Metrodata WC-Serial User manual

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 1 of 17

WC-Serial

User Manual

DATE:

19th May 2021

DOCUMENT NO:

76-02-103

REVISION:

C

PREPARED BY:

Paul Ingram

Metrodata Ltd

Laxton House, Crabtree Office Village

Eversley Way, Egham Surrey, TW20 8RY, UK

Tel +44 1 784 744700

Fax: +44 1 784 744701

E-Mail: [email protected]

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 2 of 17

METRODATA LTD

No part of this publication may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic,

mechanical, magnetic, optical, chemical, manual or otherwise, without

the prior written permission of

Metrodata Ltd, Laxton House,

Crabtree Office Village, Eversley Way,

Egham, Surrey, TW20 8RY, United Kingdom.

DISCLAIMER

Metrodata Ltd makes no representations or warranties with respect to

the contents hereof and specifically disclaims any implied warranties

or merchantability or fitness for any particular purpose. Further,

Metrodata Ltd reserves the right to revise this publication and to make

changes from time to time in the content hereof without obligation of

Metrodata Ltd to notify any person of such revision or changes.

Copyright © 2019 by Metrodata Ltd,

All Rights Reserved

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 3 of 17

Document History

10/04/2017 XA Document Created

26/04/2017 A Document Released

18/01/2019 B Minor corrections

19/05/2021 C Minor corrections

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 4 of 17

1 INTRODUCTION .................................................................................................. 6

1.1 WC-Serial ...................................................................................................... 7

1.2 Safety ............................................................................................................ 7

1.3 Electro Magnetic Compatibility ...................................................................... 7

1.3.1 EN55022 Statement ............................................................................... 8

1.3.2 FCC Declaration .................................................................................... 8

1.4 WEEE Directive ............................................................................................. 8

1.5 RoHS Compliance ......................................................................................... 8

2 INSTALLATION .................................................................................................... 9

2.1 WC-Serial Rear Panel ................................................................................... 9

2.1.1 Mains Power .......................................................................................... 9

2.1.2 DC Power ............................................................................................... 9

2.1.3 User LAN Ports .................................................................................... 10

2.1.4 Multi-Protocol Serial Port ..................................................................... 10

2.1.5 RJ45 Led Indicators ............................................................................. 10

2.1.6 Serial LED’s ......................................................................................... 11

2.1.6.1 Transmit (TX) LED .......................................................................... 11

2.1.6.2 Receive (RX) LED ........................................................................... 11

2.1.7 Power (PWR) LED ............................................................................... 11

2.1.8 Unit Status (OK) LED ........................................................................... 11

2.2 Base Label and Bit Switches ....................................................................... 12

2.2.1 Switch 1, Data Inversion ...................................................................... 13

2.2.2 Switch 2, TX Clock Inversion ............................................................... 13

2.2.3 Switch 3, RX Clock Inversion ............................................................... 13

2.2.4 Switch 4, Link Loss Forwarding ........................................................... 13

2.2.5 Switch 5, Max Frame Size ................................................................... 13

2.2.6 Network Port Configuration .................................................................. 14

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 5 of 17

2.2.6.1 Switch 5, Duplex ............................................................................. 14

2.2.6.2 Switch 6, Speed .............................................................................. 14

2.2.6.3 Switch 8, Auto Negotiation .............................................................. 14

2.3 Rack mounting ............................................................................................ 15

3 WC-Serial Fault Finding ..................................................................................... 16

3.1 RED LED ON, WAN Fault ........................................................................... 16

3.2 GREEN LED FLASH, LAN Fault ................................................................. 16

3.3 RED LED FLASH, WAN and LAN Fault ...................................................... 16

3.4 YELLOW LED ON, WAN Sync Alarm ......................................................... 17

3.5 YELLOW FLASH, LINK LOSS FORWARDING .......................................... 17

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 6 of 17

1 INTRODUCTION

The Metrodata WC-Serial is a two port auto sensing 10/100BaseT Ethernet Switch

with a multi-protocol serial uplink. The WC-Serial can be used to extend two LAN

ports across a serial WAN link to a remote site. Each LAN port may be connected

to a single LAN workstation or to a hub or switch supporting multiple workstations.

The exact configuration will depend upon the user’s network design and workload

characteristics.

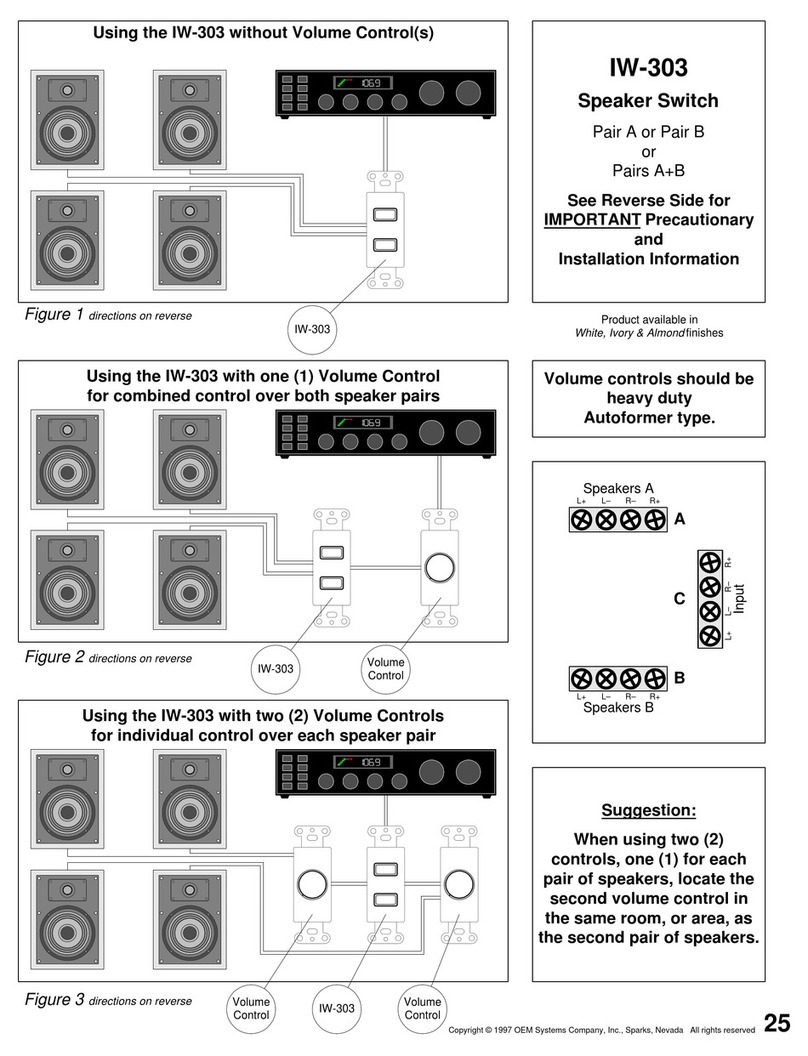

An example application is shown below, where a remote office with two users is

connected to the head office servers via a BT Kilostream X.21 service.

The WC-Serial Ethernet Switch can switch between local LANs connected to its two

ports, and the unit may thus reduce the need for local LAN hubs and switches. The

Ethernet switch has full wirespeed filtering so that the WAN serial port carries only

traffic destined for the remote WAN-linked site, and an efficient HDLC encapsulation

of packets ensures maximum throughput over the WAN link. There is internal packet

buffering to smooth out bursty traffic. WC-Serial units are used in pairs, one on either

side of a WAN link due to the proprietary encoding of the serial data.

The serial port uses a HD60 connector and is compatible with the Cisco HD60 cable

set to support DTE interfaces at X.21, EIA-530 or V.35.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 7 of 17

1.1 WC-Serial

The WC-Serial is a compact unit as shown occupying half a shelf in a traditional

19inch rack. All connectors and LED status indicators are accessible from the rear

of the unit.

1.2 Safety

The WC-Serial must not be connected to cabling which would be required by

BS6701 to equipped with over voltage protection. The following ports on the

FCM5000 are designated SELV ( Safety Extra Low Voltage ) within the scope of

EN41003

Terminal RJ45

LAN Port(s) RJ45 10/100BaseT

These ports must only be connected to SELV ports on other equipment in

accordance with EN60950 clause 2.3

1.3 Electro Magnetic Compatibility

In order to ensure EMC compliance, all signal and data cables must be shielded and

use screened connector shells. The cable screens must be terminated to the

screened connector shell and not connected to any pins of the connector. Failure to

use the correct connectors may compromise EMC compliance.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 8 of 17

1.3.1 EN55022 Statement

The WC-Serial is a Class A product. In a domestic environment, this product may

cause radio interference, in which case the user will be required to take adequate

measures.

1.3.2 FCC Declaration

This equipment has been tested and found to comply with the limits of the Class A

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the

Installation and Operation manual, may cause harmful interference to the radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the

interference at his own expense.

1.4 WEEE Directive

The WC-Serial is covered by Directive 2002/96/EC ( OJ:L37/24/2003 ) on Waste

Electrical and Electronic Equipment ( WEEE ) Units must therefore not be disposed

of in standard landfill.

1.5 RoHS Compliance

The WC-Serial is compliant with the EU RoHS Directive 2002/95/EC. The RoHS

directive bans the use of six hazardous materials in products placed on the market

after July 1st 2006. The six banned materials are Lead, Mercury, Hexavalent

Chromium, Polybrominated Biphenyls, Polybrominated Diphenyl Ethers and

Cadmium.

The FCM5000 is manufactured using a lead free soldering process and as such is

fully RoHS 6/6 compliant.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 9 of 17

2 INSTALLATION

2.1 WC-Serial Rear Panel

The WC-Serial is available with either AC Mains or DC power options.

2.1.1 Mains Power

The WC-Serial has an internal power supply and is supplied via an IEC mains power

socket. The WC-Serial operates over the wide range 100 to 250V AC and draws

less than 6 watts.

2.1.2 DC Power

The WC-Serial is available with an internal DC power supply with two variants

available,

DC -48V ( 36 to 72V DC )

DC 24V ( 7 to 36V DC )

DC powered units have an external earth stud which must be securely connected to

an earth connection to ensure EMC compliance.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 10 of 17

2.1.3 User LAN Ports

The WC-Serial has two User LAN ports presented on RJ45 connectors. The two

ports support 10/100BaseT with auto MDI/MDI-X crossover switching. The ports are

configured as a pair using the bit switches on the underside and therefore may be

manually configured with auto negotiation disabled.

The two LAN ports are connected internally via a wirespeed switch and so local

switching is supported.

2.1.4 Multi-Protocol Serial Port

The multi-protocol serial port is presented on a HD60 connector. The pinout is

compatible with Cisco, and as such uses the following conversion cables to present

the required DTE or DCE interfaces

DTE DCE

X.21 CAB-X21-MT CAB-X21-FC

EIA-530 CAB-530-MT CAB-530-FC

V.35 CAB-V35-MT CAB-V35-FC

V.36 (RS449) CAB-449-MT CAB-449-FC

Please note that DCE operating modes have a fixed data rate of 2.048Mbps and are

for lab testing purposes.

2.1.5 RJ45 Led Indicators

Each RJ45 connector has two LED’s, one green and one yellow and these are

combined to show the Link State, Link Activity and Link Speed as shown below:

The Green LED is used as a Link/Activity indicator. If the LED is off there is no link.

If the LED is on the link is up but there is no activity. If the green LED is flashing the

link is up and data is passing.

The Yellow LED is used to indicate port speed.

All LED’s off indicates the link is down.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 11 of 17

2.1.6 Serial LED’s

The Serial interface has two status LED’s as described below

2.1.6.1 Transmit (TX) LED

The transmit LED is set to pulse on for 100mS whenever a packet is transmitted on

the serial interface. With a very low packet rate, the LED may flash, but with normal

traffic conditions the TX LED will be on all the time. If no traffic is passing the LED

will be off.

2.1.6.2 Receive (RX) LED

The Receive LED is set to pulse on for 100mS whenever a packet is transmitted on

the serial interface. With a very low packet rate, the LED may flash, but with normal

traffic conditions the RX LED will be on all the time. If no traffic is passing the LED

will be off.

2.1.7 Power (PWR) LED

The Power LED is GREEN ON to indicate that the unit is powered up.

2.1.8 Unit Status (OK) LED

The OK LED is a bicolour LED with the following states

OFF Unit not powered up

RED ON The Serial WAN port has alarms

RED FLASH Both the Serial WAN and User LAN Ports have alarms

YELLOW ON Serial WAN Sync Alarm

YELLOW FLASH Link Loss Forwarding Alarm

GREEN FLASH The User LAN Port has alarms

GREEN ON No Alarms present.

The OK LED, gives an indication of the status of the device, and if it is not displaying

GREEN ON, i.e. normal operation, the user should use the status to diagnose the

problem.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 12 of 17

2.2 Base Label and Bit Switches

On the underside of the WC-Serial there are bit switches which may be used to

configure certain functions within the unit.

The bit switches are used to configure the operational mode of the WC-Serial and

will be effective immediately.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 13 of 17

2.2.1 Switch 1, Data Inversion

In normal operation the WC-Serial would be operated with the data in normal mode

with a ‘1’ representing a Mark, and ‘0’ representing Space. This switch allows this to

be inverted.

2.2.2 Switch 2, TX Clock Inversion

In normal operation the WC-Serial would be operated with the transmit clock in the

normal state. In contra-directional systems, such as X.21 if long cables are used it

may be desirable to invert the TX clock to overcome errors induced by the round trip

transit delay of the cable.

2.2.3 Switch 3, RX Clock Inversion

In normal operation this switch should be in the normal position.

2.2.4 Switch 4, Link Loss Forwarding

Link loss forwarding enables the state of the serial WAN port to be reflected in the

user Lan ports. If LLF is enabled, and the WAN port fails the LAN ports will also be

changed to the down state to alert upstream equipment there is a problem.

2.2.5 Switch 5, Max Frame Size

The WC-Serial supports a maximum frame size of 2048 bytes, however for

compatibility with legacy systems this may be limited to 1518/1522 bytes.

ON Max Packet Size 2048 bytes

OFF Max Packet Size, 1518 Untagged, 1522 Tagged

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 14 of 17

2.2.6 Network Port Configuration

Bit switches 6 to 8 are used to configure the setting for the LAN ports of the device

and are used on installation to ensure the WC-Serial physical interface matches that

of the host port it will connect to.

2.2.6.1 Switch 5, Duplex

This switch controls the duplex mode of the user LAN ports. When auto negotiation

is enabled this controls the advertised options, whilst in manual mode, it controls the

duplex mode.

ON Full Duplex

OFF Half Duplex

2.2.6.2 Switch 6, Speed

This bit switch is used to select the speed control for the LAN port. When auto

negotiation is enabled, these switches control the options that are advertised,

whereas in manual mode, the speed switches actually select the interface speed.

BitSw 6 Speed Auto Neg Advertise

OFF 100M 10/100

OFF 10M 10

2.2.6.3 Switch 8, Auto Negotiation

The Auto Negotiation switch controls whether the user LAN ports are configured

automatically, or manually.

ON Auto Negotiation Enabled

OFF Manual controlled selection of speed and duplex

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 15 of 17

2.3 Rack mounting

The WC-Serial is a standalone, desktop unit however it may be mounted in a

standard 19 inch rack using the rack mounting kit, part number 80-05-256.

To mount the WC-Serial in the 19 inch rack mount adaptor first remove the two

M3x12 screws and washers from the rear panel of the unit. Then align the WC-

Serial rear panel with the mounting bracket, and secure the unit to the adaptor using

the previously removed screws.

When rack mounting, please ensure that the bit switches on the underside are

correctly configured prior to mounting the units in the rack.

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 16 of 17

3 WC-Serial Fault Finding

The WC-Serial is designed to be a simple ‘plug and play’ device which uses an auto

sensing cable to configure the serial port. Serial port timing is provided by the

attached DCE (modem) equipment.

The LAN ports support auto negotiation and auto MDI/MDIX crossover so these

should be simply connected using LAN patch cables.

Once a serial connection is available between a pair of WC-Serial units traffic should

pass.

However, if problems arise the following section is intended to assist with the fault

diagnosis and remedy:

3.1 RED LED ON, WAN Fault

There are several possible causes for the WAN fault, which indicate that there is a

problem with the serial connection.

Check the correct cable is being used and that the HD60 is connected the

correct way round.

Check the cable is plugged into both the WC-Serial and the attached DCE

(modem).

Check the Modem is powered up.

If all looks correct, suspect a faulty cable.

3.2 GREEN LED FLASH, LAN Fault

The LAN fault is declared when both LAN ports are in the link down state. If one

LAN port is UP, then the LAN fault is cleared.

Check the correct cables are being used

Check the cables are correctly plugged in at both ends

Check, is the attached Host powered up

Check bit switches for port operating mode, speed/duplex/autoneg

3.3 RED LED FLASH, WAN and LAN Fault

Check for the WAN fault causes as per section 3.1

Check for the LAN Fault causes as per section 3.2

WC-SERIAL USER MANUAL

76-02-103 Rev.C Page 17 of 17

3.4 YELLOW LED ON, WAN Sync Alarm

The WAN SYNC alarm indicates that both transmit and receive clocks are present

but it is not possible to synchronise to the received serial. The WC-Serial expects to

receive an HDLC stream and SYNC is declared once flags have been detected and

the HDLC packet CRC error rate is low.

Check the serial cable is connected to the correct DCE (Modem)

Check the operating speed is supported by the interface type.

Check whether transmit clock inversion may help if a long (30m) X.21 cable is

being used.

Check the bit switches to ensure both units are using the same data state,

normal/inverted.

3.5 YELLOW FLASH, LINK LOSS FORWARDING

If Link Loss Forwarding is enabled, then if there is either a WAN Fault, or WAN sync

fault the LAN ports will be shut down to forward the Link Loss to the attached host

port.

Since LLF is caused by the WAN port being down, diagnose as per section 3.1

Table of contents

Popular Switch manuals by other brands

Hama

Hama 00079091 Operating instruction

Nortel

Nortel 2500 Seriess Documentation roadmap

Austin Hughes

Austin Hughes CyberView CV-801D user manual

Blade Network Technologies

Blade Network Technologies BLADEOS RackSwitch G8124 installation guide

NEMA

NEMA Reliance Controls Easy/Tran TF151 manual

Vega

Vega VEGAVIB 61 operating instructions