Metos E-PRO User manual

Blast Chiller - Shock Freezer

E-PRO

4240338, 4240339, 4040340, 4040341, 4040342, 4040343, 4040344, 4040345, 4040346, 4040347

Original instructions

+3°C

-18°C

start

stop

-

+

set

L1

L2 L3

RF50C00064 REV. 02 - 11/2022

Installation- and user manual

Rev. 02 - 11/2022 2

INSTALLATION SECTION

(reserved to skilled and authorised technicians)

SAFETY INSTRUCTIONS ............................................ 5

INSTALLATION............................................................ 8

BLAST CHILLER TECHNICAL DATA ........................... 64

Rev. 01 - 11/2022

3

This manual furnishes all necessary information

for the correct installation of the device operat-

ed by skilled personnel.

Read the instructions carefully before performing any

operations, as they provide essential indications con-

cerning the safety of the device.

Rev. 01 - 11/2022

5

• Read this manual carefully before in-

stalling and servicing the device and

keep it for any further future consul-

tation by the various operators.

•The manufacturer cannot be held liable for any

use of the device in contrast with the indications

provided in this manual. Remember that any

type of installation or maintenance different to

that indicated in the manual can cause damage,

injuries or fatal accidents.

•Unauthorised actions, tampering or modifica-

tions that do not follow the information provided

in this manual can cause damage, injuries or fatal

accidents and shall invalidate the warranty.

•Installation and special maintenance operations

must be performed by skilled and authorised

technicians, with good knowledge of the refrig-

erating and electrical systems, according to the

legal provisions in force in the country of use and

in compliance with standards concerning the

systems and workplace safety.

•Make sure the mains voltage and the frequency

correspond to those specified in the rating plate

before connecting the device to the electrical

mains.

•Disconnect the device from the mains before any

cleaning or maintenance (turn the main switch

to OFF and disconnect the plug).

•THE MACHINE HAS NOT BEEN DESIGNED TO BE

INSTALLED IN AN EXPLOSIVE ATMOSPHERE. Do

not keep explosive substances, such as pressur-

ised containers with flammable propellants in

this appliance.

•Before installation, please check:

- that the areas in which the machine will be in-

stalled are suitable for food preparation;

- that the systems comply with the legal provi-

sions in force in the country of use and meet

the specifications on the serial number plate;

- that a circuit breaker with high sensitivity (30

mA) is installed, to which the machine must

be connected;

- that a point of connection to the water mains

is near the device;

- that a socket with a suitable ground connec-

tion for the country of use is located near the

device;

- the planarity of the device support area, espe-

cially if it is assembled on wheels.

• During device installation:

- transit or permanence near the work area by

individuals not assigned to device installation

is prohibited;

- use the personal protection equipment (e.g.

gloves, safety footwear, etc...);

- work according to workplace safety regula-

tions (e.g. do not approach electrical parts

with wet hands or barefoot, etc...).

•ORIGINAL SPARE PARTS ARE RECOMMENDED.

The manufacturer denies all liability for the use of

non original spare parts.

•Given that packaging materials may be poten-

tially hazardous, they must be kept out of reach

of children or animals and correctly disposed of

according to the local standards.

•The device is shipped after passing inspections:

visual, electric and functional.

SAFETY INSTRUCTIONS

The manufacturer cannot be held liable for unintended device

use. Original document language: Italian. The manufacturer is

not liable for any transcription or translation errors. It is forbidden

to reproduce this manual, even partially.

Rev. 02 - 11/2022 8

OK

EXPRESS

MAX 200 cm

A

B

C

INSTALLATION

Fig. 2 Fig. 3

Fig. 4

Fig. 5

Fig. 1

Abb. 4

Abb. 1

Abb. 2 Abb. 3

Abb. 5

Rev. 01 - 11/2022

9

min.

5 cm

min.

50 cm

min.

5 cm

air gap

min

25 mm

1”

max 200 cm

min 4°

INSTALLATION

Fig. 6 Fig. 7

Fig. 8

Fig. 9

Fig. 10

Abb. 6 Abb. 7

Abb. 8

Abb. 9

Abb. 10

1 PH

monofase - single phase - monophasé -

einphasig - monofásico - одна фаза

scarico vano

compartment drain

compartiment évacuation

Schachtablass

descarga de compartimiento

слив отсека

ontlading ruimte van de motor

Rev. 02 - 11/2022 12

Characteristics of the installation area

Install the device in areas:

- compliant with industrial food handling;

- with adequate ventilation;

-prepared with electrical and plumbing systems compliant with

the legal provisions in force in the country of use and according

to the workplace safety requirements in the country of use;

- with temperatures from +15° to +43°C;

- that are sheltered against the elements;

- with flooring able to support the device at full load.

If the device is assembled on wheels (kit sold separately), it can-

not be levelled. Therefore the surface must be perfectly horizon-

tal, flat and completely smooth.

Protective lm removal

Fig. 5 If the machine is intact, remove the protective film slowly.

Any glue residue can be removed with a proper sol-

vent. Do not use tools or abrasive or strong detergents

that might ruin the surfaces.

The removed protective films are potentially danger-

ous for children and animals.

DO NOT LEAVE THEM UN

ATTENDED IN THE INSTALLATION AREA AND CORRECT

LY DISPOSE OF THEM IN ACCORDANCE WITH LOCAL

STANDARDS.

Positioning

The machines must be positioned on the ground only, on floors:

- that are not sensitive to heat or flammables;

- perfectly levelled;

- with a regular surface and completely smooth;

- that can support the device at full load.

Fig. 6 Keep the illustrated minimum clearances around the de-

vice: this will facilitate connections to utilities and maintenance.

Fig. 7

Always check for perfect levelling: if this is not the case,

rotate the feet until achieved.

DO NOT INSTALL THE DEVICE:

-NEAR OTHER MACHINES THAT REACH HIGH TEM

PERATURES E.G. OVENS OR FRYERS;

-NEAR WALLS OR FURNITURE THAT IS EITHER FLAM

MABLE OR SENSITIVE TO HEAT.

Only use the manufacturer’s wheel kit to make the de-

vice movable. For assembly, if necessary, read the in-

structions supplied with the kit.

Spacer installation

The devices require ventilation at the back, where the vents and

refrigerating unit are found.

Therefore, do not place them against the wall but keep them ap-

proximately 5 cm away.

Fig. 8 In order to prevent accidental movements from shifting

the device too close to the wall, install the provided spacers on

the back of the device (especially if the device is assembled on

wheels). Use supplied spacers and screws only.

Drawings on page 8

Product transport, handling

Warning markings are printed on the packaging. They indicate

the limitations that must be observed to ensure safe device load-

ing, unloading and transport.

Fig. 1 Device transport and handling must be done exclusively

as follows:

-keep the packaging in the vertical position, as per the indications

printed on it (this precaution is necessary to prevent the oil con-

tained in the compressor from circulating, which may damage

the valves and cause problems when starting the motor);

-use suitable handling means. Do not handle the goods by hand.

If hoisting systems are used, such as forklifts or pallet jacks, the

weight must be carefully balanced.

The packaging usually consists in polystyrene and stretch film on

a wooden pallet, which is secured to the bottom of the device for

safer transport and handling.

The manufacturer cannot be held liable for problems due to

transport in conditions other than those previously specified.

PAY PARTICULAR ATTENTION TO THE PACKAGING IN

CLINATION DURING TRANSPORT SINCE THE DEVICE

BARYCENTRE DOES NOT CORRESPOND TO ITS GE

OMETRICAL CENTRE.

Stacking limits

The devices, regardless of the model, CANNOT be stacked during

transport or during storage.

Device check

Fig. 2 We recommend, after removing the packaging, you

check device integrity and make sure it was not damaged during

transport. If damage or anomalies are found, do not install the

device and promptly inform the carrier. In any case, damaged

devices cannot be returned to the manufacturer without prior

notice and without prior written authorisation.

Fig. 3 AFTER UNPACKING, WHEN MOVING THE DE

VICE DO NOT PUSH IT OR PULL IT IN ORDER TO

AVOID THE RISK OF OVERTURNING OR DAMAGING

SOME PARTS FOR EXAMPLE THE FEET.

NEVER TILT THE DEVICE FROM THE DOOR SIDE.

Systems preparation

Fig. 4 Systems must comply with the legal provisions in force

in the country of use and meet the specifications on the serial

number plate.

There must be:

-A: a circuit breaker with high sensitivity (30 mA);

-B: a point of connection to the power mains;

-C: a point of discharge (optional).

Please see the specific chapters for their specifications

(for example, the chapter “Electrical connection”).

INSTALLATION

Rev. 01 - 11/2022

13

Electrical connections

THE CONNECTION TO THE ELECTRICAL MAINS AND

OTHER SUPPLIES MUST COMPLY WITH THE LEGAL

PROVISIONS IN FORCE IN THE COUNTRY OF INSTAL

LATION AND MUST BE PERFORMED BY QUALIFIED PERSONNEL

AUTHORISED BY THE MANUFACTURER.

In order to avoid any risks, damaged power supply ca-

bles must be replaced by the Manufacturer, by an ap-

proved technical support centre, or in any case by an

individual with similar qualifications.

Before connecting the device to the mains:

-read the safety instructions provided at the beginning of this

manual;

-make sure the mains voltage and frequency correspond to

those indicated in the device serial number plate. A rated volt-

age variation of +/-10% is accepted.

THE DEVICE MUST BE CONNECTED TO AN EFFICIENT

GROUND SOCKET .

THE DEVICE MUST BE INCLUDED IN AN EQUIPOTEN

TIAL SYSTEM COMPLIANT WITH THE LEGAL PROVI

SIONS IN FORCE YELLOW GREEN CONDUCTOR

WITH A MAXIMUM SECTION OF 10 MM2 IEC EN

60335242:200309 STANDARD. THIS CONNECTION MUST BE

MADE BETWEEN VARIOUS DEVICES WITH THE TERMINAL

MARKED WITH THE EQUIPOTENTIAL SYMBOL .

For mains connections, use a circuit breaker with manual reset

high sensitivity (30 mA), with adequate power that permits com-

plete cut-off in over voltage category III conditions, in order to

protect the device against over voltages or short circuits.

For the sizing of the protection device, please refer to the techni-

cal data table at the end of the manual.

Fig. 9 The single-phase appliances leave the factory with the

power cable and an Unel plug already installed on the terminal

block: it is not allowed to make any other type of electrical con-

nection and no dimensional modification of the cable other than

its lengthening, replacing it with one having the same character-

istics as the original one (rubber type, section, etc.).

Plumbing connections

THE DRAIN MUST COMPLY WITH THE LEGAL PROVI

SIONS IN FORCE IN THE COUNTRY OF INSTALLATION

AND MUST BE PERFORMED BY QUALIFIED PERSON

NEL AUTHORISED BY THE MANUFACTURER.

Outlet water

Cleansing water is collected in a tank which is under the machine.

Fig. 10 We recommend you connect the drain to a flexible hose

of maximum length 200 cm (not supplied) and lead it to a grate

in the floor or wall drain pipe, to avoid empting the tank too fre-

quently.

The drain pipe must have the following characteristics:

- is fitted with a trap;

- has a minimum inclination of 4%;

- has an air gap* of at least 25 mm;

- does not have clamps;

- has a diameter no less than that of the drain pipe coupling.

Rev. 02 - 11/2022 18

Instructions manual available in an alternative format

QR CODE

QR CODE SCAN

1

2PDF

USER MANUAL

WIRING

DIAGRAMS

Maximum storage values: 60°C

Maximum transport values: 60°C

Maximum values for the installation environment: 43°C

Do not stack or store lying down.

WOOD

POLYSTYRENE

PAPER

NSTALLATION

Congratulations on having purchased our equipment!

Work is simpler due to the intuitive user interface graphics designed to simplify access to functions, which

allow immediate identification and promote interaction between the user and the device.

A concentration of technology in a single machine that allows you to perform different and complemen-

tary activities for best efficiency in the kitchen: this way you’ll be immediately operative, without having to

run any complex procedures.

This manual furnishes all necessary information nec-essary for correct use of the device and appropriate

maintenance.

Read the instructions carefully before performing any operations, as they provide essential indications

con-cerning the safety of the device.

USER SECTION

(reserved to user)

SAFETY INSTRUCTIONS ............................................... 24

INFORMATION............................................................... 30

USE .............................................................................. 38

MAINTENANCE.............................................................. 46

ALARMS ......................................................................... 54

Rev. 02 - 11/2022 24

• Read this manual carefully before in-

stalling and servicing the device and

keep it for any further future consul-

tation by the various operators.

•Use and cleaning other than the types indicat-

ed and foreseen in this booklet are considered

improper and can cause damage, injuries or fatal

accidents, shall invalidate the warranty and re-

lease the manufacturer of any liability.

•Use is solely reserved to trained and authorised

personnel who attend periodic refresher courses.

•The appliance can be used by children under the

age of 8 and by people with reduced physical,

sensory or mental abilities, or without experience

or the necessary knowledge, as long as they are

supervised and after they have received instruc-

tions relating to the safe use of the appliance and

an understanding of the inherent dangers. Chil-

dren must not play with the appliance. Cleaning

and maintenance intended to be carried out by

the user must not be carried out by unsupervised

children.

•Keep away from electrical parts with wet hands

or bare feet.

•It is strictly prohibited to tamper with or remove

the adopted safety devices (protection grates,

hazard stickers, etc.). The manufacturer cannot be

held liable if these instructions are not heeded.

•Do not insert screwdrivers or other objects be-

tween guards (fan guards, evaporator guards,

etc.).

•For good compressor and evaporator unit opera-

tions, never obstruct the air vents.

•In the event of fire, do not use water. Install a CO2

(carbon dioxide) extinguisher and cool the mo-

tor compartment as quickly as possible.

Correct use of equipment

•This equipment is considered an agri-food ma-

chine (EC Regulation no. 1935/2004), intended

to process food products in industrial and pro-

fessional kitchens. It is not suited to store phar-

maceutical, chemical or any other non-food

products.

• Specifically:

-Blast chillers (+90/+3°C) (+90/-18°C): suited to

rapidly lower food temperature to keep senso-

ry properties unaltered.

•The following instructions must be followed for

best performance of the equipment:

-Do not place hot food (except for chiller func-

tions), uncovered liquids, live animals, various

objects or corrosive products in the equipment.

-Package or otherwise protect foods especially if

they contain aromas or spices.

-Arrange foodstuffs inside the equipment in such

a way as not to limit air circulation, avoiding

placing paper, cardboard, cutting boards, etc.,

that can hinder the flow of air on the racks.

-Avoid frequent and prolonged door opening as

much as possible.

-If the door was opened and closed again, wait a

few seconds before re-opening it.

-Gradually arrange the food starting from the

bottom up; vice versa, remove the food start-

ing from top to bottom. The maximum load

(evenly distributed) per tray or grill is equal to

20 kg (GN 1/1) or 35 kg (GN 2/1).

•Refrigerator equipment has been constructed

and designed using suitable techniques to guar-

antee user health and safety and does not have

any hazardous corners, sharp surfaces or protrud-

ing elements. Its stability is also guaranteed with

the doors open, however, hanging on doors is

prohibited.

•Failure to follow these instructions may cause

damage and injuries, even fatal, and shall inval-

idate the warranty.

In the event of equipment malfunctions...

•If the equipment does not work or functional

or structural alterations are noted, disconnect it

from the power and water mains and contact

a service centre authorised by the manufactur-

er without attempting to repair it on your own.

Original spare parts are recommended.The man-

ufacturer shall not be held liable for the use of

non original spare parts.

•To ensure that the device is in perfect use and

safety conditions, we recommend you have it

maintained and serviced by an authorised ser-

vice centre at least once a year.

SAFETY INSTRUCTIONS

Rev. 01 - 11/2022

25

Risks associated with equipment

use

•RISKS DUE TO MOVEMENTS ON WHEELS: if the

equipment is installed on wheels, take care dur-

ing movements not to suddenly push the equip-

ment, thus preventing it from overturning and

being damaged. Also look out for any roughness

on the sliding surface. Equipment with wheels

cannot be levelled, therefore make sure the

support surface is perfectly horizontal and flat.

Always lock the wheels with the specific stops.

•RISKS DUE TO MOBILE ELEMENTS: the only mo-

bile element is the fan, which however does not

constitute a risk since it is protected by a protec-

tion grate secured with screws.

•RISKS DUE TO LOW/HIGH TEMPERATURES: stick-

ers marked “TEMPERATURE HAZARD” have been

affixed near areas with low/high temperature

risks.

•RISKS DUE TO ELECTRICITY: risks of electrical na-

ture have been resolved by designing electrical

systems as per regulation CEI EN 60335-1. Spe-

cific stickers marked “high voltage” identify areas

with electrical hazards.

Rev. 02 - 11/2022 30

OK

Fig. 11 Fig. 12

Abb. 11 Abb. 12

Rev. 02 - 11/2022 32

-perform routine maintenance as indicated in the specific section;

+

For further information on how to remove the lter, see chap-

ter Vent cleaning on page 47.

How to use the needle probe

Fig. 12

The needle probe, during chilling, reads the tempera-

ture at the food “core”: when it reaches the value set by the user or

default value, it means the food is chilled (

Chilling

function).

The

needle probe is fully inserted in the food to be chilled: make sure

its tip reaches the food “core”, meaning the most internal point,

without exiting.

Be careful not to insert it in very fatty points and near bones.

In case of very thin food products, insert the probe parallel to the

support surface.

Always keep the probe clean and sanitised.

HANDLE THE PROBE WITH CARE INSOFAR AS IT IS

VERY SHARP.

+

The probe can be heated to facilitate removal from frozen

foods, see page 39.

Drawings on page 30

What does a blast chiller do?

A blast chiller is a device that quickly lowers the temperature of

the introduced food, whether fresh or cooked.

Fresh or just cooked food has the best sensory qualities and fla-

vour; however, if not eaten immediately, it loses its initial qualita-

tive properties and is subject to the proliferation of micro-organ-

isms, which are potentially harmfuly to humans.

Positive Chilling is used when food is not eaten within two

hours of its preparation, reducing the product temperature to

+3°C at the core within 90 minutes. Subsequently, the prod-

uct must be stored in a refrigerator at a temperature between

0/+3°C where it can be kept for up to 5 days.

Negative Chilling is used to keep all the sensory properties of

the food intact. The chiller reduces the product temperature un-

til reaching -18° C at its core. Subsequently, the product must be

stored in a freezer at a constant temperature of -20 degrees and

can even be eaten after 3/18 months, according to the product,

provided the cold chain regulations are met.

Storage is the next step in the blast chilling cycle, in which the

food product is maintained at a certain temperature in order to

preserve its cooling or freezing.

It is divided into:

Positive storage, in the case of cooling;

Negative storage, in the case of freezing.

Normal refrigerators and freezers, unlike a blast chiller, are unable

to rapidly lower the initial temperature of the product, which is

therefore damaged in terms of its sensory properties and flavour.

Correctly loading the equipment

Food should be placed in a single layer in containers:

- that are uncovered;

- that are food-safe;

- that are resistant to the temperatures reached by chilling;

- that have low edges (maximum 4.5 cm).

Containers should be evenly placed inside the cell.

Correct container placement will allow free air circulation in the

cell: avoid obstructing the air vents and overloading the equip-

ment beyond the admissible limits.

Achieving better results and working in

safe conditions

-Fig. 11 Keep the motor compartment air vents free of objects

and remove dust;

-periodically clean and replace the filter behind the motor com-

partment air vents:

+

For further information on how to remove the lter, see chap-

ter Vent cleaning on page 47.

-arrange food to be chilled or cooked as explained in the previ-

ous chapter;

- accurately close the doors during each work cycle;

- always keep the defrost water drain hole free;

- avoid opening doors during positive/negative chilling;

INFORMATION

Rev. 02 - 11/2022 36

+3°C

-18°C

start

stop

-

+

set

L1

L2 L3

L1

L2

L3

SET

DOWN

x4 sec.

UP

x4

SEL

x4 sec.

DOWN+UP

+x4 sec.

LED with decimal point

function to display the

time.

LED with function of

indicating the negative

blast chilling cycle

selected

steady on: LED which has

the function of indicating

the blast chilling cycle in

progress;

flashing: LED which has

the function of indicating

the storage phase in

progress

DESCRIPTION

Blast chiller start/stop operation

and confirmation

Slow decrease of the value and

buzzer switch off

During a program it displays the

cell probe temperature

Fast decrease of the value and

defrost activation

Slow increase of the value and cell

temperature display

Fast increase of the value and load

activation on the auxiliary output

(UV lamp for sterilization, needle

probe heater or auxiliary condens-

er fan)

Positive/negative alternate

program selection

Display of the elapsed time from

the start of the blast chilling cycle

or the duration of the blast chilling

cycle until the key is released

Stand-by enable

To access the configuration param-

eters press the DOWN and UP keys

simultaneously for 4 seconds

(only with blast chiller in stop phase

or if there are no programs in pro-

gress).

Short press

Short press

Short press

Short press

Continuous press

Long press

Long press

Long press

Long press

USE

Rev. 02 - 11/2022 40

Switch on

When the display switches on it performs a lamp-test (flashing of

all segments and dots for 5 seconds).

When switched on for the first time, the display is in stand-by mode

(three horizontal dashes“---”are shown on the display, one for each

digit). The next time it is switched on, or when the power supply

is restored, the blast chiller status varies depending on its status

befo

re the power supply failure.

If there is no program running, activate standby mode by press-

ing and holding SEL for 4 seconds.

Important information

The display shows programs for managing the following blast

chiller functions:

positive blast chilling or cooling (automatic or manual),

negative blast chilling or freezing (automatic or manual)

+

For automatic programs, the reference value is the tem-

perature detected by the needle probe.

For manual programs, the reference value is the time.

Both the automatic program and the manual program include

a blast chilling cycle, automatically followed by a storage phase,

which is positive or negative depending on the cycle chosen.

At the end of the blast chilling cycle, when the storage phase

starts automatically, a buzzer sounds intermittently (this can be

modified by the user under parameter P 0).

To silence the buzzer in advance, press the DOWN key.

During the execution of a program:

-the LED L2 is off if a positive blast chilling cycle was selected,

or is on if a negative blast chilling cycle was selected;

-the L3 LED is on during the blast chilling cycle and flashing

during the storage phase;

-pressing the UP key determines the display of the temperature

measured by the cell probe for a duration of 5 seconds;

-pressing and holding the SET key determines, until the key is

released, the display of the time elapsed since the start of the

blast chilling cycle if the blast chilling cycle is still in progress,

the duration of the previous blast chilling cycle if the storage

phase is in progress.

At the end of a program, before starting the next program, the

display shows the data relative to the last program run.

Automatic program

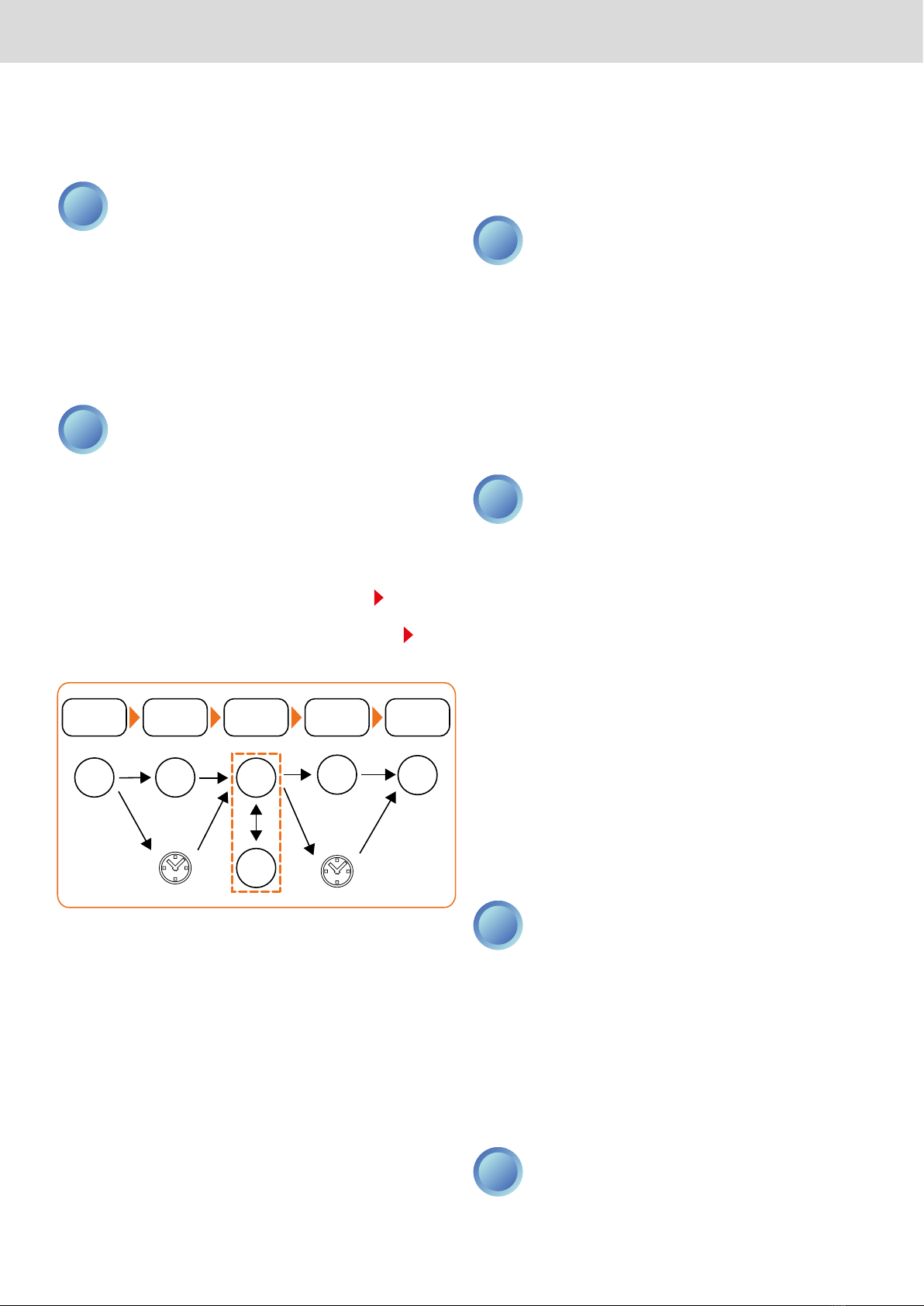

To select and start an automatic program (Fig. 8 on page 18), pro-

ceed as described below:

-Press the SEL key until the display shows the positive blast

chilling cycle (default +3°C - P13 parameter) or negative

blast chilling cycle (default -18 °C - P14 parameter).

-

+

The repeated pressing of the SEL key causes the display

to alternately flash between the value set for the posi-

tive blast chilling cycle and the value set for the nega-

tive blast chilling cycle.

-Wait 5 seconds or press the SET key to confirm (the tempera-

ture display becomes fixed).

-Press the SET key to start the program: during the execution

of an automatic program the display shows the temperature

measured by the needle probe.

+

The temperature parameters can be modified by the

User.

SEL SET

attendere

5 sec

SET

SELEZIONE

PROGRAMMA

CONFERMA

PROGRAMMA

AVVIO

PROGRAMMA

SEL SET

wait

5 sec

SET

PROGRAM

SELECTION

PROGRAM

CONFIRMING

PROGRAM

STARTING

At the end of the blast chilling cycle the display shows the tem-

perature measured by the needle probe, flashing if the target set

has not been reached (P13 -P14 parameters).

The duration of the blast chilling cycle is determined by one of

the following conditions:

-reaching the selected temperature setpoint (P13 -P14 parame-

ters);

-exceeding the set time, even if the temperature has not been

reached (parameters P19-P20).

At the end of the blast chilling cycle, the storage phase starts

(signalled by a beep). The temperature measured by the cell

probe is shown on the display.

Storage phase characteristics:

-after a positive blast chilling cycle (parameter P19) room tem-

perature setting equal to the value set for parameter P17;

- after a negative blast chilling cycle (parameter P20) room

temperature setting equal to the value set for parameter P18.

Manual program (by time)

To select and start a manual program (Fig. 9 on page 20) proceed

as described below:

-

press the SEL key until the display shows the positive blast

chilling cycle (display of P13 parameter, default +3 °C) or nega-

tive blast chilling cycle (display of P14 parameter, default -18 °C).

+

The repeated pressing of the SEL key causes the display

to alternately flash between the value set for the posi-

tive blast chilling cycle and the value set for the nega-

tive blast chilling cycle.

-Wait 5 seconds or press the SET key to confirm (the tempera-

ture display becomes fixed).

USE

Rev. 01 - 11/2022

41

-Press the UP or DOWN key to select the duration of the blast

chilling cycle (the starting value displayed is the one set by de-

fault, parameter P19 or P20 respectively for positive blast chill-

ing cycle or negative blast chilling cycle).

+

The cycle time modification is not permanent (it does

not change the default values for parameters P19 and

P20). When the cycle is next set, the default values set

under parameters P19 and P20 will be shown again.

-Wait 5 seconds or press the SET key to confirm (the cycle time

display becomes fixed).

- Press the SET key to start the program. During the blast chill-

ing cycle the display shows the total cycle time (parameter P19

or P20 respectively for positive blast chilling cycle or negative

blast chilling cycle).

+

The time is displayed in the form of a decimal number,

where the integer part represents the hours and the dec-

imal part represents the minutes (for example,“1.30”indi-

cates the time 90 minutes, i.e. 1 hour and 30 minutes).

At the end of the blast chilling cycle, the storage phase starts

(signalled by a beep). The temperature measured by the cell

probe is shown on the display.

Storage phase characteristics:

- after a positive blast chilling cycle (parameter P19) room tem-

perature setting equal to the value set for parameter P17;

- after a negative blast chilling cycle (parameter P20) room

temperature setting equal to the value set for parameter P18.8.

PROGRAM

SELECTION

PROGRAM

CONFIRMING

PROGRAM

STARTING

SEL SET SET

SELEZIONE

PROGRAMMA

CONFERMA

PROGRAMMA

SELEZIONE

TEMPO CICLO

ABBATTIMENTO

CONFERMA

TEMPO CICLO

ABBATTIMENTO

AVVIO

PROGRAMMA

UP

DOWN

SET

attendere attendere

5 sec 5 sec

SEL SET SET

BLAST CHILLING

CYCLE TIME

SELECTION

BLAST CHILLING

CYCLE TIME

CONFIRMING

UP

DOWN

SET

wait

5 sec

wait

5 sec

Selecting and starting special functions

The appliance is provided with special functions to manage the

following blast chilling functions:

-manual defrost,

-cell sterilization (optional, if provided by the blast chiller),

-needle probe heating (optional, if provided by the blast chiller).

The storage phase starts automatically at the end of the special

function and the buzzer will sound intermittently for the set time

(this can be modified by the user under parameter P 0).

To silence the buzzer in advance, press the DOWN key.

Manual defrost

Defrosting is normally performed by the User with the blast chill-

er door open (cell heating). Door opening or closure has no ef-

fect on the defrost process.

To start defrosting press and hold the DOWN key for 4 seconds.

+

The defrost configuration and duration are determined

by the parameters P 5, P 7, P11, which can be modified

by the User. During the defrost, the display shows the

“dEF”string.

Cell sterilization

Sterilization can be enabled if the value of parameter P23 is equal

to 1. To activate a sterilization cycle there must be no program or

other special function in progress and the blast chiller door must

be closed.

To start the sterilization cycle hold down the UP key for 4 sec-

onds.

+

The sterilization cycle start and duration are determined

by the parameters P 8, P24, P25, which can be modified

by the User. During the sterilization cycle the display

shows the“StE”string.

In the case of a cell probe error“Er2”:

-before the sterilization cycle start, the sterilization cycle does

not start;

-during the sterilization cycle, the sterilization cycle continues

normally.

If at start-up or during the sterilization cycle the cell temperature

is lower than the reference value (parameter P25), the display will

show the“cLd”string.

a.

Needle probe heating

Needle probe heating can be activated if the value of parameter

P23 is equal to 2. Door opening or closure has no effect on needle

probe heating. To activate needle probe heating there must be no

program or other special function in progress.

To start needle probe heating hold down the

UP

key for 4 seconds.

+

The needle probe heating configuration is determined

by the parameters P28 and P29, which can be modified

by the User. During needle probe heating, the display

shows the“Prb”string.

Stopping and restarting a program or a

special function

During the execution of a program or a special function, press

the SET key to stop it.

If a program has been completed, press the SET key again to

restart from the point in which it was interrupted.

+

If the restarted program is of the manual type, the cycle

starts from the beginning for the set cycle time.

If a special function was not completed, it is not possible to re-

start from the point where it was interrupted.

Rev. 02 - 11/2022 46

H

2

O

14

3

2

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Abb. 13

Abb. 14

Abb. 15

Abb. 16

Rev. 02 - 11/2022 48

Disuse

In the event of disuse, cut off the electrical and water supply.

Protect external parts in steel by wiping them down with a soft

cloth slightly dampened with Vaseline oil. Leave the door ajar to

guarantee correct ventilation.

Before resuming operations:

- accurately clean the equipment and accessories;

- reconnect the equipment to the power and water mains;

- inspect the equipment before using it;

-restart the equipment at a low temperature for at least 60 min-

utes without any food inside.

To ensure that the device is in perfect use and

safety conditions, we recommend you have it

maintained and serviced by an authorised ser-

vice centre at least once a year.

Disposal at end of service life

As per Legislative Decree no. 49 art. 13 dated 2014 “Implemen-

tation of WEEE Directive 2012/19/EU on electric and electronic

waste”

The barred bin marking specifies that the product was

released onto the market after August 13, 2015 and

should not be assimilated with other waste at the end of

its service life but disposed of separately.

All equipment is made of recyclable metallic materials (stainless

steel, iron, aluminium, galvanised sheet metal, copper, etc.) in

percentages over 90% in weight.

Put the equipment out of order for disposal removing the power

cord and any compartment or chamber lock devices (where ap-

plicable). Pay attention to managing this product at the end of its

service life, reducing negative impacts on the environment and

improving resource use efficiency, applying the “who pollutes

pays”, prevention, reuse, recycling and recovery preparation prin-

ciples. Please remember that illicit or incorrect product disposal

is punishable by law.

Information on disposal in Italy

WEEE equipment in Italy must be delivered to:

- collection centres (also called ecological islands or platforms)

- the dealer where new equipment is purchased, who must col-

lect it free of charge (“one to one”collection);

Information on disposal in European Union countries

The Community Directive on WEEE equipment has been assimi-

lated in different ways in each country. Therefore we suggest you

contact your local authorities or Dealer to request the correct

disposal method.

While awaiting dismantling and disposal, the equip-

ment can be temporarily stored even outdoors, provid-

ed the electrical, refrigeration and plumbing circuits are

intact and closed. Also make sure the doors cannot be

closed to avoid entrapment. Follow the environmental protec-

tion laws in the user’s country.

Drawings on page 46

BEFORE PERFORMING ANY MAINTENANCE, CUT OFF

THE POWER SUPPLY TO THE MACHINE AND WEAR

SUITABLE PERSONAL PROTECTIVE EQUIPMENT E.G.

GLOVES, ETC..

THE USER MUST ONLY PERFORM ROUTINE MAINTE

NANCE OPERATIONS MEANING CLEANING. FOR

EXTRAORDINARY MAINTENANCE, CONTACT A SER

VICE CENTRE REQUESTING SERVICE FROM AN AUTHORISED

TECHNICIAN.

THE WARRANTY IS NULL AND VOID IN THE EVENT OF

DAMAGES DUE TO NEGLIGENT OR INCORRECT MAIN

TENANCE E.G. USE OF UNSUITABLE DETERGENTS.

Fig. 13

To clean any components or accessories, DO NOT use:

- abrasive or powder detergents;

-aggressive or corrosive detergents (e.g. hydrochloric or sulphu-

ric acid, caustic soda, etc,). Warning! Do not use these substanc-

es even to clean the floor under the equipment;

-abrasive or sharp tools (e.g. abrasive sponges, scrapers, steel

brushes, etc.);

- steamed or pressurised water jets.

At first use,

wash the trays and chamber using a cloth dampened

with hot soapy water and end with rinsing and drying. To elim-

inate work residue,

run the equipment empty for about 30 min-

utes.

External steel surface cleaning

Fig. 14

U

se a cloth dampened with hot soapy water or specific

products for steel. End with rinsing and drying.

Equipment chamber cleaning

Clean the equipment chamber daily to maintain high levels of

hygiene and equipment performance.

Always use a cloth dampened with hot soapy water and end

with rinsing and drying.

Touch screen

U

se a cloth slightly dampened with a product specific for glass

following the instructions of the manufacturer of the detergent.

Do not spray too much product to avoid infiltrations that could

damage the display.

Vent cleaning

Fig. 15

Keep vents free of obstructions and dust, cleaning them

often with a normal vacuum or brush.

Fig. 16

We recommend you remove the front panel once a week

following the illustrated instructions and clean the filter with hot

soapy water. If replacement is required, contact the manufacturer

to order spare parts.

MAINTENANCE

This manual suits for next models

10

Table of contents

Other Metos Freezer manuals