METREL A 1281 User manual

Multi range AC current clamps

(1000A / 100A / 5A / 0.5A)

A 1281

Instruction manual

Version 2.1, Code no. 20 751 696

Distributor:

Manufacturer:

METREL d.d.

Ljubljanska cesta 77

1354 Horjul

Slovenia

web site: http://www.metrel.si

e-mail: [email protected]

© 2014 METREL

Mark on your equipment certifies that this equipment meets the requirements of the EU

(European Union) concerning safety and electromagnetic compatibility regulations.

No part of this publication may be reproduced or utilized in any form or by any means without

permission in writing from METREL.

A 1281 Multi range AC current clamps

3

Table of contents

DESCRIPTION OF CURRENT CLAMPS........................................................................5

CURRENT CLAMPS OPERATION.................................................................................6

OPERATION INSTRUCTIONS..............................................................................................6

SUBSTITUTE ELECTRIC MODEL FOR CURRENT CLAMPS .....................................................7

TYPICAL APPLICATIONS..............................................................................................7

POWER QUALITY MEASUREMENT.....................................................................................7

POWER MEASUREMENT ..................................................................................................8

LEAKAGE CURRENT MEASUREMENT.................................................................................8

Measurement of Leakage Current by Direct Method..............................................................8

Measurement of Differential Current and/or Current Difference...........................................8

Determining Problems in Lighting and Grounding Systems...................................................9

MAINTENANCE..............................................................................................................9

INSPECTION ...................................................................................................................9

CLEANING......................................................................................................................9

SERVICE AND CALIBRATION .............................................................................................9

TECHNICAL SPECIFICATIONS...................................................................................10

GENERAL.....................................................................................................................10

ACCURACY AND PHASE ERROR .....................................................................................11

TYPICAL PERFORMANCE CHARACTERISTICS ...................................................................11

ELECTROMAGNETIC COMPATIBILITY (EMC) ....................................................................12

A 1281 Multi range AC current clamps

4

Symbols and Warnings

To ensure a high level of operator's safety during using of A 1281 Multi range AC current

clamps the following warnings has to be considered:

!

Do not use the current clamp if any damage is noticed!

!

Consider all generally known precautions in order to avoid risk of electric shock

while dealing with electric installations!

!

Do not extend hands over safety barrier to prevent of electric shock! Only

handles are allowed to be touched during measurement!

!

Symbol on the current clamp indicates the possibility of a hazardous live

condition if the operator ignores the required safety measures.

!

If the current clamps are used in a manner not specified in this User manual, the

provided protection can be impaired!

!

Only a competent, authorized person is allowed to carry out service intervention!

!

Do not connect clamp output elsewhere than to Metrel Power Quality Analyzer’s!

Symbol on the current clamp indicates the possibility to use the current clamp on

non-insulated conductors.

Current clamps are protected by double insulation.

A 1281 Multi range AC current clamps

5

Description of current clamps

The A 1281 multi range current clamps are designed for measuring alternating currents on low

and medium power installations: 50 mA ÷ 1000 A.

They have electronic module, and can be connected only to Metrel Power Quality Analysers’,

series:

PowerQ (MI 2492)

PowerQPlus (MI 2392)

PowerQ4 (MI 2592)

PowerQ4 Plus (MI 2792)

Energy Master (MI 2883)

Power Q4 (MI 2885)

Power Master (MI 2892)

Power Master XT (MI 2893)

Clamps have four current ranges 0.5A, 5A, 100A and 1000A, which are selected directly by the

connected instrument. Embedded electronic module is powered directly from the connected

instrument and does not need any additional power supply.

The current transducer is housed in a plastic case that maintains double insulation as defined in

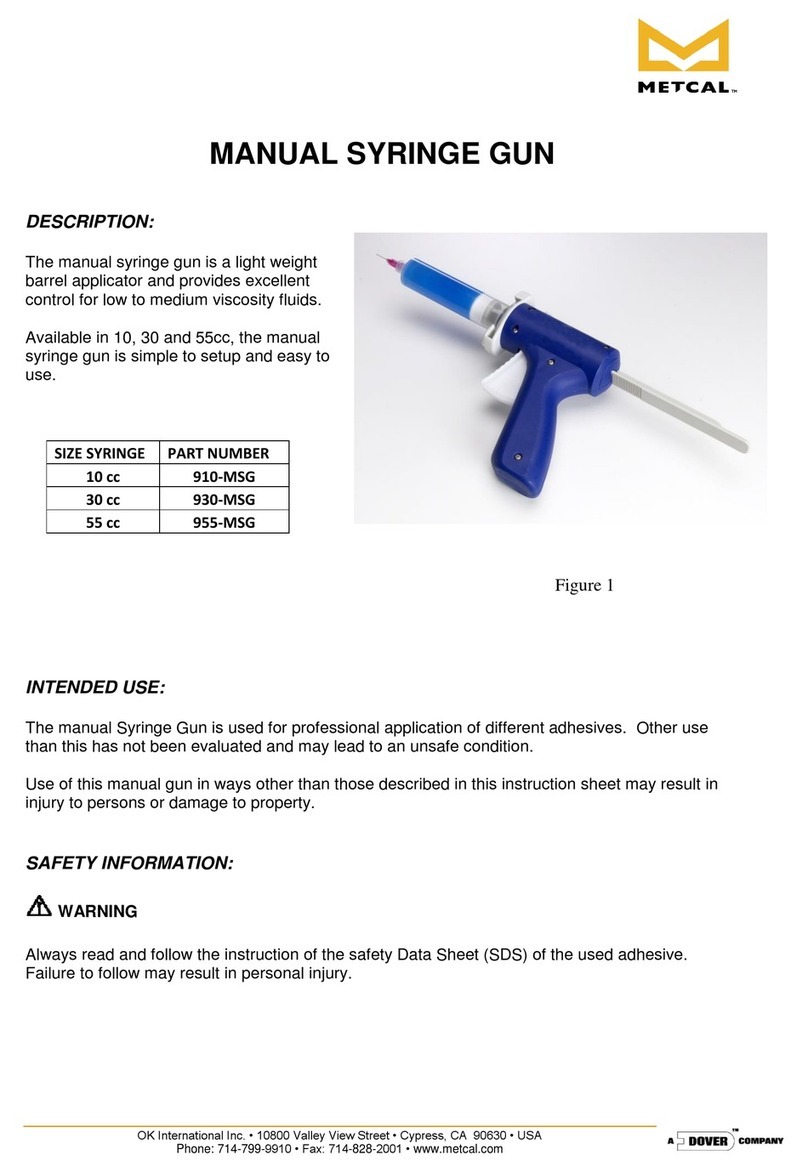

Main parts of the current clamps are shown on figure bellow:

1

2

3

4

5

1. handles,

2. safety barrier,

3. conductor opening,

4. clamps jaw,

5. cable connection with

connector.

Figure 1: Multi range AC current clamps

A 1281 Multi range AC current clamps

6

Current clamps operation

Operation Instructions

Figure 2: Current clamps A 1281 - connection to the measuring instrument

Step 1

Connect A 1281 current clamps output connector to the appropriate (Metrel Power Quality

Analyzer) measuring instrument’s current input terminal. (See figure 2)

!

Do not connect clamp output elsewhere than to Metrel Power Quality Analyzers’

series of measuring instruments!

Step 2

Switch on the measuring instrument. Set Smart clamps and range on instrument’s measuring

setup. (For further information see Instruction manual of measuring instrument.)

Step 3

Clamp the probe around the current-carrying conductor(s) to be measured. Make sure that

probe jaws are tightly closed around the conductor(s).

!

Do not extend hands over safety barrier to prevent of electric shock! Only handles

are allowed to be touched during measurement!

!

Do not use the current clamp if any damage is noticed!

!

Consider all generally known precautions in order to avoid risk of electric shock

while dealing with electric installations!

Step 4

Make measurement. (For further information see Instruction manual of measuring instrument.)

A 1281 Multi range AC current clamps

7

Step 5

Disconnect clamps from the conductor(s). Use all safety measures as described in step 3.

Substitute Electric Model for Current Clamps

Equivalent circuit diagram for current clamp measurement:

Im Is

1 : N2

I

U

Range selection:

- 500mA

- 5 A

- 100A

- 1000A

GND

U(I)

Instrument

Connector

Figure 3: Current clamps A 1281 - block diagram

Symbols on circuit diagrams have following meaning:

Im

Measured (AC) current, primary current

Is

Measured current, current transformer secondary current

N2

Number of secondary turns (N2 = 1000)

U(I)

Output voltage as function of current U = k * Im. Factor k depends on

selected current range as shown in table bellow:

Range (A)

k (V/A)

0,5

2

5

0,2

100

0,01

1000

0,001

Typical applications

Power Quality Measurement

A 1281 current clamps have linear response through wide frequency bandwidth (see Figure 8).

Therefore, they are well suited for:

Power Quality auditing,

EN 50160 or troubleshooting. Particularly for:

Current distortion measurement

Inrush measurement

Functional testing of appliances, machines, etc.

High precision (see Figure 6) and wide measurement range can cover most of practical LV

current measurements.

A 1281 Multi range AC current clamps

8

Power Measurement

A 1281 current clamps have small phase shift (see Figure 7 and Figure 9) over wide frequency

range. Therefore, they are well suited for:

Power and energy measurements (active, reactive, apparent)

Power factor measurements

Power/Energy efficiency

Leakage Current Measurement

Measurement of Leakage Current by Direct Method

This method is used when measuring the current through one (embraced) conductor.

Figure 4: Leakage current measurement –direct method

Measurement of Differential Current and/or Current Difference

The differential method sums the current passing through two or more active (embraced)

conductors. If no current is leaking to earth, the sum of the currents passing through active

conductors must be exactly zero regardless of the load currents. If a leakage current is flowing

to earth, it must be equal to the difference in current between the conductors contained in the

current clamp (although, if alternative earth paths exist, this may not be equal to the current

passing through the PE conductor).

Note

Note that the direction of currents in the conductors must be considered if the differential

method is used.

Figure 5: Leakage current measurement –differential method

A 1281 Multi range AC current clamps

9

Determining Problems in Lighting and Grounding Systems.

Faults in electrical installations and equipment can cause additional continuous or short-

lasting leakage currents. Typical faults that can cause increased leakage currents are:

Deterioration of insulation (because of pollution, moisture, corrosion). This is causing

a gradual increase of the resistive leakage current.

Faults in electronic equipment.

If the neutral and PE wiring are connected together anywhere in the installation this

can result in an improper current distribution through the neutral and PE conductors.

Note

Metrel Application note: Measuring of leakage current contain many practical aspects and

examples of leakage current measurement.

Maintenance

Inspection

To maintain operator safety and ensure reliability of the current clamp it is good practice to

inspect it on a regular basis. Check that the enclosure and optional connection are without

defects such as scratches or breaks.

Jaw surface must be clean. Pollution on jaw surfaces reduces the current clamp sensitivity.

Cleaning

Use a soft cloth moistened with soapy water or alcohol to clean non-metallic surface of the

current clamps and leave them to dry totally before using it.

!

Do not use liquids based on petrol or hydrocarbons!

!

Do not spill cleaning liquid over the current clamps!

To clean jaw cut surfaces use slightly oiled soft cloth.

Service and Calibration

It is essential that your clamp is regularly calibrated in order to guarantee the technical

specification listed in this User manual. We recommend 2-year calibration interval. Metrel

encloses an original calibration certificate with every new instrument and clamp.

For recalibration and repairs under or out of warranty time please contact your distributor for

further information.

!

Only a competent, authorized person is allowed to carry out service intervention!

A 1281 Multi range AC current clamps

10

Technical Specifications

General

Safety specification

Over voltage category: 600 V CAT III,

Pollution degree: 2

Double insulation

Environment conditions

Working temperature: -20 0C ÷ 55 0C

Storage temperature: -30 0C ÷ 70 0C

Temperature dependency (Note 1):

+/- 0.02 % of reading / °C

Humidity: 0 % ÷ 85 %,

Linearly decreasing for T > 35 0C

Altitude: 2000 m

Applied standards

Safety: EN/IEC 61010-1

EN/IEC 61010-2-32

EMC: EN/IEC 61326-1

Mechanical data

Jaw opening: 52 mm

Maximum conductor sizes:

Cable: < 50 mm

Bar: 1 bar 50 mm x 5 mm,

4 bars 30 mm x 5 mm

Housing flammability: UL94 –V-1

Dimension: 220 mm x 120 mm x 48 mm

Weight: 600 g

Note 1: No additional error in range 15 ºC – 25ºC,

for higher temperatures: Temp. error = (Temp - 25ºC) * Temperature dependency

for lower temperatures: Temp. error = (15ºC - Temp) * Temperature dependency

A 1281 Multi range AC current clamps

11

Accuracy and Phase Error

Reference conditions:

Temperature: 23 0C 1 0C

Humidity: 60 %

Current range

Nominal current (INom)

0.5 A

5 A

100 A

1000 A

Current ratio

0.5 A/V

5 A/V

100 A/V

1000 A/V

Peak current

1.5 APEAK

15 APEAK

246 APEAK

1700 APEAK

Crest factor @ Nominal current

3,0

3,0

2,46

1,7

Accuracy

Current range*

50 mA ÷1 A

0.5 A ÷10 A

10 A ÷175 A

100 A ÷1200 A

RMS Current Accuracy

0.5 % of m.v.

0.5 % of m.v.

0.5 % of m.v.

0.5 % of m.v.

Frequency range

40 Hz ÷ 700 Hz (<0.50phase error)

700 Hz ÷ 2500 Hz (<30phase error)

Continuity of measurements

1000 A continuous

1200 A (40 min / 20 min intermitted)

Load impedance

< 1 kΩ

Working voltage

600 Vrms

Influence of neighbour conductor:

< 1 mA/A at 50 Hz

Influence of conductor position:

< 0.3 % at f < 400 Hz

*Accuracy for 0÷10% range is 0.1% ·INom

m.v. –measured value

Typical Performance Characteristics

-2,00

-1,50

-1,00

-0,50

0,00

0,50

0,0 2,0 4,0 6,0 8,0 10,0 12,0

Current (A)

Accuracy (%)

Figure 6: Accuracy vs. current (for 5A range)

0,00

0,20

0,40

0,60

0,80

1,00

1,20

1,40

0 5 10 15

Current (A)

Phase Error (°)

Figure 7: Phase error vs. current (for 5A range)

A 1281 Multi range AC current clamps

12

0,00

0,50

1,00

1,50

2,00

2,50

10 100 1000 10000

Freqency (Hz)

Acurracy (%)

Figure 8: Accuracy vs. frequency (for 5A range)

0,0

0,5

1,0

1,5

2,0

2,5

3,0

10 100 1000 10000

Freqency (Hz)

Phase Error (°)

Figure 9: Phase error vs. frequency (for 5A range)

Electromagnetic Compatibility (EMC)

Current clamps A 1281 conforms to the directive 2004/108/EC for EMC, as defined by

EN-61326-1:

- Emission: Class B (domestic and industrial use).

- Immunity: Intended for use in industrial locations, but can also be used for

domestic purposes (Performance criteria B), with addition to the tables bellow:

Table 1: Immunity to radiated RF fields*

Range

Operational conditions

Disturbance < 0,2 %

Disturbance > 0,2 %

0.5A

0.05 A ÷ 0.5 A

322 MHz ÷ 1 GHz

80MHz ÷ 322 MHz

5A

0.5 A ÷ 5 A

250 MHz ÷ 1 GHz

80MHz ÷ 250 MHz

100A

10 A ÷ 100 A

80 MHz ÷ 1 GHz

–

1000A

100 A ÷ 1000 A

80 MHz ÷ 1 GHz

–

* Field strength: 10V/m, Modulation: AM, 80%, 1 kHz

Table 2: Immunity to Magnetic field*

Range

Operational conditions

Disturbance

0.5A

0.05 A ÷ 0.5 A

< 6 % of m.v.

5A

0.5 A ÷ 5A

< 0.5 % of m.v.

100A

10 A ÷ 100 A

< 0.2 % of m.v.

1000A

100 A ÷ 1000 A

< 0.2 % of m.v.

*Field strength: 30 A/m, Modulation: AM, 80%, 1kH.

Label1

Table of contents