metrofires Bay User manual

Metro Pellet Fires

INSTALLATION &

OPERATION MANUAL

Safety First.............................................................................Page 3

Installation Clearances ......................................................Page 4

Installation Configurations................................................Page 6

Installation Vent Systems ..................................................Page 7

Operation................................................................................Page 9

MX3™ Controller ...............................................................Page 10

Maintenance & Cleaning ..................................................Page 12

Troubleshooting .................................................................Page 15

Diagram & Parts List.........................................................Page 18

Warranty ..............................................................................Page 20

Bay & Bay Insert Models

PRINTED MARCH 09

2

TABLE OF CONTENTS

SAFETY FIRST ................................................................................................................................................... 3

INSTALLATION

• Clearance to Combustibles.................................................................................................................................. 4

• Installation Clearances........................................................................................................................................ 4

• Electrical Requirements ..................................................................................................................................... 5

• Fuel Requirements .............................................................................................................................................. 5

• Fuel Storage......................................................................................................................................................... 5

• Location of the Pellet Fire.................................................................................................................................... 6

• Typical Installation Congurations...................................................................................................................... 6

• Venting System .................................................................................................................................................... 7

METRO PELLET INSERT ADDITIONAL CONSIDERATIONS

• Metro Pellet Insert Additional Requirements ..................................................................................................... 8

• Fascia Surround................................................................................................................................................... 8

• Metro Pellet Insert Installation............................................................................................................................ 8

• Metro Pellet Insert Removal................................................................................................................................ 9

• Operation and Maintenance................................................................................................................................. 9

OPERATION

• General Overview and Safety Features................................................................................................................ 9

• Electric Igniter ..................................................................................................................................................... 9

• Fueling the Hopper .............................................................................................................................................. 9

• MX3™ Control and Button Description.............................................................................................................. 10

• Wall Thermostat, Wall Switch or Other Switching Device................................................................................. 11

• Starting and Stopping Your Pellet Fire .............................................................................................................. 11

MAINTENANCE & CLEANING.................................................................................................................... 12

TROUBLE SHOOTING GUIDE ..................................................................................................................... 15

ADDITIONAL INFORMATION ...................................................................................................................... 17

DIAGRAMS AND PARTS LIST ..................................................................................................................... 18

WARRANTY INFORMATION ........................................................................................................................ 20

3

SAFETY FIRST

1. Read these instructions carefully. Failure to follow them could cause a malfunction of the pellet re,

damage to the pellet re or property damage.

2. Familiarize yourself with the pellet re’s operation. (See “Operation” section) If you are not sure, ask your

dealer for an explanation on your pellet re’s proper operation.

3. The burn pot of this pellet re is designed for premium grade wood pellets. Refer to the “Fuel

Requirements” section for more information.

4. Oiling the circulation fan motor bearings should be done every 12 months. See “Maintenance” section for

more details.

5. Check your local building codes regarding restrictions or installation requirements. All installations must

comply with local building codes.

6. Combustion of wood pellet fuel leaves ash in the pellet re and venting system. These ashes must be

removed from the pellet re regularly. See “Maintenance” section for more information.

7. This pellet re is POWER VENTED. The vent pipes are under positive pressure during operation. It is

IMPERATIVE that all joints in the venting system be SEALED to prevent any leakage of exhaust gases inside

the house. All joints must be sealed using high temperature silicone sealer (RTV). Aluminum tape is NOT

an adequate sealant.

8. Use of outside combustion air is highly recommended and is mandatory in mobile home installations.

9. This appliance is wired and grounded according to the electrical code AS/NZS/EN 60335.2.30 for New

Zealand.

10. Make sure the door and any other opening in the pellet re are closed tightly during operation. Inspect the

gaskets of the door and other openings periodically to make sure they are in good condition.

11. Replace broken or defective components only with parts provided by the manufacturer. Contact your local

dealer to nd out how to purchase replacement parts.

12. Follow this manual carefully for proper installation. If you are uncertain, call your dealer. Most dealers have

qualied and trained installers. We highly recommend the use of their services.

13. During the very rst re your Metro will give off an odour and fumes as the rebox paint cures. Do not be

alarmed; open all windows and externally opening doors in that room and close any internally opening

doors. This curing process will last for approximately one hour and will only happen this one time.

IMPORTANT MESSAGE

• THE PELLET STOVE MUST NOT BE LOCATED IMMEDIATELY BELOW A SOCKET-OUTLET.

• CAUTION: PELLET FIRE HAS MOVING PARTS. DISCONNECT POWER BEFORE SERVICING

• If you have any questions, comments or concerns regarding your new pellet re, please contact

your local dealer or Pioneer Manufacturing Ltd. at www.metrores.co.nz or 06 756 6520.

Please record the following information for future reference

Customer Name.............................................................................................................................................................

Installation address .......................................................................................................................................................

Phone Hm .................................................. Mobile...............................................Work............................................

Product Type (please tick) Freestanding Insert

Model ..................................................................................................................................................................

Retailer purchased from................................................................................................................................................

Retailer Address .......................................................................................................Date Purchased ..........................

Comments ..................................................................................................................................................................

..................................................................................................................................................................

4

INSTALLATION DETAILS

Clearance to Combustibles - Installation Clearances

Please refer to the following gures for all clearances to combustibles. Please note that these

clearances are for your METRO pellet re only.

Minimum clearances shown are in mm, and all gures for clearances are to combustible materials. All

Metro pellet res are tested using all applicable procedures and equipment under AS/NZS2918:2001.

We recommend sufcient space be provided (minimum 500mm) on each side of the pellet re to service

the unit. If this is not possible, provision must be made available to remove the unit for servicing.

Freestanding Dimensions

285mm

470mm

615mm

613mm

788mm

250mm

175mm

120mm

100mm

650mm

950mm

120mm

120mm

100mm

1000mm

1280mm

100mm

100mm

5

INSTALLATION DETAILS

Electrical Requirements

1. This pellet re is an electrical appliance. This appliance requires 230- 240 Volts, 50 Hz and 1.5-2.0 Amps of

electrical power.

2. The pellet re comes with a 1.5 M long, grounded, electrical cord suitable to plug into any standard residential

electrical outlet. The electrical outlet must be grounded.

Wood Pellet Fuel Requirements

Only approved wood pellets are to be used in this appliance which have been tested to and complies with AS/NZS

4014.6. Any other fuel used that does not comply with this standard will greatly affect the performance, operation

and the warranty of this appliance.

Wood pellets must not be:-

– Longer than 38mm

– Thicker than 10mm

– Have no more than 1% ne dust particles

If you nd your fuel has excessive amounts of nes and saw dust, the fuel should be screened before use. DO NOT

USE WET PELLETS under any circumstance. Longer fuel may cause bridging of the auger and result in erratic

feeding or jamming. Fines, binders, ash, moisture will all cause your pellet re to block up and not burn efciently.

“Poor” fuels require more frequent cleaning; the ashtray must be emptied and the burn pot must be cleaned on a

regular basis. Please refer to the “Maintenance” section for further instructions on cleaning your pellet re.

Fuel Storage

All pellet fuel should be stored in a clean dry place and at a safe distance (at least one metre) away from the re.

IMPORTANT MESSAGE

• THIS APPLIANCE SHALL NOT BE USED AS AN INCINERATOR. BURNING ANY FUEL OTHER

THAN WOOD PELLETS AS DESCRIBED ABOVE WILL VOID YOUR PELLET FIRE’S WARRANTY.

WARNING

618mm

614mm

533mm 485mm

356mm

Insert Dimensions

100mm

Figure 3: Minimum Fireplace opening for the

Metro pellet fire insert

410mm

500mm

560mm

1050mm

1020mm

300mm

531mm

100mm

381mm

NOTE: “If a timber mantelshelf exists above the pellet fire opening,

it should be a minimum of 452mm above the top of the pellet fire”

6

INSTALLATION DETAILS

Location of the Pellet Fire

When selecting a location for your new pellet re consider the following:

1. Clearance to combustibles. The pellet re must be installed with the proper clearances to combustibles to

protect against the risk of re.

2. Sufcient room to service the unit and size of the appliance. Allow yourself enough room to be able to service

the pellet re. Open the side panels and remove the back panel to see how much room you will need to access

the sides and the back comfortably. When installing the pellet re, please keep in mind that you will need to

clean the pellet vent system annually. If the pellet re must be placed in a tight area, make sure to conform to

the proper clearances to combustible materials and make sure you have enough room to disconnect the vent

system for servicing. Also, these appliances are heavy and may be awkward to move in order to service. The

free-standing pellet re weighs 92 kg and the insert pellet re weighs 70 kg.

3. Access for outside combustion air if required.

4. Power within 1.5m. The power cord is only 1.5m long. Make sure that your outlet is within 1.5m of the pellet re.

5. Access for exhaust venting.

6. The pellet re must not be located immediately below a socket-outlet.

Typical Installation Configurations

The following gures illustrate some typical installations. Variations of these are possible. Common sense, safety

and compliance with local codes must be respected in any variation.

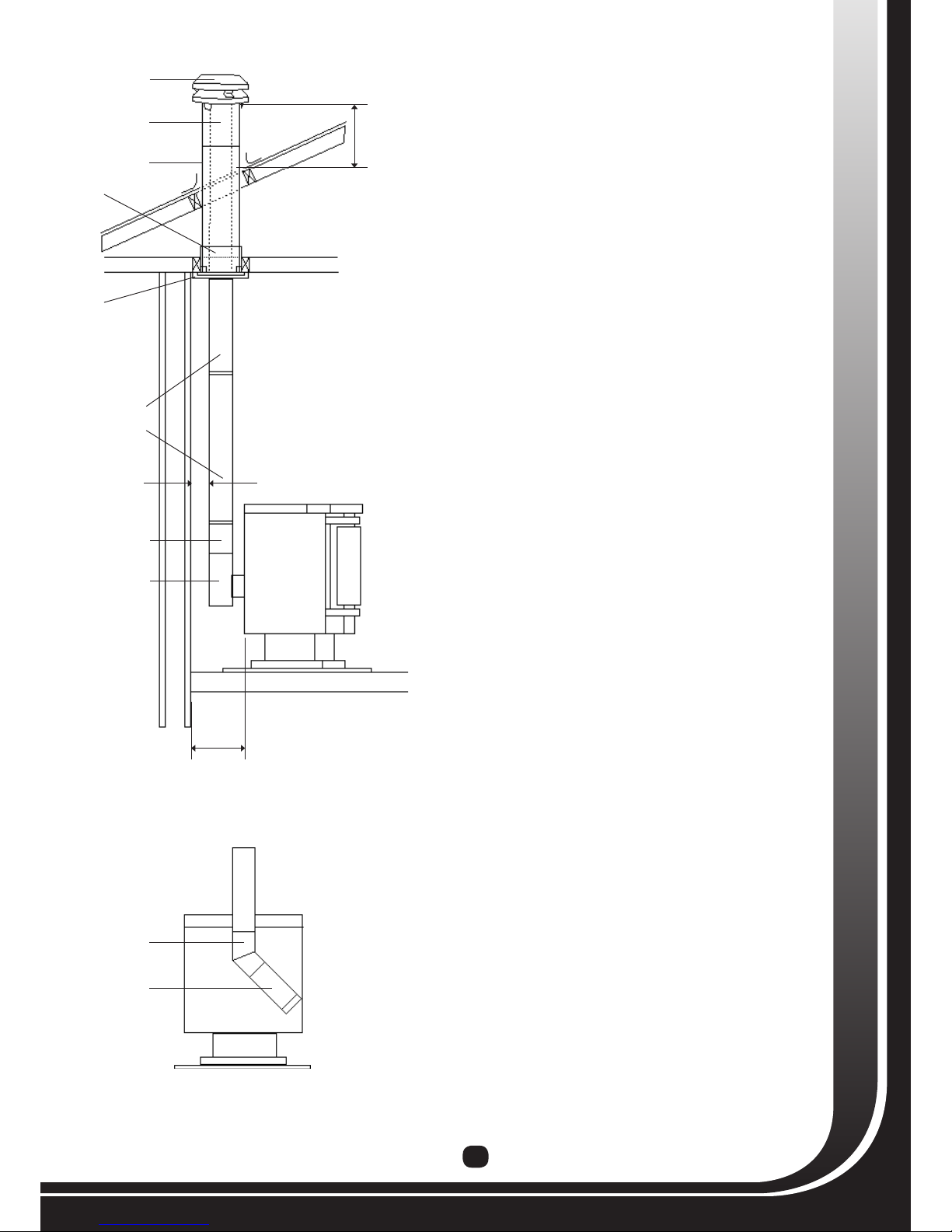

Figure1 Figure2

450mm

600mm

minimum

250mm

100mm

minimum

7

INSTALLATION DETAILS

Venting System

Your METRO pellet re works under negative pressure (vacuum). The exhaust fan of your pellet re pulls air from

the air intake, through the pellet re and pushes it out the vent system. Air passing through the burn pot is used to

burn the pellets. Proper vent pipe sizing is very important to ensure the pellet re operates properly. A proper size

approved venting should be used to provide the least resistance for movement of the combustion air.

The vent pipes on the exhaust side of the exhaust fan are under pressure. Care must be taken to ensure that all

the joints are completely sealed to prevent any leakage of exhaust fumes and smoke into the house. If you smell

smoke, the venting has not been properly sealed. Use only high temperature RTV silicone for sealing. Aluminum

tape is not considered an adequate sealant. At least 3 screws/or rivets are needed for securing all vent pipe joints.

The venting of this pellet re is not allowed to pass through any closets, concealed spaces, oors, ceilings or

attic spaces. If the venting must go through a wall or combustible partition, the installation must conform to the

Installation Code for Solid Fuel Burning Appliance and Equipment. For more detailed venting information, please

refer to your venting manufacturer’s instructions.

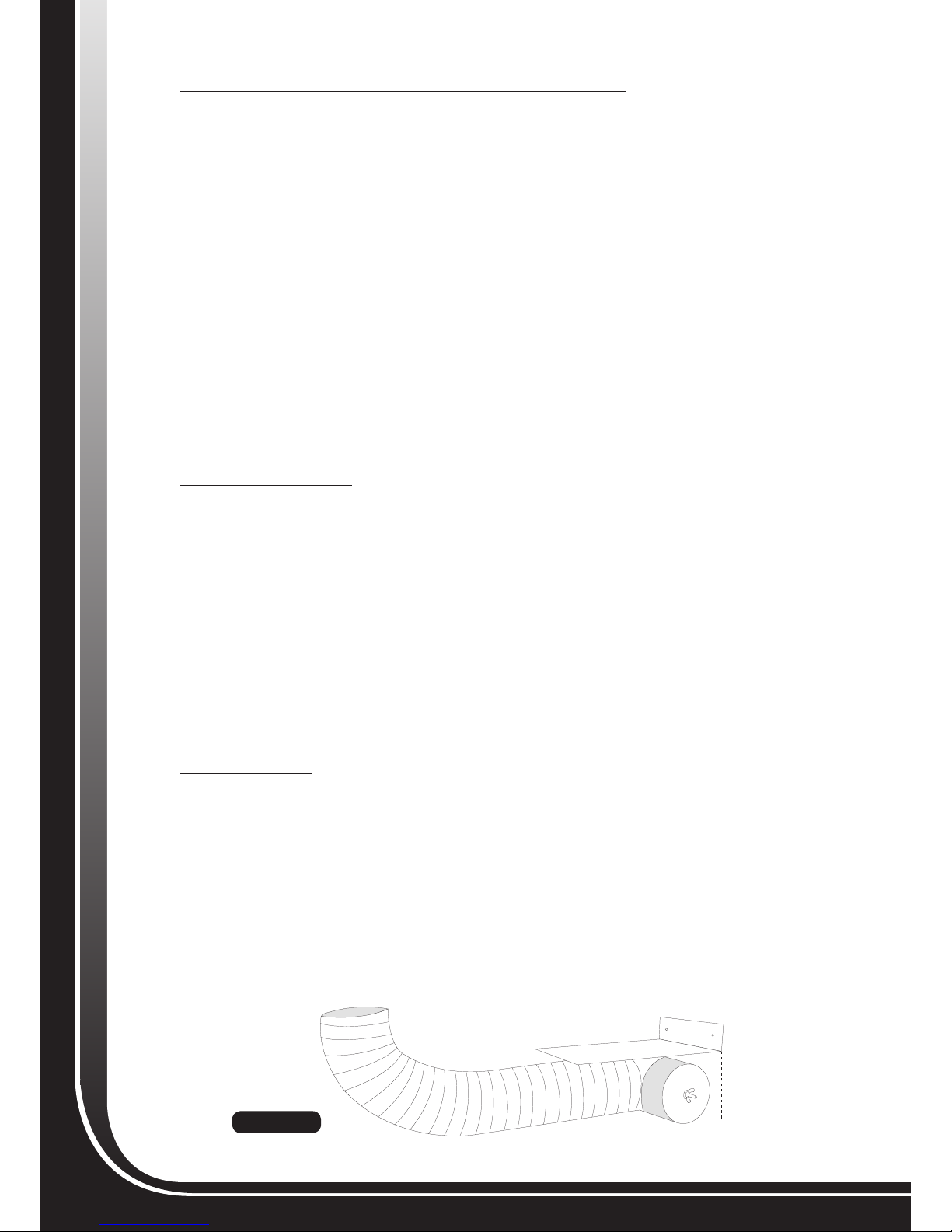

Combustion Air Intake Requirements

The Metro Bay has a direct vent option which when installed draws the combustion air from outside the home,

further improving the efciency of the pellet re. This is recommended as the Metro Bay can use up to 24 cubic

metres of room air every hour.

There are two methods of supplying the pellet re with combustion air. They are as follows;

• DV WALL KIT ducts through an outside wall

• DV FLOOR KIT ducts through the oor directly behind the Metro

IMPORTANT MESSAGE

• THE APPLIANCE AND FLUE-SYSTEM SHALL BE INSTALLED IN ACCORDANCE WITH AS/NZS

2918 AND THE APPROPRIATE REQUIREMENTS OF THE RELEVANT BUILDING CODE OR CODES.

• DO NOT USE MAKESHIFT MATERIALS OR MAKE COMPROMISES IN THE INSTALLATION. IT IS A

FIRE HAZARD.

• DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS PELLET FIRE.

• DO NOT CONNECT THIS PELLET FIRE TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

WARNING

8

PELLET FIRE FREESTANDING VENT SYSTEM INSTALLATION

IMPORTANT NOTE TO THE INSTALLER – Pellet fire “vent systems” are pressurised at all times during

the operation of the appliance, and it is crucial that every joint in the vent system is fully sealed using

suitably rated “high temperature silicone” [Pioneer supply industrial grade RTV silicone suitable for this

purpose] NOTE;

•Ifjointsarenotfullysealedashwillblowintotheroom.

•Priortocommencinginstallationensurethat;

- Abuildingconsenthasbeenissuedfortheinstallation.

- Youarecompetentandcapabletocarryoutthisinstallation.

- Youhavereadandfullyunderstandtheseinstructions.

- Youhaveasuitableashingavailablewhichisappropriatefromtheroofmaterialyouare

penetrating.Youalsohaveasuitablesiliconforboththeashingandtosealallthejointsof

theventsystem.

- Youhavecheckedtoensureallthecomponentsoftheventsystemaslistedbeloware

includedwiththekit;

A - 2 x Black Painted 100mm diameter S/S vent pipes

B - 1 x 100mm diameter S/S vent pipe

C-1x“T”piecewithcaptted[capisremovablewithgasketseal]

D - 1 x Plastic coated black ceiling plate

E -1xMountingplatewith200mmdiameterstublinerattached

F -1x150mmdiametergalvanisedcasingwith“slipliner”

G -1xCowlassembly

H - 1 x Centralising bend

I -1xBagofbolts/screws

VENT KIT INSTALLATION INSTRUCTIONS

1. Place the capped “T” on a at surface, then align the centralizing bend so it is pointing up on a 45

degree angle as illustrated below, smear the inside with silicone then push in the crimped end of the

bend and secure with 3 x s/s rivets.

2. Attach the assembled “T” piece and centralizing bend to the vent outlet of the pellet re and position

it so the top of the centralizing bend is in the centre of the pellet re and pointing vertically up

towards the ceiling. (Refer to illustration on page 2) Secure in place using 4 x self tapping screws and

silicone sealant.

3. Position the pellet re in the desired location, check that the pellet re and oor protector have

adequate clearances/projections and that the vent system will be clear of ceiling joists, trusses, etc.

(refer to the pellet re installation manual) Once you have positioned the pellet re, secure it to the

oor using suitable anchors. Drill through the oor protector and into the oor using the two 8mm

holes provided at the rear of the pellet re base.

4. At a point directly above the pellet re vent centre, cut a 200mm square hole through the ceiling and

a 150mm hole through the outer roof lining. Trim out the top face of the ceiling, using timber nogs

creating a square aperture measuring 200mm internally.

5. Fit the mount plate into the ceiling by sliding the 200mm diameter stub casing attached to the

mounting plate up into the ceiling until the two upturned edges of the mount plate rest against the

underside of the ceiling. Square the mount plate to the wall and secure into location with the

4 x screws supplied into the nogs just tted.

6. Moving onto the roof with the 150mm diameter galvanised casing, lower the slotted end of the casing

into the roof cavity until it locates inside the brackets on the top face of the mounting plate. Return

back into the room and using the two x 6mm bolts and washers supplied. Securely bolt the base of

the 150mm diameter casing to the rivet nuts pre-tted into the mount plate brackets.

7. Return back onto the roof and using a suitable ashing, weather proof the joint where the 150mm

diameter casing penetrates the roof. (By tting brackets securing the casing to the roof material will

further improve the rigidity of the installation.)

9

8. Moving back into the home, remove the plastic lm from

the ceiling plate and place it black side down onto the

top of the pellet re.

9a. Unwrap the two painted vent pipes taking care not to

mark the painted surface and proceed to assemble the 3

x 100mm diameter vent pipes as described below.

9b. Smear an adequate amount of silicone sealant inside

the top/un-crimped ends of the 2 painted vent pipes

only.

9c. Taking the unpainted vent pipe insert its top/un-crimped

end up through the mounting plate until its bottom

crimped end is about 1250mm above the top of the

pellet re

9d. Taking one of the two painted vent pipes, t its lower

crimped end into the top of the centralizing bend

previously tted to the rear of the pellet re in item 2.

Lower the unpainted vent pipe which is protruding

down from the mounting plate so that it fully connects

into the lower painted vent pipe. Ensure these two vent

pipe sections are rmly connected and aligned, then

secure using three stainless steel rivets spaced equally

around the joint.

9e. Lift the two assembled vent pipe sections so the

bottom of the lower section is 1250mm above the top

of the pellet re and repeat the above procedure to t

the remaining painted vent pipe. Wipe off any excess

silicone from joints.

9f. With all three vent pipe sections securely joined, lift the

bottom section of the vent pipe out of the centralizing

bend then move it slightly off centre and allow it to rest

on the centralizing bend. Smear an adequate amount of

silicone sealant inside the top of the centralizing bend

(move the vent pipe assembly as required to ensure the

entire surface is coated with silicone sealant) Place the

ceiling plate over the centralizing bend so the centre

hole is directly above the centralizing bend tted to

the pellet re, then lower the vent pipe into the top of

the centralizing bend, with the vertical vent pipe seam

facing the rear.

9g. Carefully move the ceiling plate up the vent pipe

ensuring not to mark the painted surface and clip the

ceiling plate onto the mounting plate.

9h. Secure the lower vent pipe attached to the centralizing

bend using three stainless steel rivets spaced equally

around the joint.

9i. Making your way back onto the roof, slide the slip

section of the outer casing up until the top of the slip

section is level with the top of the vent pipe (+ or –

10mm) then secure this slip section to the outer

casing using rivets.

9j. Fit the stainless steel cowl into the vent pipe ensuring

the three brackets xed to the cowl t outside the

casing slip section. Drill through the pre punched holes

in all 3 brackets into the casing slip and secure with

self tapping screws to allow for future easy removal

during cleaning.

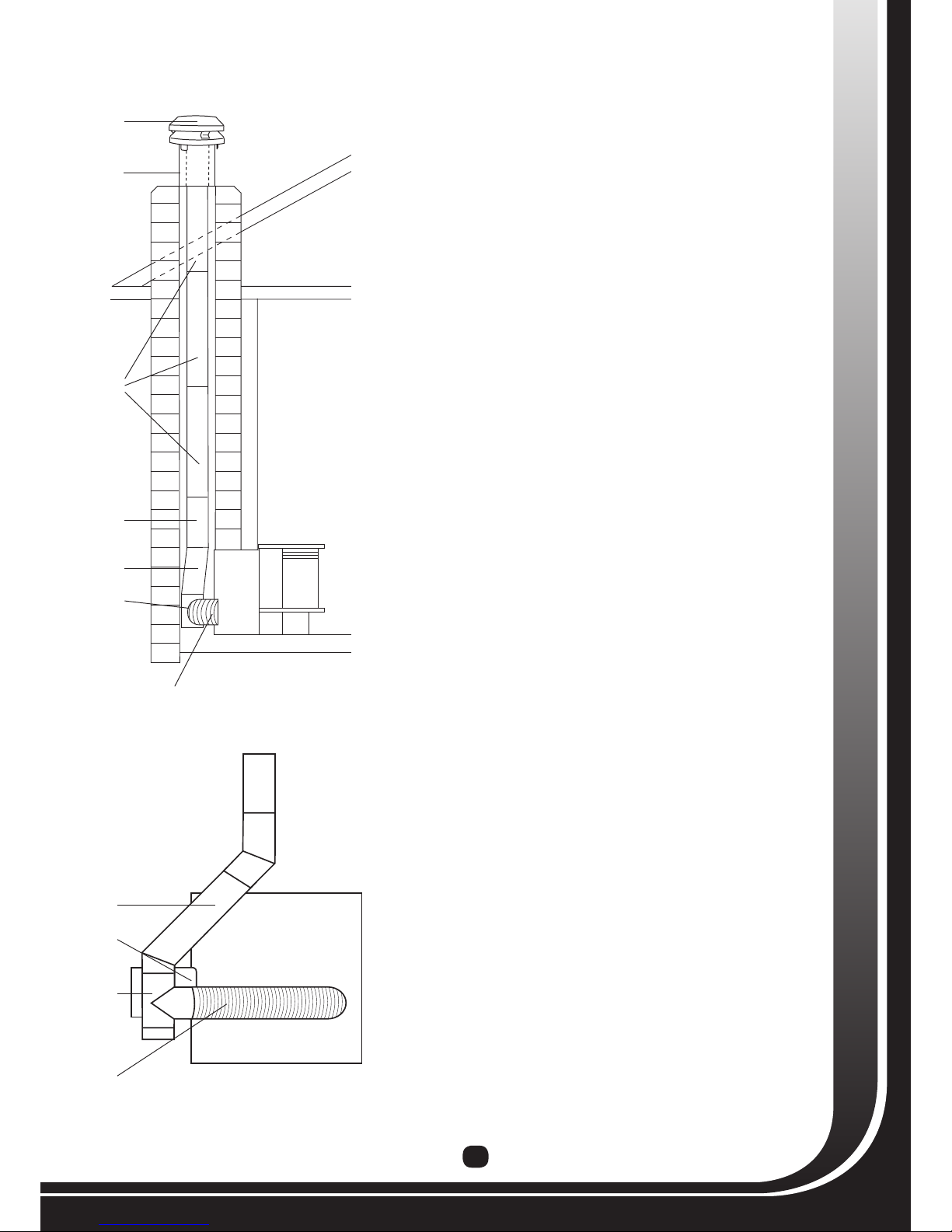

SIDE VIEW

REAR VIEW

A

D

E

F

B

G

C

H

C

H

600mm

minimum

250mm

100mm

minimum

10

PELLET FIRE INSERT VENT SYSTEM INSTALLATION

IMPORTANT NOTE TO THE INSTALLER – Pellet fire “vent systems” are pressurised at all times during the

operation of the appliance, and it is crucial that every joint in the vent system is fully sealed using suitably rated

“high temperature silicone” [Pioneer supply industrial grade RTV silicone suitable for this purpose] NOTE;

•Ifjointsarenotfullysealedashmayblowintotheroom.

•Priortocommencinginstallationensurethat;

- Abuildingconsenthasbeenissuedfortheinstallation.

- Youarecompetentandcapabletocarryoutthisinstallation.

-Somestainlesssteelcomponentsofthisventsystemhavesharpedges,beaware!

- Youhavereadandfullyunderstandtheseinstructions.

- Youhaveasuitableashingavailablewhichisappropriateforthechimney.

- Youalsohaveasuitablesiliconeforboththeashingandtosealallthejointsoftheventsystem.

- Youhavecheckedtoensureallthecomponentsoftheventsystemaslistedbeloware

includedwiththekit;

A - 3 x 1200mm lengths of 100mm diameter S/S vent pipe

B - 1 x 600mm length of 100mm diameter S/S vent pipe

C - 1 x 100mm S/S telescopic offset (2 piece)

D - 1 x 600mm length of 100mm S/S flexi flue bent 90 degrees one end

E -1x“T”piecewithcaptted[capisremovablewithgasketseal]

F - 1 x 150mm diameter galvanised casing

G - 1 x Galvanised angle bracket

H-1xCowlassembly

PRE INSTALLATION

All Metro Pellet Fires are tested using all applicable procedures and equipment under AS/NZS 2918:2001 when

installed in accordance with the installation and operation manual supplied with every Metro pellet re. Prior to

installing your Metro pellet re insert into a masonry chimney, it is important that certain clearances and other

requirements are complied with as detailed below

Chimney cavity – The chimney should be swept, rebricks removed if necessary, and the hearth of the replace

checked to ensure it is level.

Floor Protector – A oor protector must extend 531mm forward of the front of the replace cavity opening.

Electrical Requirements - Ensure a 3 pin electrical outlet is installed in the chimney cavity with a suitable isolation

switch adjacent to the appliance outside the cavity in accordance with New Zealand electrical regulations; if none exists

get a qualied electrician to install one.

Important – It is critical that the components of this Insert Pellet Fire Vent system are installed as detailed within these

instructions. This is necessary for the appliance to be moved from the chimney cavity for annual cleaning and servicing,

then reinserted without having to disconnect or alter the vent system.

INSTALLATION

1. The galvanized angle bracket supplied must be attached to the “T” Piece as a means of securing the “T” inside the

chimney cavity. This bracket has 4 sets of holes pre-punched enabling it to suit varying width chimneys. NOTE –

Most chimneys are approx 800mm wide and these instructions are based on this measurement [move the bracket

location on the “T” accordingly if the internal chimney width of your installation is more or less than 800mm]

- Place a liberal amount of silicon inside the “STRAIGHT END” of the S/S exi ue, and t this over the side entry of

the “T” piece. Place these two components on a at surface and ensure the 90 degree bend “IS AT THE LEFT END

POINTING UP” and the capped end of the “T” is “FACING YOU” [as illustrated in Figure 1]. Secure the exi ue to

the “T” using four stainless steel rivets at 90 degree spacings around the circumference of the joint.

- Now position the galvanised angle bracket in place with the 50mm fold “TO THE RIGHT FACING UP” and hanging

over the “T” by 15mm (as illustrated in gure 1).

Note – This bracket must be positioned “parallel” with the exi ue and “JUST TOUCHING” the removable cap of the “T” piece.

Firmly secure the bracket in position with a minimum of 4 stainless rivets drilling through the appropriate pre-punched holes and/

or drill others as required.

15mm

Figure 1

11

- With the “T piece, exi ue and bracket” now assembled, position

this pre-assembly into the “RIGHT HAND SIDE” of the chimney

cavity with the centre height of the “BRACKET” 300mm above the

base of the chimney cavity, and the two holes to be drilled into

the masonry through the brackets return fold 270mm back from

the chimney cavity entrance. Secure using two 6mm dynabolts or

equivalent masonry anchors.

2. Smear an adequate amount of silicone sealant inside the top/

un-crimped ends of the vent pipes. Secure the vent pipes together

ensuring the vent seams are in line. Vent pipe joints must be fully

compressed to ensure a good seal, and then riveted together at

3 even points around the vent join. For installations where extra

lengths of vent pipe are required, or when the weather is poor, it

will be easier to assemble the vent pipe lengths as they are lowered

into the masonry chimney. Prior to installing the assembled vent

pipe into the masonry chimney cavity, take careful note to ensure

there are no overhead power lines in close proximity. Lower the

vent pipe into the masonry chimney, with the crimped end entering

the top of the chimney cavity rst.

3. From inside the cavity hold the lower section of the vent pipe in its

approximate position and measure from the centre of the vent pipe

to the centre of the top outlet of the “T” piece. Smear an adequate

amount of silicone onto the slip section of the offset to ensure a

good seal and then adjust the telescopic offset to the centre to

centre measurement from the “T” piece to the vent pipe. Rivet the

offset in three locations around its circumference. (If the offset is

used in its fully compressed form, it will be necessary to modify the

end of the male slip section otherwise it will restrict the internal

diameter) Apply a liberal amount of silicone around the crimped

end of the lower vent pipe, lift the assembled vent pipes up high

enough to allow it to be inserted into the un-crimped end of the

offset, rivet together at 3 even points around the join, then t the

lower crimped end of the offset into the “T” outlet, silicone and rivet

into position.

4. Making your way back onto the roof secure the outer casing with

suitable fasteners and weatherproof seal to the masonry chimney

top with mortar or silicone. A masonry chimney ashing plate is

recommended and will need to be fabricated with an upturn to

secure the 150mm outer casing. Note: The top of the outer casing

must be “level” ( + or - 10mm) with the top of the 100mm stainless

steel vent pipe. Place the 100mm cowl over the vent and screw to

the 150mm casing and secure with S/S screws.

5. Moving back into the home, mark a line 320mm from the front

wall of the re place cavity opening out into the room, this will

give a 28mm gap for the facia to slide into once the pellet re is in

position.

6. Position the rear of the pellet re just out of and to one side of the

opening to allow maximum access, pull the exi pipe out to the re,

smear a liberal amount of silicone inside the pre-bent end of the

exi ue and push over the pellet re outlet then screw in place.

7. Fit the fascia and MX3 controller as per the instructions supplied

with the fascia.

8. Slide the unit back into the cavity until the mark lines up with front

of the base, TAKE CARE NOT TO DAMAGE THE EXHAUST FAN

WHICH PROTRUDES OUT TO THE LEFT.

9. Open the pellet re door drill and t 2 suitable fasteners to x

the unit to the oor, if using masonry fasteners use a rawl bolt or

similar so that the re can slide out over them when the bolts are

removed.

SIDE VIEW

REAR VIEW

A

B

C

E

D

F

H

C

G

D

E

12

Figure 4: Metro Pellet Fire

Insert Surround

USE NUTS

AND BOLTS TO

SECURE HERE

INSERT MX

CONTROL

PANEL HERE

(SECURE WITH

BLACK RIVETS

PROVIDED)

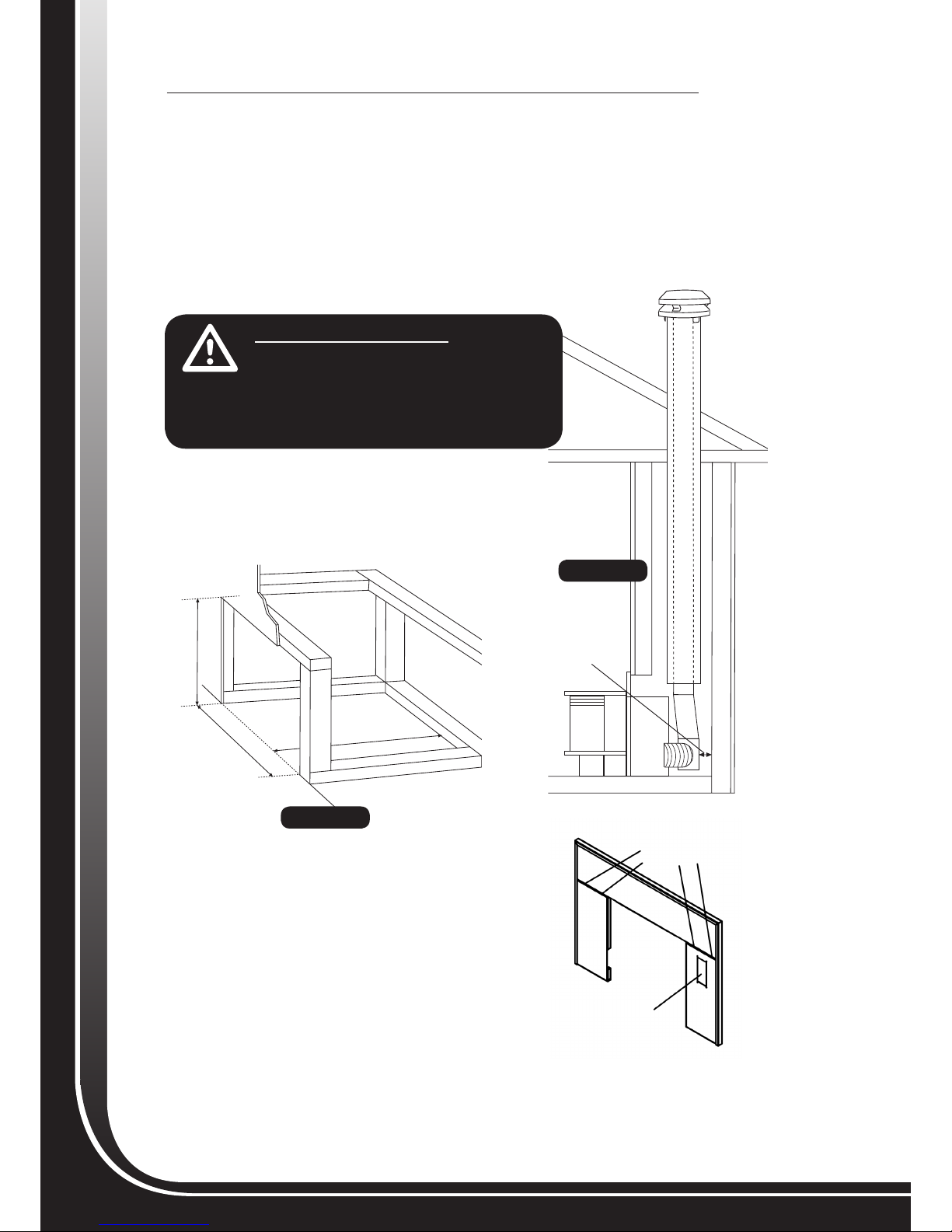

INSTALLING THE METRO PELLET FIRE INTO A TIMBER CAVITY

If the pellet re is being installed into a timber cavity installation,

1. Prepare the cavity opening to the minimum dimensions shown in gure 2 and line with non-combustible

material such as villa board.

2. The 100mm vent pipe must be fully cased with 150mm galvanised casings from the top of the

telescopic offset to the top of the vent pipe exiting the roof. (as shown in gure 3)

• These casings must be supported in position, either attached to the vent pipe, or to the inside of the cavity.

• This installation into a timber framed cavity will require a “Metro Pellet re Insert vent system”,

plus additional lengths of 150mm diameter galvanised casings with centralising brackets.

3. If heat sensitive material (i.e wooden oor)is located below the pellet re an insulated oor protector must

be installed. This oor protector must extend 150mm forward of the ashlip.

Figure 3

Figure 2

575MM

850MM

720MM

130MM MINIMUM

IMPORTANT MESSAGE

• ALL EXPOSED 100MM VENT PIPE INSIDE THE

CAVITY MUST BE A MINIMUM OF 130MM FROM ANY

COMBUSTIBLE MATERIAL.

• THE INSTALLATION OF THIS VENT SYSTEM AND

APPLIANCE IS TESTED AND APPROVED FOR THE

METRO BAY INSERT PELLET FIRE ONLY.

WARNING

WARNING

Fascia Surround

The METRO pellet insert surround can be seen in Figure 4.

The surround comes in 3 separate pieces and needs to be

assembled before being attached to the pellet re. Layout the

top and sides of the surround on the oor as shown in Figure

4. Verify that each side piece mounting holes are aligned

with the top piece mounting holes. Using the supplied nuts

& bolts, secure the side pieces to the top. Mount the MX3™

Control board as shown. Your surround is now ready to

mount to the insert.

13

Metro Pellet Fire Insert Removal

There may be some situations where the METRO pellet insert needs to be removed from the replace; venting

may need to be resealed, regular maintenance performed, etc....

Removal of the METRO pellet re insert from a replace is the reverse of installation with the following

exceptions: make sure the insert is not operating, has had sufcient time to cool down and that power to the

insert has been removed.

Operation and Maintenance

Please refer to the “Pellet Fire Operation” section of this manual for complete instructions on how to operate

your METRO pellet insert. The maintenance of the METRO pellet re insert is the same as the maintenance of a

free standing pellet re. Please read the “Maintenance” section for instructions on cleaning your insert, venting

and other maintenance precautions.

OPERATION – GENERAL OVERVIEW

The rst step in understanding your new METRO pellet re is to familiarize

yourself with its operation. Your pellet re has 3 main systems: Feed,

Combustion and Circulation.

These 3 systems work together to produce enough heat for your room. The

feed system uses an auger to “feed” the pellet fuel into the burn pot. The

combustion system provides the air for the fuel to burn and pushes the

smoke outside through the vent pipes.

The circulation system takes cold air from the room and pushes it through

the heat exchanger where it will warm up and ow back into the room as hot

air. These 3 main systems are all control by the MX3™ control system (see

Figure 5).

Safety features

1. Pressure Switch: This safety device is used to turn the feed off if pressure

is lost in the pellet re.

2. Circulation Fan Override: If your pellet re begins to overheat, this safety

device switches the circulation fan to the highest possible setting to try to

cool your pellet re down to a safe temperature.

3. High Limit/Manual Reset Thermal Disk: If the circulation fan fails to cool

the pellet re down fast enough, this thermal disk will turn the feed off .

This nal safety device guards against your pellet re from overheating. If

this thermal disk trips, the right side panel will need to be opened and the

thermal disk reset. See “Maintenance” and “Troubleshooting” sections for

more information.

Electric Igniter

Your METRO pellet re is equipped with an electric igniter. The electric igniter

is a convenient way of lighting a re in your pellet re without the use of lighter

gels or starter fuels.

Fueling the Hopper

On the free standing pellet re model there is a lid covering the hopper. Pull

up on the handle, as shown in Figure 6 to load the hopper with fuel (the free

standing pellet re can hold up to 20 kgs of fuel). For the insert pellet re

models, remove the cover plate as shown in Figure 7. Load the fuel into the

opening to ll the hopper. The insert pellet re model can hold up to 18 kgs

of fuel.

Figure 6: Free standing

Pellet Fire Hopper Lid

Figure 7: Insert Pellet

Fire Hopper Opening

Figure 5: MX3™ Controller

14

OPERATION – MX3™ CONTROLLER

Basic Description

The MX3™ control is a digital control that uses a computer to control the operation of your pellet re. You should

be familiar with all of the buttons on this control before using your pellet re. Each button and their function are

described here.

“AUTO,HIGH/LOW,MANUAL” Switch

Your pellet re is capable of operating in 3 different modes; “AUTO”, “HIGH/LOW” and “MANUAL”.

Mode Selection Guide

Switch Position Thermostat/Timer

Required Description

MANUAL NO

Relies on a person to press the ON/OFF button located on the control

panel. The pellet re will automatically light.

HIGH/LOW YES

Switches heater from user setting to factory LOW setting based on

wall thermostat, remote control, wall switch or other switching device.

AUTO* YES

Turns Heater ON and OFF based on wall thermostat, remote control,

wall switch or other switching device. Turns Heater ON and OFF based

on wall thermostat, remote

1. “MANUAL” Mode: When used in this mode, your pellet re is controlled from the control panel only. When the

pellet re is in the “MANUAL” mode, the pellet re will not respond to any external switch (i.e. thermostat).

The pellet re will automatically light itself when it is rst turned on. When the “HEAT SELECT” light comes

on, choose the heat setting you want to operate the pellet re at. The pellet re will continue to operate at this

heat setting until you decide to change it or want to turn the pellet re off (by pressing the ON/OFF button).

2. “HIGH/LOW” Mode: With the switch in this position, your pellet re will alternate from a factory preset low

level to the setting you have chosen with the “HEAT SELECT” button (see “HEAT SELECT: Button” section

for more information). This mode is almost exclusively used with an externally wired switch and is highly

recommended since it can create substantial fuel savings. The pellet re will automatically light itself when it

is rst turned on. When the thermostat senses that heat is required, the pellet re will operate at the setting

you have chosen with the “HEAT SELECT” button. When the thermostat is satised, the pellet re goes down

to the factory preset low level.

3. “AUTO” Mode: With the switch in this position, your pellet re will turn itself on and off based on an externally

wired switch. The most common use of this mode is a programmable or non-programmable wall thermostat.

When wired to a thermostat, the pellet re will automatically light itself when the thermostat senses that heat

is required and will automatically turn itself off when the thermostat is satised. This mode can also be used

with a wall switch or remote controls. Consult your local dealer or visit WWW.METROFIRES.CO.NZ for more

information on available options.

“ON/OFF” Button

This button allows you to turn the pellet re on and off. Once pressed, the pellet re will go through a start-up

sequence and the ON/OFF light will blink. During this time, the feed rate is preset and the “HEAT SELECT” button

is disabled. Once the pellet re is warm enough, the “ON/OFF” light will stop blinking and you will be able to

change the heat setting with the “HEAT SELECT” button.

“HEAT SELECT” Button & Bar Graph

There are 5 possible heat settings for your

pellet re. Each setting is indicated in the

bar graph; 1 being the lowest, 5 being the

highest. Pressing the “HEAT SELECT” button

will change the heat setting as indicated

in the bar graph. Each time the button is

pressed, your pellet re will go to the next higher heat level (from 1 to 2, 2 to 3 etc...). Once the heat level reaches

the highest setting (5) and the “HEAT SELECT” button is pressed again, the heat level will return to the low setting

(1). Please note that during the start-up period, the “HEAT SELECT” button is disabled. At some point during the

start-up period, you will be able to set the heat level but the pellet re will not operate at the desired setting until it

IMPORTANT MESSAGE

• DAMPER CONTROL – PLEASE ENSURE

DAMPER IS FULLY OUT FOR SETTINGS 3,4 &

5 AND FULLY IN FOR SETTINGS 1 & 2.

WARNING

15

has warmed up properly. Also, your pellet re will always remember which heat setting was used last and return to

that setting next time the pellet re is turned on (Power failures will result in this setting being lost). Depending on

conditions you may need to adjust the side damper, generally IN for setting 1 and 2, fully OUT for settings 3, 4 and 5.

“AUGER” Button

Your pellet re uses an auger system to feed fuel into the burn pot. When the auger system is working, the

“AUGER” light will be on. During normal operation, this light should blink periodically. Holding the “AUGER”

button will run the auger system continuously. This button should only be used to ll the auger with fuel. Using

this button during normal operation will cause too much fuel to fall into the burn pot and may result in damage to

the pellet re or an unsafe situation.

“FAN” Button

During normal operation of your pellet re, the circulation fan (blows air into the room) speed can only be changed

by changing the heat setting (see “HEAT SELECT” button) The “FAN” button is used to override the factory fan

setting and run the circulation fan on the highest setting. Pressing the “FAN” button again will return the fan to its

original setting.

“TRIM” Button

Not set for use with the Metro Pellet Fires.

Wall thermostat, wall switch or other switching device.

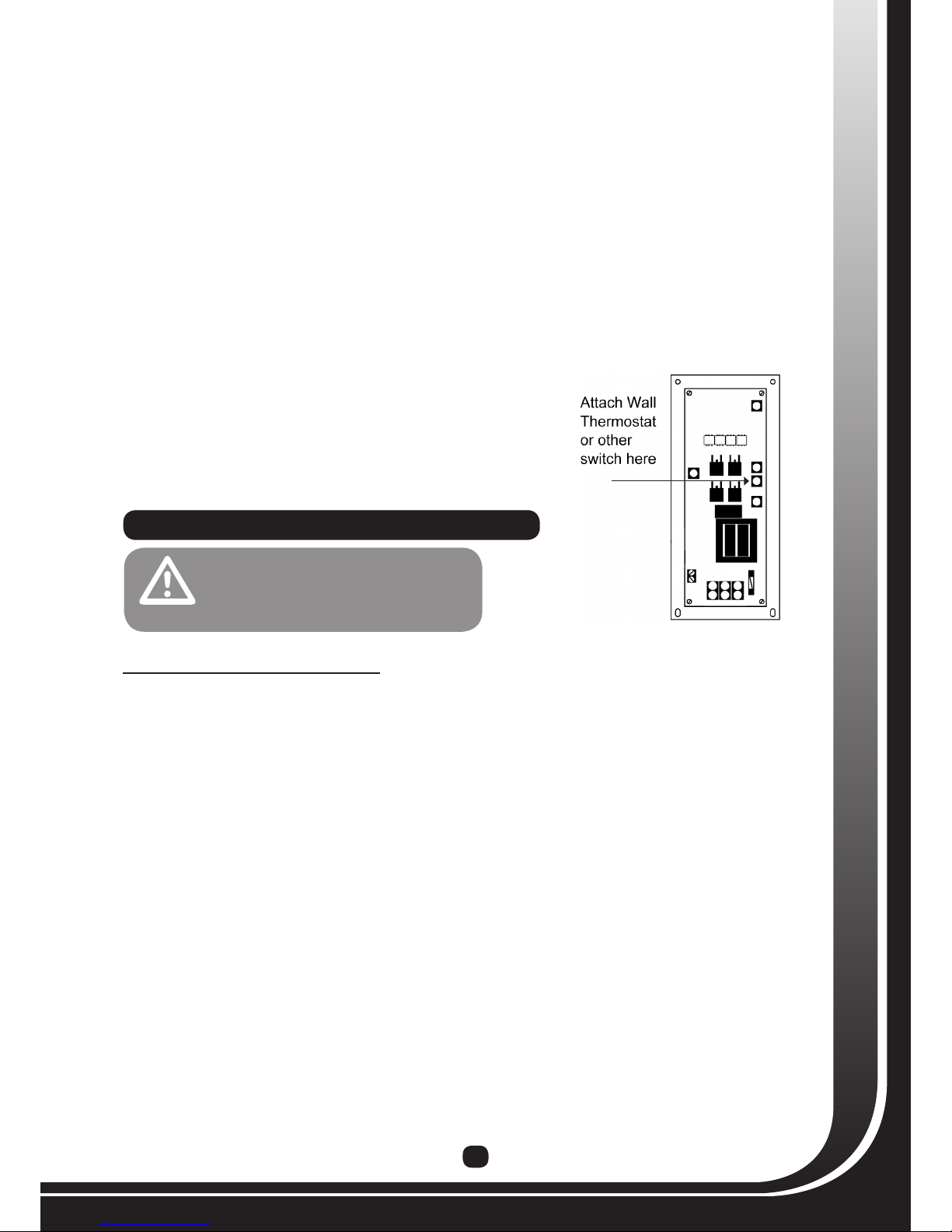

The MX3™ control is capable of using an external switch (such as a

millivolt programmable or non-programmable wall thermostat) to turn

the pellet re on and off. The switch/thermostat must be wired to the

blue terminal block as shown in Figure 8.

Please Note: Thermostat option not available in Canterbury

STARTING YOUR PELLET FIRE

This method applies to all modes of operation (“AUTO, HIGH/LOW, “MANUAL”). For “AUTO” mode, use thermostat

or other switching device in lieu of “ON/OFF” button. Once your pellet re is properly installed, complete the

following steps to start your pellet re:

1. Ensure that there is adequate fuel in the hopper and that all ash gates and doors are closed.

2. Make sure side damper is fully out

3. Press the “ON/OFF” button. The following should happen

a. The “AUGER” and “ON/OFF” light will blink.

b. The exhaust fan will start.

c. The circulation fan will remain off (will come on after the start up cycle when the pellet re reaches

operation temperature.

d. Igniter will come on.

4.

If the auger tube is full with wood pellets, proceed to step 4. If the auger tube is empty, (i.e if this is the rst time

you are starting the pellet re or it has been run out of wood pellets) proceed with the following instructions:

a. Press and hold the “AUGER” button; the “AUGER” light should stay lit until the button is released.

b. Continue to hold the “AUGER” button until fuel begins to drop into the burn pot. This may take several

minutes.

c. Once the fuel begins to drop into the burn pot, this means that the auger tube is full with wood pellets.

Release the “AUGER” button.

d. If the pellet re turns off before the fuel begins to drop into the burn pot, press the “ON/OFF” button to

restart the pellet re. Repeat steps a-c.

5. After the fuel begins to drop into the burn pot it takes about 5-8 minutes for a ame to appear. Allow the

ame to stabalize for 15 minutes

6. Adjust the heat setting as desired (see “MX3™ Control” section).

7. If the pellet re shuts OFF during the start up cycle and there is still a ame, press the “ON/OFF” button again.

• TO PREVENT INJURY OR DAMAGE TO

THE PELLET FIRE, ALWAYS UNPLUG

THE PELLET FIRE FROM THE POWER

OUTLET BEFORE SERVICING.

CAUTION

Figure 8: Wall thermostat terminals

16

Stopping your Pellet Fire

To stop your pellet re, simply press the “ON/OFF” button (for “AUTO” mode, switch the thermostat or other

switching device to “OFF”). This will cause the feed system to stop (the “AUGER” light will stop blinking) and the

ame should die out within 5 minutes. The exhaust fan and circulation fan will continue to run until you pellet re

is cold (approximately 30 minutes). DO NOT turn OFF electrical power to stop the pellet re, as this may result in

your pellet re overheating.

IMPORTANT MESSAGE

• DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS TO START OR REKINDLE THE FIRE.

• DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHEN IT IS OPERATING.

• MAKE SURE THE AMOUNT OF FUEL IN THE BURN POT DOES NOT EXCEED THE HEIGHT OF THE BURN

POT AT ANY POINT DURING OPERATION. THIS CAN CAUSE SEVERE DAMAGE TO YOUR PELLET FIRE.

• DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS SUCH AS GASOLINE, NAPHTHA OR ENGINE OIL

• THE PELLET FIRE IS HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS.

WARNING

MAINTENANCE & CLEANING

During normal operation, your pellet re produces a lot of yash. This yash will collect in the vent pipes and

inside your pellet re and restricts the ow of the ue gases. Improper maintenance leads to poor performance,

component failure and can be dangerous. Please adhere to the following maintenance schedule :

Before each heating season:

1. Clean the venting system. If there is a signicant amount

of soot build up, it should be removed to prevent the risk

of a chimney re. By making sure the exhaust venting

system and the pellet re itself are being maintained

properly and are cleaned on a regular basis, you reduce

the likelihood of a chimney re occurring.

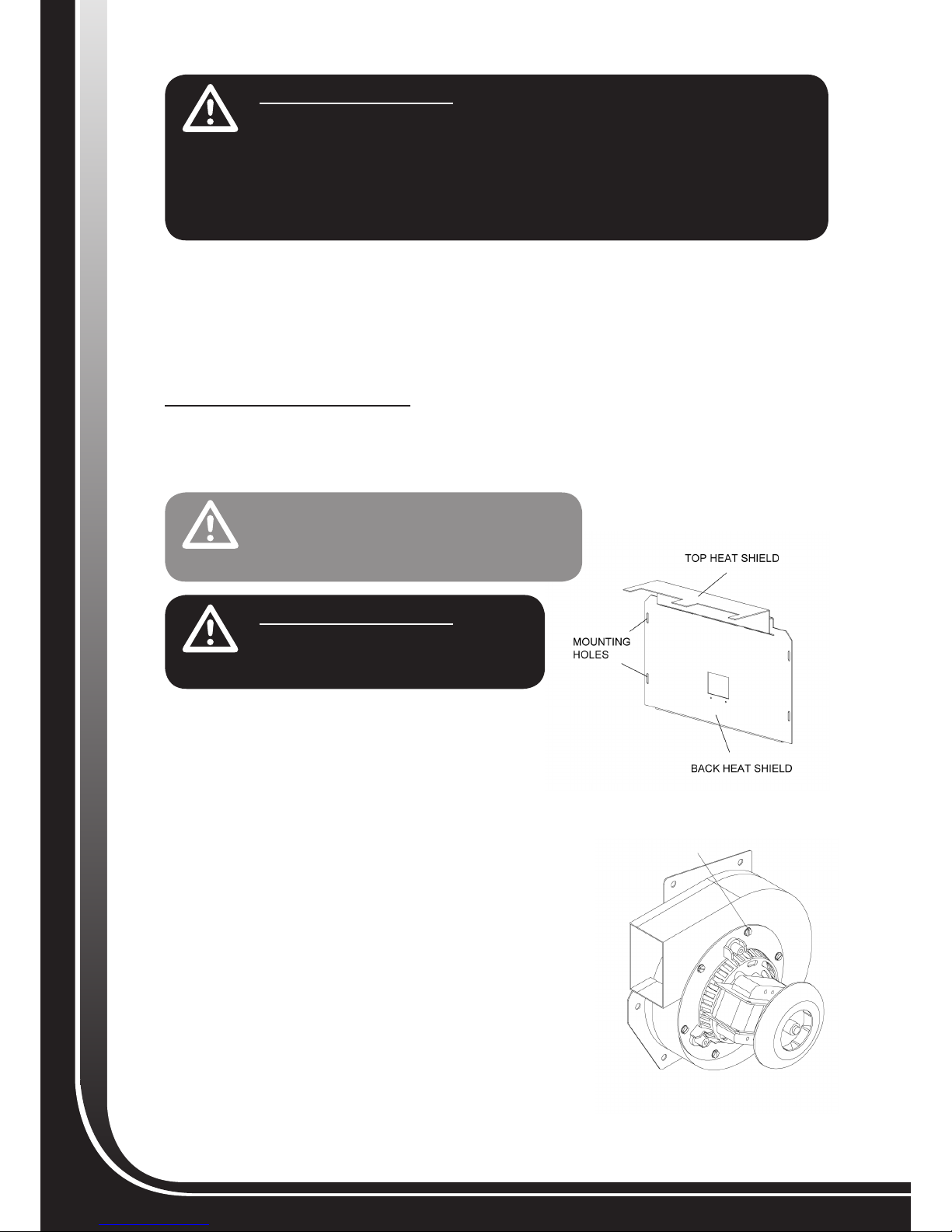

2. Clean behind the back heat shield as well as all exhaust

passages. Ashes can build up behind the back heat shield

and inside the exhaust passages.

To remove the back heat shield you must remove 4 bolts

located at each corner of the heat shield. On some models

the side heat shields must rst be removed by removing the 2

bolts holding them in place. Using a brush, remove all of the

ashes that have built up on the back wall of the combustion

chamber, on the inside of the heat shield as well as in the

exhaust passage. Inspect the auger chute gasket at this time.

Make sure the gasket is still in good condition and that it is in

the original position when the back heat shield is bolted back

into position. Make sure to clean behind the back heat shield

after every 3 tons of fuel burned.

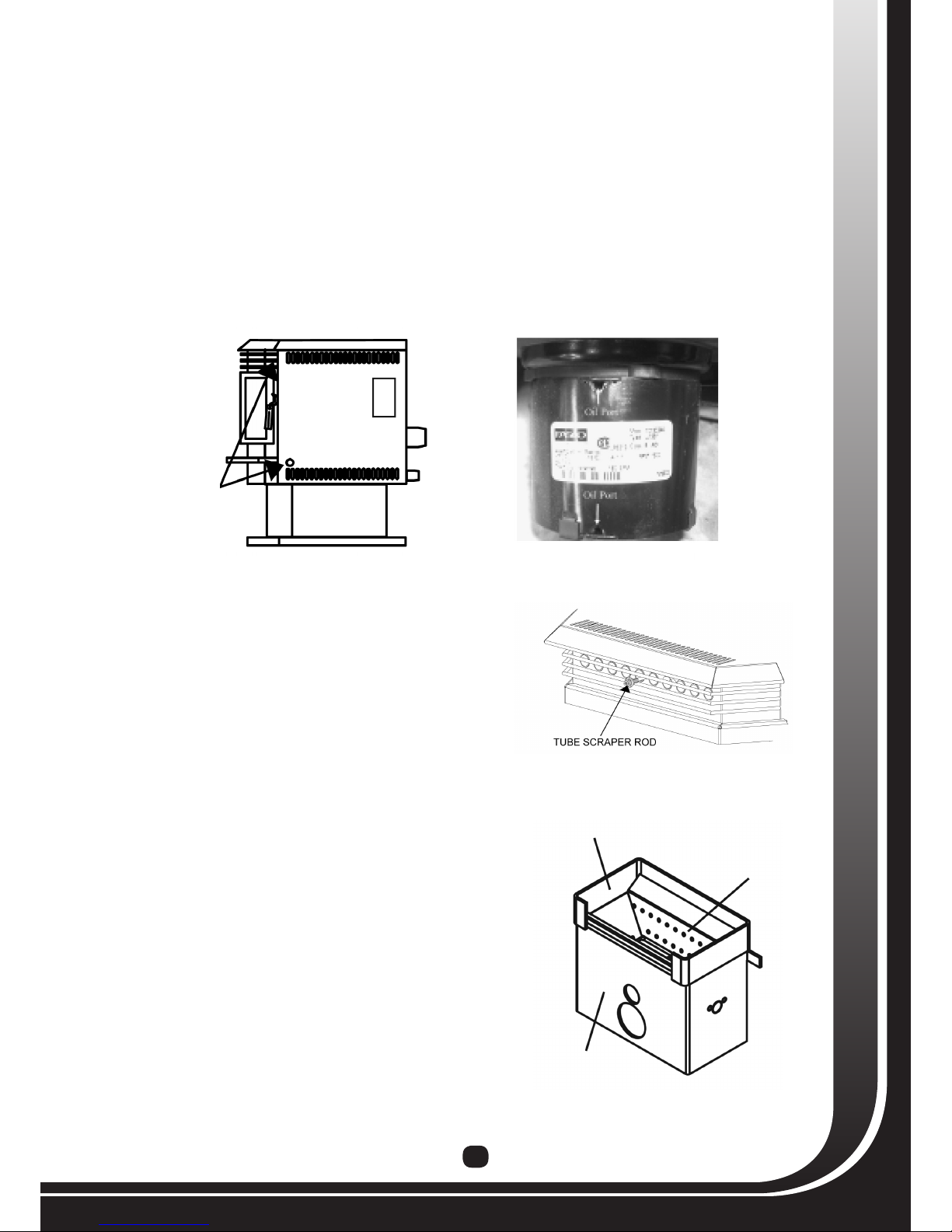

Figure 10: Exhaust fan housing

Figure 9: Heat Shield

• DO NOT USE ABRASIVE CHEMICALS TO CLEAN THE

PELLET FIRE AND/OR LABELS PLACED ON THE

PELLET FIRE. THESE CHEMICALS CAN DAMAGE BOTH

THE PAINT AND LABELS ON THE PELLET FIRE.

CAUTION

IMPORTANT MESSAGE

• ALLOW THE PELLET FIRE TO COOL TO ROOM

TEMPERATURE AND UNPLUG THE PELLET FIRE

BEFORE PERFORMING ANY MAINTENANCE.

WARNING

REMOVE THESE

SCREWS

17

3. Clean the exhaust fan and housing. Ash accumulation on the fan blades will reduce the life of your exhaust

fan. Frequent cleaning will help extend the life of this component. Open the left side panel to access the

exhaust fan. Using a Common (at head) screw driver, remove the 6 sheet metal screws holding the fan motor

to the housing (See Figure 10). Using a brush, clean all ash from the exhaust fan blades and housing.

4. Inspect the condition of the door gasket periodically and replace it as necessary. It is important to make

sure the door gaskets are in good condition. Gaskets in poor condition will not allow the door to seal properly

and the pellet re will not function as efciently.

5. Oil the circulation fan motor. To oil the motor bearings, the right hand side panel must rst be opened. This

is done by removing the 2 screws near the front of the pellet re as shown in Figure 11. Use a square head

or Phillips screwdriver to remove the screws. You will now be able to swing the panel open and access the

circulation fan. There are 2 oil ports located on the top of the motor, one near the end and one near the fan

housing as shown in Figure 12. There may be rubber plugs in one or both of these oil ports. These plugs must

be removed prior to and replaced after oiling. Place a few drops of light oil, such as sewing machine oil, in

each port.

6. Perform weekly maintenance.

1. Pull and push the tube scraper rod located in the center,

above the door (See Figure 13). This will remove the ash

deposits on the heat exchanger tubes. The removed ash will

fall on the top heat shield, located in the burn chamber.

2. Lift the top heat shield and remove it carefully as there may

be a signicant amount of ash on it. Using a brush, clean the

top heat shield and dump the ashes into the burn chamber.

3. Clean the burn pot assembly (Figure 14) thoroughly. Lift the

splash guard up off of the burn pot assembly and remove.

Lift the burn pot out of the burn pot stand. Remove any

ashes that have built up inside of the burn pot and make

sure that all of the holes are clear of ashes and debris. Lift

up on the burn pot stand and pull towards you to remove.

Make sure there are no ashes remaining in the burn pot

stand. Failure to do so can be a re hazard. Place all ashes

into a metal container with a tight tting lid.

4. Using the brush, clean the walls and oor of the burn

chamber.

5. If your unit is equipped with the large ashtray, open the

ashtray slightly and pull on each ash gate (Figure 15) until

the ash falls from the burn chamber into the ashtray. Do

not pull the ash gates too far as they may fall out. Sweep

remaining ashes into the ashtray. For models with no

ashtray, scoop out the ashes into a metal container with a

tight tting lid.

Figure 11: Holes for screws on thr right side panel Figure 12: Oil ports on a circulation fan

REMOVE THESE SCREWS TO

OPEN THE SIDE PANEL

Figure 13: Tube scraper rod to clean the heat

exchanger pipes

Figure 14: Burn pot stand assembly

SPLASH GUARD

BURN POT

BURN POT STAND

18

6. Close the ash gates (if equipped) and remove the

ashtray. Dispose of the ashes in a safe manner.

If the ashes are stored in a container, make sure

the lid is secure. DO NOT place the container on

a combustible surface. Replacement of ashtray is

reverse of removal.

NOTE: Ashes should be placed in a metal container with a tight

tting lid. The closed container of ashes should be placed on

a noncombustible oor or on the ground, well away from all

combustible materials, pending nal disposal. If the ashes are

disposed of by burial in soil or otherwise locally dispersed,

they should be retained in the closed container until all

cinders have been thoroughly cooled. Do not place any other

waste materials in this container.

7. Empty out the hopper once every 2 weeks. Vacuum

all the sawdust build up in the hopper and auger

chute opening.

8. Reinstall all removed parts to their original positions.

9. Clean the glass with a mild glass cleaner when dirty. DO NOT clean the glass when the door is hot. This is

very important to see if the pellet re is burning properly or not. DO NOT hit the glass or slam the door shut.

This may cause the glass to crack or break. DO NOT operate the pellet re if the glass is cracked or broken.

DO NOT replace the glass with any type of glass other then an APR Industries Ltd. factory approved glass. If

the glass cracks or breaks, turn the pellet re OFF. DO NOT operate the pellet re until the glass has been

replaced.

NOTE: Depending on the type of fuel you use and the frequency that you use the pellet re, you may need to clean the pellet re

more frequently.

After each heating season:

1. Remove all the pellet fuel from the hopper. Run the pellet re to empty the auger tube. Vacuum the hopper

and auger tube. Clean the rest of the pellet re.

2. Open up both side panels and clean out any pellets, dust, ashes or debris that may have built up in the back of

the pellet re. Once at the back of the pellet re is cleaned, close both side panels.

Figure 15: Ash gates for a Metro pellet fire

ASH DOOR GATES

19

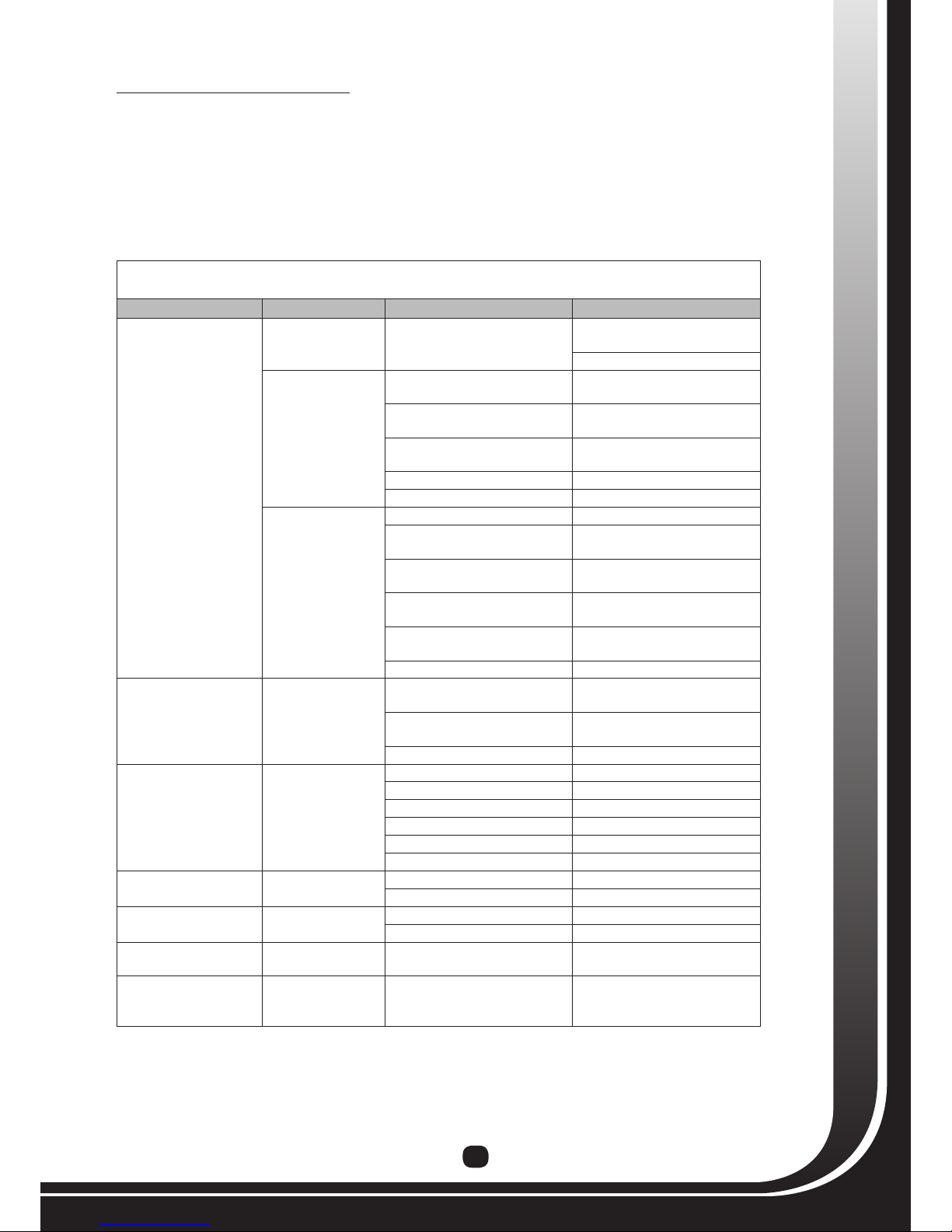

TROUBLESHOOTING GUIDE

Troubleshooting

Your METRO pellet re is equipped with a diagnostic light feature. When a problem occurs, the heat setting bar

graph will light up to indicate where the problem may be.

Each light has been numbered for easy identication. The chart below has been included to help you determine

which corrective action should be taken. A complete description of each corrective action is included in the

following pages of this manual. Some problems, such as ame problems, will not cause the diagnostic lights to

light up.

MX3™ Control Trouble Shooting Guide

Problem Light Status Possible Causes Remedy

Heaterwillnot

feed pellets

All lights off No power.

Check to see if heater is plugged

in.

Check electrical outlet for power.

#2 light blinks

(Pressure system

failure)

Exhaust vent and exhaust fan are

blocked

Clean exhaust venting and

exhaust fan.

Exhaust passage and exhaust box

pressure tap are blocked.

Clean exhaust passage and

pressure tap.

Pressure switch tube is cracked

or broken Replace pressure switch tube.

Pressure switch has failed. Replace pressure switch.

Exhaust fan has failed. Replace exhaust fan.

#3 light blinks

(Proof of ame

failure)

Hopper is empty. Fill hopper with fuel.

Manual reset thermal disk has

tripped.

Reset the manual reset thermal

disk.

Manual reset thermal disk has

failed.

Replace the manual reset

thermal disk.

Exhaust fan thermal disk has

failed. Replace exhaust fan thermal disk.

Auger jam. Empty hopper and clean out

auger

Auger motor has failed. Replace auger motor.

Stovewon’tturnoff. Normal

Exhaust fan thermal disk has

failed. Replace exhaust fan thermal disk

Stove in “Cool Down” mode. Allow sufcient time for the stove

to cool down.

MX Control board has failed. Replace MX Control Board

Stovewillnotlight Normal

No pellet fuel. Add fuel to hopper.

Burn pot dirty. Clean burn pot.

Fuse blown. Replace fuse

Igniter slipped out of igniter tube. Push igniter back into place.

Igniter has failed Replace igniter.

No power to igniter. Replace MX Control Board

Fuelpilesup. Normal Burn pot dirty. Clean burn pot.

Poor quality fuel. Change fuel supplier.

Short flame on high feed Poor quality fuel. Change fuel supplier.

Heat exchanger requires cleaning Clean heat exchanger.

Too large and dark

orange flame Poor quality fuel. Change fuel supplier.

Smell of smoke

in the room Normal The pellet venting joints not

sealed properly.

Seal all joints with high

temperature RTV siliconne

sealant.

20

Corrective Actions

Proof of Flame Failure

1. Verify that there is sufcient fuel in the hopper and that the pellet re has run for long enough to ll the auger

tube. (See “Starting (lighting) your Pellet Fire for the First Time” section)

2. Verify that the auger has not jammed. Occasionally, fuel can become lodged in the auger and prevent the

auger’s proper operation. Open one of the side panels and grasp the auger motor. Move the auger motor back

and forth. It may be difcult to move at rst but should move relatively freely. If it will not move, empty the

hopper and look for foreign objects in the auger.

3. Verify that the auger motor is working. Plug the pellet re in. Without lighting a re, start the pellet re. Verify

that the white plastic fan on the auger motor is turning. If it does not turn, check for power at the auger motor

and replace the auger motor as necessary. Remember to unplug the pellet re before attempting any service.

4. Verify that the auger is properly secured to the motor. Empty the hopper and locate the auger bolt

(approximately 1/4” square heat) on the auger. Remove the bolt and make sure the hole is aligned with the at

portion of the auger motor shaft. Reinstall the bolt and tighten.

5. Check the manual reset thermal disk. If the manual reset thermal disk has tripped, you will need to reset it.

6. If none of the above resolve your problem, contact your local METRO dealer.

Pressure Switch Failure

1. Verify that all doors, ashtrays and ashgates are properly closed and well sealed. If any leakage is present,

replace appropriate gaskets.

2. Verify that the pellet re is clean. Clean all venting and exhaust passages in the pellet re. Refer to

“Maintenance” section for more information on cleaning your pellet re.

3. Verify that the pressure switch tube is not cracked or loose. Replace as required. Also verify that the pressure

port on the pellet re is clean.

4. Verify that the exhaust fan is in good working condition. When you start your pellet re you should hear the

exhaust fan start instantaneously. If the exhaust fan is not working, check for power at the exhaust fan and

replace the exhaust fan as necessary. Remember to unplug the pellet re before attempting any service.

5. Verify that the pressure switch is working properly. Apply a slight vacuum to the pressure switch tube. The

pressure switch should “click” when a vacuum is applied. Replace as necessary. Note: Pressure Switches

rarely fail.

6. If none of the above resolve your problem, contact your local METRO dealer.

Manual Reset Thermal Disk Failure

The manual reset thermal disk is a safety device to prevent the pellet re from overheating. This thermal disk will

trip when the body of the pellet re reaches a certain temperature. This section will describe the possible reasons

for the pellet re to overheat.

1. The circulation fan may have failed. Verify that the circulation fan is in good working condition. Start your

pellet re by pressing the ON/OFF button. Allow the pellet re to go through it’s normal start up cycle. Once

the pellet re has nished it’s start up cycle, the circulation fan should come on. Cycle through each setting by

pressing the Heat Select button. The fan should operate faster at the higher Heat Select settings.

2. The circulation fan override thermal disk may have failed. Verify that the circulation fan override thermal disk

is working properly.

3. The manual reset thermal disk itself may have failed. Verify that the manual reset thermal disk is working

properly.

4. If your Manual Reset Thermal Disk is continuously tripping, contact your local METRO dealer.

IMPORTANT MESSAGE

• BEFORE PERFORMING ANY SERVICE, MAKE SURE THE PELLET FIRE IS COLD AND UNPLUGGED. DO

NOT UNPLUG THE PELLET FIRE WHILE THE PELLET FIRE IS OPERATING OF IF THERE IS A FLAME.

WE STRONGLY RECOMMEND USING QUALIFIED SERVICE PEOPLE.

WARNING

This manual suits for next models

1

Table of contents

Popular Pellet Stove manuals by other brands

Centrometal

Centrometal PelTec 12 Technical instructions

Extraflame

Extraflame VIVIANA EVO user manual

RIKA

RIKA Memo operating manual

Ariterm

Ariterm MYSINGE Installation and operating instructions

calimax

calimax Solida operating instructions

Stanley

Stanley FUSION PELLET STOVE Operating & installation manual

Sierra Products

Sierra Products EF-5001UB Installation & operating instructions

Harman

Harman PC45 Installation & operating manual

England's Stove Works

England's Stove Works 25-PI Installation & operation manual

Ariterm

Ariterm EKERUM Installation and operating instructions

Heatilator

Heatilator ECO CHOICE ECO-ADV-PS35 installation manual

IronStrike

IronStrike Cascade Installation and operation manual