Metronic DL7 Series User manual

DL7, DL7L

MULTICHANNEL ELECTRONIC

DATA LOGGER

OPERATING MANUAL

Version: 210705EN

DL7, DL7L

2

Information from the Manufacturer

MODBUS® is a registered trademark of Modbus Organization, Inc., North

Grafton, MA 01536 USA

Before installation, carefully read all the instructions, especially those concerned

with Environment, Health and Safety (EHS).

The recorder has been manufactured according to the requirements of relevant

EU directives.

These instructions must be stored in a safe place near the installation of the

device at all times.

All functions of the recorder are subject of modifications for the benefit of

technical progress.

DL7, DL7L

3

TABLE OF CONTENTS

1SAFETY INFORMATION AND INSTRUCTIONS .....................................................7

2DELIVERY CONTENT, ACCESSORIES AND STORAGE.....................................10

2.1 Basic components DL7 ...............................................................................10

2.2 Basic components DL7L .............................................................................10

2.3 Storage...........................................................................................................10

2.4 Accessories (optional)....................................................................................10

3GENERAL PRODUCT OVERVIEW........................................................................11

3.1 Purpose..........................................................................................................11

3.2 Basic functions...............................................................................................11

3.3 Software for PC..............................................................................................12

3.4 Available options DL7 / DL7L.........................................................................13

3.5 Device configuration.......................................................................................13

3.6 Galvanic separation in the device ..................................................................14

4AVAILABLE I/O MODULES...................................................................................15

4.1 Base set.........................................................................................................15

4.2 IN6I(24V) –six channel 0-20mA or 4-20mA input type module......................15

4.3 IN6I –six channel 0-20mA or 4-20mA input type module ..............................15

4.4 IN6RTD (IN3RTD) –six (three) channel RTD / R input type module .............15

4.5 IN6TC –six channel mV type input module ...................................................16

4.6 IN6V –six channel voltage type input module................................................16

4.7 IN3 –three channel universal type input module ...........................................16

4.8 IN6D –six channel binary inputs module.......................................................16

4.9 2RS485(24V) –two RS485 port input module (Modbus RTU Master)...........17

4.10 2RS485 –two RS485 port input module (Modbus RTU Master)....................17

4.11 1HRT –HART (4-20 mA) port input module...................................................17

4.12 OUT6RL –six channel relay outputs module.................................................17

4.13 OUT3 –three channel analogue outputs module...........................................18

4.14 PSBATT –module for operation with a back-up battery ................................18

5MECHANICAL INSTALLATION.............................................................................19

5.1 Mechanical installation of DL7 device ............................................................19

5.2 Mechanical installation of DL7L device ..........................................................20

6ELECTRICAL INSTALLATION ..............................................................................21

6.1 Power supply connection (module M)............................................................22

6.2 I/O modules –wiring diagrams (slot A, .., G)..................................................22

6.2.1 IN6I(24V) –six channel 0-20mA or 4-20mA input type module...............22

DL7, DL7L

4

6.2.2 IN6I –six channel 0-20mA or 4-20mA input type module........................23

6.2.3 IN6RTD –six channel RTD / R input type module...................................24

6.2.4 IN3RTD –three channel RTD / R input type module...............................25

6.2.5 IN6TC –six channel mV type input module.............................................25

6.2.6 IN6V –six channel voltage type input module.........................................26

6.2.7 IN3 –three channel universal type input module.....................................27

6.2.8 IN6D –six channel binary inputs module.................................................29

6.2.9 2RS485(24V) –two RS485 port input module (Modbus RTU Master) ....30

6.2.10 2RS485 –two RS485 port input module (Modbus RTU Master).............31

6.2.11 1HRT –HART (4-20 mA) port input module............................................32

6.2.12 OUT6RL –six channel relay outputs module ..........................................33

6.2.13 OUT3 –three channel analogue outputs module....................................33

6.2.14 PSBATT –back-up battery module.........................................................35

6.3 Wiring diagrams for module M .......................................................................37

6.3.1 Connection of RS-485 data transmission line..........................................37

6.3.2 Ethernet port............................................................................................37

7FRONT PANEL AND MAIN FUNCTION BUTTONS ..............................................38

7.1 Front panel.....................................................................................................38

7.1.1 Title bar....................................................................................................39

7.1.2 Menu bar .................................................................................................39

8FIRST START UP AND KEY ACTIVITIES .............................................................40

8.1 Access control, login and change of user password ......................................40

8.1.1 Access control.........................................................................................40

8.1.2 Login........................................................................................................40

8.1.3 Changing the password...........................................................................41

8.2 Change of the language.................................................................................41

8.3 Recommended order for configuration of the device......................................41

8.4 Reading and saving files using the USB port.................................................43

8.5 Factory settings..............................................................................................44

9TECHNICAL SPECIFICATIONS.............................................................................45

10 ENTITY LAUNCHING THE PRODUCT ON EUROPEAN UNION MARKET..........53

11 USER SCREENS....................................................................................................54

11.1 Information about the device..........................................................................54

11.2 Results Tables ...............................................................................................55

11.3 Trends............................................................................................................55

11.4 Single result window ......................................................................................56

DL7, DL7L

5

11.5 Archive...........................................................................................................57

11.5.1 View Archive............................................................................................58

11.6 Main Menu .....................................................................................................61

11.7 Alarms............................................................................................................62

12 PROGRAMMING SETTINGS .................................................................................63

12.1 General settings.............................................................................................63

12.1.1 General....................................................................................................63

12.1.2 Display.....................................................................................................64

12.1.3 Date & Time.............................................................................................64

12.1.4 Service.....................................................................................................65

12.2 Input and output settings................................................................................65

12.2.1 Programming options for the individual modules.....................................66

12.3 Communication settings.................................................................................71

12.3.1 Ethernet port............................................................................................71

12.3.2 E-mail ......................................................................................................71

12.3.3 Modbus TCP (Client)...............................................................................73

12.3.4 RS-485 port.............................................................................................74

12.4 Channels settings...........................................................................................74

12.4.1 Inputs.......................................................................................................75

12.4.2 General....................................................................................................76

12.4.3 Alarm.......................................................................................................77

12.4.4 Totalizers.................................................................................................78

12.5 Screen settings ..............................................................................................79

12.5.1 Results Tables.........................................................................................79

12.5.2 Trends .....................................................................................................80

12.6 Archive settings..............................................................................................80

13 ARCHIVE................................................................................................................82

13.1 Start, resume and stop archiving....................................................................82

13.2 Archive settings..............................................................................................82

13.3 Archive files types..........................................................................................82

13.4 Way of creating an archive file.......................................................................82

13.5 Time interval of archiving data .......................................................................82

13.6 Archive files organization ...............................................................................83

13.6.1 Data archive ............................................................................................83

13.6.2 Totalizer archive......................................................................................84

13.6.3 Event archive...........................................................................................84

DL7, DL7L

6

13.7 Copying archive files from the device.............................................................85

13.7.1 Copying archive files to USB flash memory.............................................85

13.7.2 Copying archive files using device web server........................................85

14 ADDITIONAL FUNCTIONS ....................................................................................86

14.1 Additional channel functions...........................................................................86

14.1.1 Math channels.........................................................................................86

14.1.2 User characteristics.................................................................................87

14.1.3 Copying channel settings ........................................................................88

14.2 Print screen....................................................................................................88

14.3 Change the background colour......................................................................89

14.4 Web server.....................................................................................................89

14.5 Software for PC..............................................................................................91

14.5.1 DL7 Config...............................................................................................91

14.5.2 DL7-RP (DL7-RPplus).............................................................................91

15 FAILURE SYMBOLS..............................................................................................94

15.1 Failure symbols for 1HRT module..................................................................94

16 MODBUS RTU / MODBUS TCP TRANSMISSION PROTOCOL ...........................95

16.1 General information........................................................................................95

16.1.1 Data types ...............................................................................................95

16.2 Registers addresses ......................................................................................95

16.2.1 Addresses table of Process values..........................................................95

16.2.2 Addresses table of Totalizer 1.................................................................96

16.2.3 Addresses table of Totalizer 2.................................................................96

DL7, DL7L

7

1 SAFETY INFORMATION AND INSTRUCTIONS

Safe operation of this product can only be guaranteed if it is properly installed,

commissioned, used and maintained byqualified personnel in compliance with the operating

instructions. General installation and safety instructions for pipeline and plant construction,

as well as the proper use of tools and safety equipment must also be complied with.

Symbols

Equipment is protected throughout by double insulation or reinforced

insulation.

Functional earth (ground) terminal, to enable the product to function

correctly. Not used to provide electrical safety.

Caution, risk of electric shock.

Caution, risk of danger, refer to accompanying documentation.

Caution, Electrostatic Discharge for sensitive circuit. Do not touch or

handle without proper electrostatic discharge precautions.

!

Important comments and information.

Warning

This product is designed and manufactured to withstand the forces encountered during

normal use. Use of the product contrary to its intended purpose or incorrect installation of it,

any type of modifications or repairs incompatible with the following instructions could:

cause damage to the product/property,

cause injury or fatality to personnel,

void the warranty of product,

invalidate the marking.

!

Always isolate the mains supply before opening the product as hazardous

voltages may be exposed.

DL7, DL7L

8

Warning

This product complies with the requirements of the following directives and harmonized

standards:

EMC Directive 2014/30/EC to the following standards and specifications:

For EMC immunity for industrial environments according to EN 61326-1:2013 (Table 2).

For EMC conductive and radiated emissions according to EN 61326-1:2013

Class A equipment.

The product may be exposed to interference above the limits of EN 61326 if:

The product or its wiring is located near a radio transmitter.

Excessive electrical noise occurs on the mains supply. Power line protectors (AC) should

be installed if mains supply noise is likely to happen. Protectors can combine filtering,

suppression, surge and spike arresters.

Cellular telephones and mobile radios may cause interference if used within

approximately 1 metre (39") of the product or its wiring. The actual separation distance

necessary will vary according to the surroundings of the installation and the power of the

transmitter.

Warning

This device is an Class A type instrument. In operational environment, it may cause

radio interference. In such cases, one can request to the users for appropriate measures to

avoid it.

Intended use

Check that the product is suitable for use with the application.

Determine the correct installation and physical situation.

Prior to installation of Metronic AKP products, take into account any environmental

limitations of devices, specified in the manual.

Access

Ensure safe access and if necessary a safe working platform (suitably guarded) before

attempting to work on the product.

Lighting

Ensure that there is adequate lighting, particularly where detailed or complicated work

is required.

Hazardous environment around the product

Consider: explosion risk areas, lack of oxygen (e.g. tanks or pits), dangerous or harmful

gases, extremes of temperature, hot surfaces, fire hazards (e.g. during welding), excessive

noise, moving machinery.

The system

Consider the effect on the complete system of the work proposed. Will any proposed

action put any other part of the specific system or any personnel at risk?

Dangers might include isolation of vents or protective devices or the rendering ineffective

of controls or alarms.

DL7, DL7L

9

Tools and consumables

Before starting work ensure that you have suitably required tools and/or consumables

available at the work place.

Protective clothing

Consider whether you and/or others in the vicinity require any protective clothing to

protect against the hazards of, for example, chemicals, high / low temperature, radiation,

noise, falling objects, and dangers to eyes and face.

Permits to work

All the work must be carried out or be supervised by a suitably competent person.

Installation and operating personnel should be trained in the correct use of the product

according to the Installation and Maintenance Instructions. Where a formal 'permit to work'

system is in force it must be complied with. Where there is no such system, it is

recommended that a responsible person should know what work is going on and, where it

is necessary, arrange to have an assistant whose primary responsibility is safety.

Post 'warning notices' if it is necessarily required.

Cleaning and maintenance

Metronic AKP products require no maintenance beyond periodic battery replacement.

Expected battery life is 10 years after the expiry of which must be returned to the

manufacturer for a replacement.

From time to time you should clean the casing with a dry, soft cloth. When cleaning, do

not use solvents or abrasives. They may cause discoloration or scratch the surfaces of the

device.

Disposal

The DL7 / DL7L contains a battery. On disposal of the unit or component, appropriate

precautions shall be taken in accordance with Local/National regulations.

Unless otherwise stated in the Installation and Maintenance Instructions, with the

exception of the battery, this product is recyclable and no ecological hazard is anticipated

with its disposal providing due care is taken.

Returning products

Customers are reminded that under EHS regulations, when returning products to

Metronic AKP they must provide information on any hazards and the precautions to be taken

due to contamination residues or mechanical damage which may present an Environment,

Health and Safety (EHS) risk. This information must be provided in writing including Health

and Safety data sheets relating to any substances identified as hazardous or potentially

hazardous.

DL7, DL7L

10

2 DELIVERY CONTENT, ACCESSORIES AND STORAGE

Prior to dispatch, each Metronic AKP device is inspected and calibrated to ensure

proper and efficient operation.

CAUTION

Upon receipt, each package should be inspected for any potential damage.

The content of the whole package should be checked and the actual number of elements

should be compared with the manufacturer's list of items presented in the consecutive

subsection. In the case of damage or lack of elements, a report should be drawn up in the

presence of the carrier specifying the date of receipt and signature of the person delivering

the package.

2.1 Basic components DL7

The DL7 Data Logger configured to individual customer's order 1 pc.

A set of plug-in type screw connection 1 set

Fixing clamp 4 pc.

Seal (assembled between case and panel) 1 pc.

Warranty Card 1 pc.

Certificate of Calibration 1 pc.

2.2 Basic components DL7L

The DL7L Data Logger configured to individual customer's order 1 pc.

A set of plug-in type screw connection 1 set

Warranty Card 1 pc.

Certificate of Calibration 1 pc.

2.3 Storage

If the device is to be stored because it is not used for a period of time, the required

storage conditions must be observed prior to assembly. The device should be kept in

ambient temperature range from -30 °C to 70 °C at the relative humidity at 5% to 95% (non-

condensing).

Prior the installation and connecting the device to the power supply make sure that there

is no condensate water inside the device.

2.4 Accessories (optional)

CONV485E

CONV485USB-I

CONV485USB

Power supply unit

USB flash drive

DL7, DL7L

11

3 GENERAL PRODUCT OVERVIEW

3.1 Purpose

DL7 / DL7L is a multi-channel microprocessor-based measuring device with

electronically recorded measurement results. The device is intended to measure process

signals in industrial applications and may be used to measure physical values processed

into a standard current loop signal 0-20mA or 4-20mA, e.g. temperature, humidity, pressure,

flow, level and chemical composition, etc. The device is perfectly suited for slow rate variable

runs with changes at a few seconds intervals. Process values recording and flexible I/O

configuration, makes the data logger suitable for monitoring parameters in warehouse

settings or in the supervision of production lines. The device has math channels that enable

selected mathematical operations on the measured values, according to the formulas

entered by the user. The user configurable display and browse functions makes the device

suitable for use as a paper-less electronic logger. The device may be connected to a PC or

plant control system via Ethernet or RS-485 communication ports.

Each device is provided with a basic module and can be extended with an additional I/O

modules. Details are provided in section AVAILABLE I/O MODULES.

The device is supplied with 24 VDC source. Detailed information concerning the power

supply is given in consecutive parts of the document, in section Power connection.

3.2 Basic functions

100 programmable channels

The device enables setting up to 100 freely programmable channels. For each of them

the current, the maximum and the minimum value of the channel is displayed.

Measurement of the process values

Depending on the needs, the device may be provided with up to 42 measurement

inputs/outputs. The read values can be assigned to channels and archived.

Remote reading transmitter in the HART protocol

If seven 1HRT modules are installed, then the device enables remote reading of up to

100 values in the HART protocol. For one module, up to 25 values can be read. It is possible

to read the variables PV, TV, SV, FV and DVC. The read values can be assigned to channels

and archived.

Remote reading transmitter with digital output Modbus RTU

If four 2RS485(24V) or seven 2RS485 modules are installed, then the device enables

remote reading of up to 100 values (Modbus RTU protocol). For one module, up to 25 values

can be read. The read values can be assigned to channels and archived.

Remote reading transmitter with digital output Modbus TCP (Client)

The device enables remote reading of up to 100 values from 20 devices (Modbus TCP

protocol). The read values can be assigned to channels and archived.

Flow measurement

Each measurement input (including binary inputs) and each calculated value have two

independent totalizers assigned. Totalizers for pulse inputs can provide precise pulses

count. Message containing totalizers values can be sent automatically in the form of an

DL7, DL7L

12

e-mail (up to 5 recipients) at the indicated hour every day, on a selected day of the week or

on a selected day of the month.

Alarms and control

Two alarm thresholds may be set for every channel. Binary outputs can be assigned to

alarm thresholds. Two modes are available for alarms: latched (‘Alarm’ mode) and

non-latched (‘Control’ mode). The binary output module (OUT6RL) contains 6 outputs

relays. The message about exceeding the alarm threshold and return to the normal value

can be sent automatically in the form of an e-mail (up to 5 recipients).

Math channels

Within the math channels, selected mathematical operations are available: addition,

subtraction, division, multiplication, raising to the 2, 3 or any power and square root. The

formula entered in the math channel can contain up to 200 characters.

Results recording

Process values, math channels and totalizers can be recorded into internal flash memory

with the capacity of 2 GB. Data are saved as text files and protected with encoded

checksum. Apart from the measured values, the recorder also saves events (power loss,

resetting, exceeded threshold values, etc.) and authorised operations.

Displaying the results

Measured and calculated results can be displayed on the 7” colour LCD screen.

Depending on the configuration, results are displayed as graphs or digits (max. 11 signs

displayed for process values and max. 14 signs displayed for totalizers; after exceeding the

measuring range for process value or totalizer value, the ----- symbol will be displayed on

the screen and will be saved in the archive). The results can be also displayed collectively

as trend charts or tables (max. 11 signs for process values and totalizers values).

Measurement screens can be browsed sequentially or set to a selected channel.

Communication with a supervisory computer or a control system

The recorder enable data transmission to a supervisory computer or a control system by

means of:

a built-in RS-485 serial port; available Modbus RTU protocol,

Ethernet port; available Modbus TCP protocol.

3.3 Software for PC

Additional dedicated software can be downloaded from the Manufacturer's website:

www.metronic.pl.

Software for device configuration

DL7 / DL7L - dedicated software (DL7 Config.exe) enables device configuration through

the use of the computer. The software is intuitive and has an interface which is very similar

to the interface of the device. The software can be installed on the computers with the MS

Win operating system. Additional information in section DL7 Config.

Software for archived data visualization and analysis

The REPORT software (DL7-RP.exe) for archived data enables visualization and

analysis, using the computer. The DL7-RPplus.exe program enables online transfer of

archived data. Additional information in section DL7-RP (DL7-RPplus).

DL7, DL7L

13

3.4 Available options DL7 / DL7L

Data recorder is created with a view to enabling the best possible adaptation of the

device to the individual needs ofthe customer. Eachdevice is composed of the basemodule

to which (depending on the metrological needs) additional, carefully selected, input and

output modules can be attached. Depending on the needs, the device may have installed

up to seven additional modules. Each of them is optionally provided with 3 or 6 measurement

channels.

Device is available in panel-mount version (DL7) and in standalone version (DL7L). Both

device versions have the same features.

Configuration settings and wiring diagrams described in Operating Manual are the same

for both version of the device.

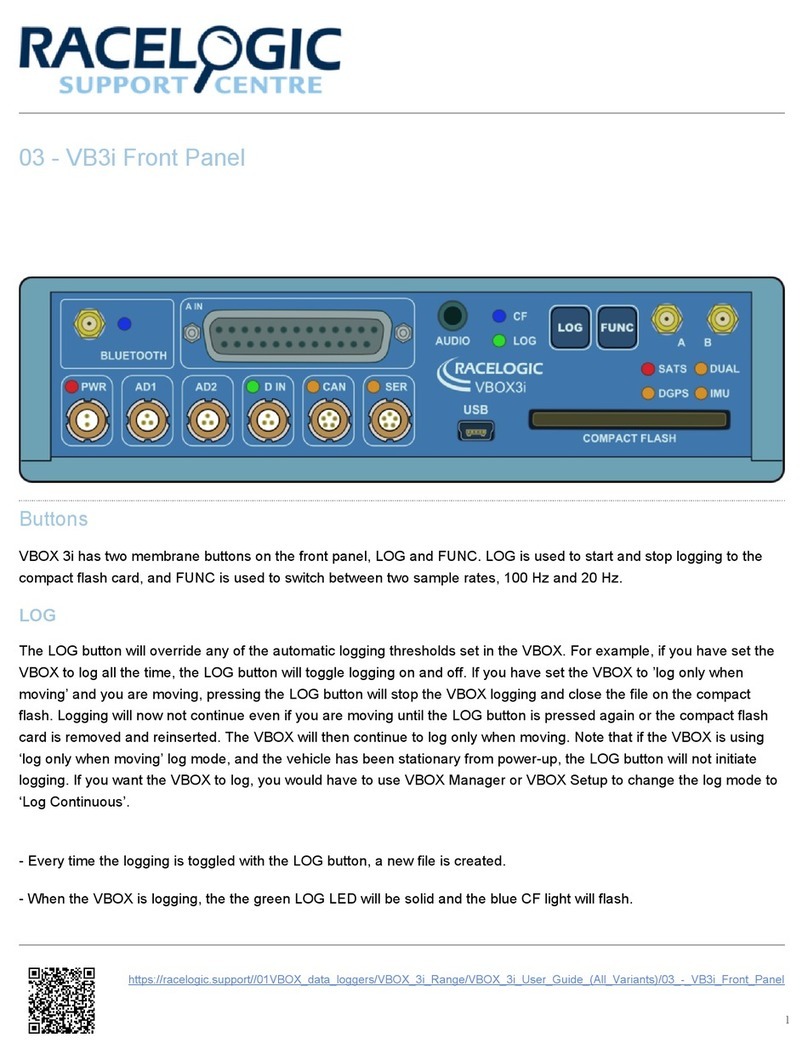

Front panel

Side view

DL7

Panel-mount version

DL7L

Standalone version

3.5 Device configuration

In the place of letter X, in a factory configuration code, a suitable module number should

be given as per the instruction described in the table below.

For example:

Device in panel-mount version, with 6 TC temperature inputs and 6 relay outputs has

code: DL7-31-81-00-00-00-00-00

Numbers 00 in this code mean, that in the device is only 2modules (installed on SLOT A

and SLOT B).

Module code

Module type

11

IN6I(24V)

12

IN6I

DL7, DL7L

14

21

IN6RTD

22

IN3RTD

31

IN6TC

41

IN6V

51

IN3

61

IN6D

71

2RS485(24V)

72

2RS485

75

1HRT

81

OUT6RL

91

OUT3

95

PSBATT

Hardware configuration data may also be verified from the device level in the window

Information about the device .

The device is configured by the manufacturer to customer's order. A list of individual

modules and their detailed descriptions are given in chapter AVAILABLE I/O MODULES.

3.6 Galvanic separation in the device

Fig. 3.1 Galvanic separation in DL7 / DL7L device (functional separation 500VAC @ 1min).

DL7, DL7L

15

4 AVAILABLE I/O MODULES

Individual electrical connection diagrams are given in section ELECTRICAL

INSTALLATION.

4.1 Base set

Each device is composed of:

housing,

front panel with touchscreen colour LCD, LED diode and USB port (type –A),

the basic M module, which is made up of:

USB port (type –A) –second port,

USB port (type –B mini) –service,

Ethernet port,

RS-485 communication interface connector,

Power supply from 24 VDC.

Depending on the client needs, in the device can be installed up to seven input/output

modules. Detailed technical descriptions of individual modules are given in section

TECHNICAL SPECIFICATIONS.

4.2 IN6I(24V) –six channel 0-20mA or 4-20mA input type module

standard current loop inputs 0-20mA or 4-20mA for passive or active transducers (internal

24 VDC voltage source for loop power supply),

linear current measurement within the range or sub-range of -20 .. +20 mA,

galvanic separation from the remaining device circuits, no separation among the input

channels,

each input has a separate four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

Note: The maximum number of IN6I(24V) modules in the device: 4.

4.3 IN6I –six channel 0-20mA or 4-20mA input type module

standard current loop inputs 0-20mA or 4-20mA for active transducers (no internal

24 VDC voltage source for loop power supply),

linear current measurement within the range or sub-range of -20 .. +20 mA,

galvanic separation from the remaining device circuits, no separation among the input

channels,

each input has a separate four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

4.4 IN6RTD (IN3RTD) –six (three) channel RTD / R input type module

inputs dedicated for temperature measurements using the Pt, Ni, Cu, KTY type sensors

(see technical data for complete list of sensor types),

linear measurement of the resistance within the range or sub-range 0 .. 4000 Ω,

galvanic separation from the remaining device circuits, no separation among the input

channels,

each input has a separate four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

DL7, DL7L

16

4.5 IN6TC –six channel mV type input module

inputs dedicated for temperature measurements with thermocouples (see technical data

for complete list of sensor types),

compensation of cold junction with a fixed value or a measurement using another

channel: internal or additional sensor (external),

linear measurement of the voltage within the range or sub-range -140 .. +140 mV,

galvanic separation from the remaining device circuits, no separation among the input

channels,

each input has a separate four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

4.6 IN6V –six channel voltage type input module

standard voltage type inputs: 0-10V, 2-10V, 0-5V, and 1-5V,

linear measurement of the voltage within the range or sub-range -10 .. +10 V,

galvanic separation from the remaining device circuits, no separation among the input

channels,

each input has a separate four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

4.7 IN3 –three channel universal type input module

software configurable input type:

current loop 0/4-20mA (active transducers),

temperature measurements using the Pt, Ni, Cu, KTY type sensors,

temperature measurements using thermocouples, compensation of cold junction with

a fixed value or a measurement using another channel: internal or additional sensor

(external),

voltage type inputs 0 .. 10 V, -10 .. +10 V,

linear current measurement within the range or sub-range of -20 .. +20 mA,

linear measurement of the resistance within the range or sub-range 0 .. 4000 Ω,

linear measurement of the voltage within the range or sub-range -140 .. +140 mV,

-10 .. +10 V,

galvanic separation from the remaining device circuits, no separation among the input

channels,

each input has a separate four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

4.8 IN6D –six channel binary inputs module

dedicated to measure frequency, pulse counting or state tracking,

frequency range of 0.1 .. 1000 Hz (pulse counting in range 0 .. 100 Hz),

0 .. 4 VDC / 5.5 .. 34 VDC (3.6 mA) according to EN61131-2 characteristics,

other switching current level at 0.45mA, 1.55mA or 2.44mA can be selected with jumpers

located on the module PCB,

accepts passive pulse transmitter (contact or transistor configuration OC), the source

voltage or current pulses,

galvanic separation from the remaining device circuits, no separation among the input

channels,

each input has a separate three-pole plug-in terminal block,

DL7, DL7L

17

each input has a LED to indicate the input state level,

two colour LED informing about the module's operating status.

4.9 2RS485(24V) –two RS485 port input module (Modbus RTU Master)

developed to read process values from instruments and sensors over the RS-485 bus

according to the Modbus RTU protocol,

up to 25 digital values can be read by one module, available formats: unsigned or signed

16 bit or 32 bit integer, signed 64 bit integer, 32 bit or 64 bit floating point,

2 independent and galvanically separated RS485 ports,

each port has a four-pole plug-in terminal block,

extra 24 VDC /max 200 mA voltage source power supply for external transducers,

two colour LED informing about the module's operating status.

Note: The maximum number of 2RS485(24V) modules in the device: 4.

4.10 2RS485 –two RS485 port input module (Modbus RTU Master)

developed to read process values from instruments and sensors over the RS-485 bus

according to the Modbus RTU protocol,

up to 25 digital values can be read by one module, available formats: unsigned or signed

16 bit or 32 bit integer, signed 64 bit integer, 32 bit or 64 bit floating point,

2 independent and galvanically separated RS485 ports,

each port has a four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

4.11 1HRT –HART (4-20 mA) port input module

HART port, reading passive or active transducers (4-20 mA current loop), internal 24 VDC

voltage source for loop power supply,

the module can operate in the multidrop mode (max. 15 devices),

the device can operate as a Primary Master or as a Secondary Master (compatible with

rev 4, rev 5, rev 6, rev 7),

possibility of reading and recording up to 25 variable values (max. 15 devices) with one

module,

reading the Long Address (rev 5, rev 6, rev 7),

changing the Short Address (rev 4, rev 5, rev 5, rev 7),

reading the unique identifier frame (test),

250 Ω internal resistor (disabled by default, resistor can be enabled in the settings menu),

galvanic separation from the remaining device circuits, no separation among connectors,

six four-pole plug-in terminal blocks (internal parallel connection between terminals),

two colour LED informing about the module's operating status.

4.12 OUT6RL –six channel relay outputs module

galvanically separated from each other 24 VAC or 36 VDC,

0.5 A solid state relays (SSR),

each port has a four-pole plug-in terminal block,

two colour LED informing about the module's operating status.

DL7, DL7L

18

4.13 OUT3 –three channel analogue outputs module

universal type analogue outputs, each can work as an active current loop source in the

ranges: 0-20mA, 4-20mA, 0-24mA or as an voltage source in the ranges: 0-5V, 0-10V,

12 bits D/A converter resolution,

each channel has two four-pole plug-in terminal blocks, one is for connecting the current

loop receiver, the other one for the voltage receiver (it is not possible to use both current

and voltage source at the same time for the channel),

two colour LED informing about the module's operating status.

4.14 PSBATT –module for operation with a back-up battery

supplying the device with NiMH storage batteries in the event of voltage break (backup)

or periodic operation of the device with battery power supply,

operating time from 1 to 20 hours (depending on the number and types of installed I/O

modules),

two colour LED informing about the module's operating status.

Note: The maximum number of PSBATT modules in the device: 1.

From April 1, 2020, the PSBATT module is manufactured only in version 1.2. Version

1.2 of the module is not backward compatible. The Operating Manual contains

information on connecting and configuring the module only in version 1.2. Technical

details about the module in version 1.0 and in version 1.1 are available from the

Manufacturer. Version 1.0 and 1.1 of the module is not visible in the Hardware

configuration in the Information about the device window (the "-------" sign and the red

color of the bar is displayed) and in the I/O settings window (the "------- " sign is

displayed).

CAUTION

If module IN6I(24V) or 2RS485(24V) installed and operating as a power supply source

for external devices, ambient temperature is limited to 0 .. +40 °C. In all other configurations

the ambient temperature range is 0 .. +50 °C.

DL7, DL7L

19

5 MECHANICAL INSTALLATION

!

Prior to the commencement of any assembly work, read carefully the

information concerning safety described in section SAFETY INFORMATION.

5.1 Mechanical installation of DL7 device

DL7 is a panel-mounted device. It can be mounted into panels at least 1 mm thick.

Before installation, a 186(+1.1) mm X 138(+1) mm rectangular opening must be cut out in the

panel. The mounting depth of the device (with connected terminals) is 97 mm. In order to

ensure easy installation of electrical connections, it is recommended to leave an extra space

of approx. 30 mm behind the device.

When installing the recorder in the panel opening, the seal between the housing frame

and the panel have to be fitted. After inserting the recorder into panel opening, the fixing

clamps should be latched on both side walls and then tighten the screws.With the removable

screw terminal block, one can first install electrical connections and then fit the recorder.

DL7

Mounting cut-out in panel –width

186(+1.1) mm

Mounting cut-out in panel –height

138(+1) mm

Depth of mounting with connectors

97 mm

Fig. 5.1 Housing dimensions of DL7 device and cut-out dimensions in an assembly panel.

DL7, DL7L

20

5.2 Mechanical installation of DL7L device

DL7L is a standalone device, equipped with a housing with special stands for

comfortable use of the device.

Fig. 5.2 Housing dimensions of DL7L device.

!

The recorder cannot be exposed to direct heat generated by other equipment.

When assembled, the operating device cannot be affected by interference

from other components (contacts, power relays, inverters).

Other manuals for DL7 Series

1

This manual suits for next models

1

Table of contents

Other Metronic Data Logger manuals