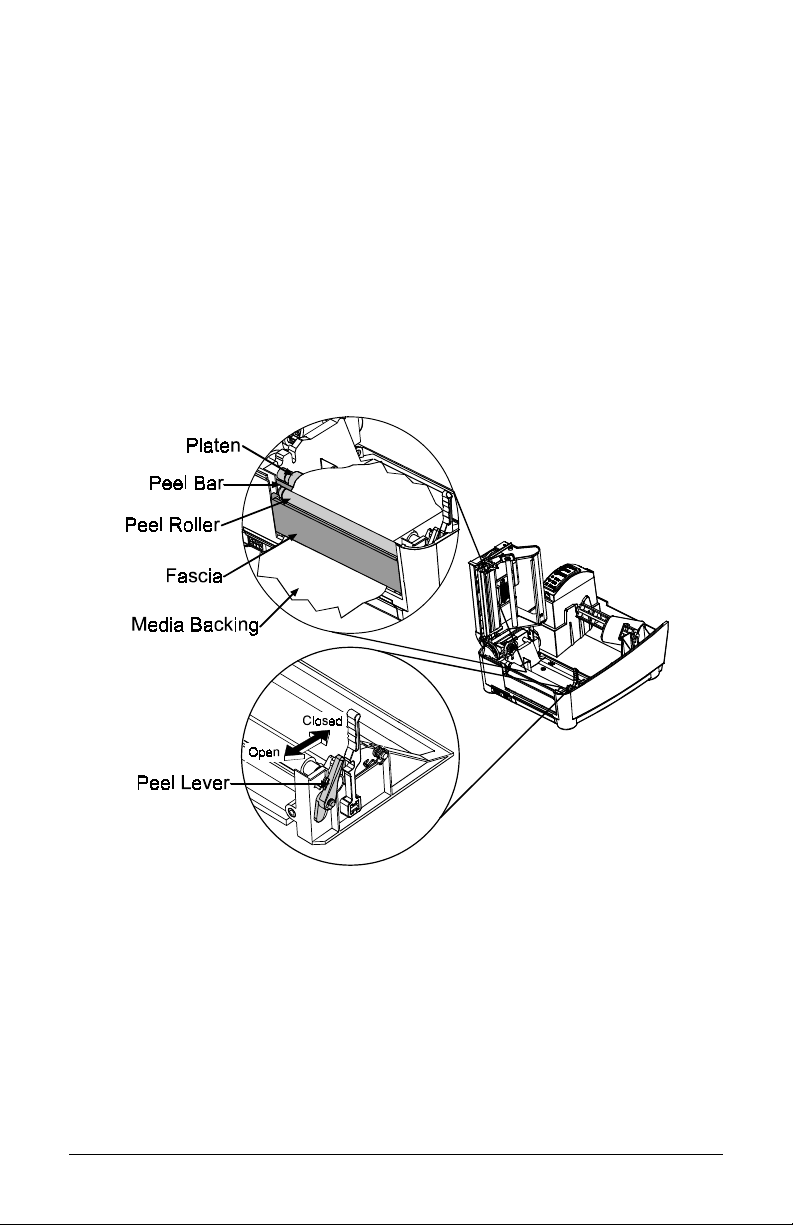

3.2.1 Loading Media for Peel Configuration

1. Open the cover.

2. Push the Printhead Latch toward the back of the printer and raise the

Printhead Carrier Assembly.

3. Place a roll of media (labels facing up) on the media hub and insert

them into the printer. Slide the Media Hub Flange against the roll of

media.

4. Pull the Peel Lever forward to the ‘Open’ position.

5. Remove 6″(152 mm) of labels from the backing. Route the backing

over the Platen and Peel Bar and behind the Peel Roller and Fascia

as shown below.

6. Push the Peel Lever back to the ‘Closed’ position

7. Close the printhead carrier assembly and press down until it locks

into place.

8. Close the cover and press the ‘Feed’ button several times to feed the

media and ensure proper tracking. The labels will separate

automatically as it is feed through the printer. If the printer does not

correctly sense the top of each label it may be necessary to perform

the Calibration Procedure, Section 4.5.

14

mn-4203

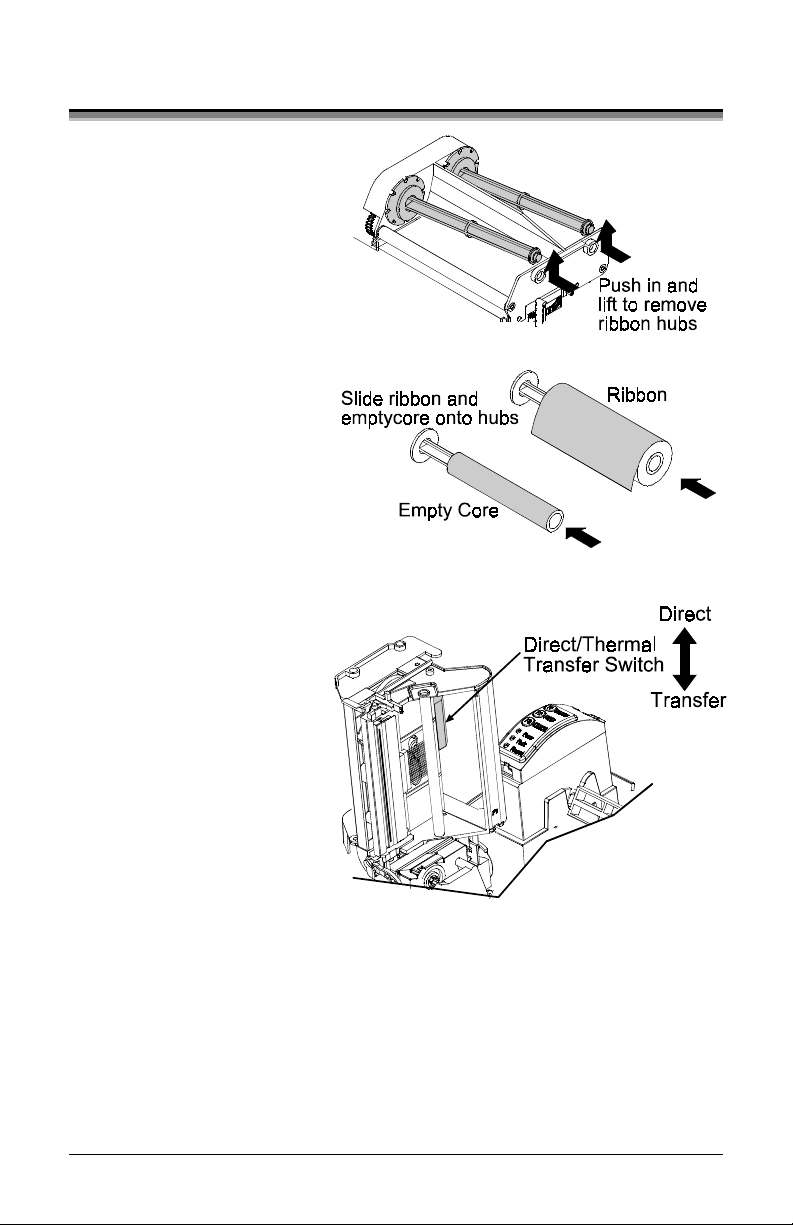

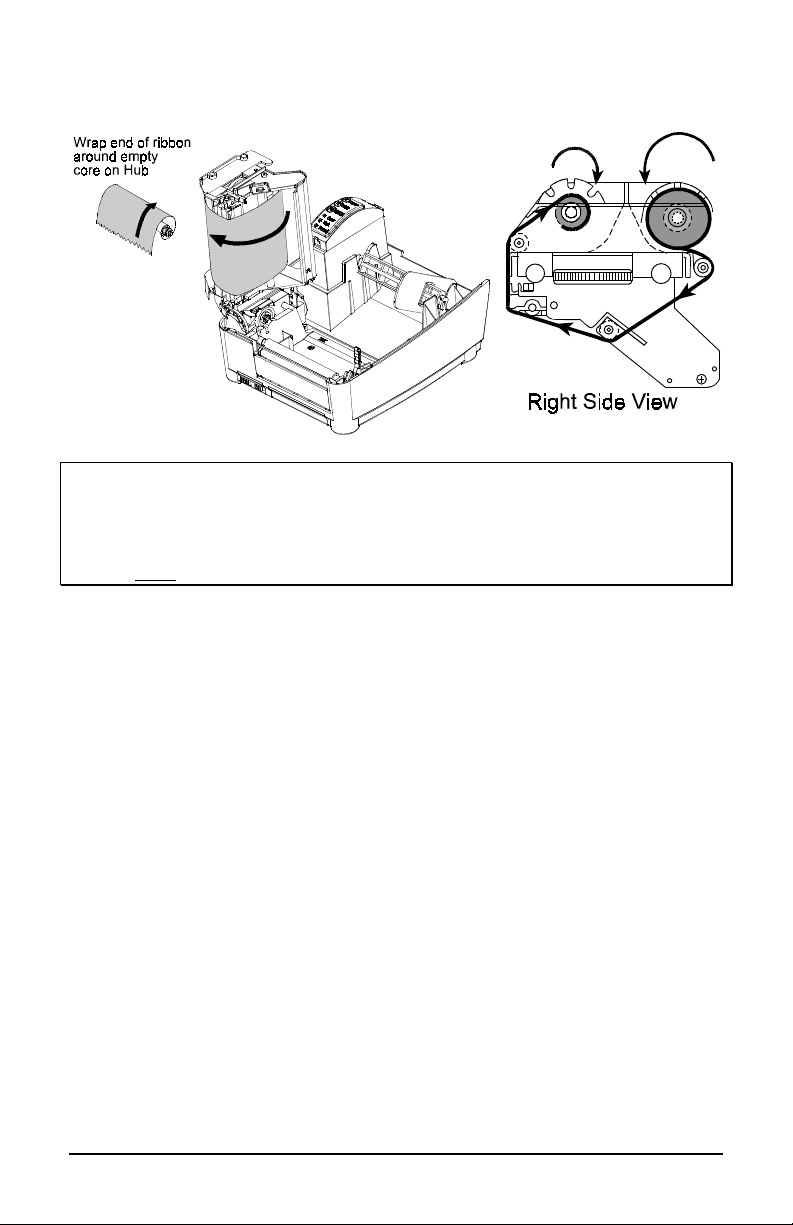

3.3 Loading Ribbon (Thermal Transfer)

1. Open the cover.

2. Remove the two

ribbon hubs.

3. Slide a roll of Ribbon

onto one of the Ribbon

Hubs and an Empty

Core onto the other

hub.

4. Push the Printhead

Latch toward the back

of the printer and raise

the Printhead Carrier

Assembly.

5. Slide the

Direct/Thermal

Transfer switch to the

‘Transfer’ position.

mn-4203

15

6. Place the Ribbon Hubs back into the printer and route the ribbon

through the printhead carrier assembly as shown below.

Note: The above ‘Right Side View’ shows proper ribbon routing for “ink side

wound-in” ribbons. For “ink side wound-out” ribbons the ribbon supply

hub will rotate in the opposite direction from that shown above. In either

case always make sure the ink side of the ribbon faces the media and

NOT the printhead.

7. The ‘Media Type’ setting within the printer’s setup must be set to

‘Thermal Transfer’ to print using a ribbon. See Section 4.4.

E-4203 16

4

4.0 Front Panel Operation

The Front Panel consists of

three lights and three dual-

function buttons. The functions

of these lights and controls are

listed below.

4.1 Lights

¾Both the POWER and PAUSED lights will be on during power-up

initialization, or “warm reset”.

mn-4203

17

4.2 Buttons

Three buttons perform different functions based on the mode the printer

is in. The printer operates in one of the following modes:

Normal: Normal printer functions (i.e. Pause, Feed, and Cancel). See

Section 4.3

Printer Setup: Allows setting of the printer’s operating menu items (i.e. Media

Settings, Communications, and Options. See Section 4.4

Calibration: Allows the printer to ‘calibrate’ the media for sensing of the

Top of Form. See Section 4.5

4.3 Normal Mode - Button Functions

In ‘Normal Mode’ the printer’s buttons control normal operations such as Pause,

Feed, and Cancel as well as test and reset functions by using button

combinations.

Button Combinations (push buttons simultaneously)

+Prints the Test Label, see section 4.6.2.

+Performs a warm reset and return to the Normal Mode of

operation.

+Will cause the printer to print the Database Configuration and

Dot Pattern Labels.

Table of contents

Other Meto Printer manuals