9SHK 200S

SHK 200S-6

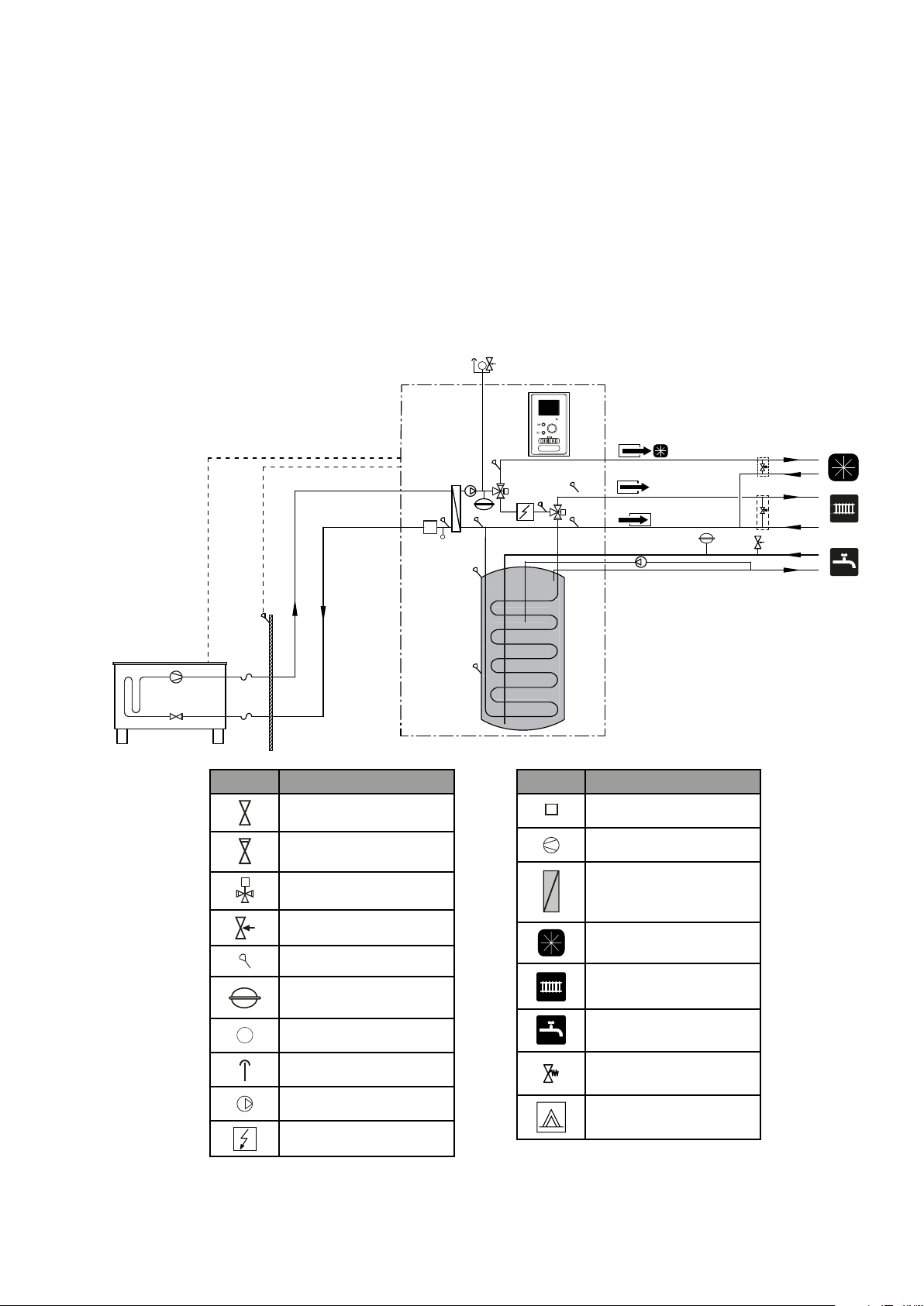

4 Pipe connections

General pipe connections

Pipe installation must be carried out in accordance

with current norms and directives.

The pipe dimension should not be less than the recom-

mended pipe diameter according to the table below.

However, each system must be dimensioned individu-

ally to achieve the recommended system ows.

The system can cooperate with a low- and medium

temperature heating system. Recommended temper-

ature of the heating medium at minimum designed

outdoor temperature DOT must not exceed 55°C on

supply, and 45 °C on return circuit from the heating

system, whereas HK 200S / HK 200S-6 can achieve

even 65 °C when using a ow-through heating mod-

ule or another peak heat source.

Excess medium owing out of the safety valve must

be discharged via a pipe to a oor drain. The over-

ow pipe must be slanted at the entire length from the

safety valve, and must be secured against freezing.

In order to achieve maximum system efciency, we

recommend the installation of HK 200S / HK 200S-6

as close to the heat pump as possible.

The HK 200S / HK 200S-6 module is not equipped with

cut-off valves, which must be installed outside the in-

door module to make future maintenance easier.

The HK 200S / HK 200S-6 module can be connected

to the central heating, cooling, and domestic hot wa-

ter installation. Install the supplied safety valve and

the manometer.

Air/water

heat pump

Minimum

ow during

defrosting

(100%

pump

speed (l/s)

Minimum

recom-

mended

pipe

dimension

(DN)

Minimum

recom-

mended

pipe

dimension

(mm)

SHK 200S-6 / L6 0,19 20 22

SHK 200S / L8 0,19 20 22

SHK 200S /

L12 0,29 20 22

IMPORTANT

Any high points in the climate system, must be

equipped with air vents.

IMPORTANT

The pipe systems need to be ushed out before

the indoor module is connected so that

any debris cannot damage component parts.

IMPORTANT

As long as heating circuits in the system have not been

lled with the heating medium, do not set the switch

(SF1) in the controller in position “I” or “ ”. The com-

pressor in the heat pump and the ow-through heating

module can be damaged.

MINIMUM SYSTEM FLOWS

The installation must be dimensioned at least to man-

age the minimum defrosting ow at 100% pump op-

eration, see table.

IMPORTANT

All connections require free ow, hence a discharge

valve must be installed.

IMPORTANT

An undersized system can result in damage to the

machine and lead to malfunctions.

Chapter 4 | Pipe connections

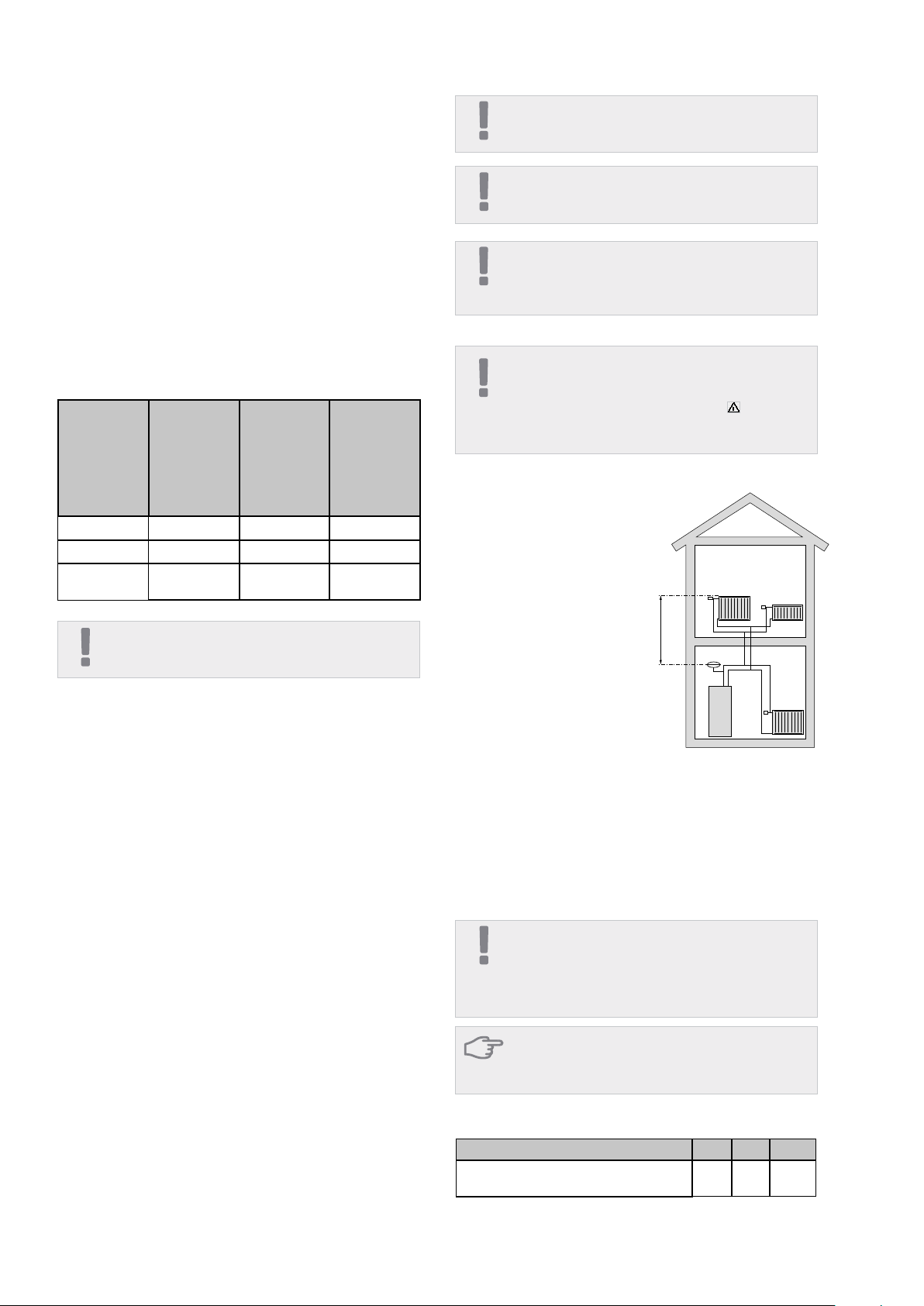

SHK 200S / SHK 200S-6

is equipped with a pres-

sure expansion vessel of

10 litres. The pre-pres-

sure of the pressure ex-

pansion vessel must be

dimensioned according to

the maximum height (H)

between the vessel and

the highest positioned

radiator, see gure. A

pre-pressure of 0.5 bar (5

mvp) means a maximum

permitted height differ-

Expansion vessel

Volume expansion

Minimum volume of the heating system

CAUTION

The diaphragm expansion vessel at the domestic hot

water installation is not required. It is, however, required

to install a safety valve with opening pressure of 3 bar.

ence of 5 m. The maximum system volume excluding

the boiler is 220 litres at the above pre-pressure.

Approx. 10 l/kW is required for connection to the heat

pump, and many heating systems do not have this

volume. To prevent operational problems, the volume

is then expanded using a UKV buffer vessel.

METROAIR L 6 8 12

Minimum volume of the heating system

during heating / cooling 50l 80l 100l

IMPORTANT

In order to achieve undisturbed ow of the heating sys-

tem, use a hydraulic coupling or open heating loops.

Remember to always keep the minimum required ow

in the installation - see the section "Minimal ow in the

installation".