10

Pioneer manufacture an Outdoor 850 ‘Ash Floor Protector’ which complies

with the minimum floor protector requirements of AS/NZS2918, and can

be installed with any Outdoor 850 fire. Outdoor 850 fires do not require

an insulated floor protector as they comply with the minimum floor

protector requirements of AS/NZS2918. These minimum floor protector

requirements are;

• They must be of adequate size to give appropriate wall, rear and front

clearances/projections as detailed in the chart illustrated on page 6.

• The floor protector must extend 200mm horizontally to the rear and

each side directly below the door opening, and 300mm forward of the

door opening

• The upper surface of the floor protector must be made of non-

combustible material.

A suitable floor protector for an Outdoor 850 fire is therefore any non-

combustible material which could include;

• Cement based tiles or similar with grouted joints fixed directly to a hard

base over combustible flooring

• A sheet of toughened glass, panel steel etc. laid directly onto any

combustible floor.

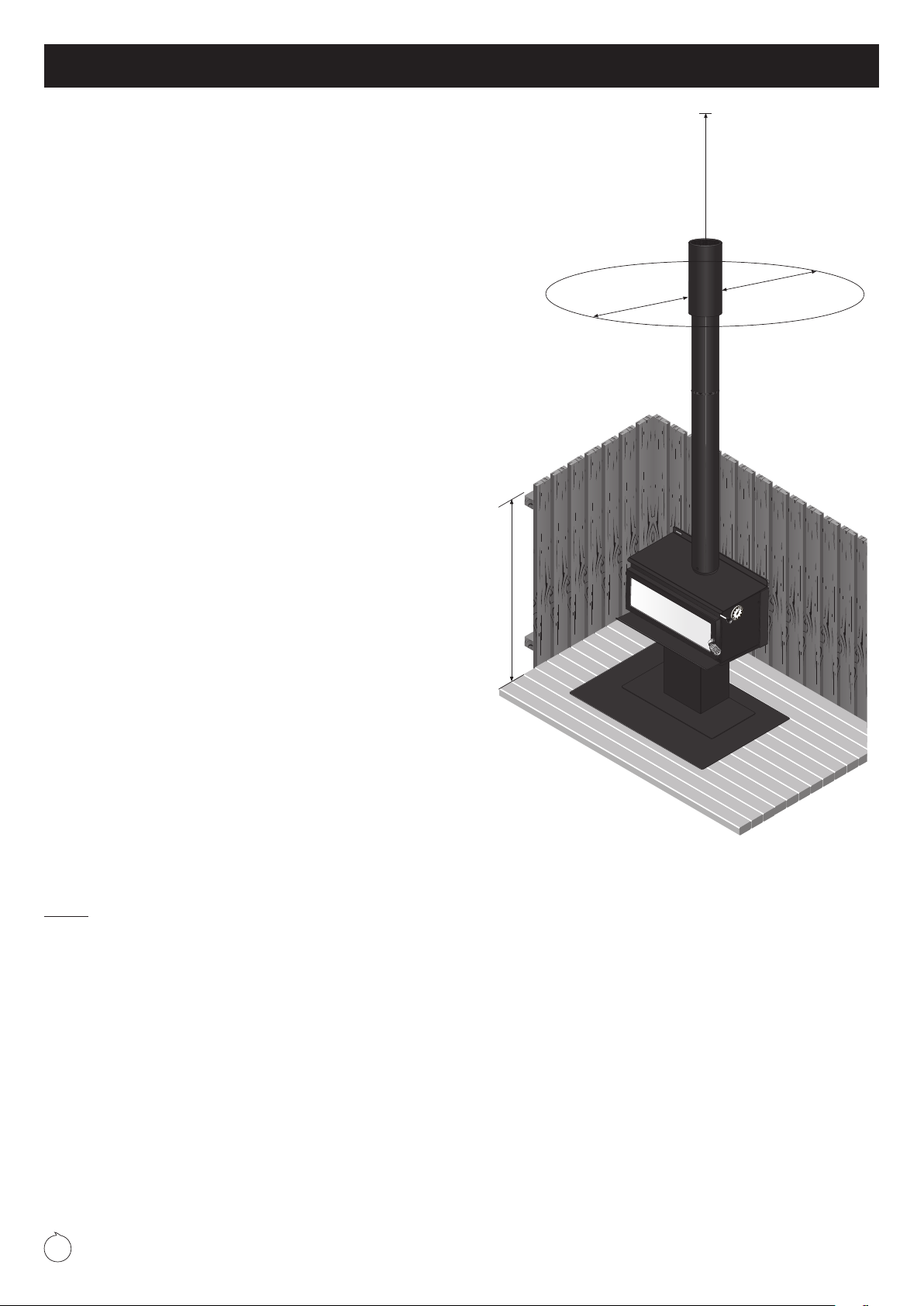

Once installed all minimum clearances and floor protection dimensions

must be adhered to. This includes the critical clearances vertically and the

clearance radius of the flue system termination.

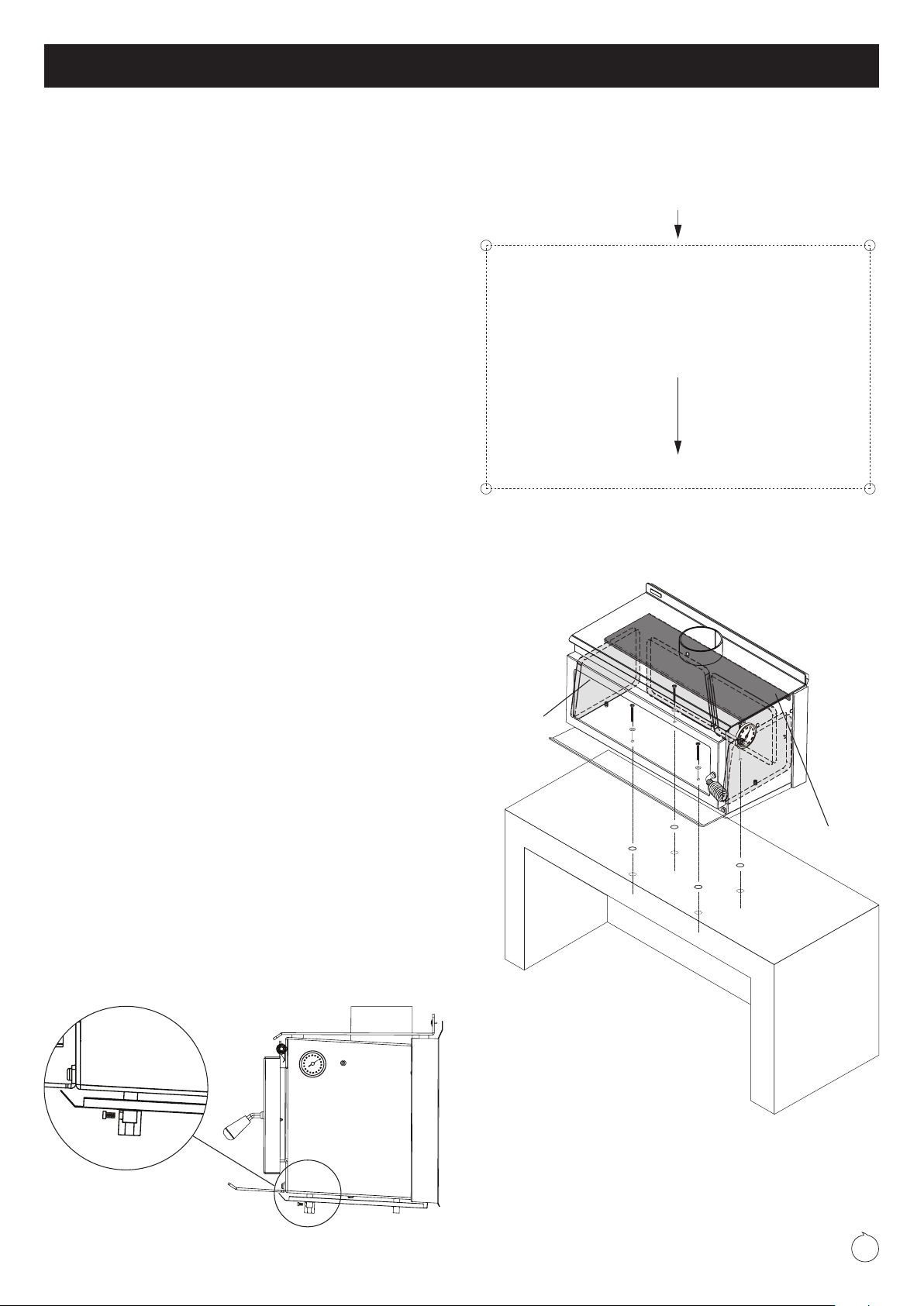

Floor protector positioning

Your Outdoor 850 Floor Protector has two sets of fixing points

pre-drilled for the seismic restraint of the Outdoor 850-P.

Using the most forward set of fixing points will require you to position

your Pioneer floor protector a minimum of 106mm from the nearest rear

combustible wall/fence. This will ensure the minimum rear clearance of

150mm to the fire is achieved once your Outdoor 850-P is installed.

Using the rear set of fixing points will require you to position your Pioneer

floor protector a minimum of 266mm from the nearest rear combustible

wall/fence. This will ensure the minimum rear clearance of 150mm to the

fire is achieved once the Outdoor 850-P is installed.

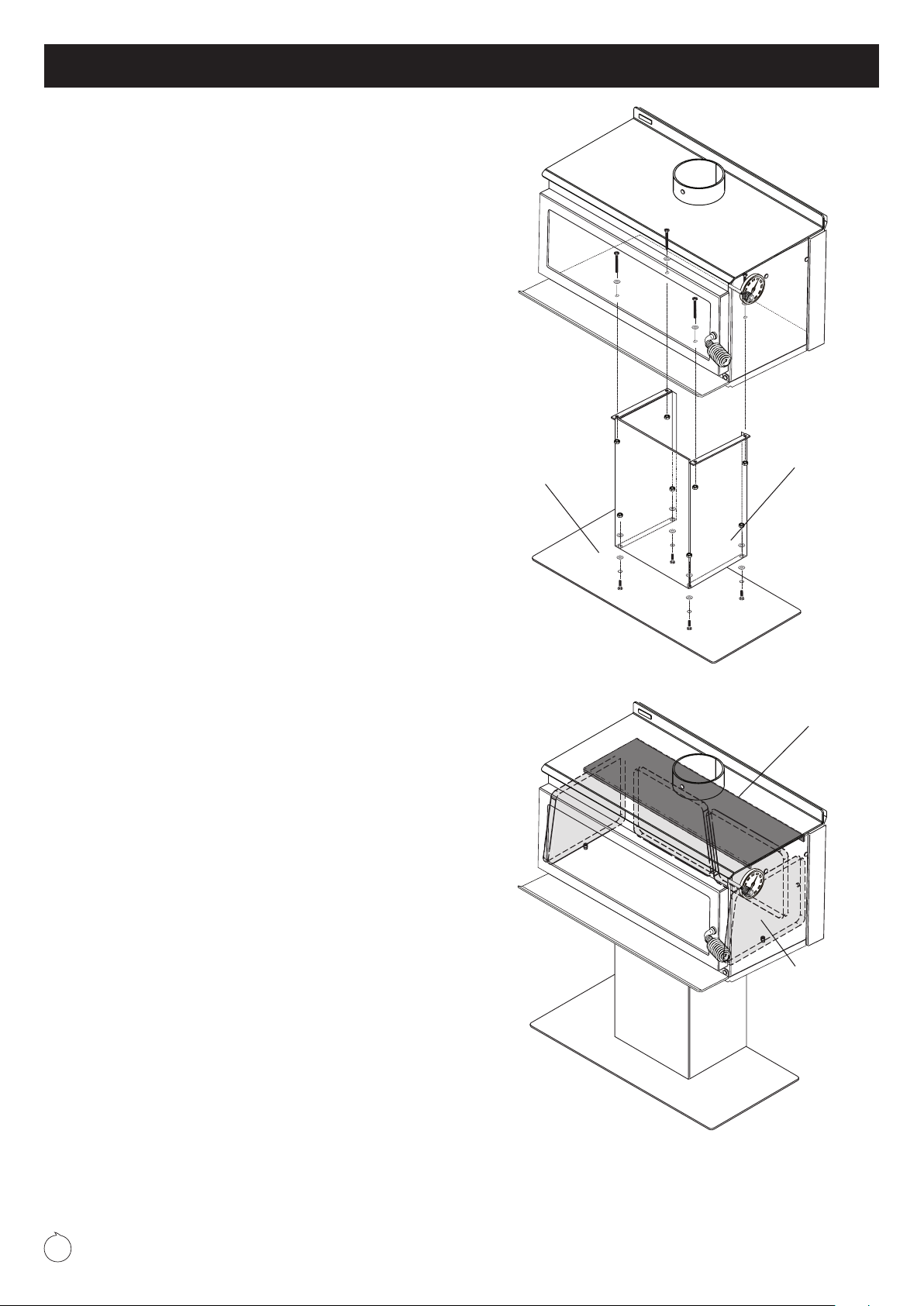

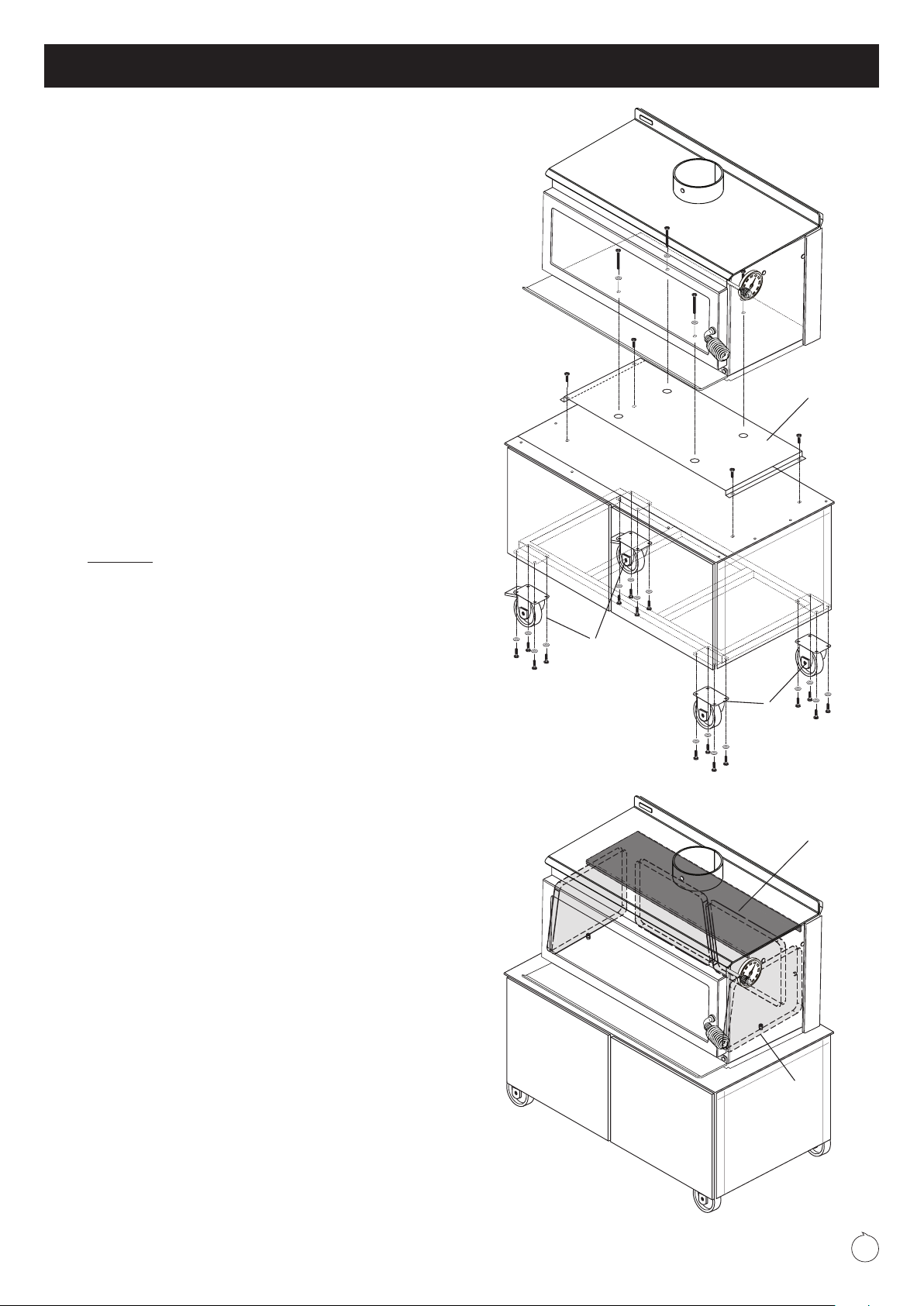

Floor protector installation

Move the Outdoor 850 fire onto the floor protector and using a suitable

measuring device, ensure that the minimum wall clearances and front

floor protector projections as detailed in the chart on page 6 are met or

exceeded. Once the fires location on the floor protector is established,

seismic restraint is required. Using masonry anchors if the floor protector

is on a concrete floor or coach bolts if a wooden floor, secure the Outdoor

850-P through the holes provided in the base plate, at each side of the

pedestal leg. The Outdoor 850-T must have the braked castors locked.

Note: The anchors must pass through the floor protector and securely

anchor the Outdoor 850-P fire to the floor.

Floor protector size, construction and fitting

Your Outdoor 850 comes complete with a cooking tool kit and a stainless steel

hanging bracket for hanging your cooking tools. Packed under the fire’s ashlip

are your cooking tool kit aluminium handles and the stainless steel tool ends

are packaged inside the firebox. Assemble your tools using the 4mm Allen

key supplied with the firebox. Please remove all plastic film where applicable.

Your cooking tool kit includes: 1x grill lifter, 1x fire rake and 1x pizza peel.

Assembly of the Grill Lifter tool (A)

Insert the stainless-steel removal tool end into the aluminum extruded handle,

this is the second longest handle (835mm). Line up the holes and use the 4x

M6x8mm stainless dome head socket screws with washer’s (1 washer under

each bolt head). Insert bolts and tighten.

Assembly of the Fire Rake (B)

Use 2x M6x12mm dome head socket screws and two flat washers one under

each bolt head. Attach the fire rake end to the shortest aluminum handle

(810mm). The handle has two threads inserted at one end so nuts are not

required. The return fold of the fire rake end goes towards the front of the

handle.

Assembly of the Pizza Peel (C)

Use 2x M6x12mm dome head socket screws and two flat washers, one under

each bolt head. Attach the pizza peel end to the longest aluminum handle

(920mm). This handle has two threads inserted at one end so nuts are not

required. You will notice the handle end has an angle cut that matches the

angled profile of the pizza peel end.

Cooking Tool Kit - Tool assembly instructions

(A)

(B)

(C)