Metreco HVAC MK1 User manual

English v1-3

metreco

MANUAL

Metreco HVAC MK1

2

Declaration of Conformity

This is to certify that this equipment, designed and manufactured by Panimpex NV, Veurne-

straat 162, B-8660 De Panne, Belgium, meets the essential safety requirements of the Euro-

pean Union and is placed on the market accordingly. It has been constructed in accordance

with good engineering practice in safety matters in force in the Community and does not

endanger the safety of persons, domestic animals or property when properly installed and

maintained and used in applications for which it was made.

• Equipment Description :

• Applicable Directives :

• CE Implementation Date :

• Authorized Representative:

Metreco, electronic wireless measurement device

2014/30/EU; 2014/35/EU; 2014/68/EU; 2014/53/EU

14 September 2010

Bernard Peirs, CEO

Any questions relative to this declaration or to the safety of Metreco products should be di-

rected, in writing, to the support & quality assurance department at the above address.

Thank you for buying a Metreco!

Warnings & Dangers

-> Dangers and warnings indicated in this manual are marked with the following symbol:

IP64 : dust tight & splashingwater tight = don’t submerse or hold under tap upside down, •

can be used in the rain.

Do not open in order to prevent electrocution.•

Repair & maintenance should be done by qualied personel.•

Warranty is void if you have attempted to open the product or dismantle it.•

Don’t wet or short-circuit the battery charging contacts.•

For charging the batteries, only use the dedicated spaces in the charging station.•

Use only included AC adaptor for connecting the charging station to the mains.•

Use only included cigarette lighter plug for connecting the charging station to your 12V•

source (car etc.).

Use only a USB 2.0 compliant cable (included) with the correct plugs to connect the hand-•

held to the PC.

If irradiance occurs of an electromagnetic eld of 30 V/m at the frequencies of 325-340 •

MHz and 865-880 MHz, the wireless communication can get disturbed.

Working temperature: -30..+70 °C (for optimal battery capacity: -20..+60°C).•

Load batteries 12h before rst use.•

When stocking for longer period: keep the batteries at 50% charged.•

Contact:

www.metreco.com T +32 58 42 91 00

[email protected] F +32 58 42 14 46

3

Table of contents:

Declaration of Conformity

Warnings & Dangers

Table of contents

Metreco Concept

Working with Metreco

1. Basics

2. Conguration

3. Measuring

4. ACR

4.1. System management

• Create new ACR system

• Choose existing ACR system

• Edit current ACR system

• Remove existing ACR system

4.2. Performing measurement and Diagnosis

• Measurements

• Diagnosis

4.3. Logging & Reports

• Logging

• Measurement Report

• Intervention Report

4.4.Tests

• Pressure Decay Test

• Vacuum Decay Test

• COP Test

4.5. Customer & Systems follow-up

• Follow-up on Metreco

• Follow-up on PC

4.6. A word on ‘Sensor Placement’

4.7. How to use the hoses & connectors?

• Fill refrigerant

• Remove refrigerant

• Vacumize

5. Service & Support, Calibration and Updates

5.1. Service & Support

5.2. Calibration

5.3. Firmware updates

5.4. Extra Languages and Refrigerants

Technical data

• Metreco

• Sensors

Spare Parts

4

Metreco Concept

Thank you for choosing the Metreco Concept. This new way of working brings you

on the edge of the most recent technological possibilities in wireless developments

and gives you a huge competitive advantage.

SMART MOBILE MEASURING

Dynamic measuring with METRECO, Smart Mobile Measuring, instead of static •

measuring with traditional manifold with hoses and temperature probes.

Up to 10 sensors transmit their measurements simultaneously to the Handheld: •

no hoses - no lines.

The user positions himself where he wants/walks around and can read out the•

measurements in real time.

Intuitive/natural easy-to-use interface is operated with a capacitive touch-•

screen.

Dene your measurement/value targets - get a warning when they are o.•

Measurement - Diagnosis - Suggestions / Solutions.•

Database of serviced ACR systems available on Handheld & PC.•

Measurement reports on Handheld & PC.•

Intervention reports on Handheld & PC.•

Charge your handheld and sensor batteries in the specially designed case -•

docking station.

Extra hoses and connectors for handling refrigerant.•

5

• Scenario:

Engineer Jason services a system of a new client who claims that it ‘doesn’t cool’ any longer.

He places the sensors on the system: low pressure, high pressure and the two temperature

sensors. Jason has instantly, while walking around, access to the measurements in the ‘All

Sensors’ menu.

He creates a new client and system through the touchscreen of the Metreco. He chooses a

refrigerant and the targets for subcool, superheating and evaporator exit air temperature. He

is now looking at the ‘All Measurements’ level and has an instant idea of the measured and

calculated values. If one of the targets is o, he gets a warning with a diagnosis and a possible

cause.

The measured values can be logged, this creates automatically a Measurement report. Jason

also makes an Intervention report where he can keep track of the interventions he has done:

leak detection, lter-dryer, refrigerant adjustment, oil test, pressure test, vacuum test, etc.

Back at the oce Jason connects his Metreco handheld to his PC and makes a report for

internal use and a customer report which is sent by e-mail.

C

omp

re

s

s

o

r

F

ilter-

d

ryer

E

xpan

s

ionvalve

R

ec

ei

v

er

EVAPORATOR

CONDENSOR

HANDHELD

6

Working with Metreco

1. Basics

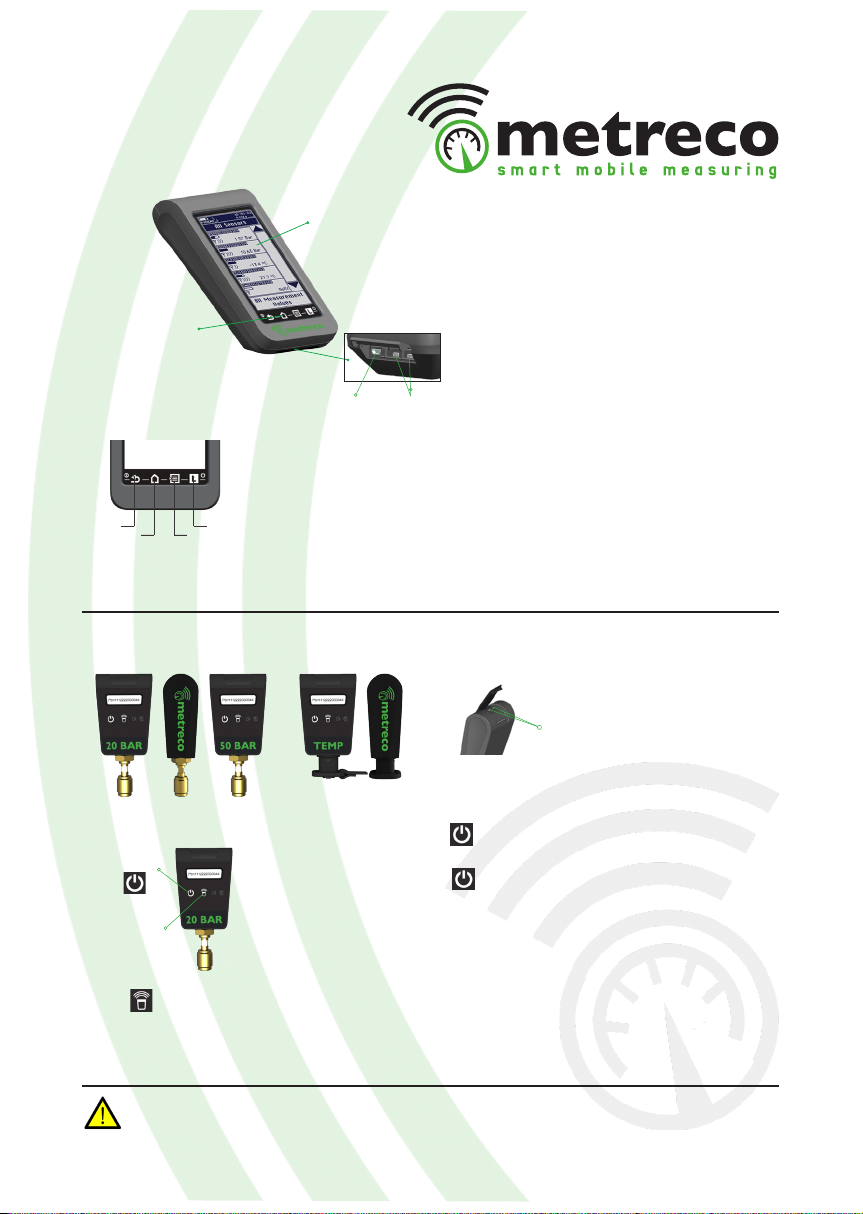

Metreco is supplied with:

- 1 Charging station - case

- 1 Low Pressure Sensor 20 Bar

- 1 High Pressure Sensor 50 Bar

- 2 Temperature sensors -50+150°C

- Metreco Handheld

- Adaptor 230V

- 12V cigarette lighter plug

- USB cable

- Space for 3 extra sensors

- Manual

- Set of hoses & connectors

- 4 Hoses (1/4”SAE-1:4”SAE: Red, Blue, 2*Yellow)

- 2 R410A adaptors (1/4”SAE Male - 5/16”SAE Female)

- 1 X-connector (4* 1/4”SAE Male)

- 2 T-connectors (1/4”SAE Female – 2* 1/4”SAE Male)

Space for 3

extra sensors

Sensors

Charging LED

Handheld

Lid with

protective foam

Storage

Socket for charging-

cable 12V & 220V

Hoses & Connectors

Batteries

Batteries have to be charged during

12hours before rst use!

- The case acts as the docking station for charg-

ing the batteries.

- Charging batteries: put the parts you want to

charge back in the case. Connect the charging-

cable to the 12V power supply in your car or the

230V(110V) AC.

Socket for chargingcable

12V & 220V

7

When your sensor has endured an overpressure of more than 2 times the max. pressure, you have

to recalibrate your sensor. (see 5. Service & Support, Calibration and Updates)

Handheld

Sensors

ON

OFF

1 Back

2 All Sensors

3 Main Menu

4 Logging

: Swipe to the right (->) 1-2-3-4 (min 1 s)

: Swipe to the left (<-) over 4-3-2-1

: back to preceding menu item

: to ‘All Sensors’

: to ‘Main Menu’

: start/stop logging

1 4

32

Touchscreen

Shortcuts

Power socketsUSB socket

Power sockets

ON

OFF

Calibration

Locate

Red LED

Green LED

: Push the button while the red LED ashes (2 s).

Flashing slows down once activated.

: Push the button for at least 2 s while the red LED

ashes quickly. Flashing stops when the sensor is O.

: Calibration (see 5.2 Calibration)

: Locate the sensor when assigning placement to sys-

tem (see ‘Step 10’ in 4.1 ACR System Management)

: ON/OFF & Data sending

: Calibration (see 5.2 Calibration)

ON / OFF

Calibration

&

Locate

8

2. Conguration

This is the list of parameters you can adapt:

- Units

- Language

- Log interval

- Date & Time

- Screen intensity

- Target Margins

- Update rmware (see 5.3.)

Units Language

Log interval

(go to ‘4.3. Logging’)

Date andTime

3. Change the congurations as desired.

2. Select ‘Congurations’.

Target margins

Screen intensity

1. Go to ’Main Menu’.

Modifying the target margins makes the Metreco more or less tolerant to target value variations

= quicker or slower reaction of the warning pop-up.

Main Menu

9

3. Measuring

In this part you learn how to quickly measure a pressure, temperature or vacuum:

1. Turn the device ON, slide to the right on the shortcut buttons (during min 1 s).

3. Place the sensors (temperature, pressure, vacuum) on the system and turn them on by

pressing at least for 2 seconds on the button.

4. Observe the measured values.

2. You will see the ‘All Sensors’ screen.

In chapter ‘4. ACR’ the following applications are treated:

- Creating a new ACR system

- Choosing an existing ACR system

- Diagnosis

- Logging

- Measurement report

- Intervention report

- Pressure Decay Test

- Vacuum Decay Test

- Follow-up on Metreco & PC

- Using the hoses & connectors

- Sensor calibration & rmware updates

10

4. ACR

In order to correctly apply the treated subjects of this chapter, we strongly advise you to

congure your handheld rst (go to ‘2. Congurations’).

4.1. ACR System management

You can dene and save ACR Systems on your Metreco.

1. Go to ‘Main Menu’.

2. Choose ‘ACR System’.

This menu gives you the possibility to:

- create a new ACR system

- choose an existing ACR system

- edit current ACR system

- remove an existing ACR system

1. Choose ‘New ACR System’ and select

‘Client’. Create a new one if needed or select

an existing one.

2. Choose ‘Name’ and complete the name

you want to give to the system

(a client can have many systems).

3. Select the refrigerant of the system.

-> This is an intelligent list. It will change the

order of your refrigerants according to the

frequency of selection of the refrigerants.

Most selected refrigerants will go on top.

•Create new ACR system

Main Menu

11

4. Determine the Superheat, Subcool and

evaporator exit air temperature target.

7. Assign the sensors, choose ‘Place sensors’

(If you haven’t physically put the sensors on the

system, put the sensors on the system).

9. Select a spot on the system. You will get

a list of available sensors eligible for this

position and whose signal is received.

10. You can also press the locate button

on the sensor. The sensor code will start

blinking on the handheld.

11. When all sensors are assigned (*), select

‘OK’ in the right bottom corner. This will give

you the ‘ACR Sytem’ again.

8. You have the possibility to assign pressure,

temperature, vacuum sensors and amperage

sensors. Or you can choose to give them a

name in generic sensors:

12. Select ‘Save System’ when all data is

correct. The system is saved. You get the

‘All Values’ menu with all the measured and

calculated values (You will get a warning if

you didn’t select or create a system.).

(*) (Sensors can only be assigned on a dened

ACR system.)

Warning ‘All Values’

12

If you have created and saved ACR systems, you can choose a system in your list of clients and

their systems. By choosing this, the placement of the sensors of your current system will be

lost.

All the necessary data is available, you don’t have to re-enter the data at each service:

4. Select the customer whose system you are

servicing.

5. Select the ACR system.

10. Observe the measured values in

‘All Values’.

• Choose existing ACR system

3. Select ‘Choose Existing ACR System’.

6. Change the data if necessary.

7. Check the targets.

8. ’Place sensors’ & ‘OK’.

9. ‘Save system’.

11. Consult Diagnosis. (see 4.2.)

12. Use the measured values in a

Measurement Report. (see 4.3.)

1. Go to ‘Main Menu’.

2. Select ‘ACR System’.

Main Menu

13

If you have created and saved ACR systems,

you can modify the data. The main idea is to

change the placement of the sensors while

servicing.

1. Repeat ‘Choose existing ACR system’ till

step 3 if you have chosen the system or till

step 5 if you still need to choose the system.

4. Change the placement of the sensors. By

selecting a placed sensor you can undo it’s

placement and assign it on a dierent spot.

(system can be saved without sensors being

placed).

5. Conrm with ‘OK’.

6. ‘Save System’.

• Edit current ACR system

Saved systems can be removed (deleted):

1. Select ‘Remove Existing ACR System’.

2. Select a client.

3. Select the system you want to remove.

4. Conrm removal of system.

• Remove existing ACR system

2. Change refrigerant if needed.

3. Change targets.

7. Continue your working procedure in ‘All

System Values’ and obeserve the measured

values while walking around.

Entire clients can only be removed on PC.

14

4.2. Performing measurement and diagnosis

• Measurements

Measurements, measured and calculated (in ‘All System Values’), can be performed from

the moment sensors are placed physically onto the ACR system. The sensors also need to be

‘placed’ on an existing system in Metreco. (‘ACR System’ - ‘Place Sensors’).

By combining dierent sensors, e.g. pressure and temperature, extra values can be

calculated.

This is the list of the dierent values that can be measured or calculated:

: Low pressure

: Saturated Evaporation temperature (refrigerant)

: Superheat

: High pressure

: Saturated Condensation temperature (refrigerant)

: Subcool

: Oil pressure

: Temperature low pressure side

: Temperature high pressure side

: Air temperature at condensor inlet

: Air temperature at condensor outlet

: Temperature Delta of air over condensor

: Air temperature at evaporator inlet

: Air temperature at evaporator outlet

: Temperature Delta of air over evaporator

: Pressure at condensor outlet

: Pressure Delta over condensor

: Pressure at lter outlet

: Pressure Delta over lter

: Pressure at evaporator inlet

: Pressure Delta over evaporator

: Vacuum pressure

(measured)

(calculated)

(calculated)

(measured)

(calculated)

(calculated)

(measured)

(measured)

(measured)

(measured)

(measured)

(calculated)

(measured)

(measured)

(calculated)

(measured)

(calculated)

(measured)

(calculated)

(measured)

(calculated)

(measured)

When saving a system, the placement of the sensors is not saved, this is a dynamic process.

(see ‘4.6. A word on Sensor Placement’)

- Values that don’t have a sensor assigned show ‘no sensor’.

- Calculated values which can’t be calculated due to missing sensor show what value they are

missing

- Values that are available are shown at the top of the list.

- LP

- Tevap

- SH

- HP

- Tcond

- SC

- POIL

- LT

- HT

- TACONDIN

- TACONDOUT

- DTAcond

- TAEVAPIN

- TAEVAPOUT

- DTAevap

- PCONDOUT

- DPcond

- PFILTOUT

- DPlt

- PEVAPIN

- DPevap

- PVAC

15

• Diagnosis

In this chapter you will learn how to use the diagnosis tool. Metreco can suggest possible

causes (*) for o-target measurements.

First of all you will need to dene targets for the following measurements:

Superheat Subcool Evaporator exit

air temperature

Check the dynamic history of every measured and calculated value and its divergence to the

dened target on your Metreco Handheld. Per sensor, the last 10 measured values are shown.

(*) This is a non-limited list that serves only as an indication. The engineer has to make his own diagnosis and has

to be in possession of the certicates mandatory by law and the knowledge to service ACR systems.

1. Select a value in ‘All Values’. 2. You will get a history of this value. If the

value has a dened target you can consult a

diagnosis (*) with possible causes.

3. By selecting ‘Plot history’ the data will be

plotted on the screen.

History Diagnosis (*)History

with target

1. Choose an ACR system (see 4.1.).

2. Dene the 3 targets and select ‘Done’.

3. From now on you will get a warning if a

value is o-target.

4. Select ‘OK’ to continue or ‘Value’ to check

the o-target value.

16

4.3. Logging & Reports

- Logging data creates a logle (.csv) and a Measurement Report

- Pressure Decay Test creates a logle (.csv) and a Pressure Decay Test Report (long & short)

- Vacuum Decay Test creates a logle (.csv) and a Vaccum Decay Test Report (long & short)

• Logging

When you apply ‘logging’, the measured values will be memorised with a standard interval of

5 seconds. This data can be used in Measurement Reports. You’re getting a list of saved data

(time & value) that you can retrieve from the Metreco on your PC via USB. This can then be

used for technical or commercial purposes (see ‘4.5. Customer & Systems follow-up’).

The standard interval between 2 loggings is 5 seconds. You can modify this interval in

the conguration menu (see ‘3. Conguration’).

1. Select ‘Logging’ to start the logging process. The logging icon ‘L’ will start blinking.

2. Select ‘Logging’ again to end the process. The logging icon ‘L’ will stop blinking.

When you end the logging process, a new Measurement report with the last logged measured

values is automatically created (see next point -> Measurement Report), all the logged values

are saved in a ‘LOG’ le (.csv).

There are over 1.000.000.000 data points...

Logging

17

• Measurement Report

- A Measurement Report is a survey of the performed measurements that you can use for tech-

nical and commercial purposes.

- A Measurement Report gives you the last logged measured values before ending the logging.

The report is saved automatically when ending the logging and can be recalled on Metreco and

downloaded on PC for later use in internal reports or reports to your customer.

5. The Measurement Report contains a

summary of:

- customer data

- system data

- placed sensors

- measurements

on Metreco

on PC (see ‘4.5. Customer & Systems follow-up’)

1. Follow the ‘Logging’ procedure as

explained in the preceding paragraph.

2. Select ‘Reports’ in the ‘Main Menu’.

3. Select Measurement Reports.

4. Select the customer, system and report.

Main Menu

18

• Intervention Report

In the Intervention Report you can save data on the servicing you have done and recall the data

on Metreco or use it on your PC:

- Leak detection (leak detector & result)

- Vacuum decay test (possibility to store the vacuum sensor value)

- Pressure test with N2 or N2H2 (possibility to store the pressure sensor value)

- Refrigerant changes: recovered & charged

- Filter-dryer replaced?

- Oil test

- Refrigerant acid test & refrigerant moisture test

- Time spent on the job

- Notes

1. Select a system (see 4.1.). Intervention Reports can only be made when an ‘ACR system’ is

selected.

3. Select ‘New Intervention Report’.

4. Select ‘Leakdetector’.

2. Select ‘Main Menu’ and select ‘Reports’. 5. Select ‘Leak detector type’ and the result.

6. Select ‘Vacuum Decay Test’ .

7. Choose manual input or an existing report

(see ‘4.4. Tests’). When choosing manual in-

put, enter the measured value OR take a live

read-out from your vacuum sensor, if placed

on the installation and assigned in Metreco

(vacuum sensor not incl.).

8. Enter evacuation time.

Main Menu

19

12. Select ‘Refrigerant Recovered’ and enter

the quantity.

13. Select ‘Refrigerant Charged’ and enter the

quantity.

14. Scroll downwards.

15. Select ‘Oil test’ and enter the result.

9. Select ‘Pressure Decay Test’.

10. Choose manual input or an existing report

(see ‘4.4. Tests’). When choosing manual in-

put, enter the measured value OR take a live

read-out from your vacuum sensor, if placed

on the installation and assigned in Metreco.

11. Select the used gas (N2 or N2+H2)

17. Select ‘Moisture test’ and enter the result.

19. Select ‘Notes’ and add remarks.

16. Select ‘Acid test’ and enter the result.

20. Example of an Intervention Report on

Metreco (for use on PC see4.4.).

- Not all data has to be entered to create an Intervention Report.

- You will nd more explanations on the use of Reports on PC in the next chapter (4.5.).

- Recalling an Intervention Report is similar to recalling a Measurement Report (4.3.).

18. Select ‘Start/End’ and complete.

20

4.4.Tests

• Pressure Decay Test - PDT

The pressure decay test gives you the possibility to follow up and log the legaly imposed pres-

sure test. There is the possibility to automatically compensate the pressure for temperature

variations. A temperature and pressure sensor are what you need for this test.

2. Select ‘Pressure Decay Test’.

3. Complete the Pressure Decay Test Setup.

You must assign a pressure sensor

You are free to choose to assign a:

- System Temperature sensor

- Ambient Temperature sensor

- Target Pressure

- Pressure Medium (N2 or N2H2)

1. Select ‘Main Menu’ and select ‘Tests’. 4. Press ‘Start’

You get the Pressure Decay Test Status

5. End the PDT by pressing ‘Stop’.

You get the report.

6. Consulting the PDT:

- on the handheld can be done similarly as

a Measurement Report.

(See 4.3 - Measurement Report)

- on the PC can be done similarly as a

Measurement Report & Logle.

(See 4.5 - Follow-up on PC)

Main Menu

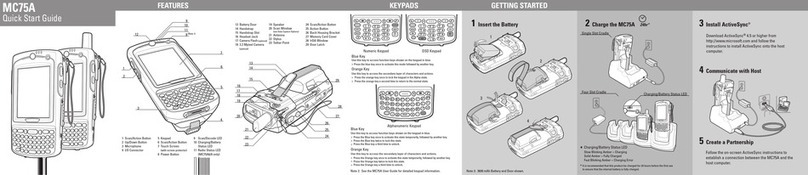

This manual suits for next models

1

Table of contents

Popular Handheld manuals by other brands

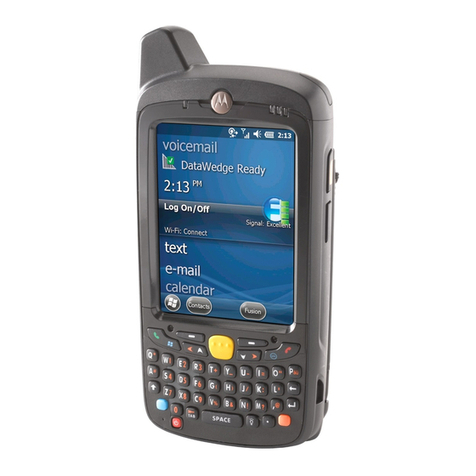

Motorola

Motorola MC75A quick start guide

Fujitsu Siemens Computers

Fujitsu Siemens Computers Pocket LOOX 710 operating manual

Motorola

Motorola MC9094 Guide

Intermec

Intermec Oracle-Ready CK31 user manual

Motorola

Motorola MC9090K - Win Mobile 6.1 624 MHz Specifications

Honeywell

Honeywell ScanPal Series user guide