-1-

Content

1Generalremarks.........................................................................................................2

1.1 Descriptionofdangersigns.......................................................................................2

1.2 Purposeofinductioncookers....................................................................................3

2Descriptionofproducts...............................................................................................4

2.1 Scopeofsupply........................................................................................................4

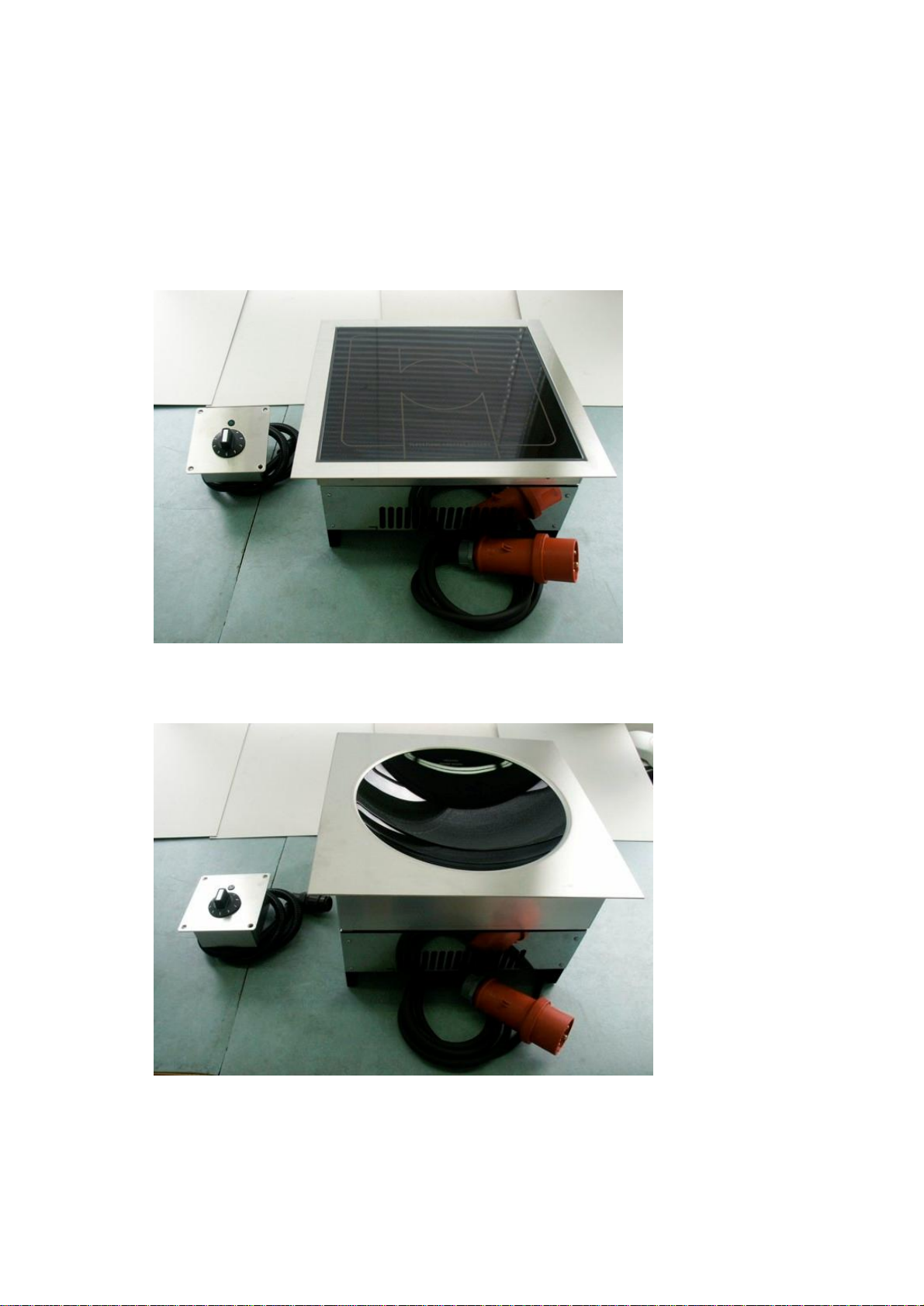

2.2 Products...................................................................................................................4

2.3 Install-unitsataglance.............................................................................................5

2.4 Technicalspecifications............................................................................................6

3Installation...................................................................................................................8

3.1 Scopeofdelivery......................................................................................................8

3.2 Requirementsofinstallation.....................................................................................8

3.3 Definitionofinterfaces.............................................................................................8

3.4 Installationclipping BH/IN2500..............................................................................9

3.5 Installationclipping SH/IN3500 andSH/IN5000..................................................10

3.6 Installationclipping SH/WO/IN3500, SH/WO/IN5000 andSH/WO/IN8000.......11

3.7 Advice forinstallation............................................................................................11

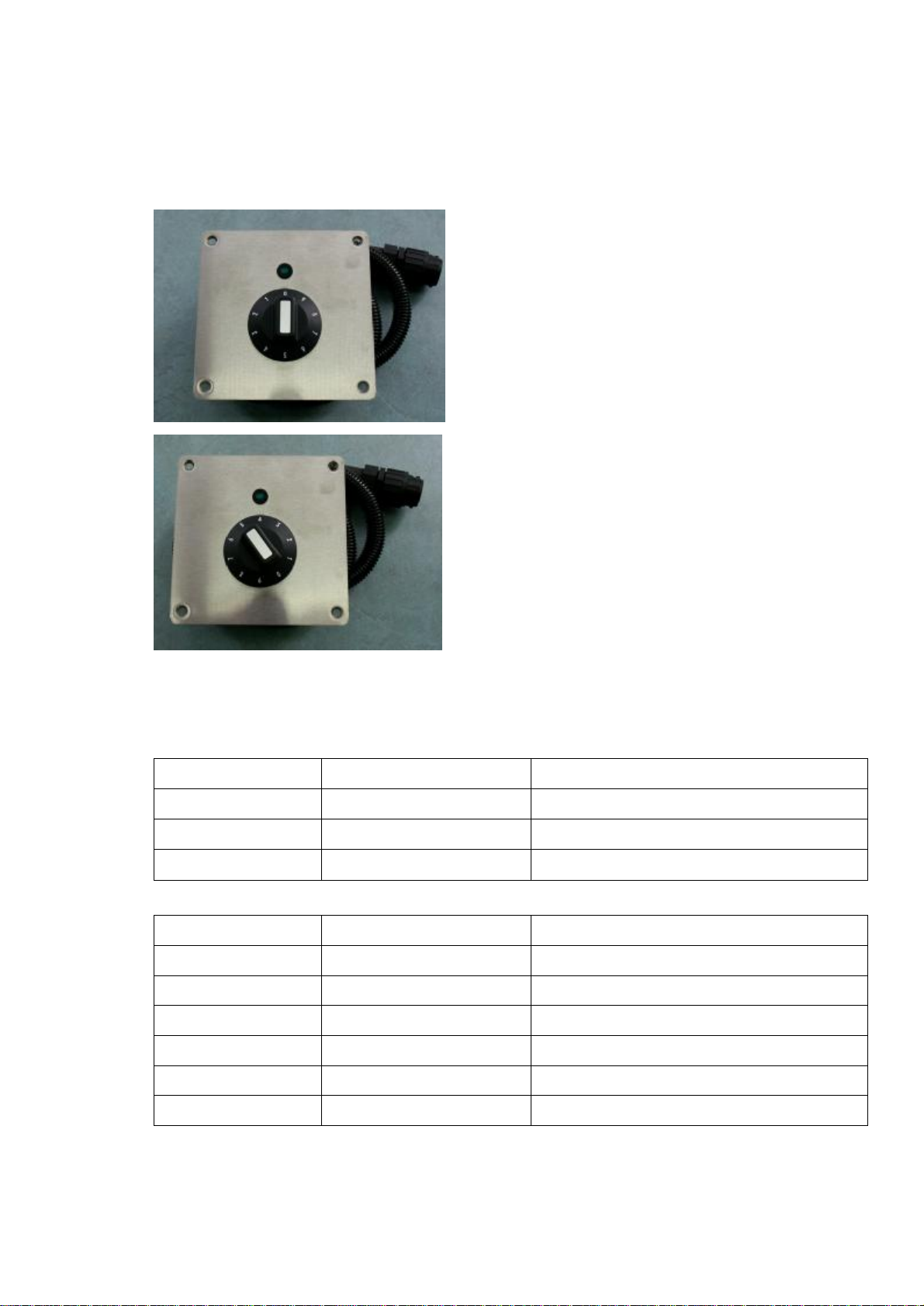

3.8 Installationoperatingunit.......................................................................................12

3.9 Electricalinstallation..............................................................................................13

4Operatingtest............................................................................................................14

5Operation...................................................................................................................15

5.1 Cookingprocess.....................................................................................................15

5.2 Comfort..................................................................................................................15

6Safetyinstructions.....................................................................................................16

6.1 Riskintheeventofnon-observanceofthesafetyinformation................................16

6.2 Safetyconsciouswork............................................................................................16

6.3 Safetyinformationfortheoperator/operatingpersonnel..........................................16

6.4 Unauthorizedreconstructionanduseofspareparts.................................................17

6.5 Improperoperatingmethods...................................................................................17

6.6 Pandetection..........................................................................................................17

6.7 Controloftheheatingarea......................................................................................17

7Outofoperation........................................................................................................18

8Faultfinding/Rectification........................................................................................19

8.1 Malfunctionwitherrorcode...................................................................................19

8.2 Malfunctionwithouterrorcode..............................................................................20

9Cleaning.....................................................................................................................22

10 Support......................................................................................................................23

11 Wastedisposalconcept.............................................................................................24