Metronic DL7 Series User manual

DL7, DL7L

MULTICHANNEL ELECTRONIC

DATA LOGGER

USER’S MANUAL

Version: 180228EN

DL7, DL7L

2

Information from the Manufacturer

All functions of the recorder are subject to modifications for the benefit of

technical progress.

Before installation, carefully read all the instructions, especially those

concerned with safety.

The recorder has been manufactured according to the requirements of

relevant EU directives.

These instructions must be stored in a safe place near the installation of the

steam flow computer at all times.

DL7, DL7L

3

TABLE OF CONTENTS

1MARKING AND DOCUMENTATION........................................................................6

2SAFETY INFORMATION..........................................................................................7

3EQUIPMENT DELIVERY, HANDLING AND STORAGE........................................10

3.1 Basic components.....................................................................................................................10

3.2 Storage......................................................................................................................................10

3.3 Accessories...............................................................................................................................10

4KEY INFORMATION ABOUT THE DEVICE...........................................................11

4.1 Intended use..............................................................................................................................11

4.2 Basic functions ..........................................................................................................................11

4.3 Device Versions ........................................................................................................................12

4.4 Device configuration..................................................................................................................13

5. DL7 MODULES.......................................................................................................14

5.1 DL7 basic kit..............................................................................................................................14

5.2 Basic M module.........................................................................................................................14

5.3 The 0/4-20mA inputs modules DL7-IN6I(24V)..........................................................................14

5.4 The 0/4-20mA inputs modules DL7-IN6I...................................................................................14

5.5 The RTD inputs modules DL7-IN6RTD (DL7-IN3RTD) ............................................................14

5.6 The input module measuring the temperature and voltage mV DL7-IN6TC.............................15

5.7 The voltage input module DL7-IN6V.........................................................................................15

5.8 Universal input module DL7-IN3 ...............................................................................................15

5.9 Binary inputs module DL7-IN6D................................................................................................15

5.10 Digital Input Module (Modbus RTU) DL7-IN2RS485 (24V) ......................................................15

5.11 Digital Input Module (Modbus RTU) DL7-IN2RS485 ................................................................16

5.12 The two-state outputs module DL7-OUT6RL............................................................................16

5.13 Analogue outputs module DL7-OUT3.......................................................................................16

5. TECHNICAL DATA.................................................................................................17

RTD inputs module measuring the temperature and the resistance DL7-IN6RTD (DL7-IN3RTD) .......19

Input module measuring the temperature and voltage mV DL7-IN6TC.................................................19

Universal input module DL7-IN3 ............................................................................................................19

Voltage input module DL7-IN6V.............................................................................................................20

Analogue outputs module DL7-OUT3....................................................................................................22

7MECHANICAL INSTALLATION.............................................................................24

8ELECTRICAL INSTALLATION ..............................................................................26

8.1 Galvanic insulation in the device...............................................................................................27

8.2 DL7 modules –connection diagrams........................................................................................27

8.3 Power connection......................................................................................................................33

8.4 Connection of RS-485 data transmission line...........................................................................33

DL7, DL7L

4

8.5 Port Ethernet .............................................................................................................................33

9DISPLAY STRUCTURE AND MAIN FUNCTION KEYS.........................................34

9.1 Face plate..................................................................................................................................34

9.1.1 Title strip...............................................................................................................................34

9.1.2 Side menu ............................................................................................................................35

9.1.3 Main screen..........................................................................................................................36

9.1.4 USB Port ..............................................................................................................................36

9.2 Screen keyboard .......................................................................................................................36

10 FIRST START UP AND KEY ACTIVITIE ...........................................................37

10.1 Access control, login and change of user password.................................................................37

10.1.1 Access control.................................................................................................................37

10.1.2 Login................................................................................................................................37

10.1.3 Change of password .......................................................................................................38

10.2 Recommended order for configuration of the device................................................................38

10.3 Change of the language............................................................................................................39

10.4 Configuration using the software...............................................................................................39

10.5 Reading and saving device settings using the USB port ..........................................................39

11 ENTITY LAUNCHING THE PRODUCT ON EUROPEAN UNION MARKET......40

12 USER SCREENS ..........................................................................................41

12.1 Information about the device.....................................................................................................41

12.2 Results Tables...........................................................................................................................42

12.3 Trends .......................................................................................................................................43

12.4 Archive.......................................................................................................................................44

12.5 Main menu.................................................................................................................................45

12.6 Single result window..................................................................................................................46

12.7 Alarms .......................................................................................................................................47

13 SETTINGS OF CALCULATION CHANNELS ................................................49

14 PROGRAMMING SETTINGS .......................................................................51

14.1 General settings ........................................................................................................................51

14.1.1 General............................................................................................................................51

14.1.2 Display.............................................................................................................................51

14.1.3 Date & Time ....................................................................................................................52

14.1.4 Service ............................................................................................................................52

14.2 Input and output settings...........................................................................................................52

14.3 Channel settings........................................................................................................................55

14.3.1 Inputs...............................................................................................................................55

14.3.2 General............................................................................................................................56

14.3.3 Alarm...............................................................................................................................57

DL7, DL7L

5

14.3.4 Totalizers.........................................................................................................................58

14.4 Communication settings............................................................................................................58

14.4.1 PORT ETHERNET..........................................................................................................58

14.4.2 Port RS-485.....................................................................................................................59

14.5 Screen settings..........................................................................................................................59

14.5.1 Tables..............................................................................................................................59

14.5.2 Trends.............................................................................................................................60

15 ARCHIVE.......................................................................................................61

15.1 How to initiate, restart and stop recording.................................................................................61

15.2 Archive settings.........................................................................................................................61

15.3 Archive field types .....................................................................................................................61

15.4 Erasing and copying the files to USB drive...............................................................................62

16 ADDITIONAL FUNCTIONS ..........................................................................64

16.1 Copying channel settings ..........................................................................................................64

16.2 User characteristics...................................................................................................................64

16.3 Print screen ...............................................................................................................................64

16.4 Changing the background color ................................................................................................65

Fig. 16.1 Changing the background color ..............................................................................................65

16.5 Web server................................................................................................................................65

17 FAILURE SYMBOLS ....................................................................................67

18 DL7L –FREE-STANDING VERSION ...........................................................68

19 MODBUS RTU / MODBUS TCP TRANSMISSION PROTOCOL..................70

19.1 Insights......................................................................................................................................70

19.2 Functions...................................................................................................................................70

19.3 Map of Registers for Reading Current Results and Counters...................................................71

Sections marked with are available only in the CD-ROM version of this manual

attached to the recorder.

DL7, DL7L

6

1 MARKING AND DOCUMENTATION

Equipment protected throughout by double insulation or

reinforced insulation.

Functional earth (ground) terminal, to enable the product to

function correctly. Not used to provide electrical safety.

Caution, risk of electric shock.

Caution, risk of danger, refer to accompanying documentation.

.

Caution, Electrostatic Discharge (ESD) sensitive circuit. Do not

touch or handle without proper electrostatic discharge

precautions.

!

Important comments and information.

DL7, DL7L

7

2 SAFETY INFORMATION

Safe operation of this product can only be guaranteed if it is properly installed,

commissioned, used and maintained by qualified personnel in compliance with the

operating instructions. General installation and safety instructions for pipeline and plant

construction, as well as the proper use of tools and safety equipment must also be complied

with.

Warning

This product is designed and constructed to withstand the forces encountered during

normal use. Use of the product other than as a steam flow computer, or failure to install the

product in accordance with these Instructions, product modifications or repair could:

Cause damage to the product / property.

Cause injury or fatality to personnel.

Invalidate the marking.

Void your warranty.

!

Isolate the mains supply before opening the product as hazardous

voltages may be exposed.

Warning

This product complies with the requirements of the following directives and

harmonized standards:

EMC Directive 2004/30/EC to the following standards and specifications:

For EMC immunity for industrial environments according to EN 61326-1:2013 Table 2.

For EMC conductive and radiated emissions Group1 Class A equipment according to EN

55011:2009+A1:2010.

The product may be exposed to interference above the limits of EN 61326 if:

The product or its wiring is located near a radio transmitter.

Excessive electrical noise occurs on the mains supply. Power line protectors (ac) should

be installed if mains supply noise is likely. Protectors can combine filtering, suppression,

surge and spike arrestors.

Cellular telephones and mobile radios may cause interference if used within

approximately 1 metre (39") of the product or its wiring. The actual separation distance

necessary will vary according to the surroundings of the installation and the power of the

transmitter.

Intended use

Check that the product is suitable for use with the application.

Determine the correct installation situation.

Prior to installation Metronic AKP products should take into account any environmental

limitations of devices, specified in the manual.

DL7, DL7L

8

Access

Ensure safe access and if necessary a safe working platform (suitably guarded) before

attempting to work on the product.

Lighting

Ensure adequate lighting, particularly where detailed or intricate work is required.

Hazardous environment around the product

Consider: explosion risk areas, lack of oxygen (e.g. tanks, pits), dangerous gases,

extremes of temperature, hot surfaces, fire hazard (e.g. during welding), excessive noise,

moving machinery.

The system

Consider the effect on the complete system of the work proposed. Will any proposed

action put any other part of the system or any personnel at risk?

Dangers might include isolation of vents or protective devices or the rendering

ineffective of controls or alarms.

Tools and consumables

Before starting work ensure that you have suitable tools and / or consumables available.

Protective clothing

Consider whether you and / or others in the vicinity require any protective clothing to

protect against the hazards of, for example, chemicals, high / low temperature, radiation,

noise, falling objects, and dangers to eyes and face.

Permits to work

All work must be carried out or be supervised by a suitably competent person.

Installation and operating personnel should be trained in the correct use of the product

according to the Installation and Maintenance Instructions. Where a formal 'permit to work'

system is in force it must be complied with. Where there is no such system, it is

recommended that a responsible person should know what work is going on and, where

necessary, arrange to have an assistant whose primary responsibility is safety.

Post 'warning notices' if necessary.

Cleaning and maintenance

Metronic AKP products require no maintenance beyond periodic battery replacement.

Expected battery life is 10 years after the expiry of which must be returned to the

manufacturer for a replacement.

From time to time you should clean the casing with a dry, soft cloth. When cleaning

machine, do not use solvents or abrasives. They may cause discoloration or scratch the

surfaces of device.

DL7, DL7L

9

Disposal

The DL7 / DL7L contains a battery. On disposal of the unit or component, appropriate

precautions should be taken in accordance with Local / National regulations.

Unless otherwise stated in the Installation and Maintenance Instructions, with the

exception of the battery, this product is recyclable and no ecological hazard is anticipated

with its disposal providing due care is taken.

Returning products

Customers and stockists are reminded that under EC Health, Safety and Environment

Law, when returning products to Metronic AKP they must provide information on any

hazards and the precautions to be taken due to contamination residues or mechanical

damage which may present a health, safety or environmental risk. This information must be

provided in writing including Health and Safety data sheets relating to any substances

identified as hazardous or potentially hazardous.

DL7, DL7L

10

3 EQUIPMENT DELIVERY, HANDLING AND STORAGE

Prior to dispatch, each Metronic AKP device is inspected and calibrated to

ensure efficient operation.

CAUTION!!

Upon receipt, each package should be inspected for any potential damage.

The content of the package should also be checked and the actual number of elements

should be compared against the manufacturer's list of items presented in the consecutive

sub-section. In the case of damage or lack of elements, a report should be drawn up in the

presence of the carrier specifying the date of receipt and signature of the person delivering

the package.

3.1 Basic components

The DL7 / DL7L made according to individual customer's order

1pc.

A set of plug-in type connection modules with four yokes

1set

Holders for fixing the device

4pc.

A seal

1pc.

Quick start guide - printed

1pc.

Warranty Card

1pc.

Certificate of Calibration

1pc.

A CD with the user instructions and configuration software

1pc.

3.2 Storage

If the device is to be stored if not used for a period of time and prior to the assembly, the

required storage conditions should be observed. The device should be kept in ambient

temperature range from -30 °C to 70 °C at the relative humidity at 5% to 95% (non-

condensing).

Prior the installation and connecting the device to the power supply make sure that there

is no condensation water inside the device

3.3 Accessories

CONV485E

CONV485USB-I

CONV485USB

Power supply unit

USB flash drive

DL7, DL7L

11

4 KEY INFORMATION ABOUT THE DEVICE

4.1 Intended use

DL7s are versions of a multi-channel microprocessor-based measuring device with

electronically recorded measurement results. The recorder is intended to measure process

signals in industrial settings and may be used to measure temperature values and other

physical quantities processed into a standard current signal 0/4-20mA, and in particular,

humidity, pressure, flow, level and chemical composition, etc. With the special structure of

the processing route applied, this recorder is perfectly suited for slow variable runs with

changes taking place at a few seconds intervals. With results recording function and

possibility to expand the device, this instrument is appropriate for use in monitoring

parameters in warehouse settings, process lines where multipoint measurements are

necessary, especially in the glass making industry, food processing, refineries, as well as

chemical and pharmaceutical industries. The device has math channels that enable the

execution of selected mathematical operations based on the values measured in the

measurement channels, according to the formulas entered by the user. The volume of data

saved as well as process display and browse functions makes the device suitable for use as

a paper-less electronic recorder.

Each device is provided with a basic module which, depending on the metrological

needs, can be appended with additional modules. Details of the individual modules are

provided in Sec. DL7 MODULES.

The device is intended to be supplied with 24V current: Detailed information concerning

the power supply is given in consecutive parts of the document Power connection

4.2 Basic functions

Measurement of the process values

Depending on the needs, the device may be provided with 3 to 42

measurement inputs/outputs. The product enables setting up to 100 freely programmable

channels. For each of them the current, the maximum and the minimum values of the

measurements are displayed.

Flow measurement

Each measurement input (incl. binary inputs) and each calculated value have two

independent totalizers assigned. Totalizers can measure slow variable flows, etc. Totalizers

for pulse inputs can provide precise pulse aggregation.

Control and alarm indicators

The bi-state output module activates the alarm controls if the value of the measurement

results are exceeded or simple bi-state control of the on-off type.

Calculation of selected values

Within the math channels, selected mathematical operations are available: addition,

subtraction, division, multiplication, raising to the power of 2 and 3, and square root. The

formula entered in the calculation channel can contain up to 200 characters.

DL7, DL7L

12

Results recording

Measurement and calculation results as well as totalizer readings can be recorded in

the recorder’s internal memory with the capacity of 2 GB. Data are saved as text files and

protected with encoded checksum. Apart from the measured values, the recorder also

saves events (power loss, resetting, exceeded threshold values, etc.) and authorised

operations.

Displaying the results

Measurement results can be displayed on the recorder screen or moved to a PC. There

is an LCD 7" touch screen graphical display on the face plate. Depending on the

configuration, the measurement and calculation results are displayed as digits or graphs.

The results can be also displayed collectively as tables or trend charts. Measurement

screens can be browsed sequentially or set to a selected channel.

Communication with a computer system

The recorder can be connected to a master computer system by means of:

a built-in RS-485 serial port; Modbus RTU protocol,

Ethernet port; available Modbus TCP protocol.

Supplementary software (optional)

Additional, DL7 - dedicated software enables device configuration through the use of

the computer. The software enables intuitive use and has an interface which is very similar

to the interface of the device. The software can be installed on the computers with the MS

Win operating system.

4.3 Device Versions

DL7 is a data recorder created with a view to enabling the best possible adaptation of

the device to the individual needs of the customer. Each device is composed of the base

module to which depending on the metrological needs additional, carefully selected, input

and output modules can be attached. Depending on the needs, the device may have

attached up to seven additional modules. Each of them is optionally provided with 3 or 6

measurement channels.

The device is available in a panel mount version (DL7) and free-standing (DL7L).

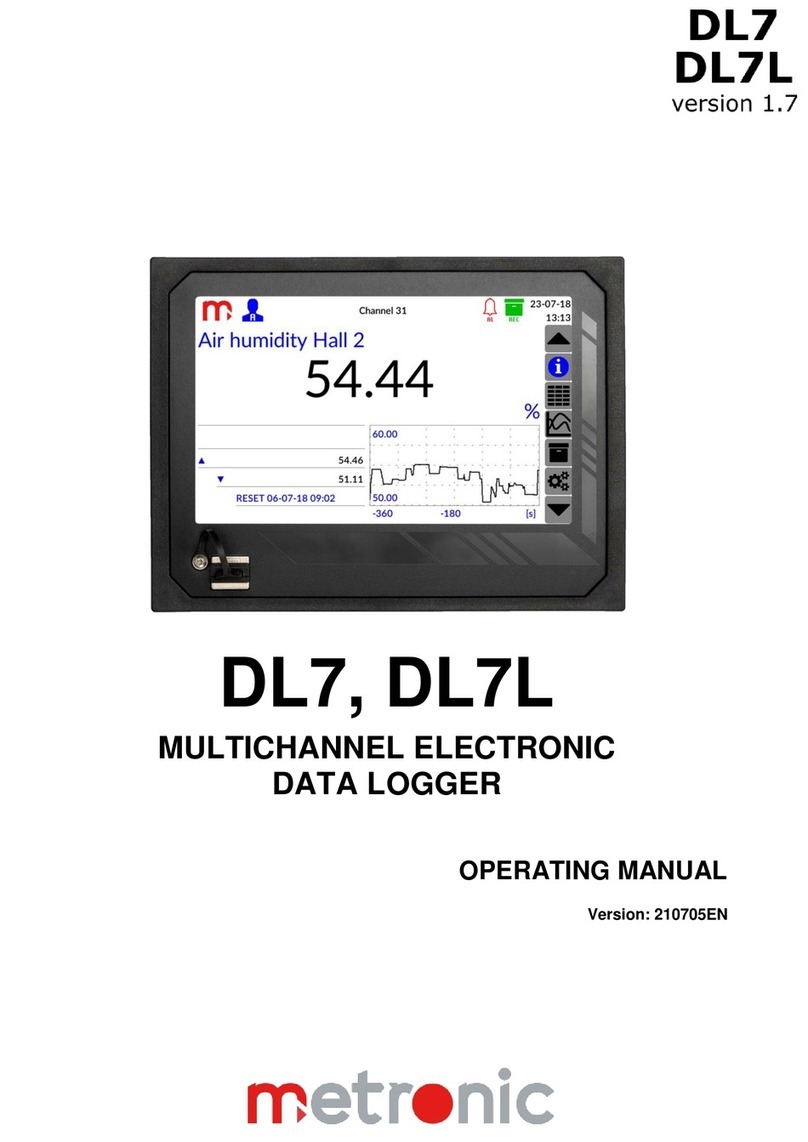

Fig. 4.1 Data recorder DL7L (left) and DL7 (right) - side view. .

DL7, DL7L

13

4.4 Device configuration

A factory configuration code is stated on the name plate.

DL7-A-B-C-D-E-F-G or DL7L-A-B-C-D-E-F-G

where:

Mark

Housing version

DL7

For mounting in panels

DL7L

Freestanding

In the place of each letter, a suitable module number should be provided as per the

instructions given in the tables below:

Number

Mark

11

DL7-IN6I(24V)

12

DL7-IN6I

21

DL7-IN6RTD

22

DL7-IN3RTD

31

DL7-IN6TC

41

DL7-IN6V

51

DL7-IN3

61

DL7-IN6D

71

DL7-IN2RS485(24V)

72

DL7-IN2RS485

81

DL7-OUT6RL

91

DL7-OUT3

Hardware configuration data may also be verified from the device level in this window

Information about the device.

The device is configured by the manufacturer to customer's order. A list of individual

modules and their detailed descriptions are given in chapter DL7 MODULES.

DL7, DL7L

14

5. DL7 MODULES

Individual electrical connection diagrams are given in section ELECTRICAL

INSTALLATION.

5.1 DL7 basic kit

Each DL7 device is composed of the following:

case

face plate with an LCD display and USB port type A

basic M module

5.2 Basic M module

The basic M module is made up of the following:

USB type A port,

Ethernet port,

RS-485 communication interface connector,

mini USB B socket with a button –for maintenance,

connector for connecting the device to power supply.

5.3 The 0/4-20mA inputs modules DL7-IN6I(24V)

interfacing with the passive transducers with standard 0-20mA or 4-20mA output,

transducers supplied with 24 VDC,

linear current measurement within the range or sub-range of -20 .. +20 mA,

6 measurement inputs galvanically separated from the remaining circuits.

each input has a separate pin type four-wire terminal block.

a two-colour LED diode informing about the module's operating status.

CAUTION: The maximum number of modules in the device –4.

5.4 The 0/4-20mA inputs modules DL7-IN6I

interfacing with the active transducers with the standard current output 0/4-20mA (or

passive transducers with additional external power supply),

linear current measurement within the range or sub-range of -20 .. +20 mA,

6 measurement inputs galvanically separated from the remaining circuits.

each input has a separate pin type four-wire terminal block.

a two-colour LED diode informing about the module's operating status.

5.5 The RTD inputs modules DL7-IN6RTD (DL7-IN3RTD)

temperature measurements using the Pt, Ni, Cu, KTY type sensors (a complete list of

sensors is given in the chapter discussing the technical data),

linear measurement of the resistance within the range or sub-range 0 .. 4000 Ω,

6 (3) measurement inputs galvanically separated from the remaining circuits.

each input has a separate pin type four-wire terminal block.

a two-colour LED diode informing about the module's operating status.

DL7, DL7L

15

5.6 The input module measuring the temperature and voltage mV DL7-IN6TC

temperature measurements using thermometers (a complete list of sensors is given in

the chapter discussing the technical data),

compensation of the junction compensation - with a fixed value or a measurement using

another channel

linear measurement of the voltage within the range or sub-range -140 .. +140 mV,

6 measurement inputs galvanically separated from the remaining circuits.

each input has a separate pin type four-wire terminal block.

a two-colour LED diode informing about the module's operating status.

5.7 The voltage input module DL7-IN6V

interface with the standard output transducers and the voltage of 0-10V, 2-10V, 0-5V,

and 1-5V,

linear measurement of the voltage within the range or sub-range -10 .. +10 V,

6 measurement inputs galvanically separated from the remaining circuits.

each input has a separate pin type four-wire terminal block.

a two-colour LED diode informing about the module's operating status.

5.8 Universal input module DL7-IN3

interfacing with the active transducers with the standard current output 0/4-20mA (or

passive transducers with additional external power supply); temperature measurements

using the Pt, Ni, Cu, KTY type sensors (a complete list of sensors is given in the chapter

discussing the technical data); temperature measurements using thermocouples;

interface with the standard output transducers and the voltage of 0 .. 10V, -10 .. +10V;

linear current measurement within the range or sub-range of -20 .. +20 mA; linear

measurement of the resistance within the range or sub-range 0 .. 4000 Ω; linear

measurement of the voltage within the range or sub-range -140 .. +140 mV, -10 .. +10 V;

3 measurement inputs galvanically separated from the remaining circuits;

each input has a separate pin type eight-wire terminal block;

a two-colour LED diode informing about the module's operating status.

5.9 Binary inputs module DL7-IN6D

the ability to work in a toggle mode, frequency measurement mode or pulse counting,

the ability to track a binary signal open / close,

Frequency measurement in the range of 0.1 .. 1000 Hz (pulse counting 0.1 .. 100 Hz),

Cooperation with passive pulse transmitter (contact transistor configuration OC), the

source voltage or current pulses,

6 measurement inputs galvanically separated from the remaining circuits,

each input has a separate pin type three-wire terminal block,

a two-colour LED diode informing about the module's operating status.

5.10 Digital Input Module (Modbus RTU) DL7-IN2RS485 (24V)

designed to work with instruments and sensors that communicate with the RS-485 bus

according to the Modbus RTU protocol,

Possibility of reading and recording up to 25 digital values,

DL7, DL7L

16

2 independent RS485 ports galvanically separated,

each input has a separate four-pole terminal block,

24 VDC (max 200 mA) output for powering external transducers,

a two-colour LED diode informing about the module's operating status.

5.11 Digital Input Module (Modbus RTU) DL7-IN2RS485

designed to work with instruments and sensors that communicate with the RS-485 bus

according to the Modbus RTU protocol,

Possibility of reading and recording up to 25 digital values,

2 independent RS485 ports galvanically separated,

each input has a separate four-pole terminal block,

a two-colour LED diode informing about the module's operating status.

5.12 The two-state outputs module DL7-OUT6RL

6 outputs galvanically separated from each other and the remaining circuits,

output types - semiconducting output relays (SSR) AC/DC rated at 0.5 A,

each input has a separate pin type four-wire terminal block,

a two-colour LED diode informing about the module's operating status.

5.13 Analogue outputs module DL7-OUT3

3 galvanically separated channels of analogue outputs, each can work as a power source

or a voltage source in the following ranges:

0-20 mA (active power source),

4-20 mA (active power source),

0-24 mA (active power source),

0-5 V (voltage source),

0-10 V (voltage source).

Program mode selected, each channel can be configured to work in a different mode and

range,

Each channel has two connectors for connecting the receiver, one is for connecting the

current loop receiver, the other one for the voltage receiver, there is no possible to use

both: current and voltage source for a given channel at the same time,

Analogue output is based on a specialized A/D converter with a resolution of 12 bits.

Detailed technical descriptions of individual modules are given in section

TECHNICAL DATA.

DL7, DL7L

17

6. TECHNICAL DATA

FRONT PANEL

Type of display:

LCD TFT 7” 800 px X 480 px

LED lbacklight

Reading field size:

152 mm X 91 mm

Keyboard:

resistive touch panel

Indication:

LED red/blue

Port USB (front panel)

Version

USB 2.0 ( with limited functionality, for

connection of FLASH storage)

Port socket

USB standard ‘A’ type socket

Protection class

IP54 (with silicone dust cover)

Port Ethernet (rear panel)

Interface

10/100Base-T Ethernet

Transmission protocol

Modbus TCP

ICMP (ping)

Number of connections opened simultaneously:

Max 4

Connection

RJ-45

RS-485 SERIAL PORT(rear panel)

Signals output on terminal block:

A(+), B(-), G, G (G - signal ground)

Maximum load:

32 receivers / transmitters

Transmission protocol:

Modbus RTU

Transmission rate:

1.2, 2.4, 4.8, 9.6 ,19.2, 38.4, 57.6, 115.2 kbps

Parity control:

Even, Odd, None

Frame

1 start bit, 8 data bits, 1 stop bit

Galvanic separation:

250 VAC; 1500 VAC for 1 minute

Maximum length of line

1200 m

Internal terminating resistor

Vcc-A(+)-B(-)-G: 390Ω-220Ω-390Ω

(activated by DIP-switches)

Maximum differntial voltage A(+), B(-), G

-9V ... +14 V

Minimum output signal of transmitter

1.5 V (at RL= 54 )

Minimum sensitivity of receiver

200 mV / RIN= 12 k

Minimum impedance of data transmission line

54

Short-circuit / thermal protection

Yes / Yes

Port USB (rear panel)

Version

USB 2.0 ( with limited functionality, for

connection of FLASH storage )

Port socket

USB standard ‘A’ type socket

Port mini USB (rear panel)

Version

USB service port, use only in accordance with

the service instructions

Port socket

USB standard ‘mini B’ type socket

INTERNAL DATA MEMORY

Memory type

Flash

Capacity

2 GB

Estimated recording time for recording speed every

10 s for 20 measuring channels

ca. 2 years

DL7, DL7L

18

SUPPLY

Supply voltage

24 VDC (18 .. 36 VDC)

Maximum power consumption

48 W ( when installed seven modules )

Security

The internal delay fuse 3.15 A, the exchange

only by the service company

ELECTRICAL CONNECTIONS (terminal connectors)

Type

screw terminal connectors

Wire cross section

wire 1.5 mm2max

cord 1 mm2max

cord with sleeve connectors 0.25 .. 1.5mm2

AWG 30 / 14

MECHANICAL DIMENSIONS –HOUSING

Type of housing

DL7

DL7L

For mounting in panels, non-flammable

Lexan Resin 920

Freestanding, non-flammable Lexan

Resin 920

Dimensions (h X w X d)

144 mm X 192 mm X 82.5 mm

Dimensions of panel cut-out

138 mm X 186 mm

Weight

ca. 650 g –base set

ca. 1250 g –full option

Protection class

IP54 on front panel side

IP20 on rear panel side

ENVIRONMENTAL CONDITIONS

Ambient temperature

0 .. +50° C

Relative humidity

5 .. 95% (without steam condensation)

Height

< 2000 m n.p.m.

Storage temperature

-30 .. +70° C

Degree of pollution

PD2

EMC

EMC Directive 2014/30/EC

EN 61326-1:2013 Table 2 (immunity)

EN 55011:2009+A1:2010 Class A (emission)

RoHS

RoHS Directive 2011/65/EU

0/4-20mA inputs module DL7-IN6I(24V), DL7-IN6I

Number of inputs

6

Measuring range

0–20 mA; 4–20 mA;

(the actual range -22 .. 22 mA)

Resolution

0.001 mA

Measurement accuracy (Ta= +25° C)

< ±0.1% measuring range

(typically < ±0.05%)

Temperature drift

< ±0.02% /°C measuring range

Input resistance

12 ±10%

Maximum input voltage

± 40 VDC

Input protection

Polymer fuse 50 mA (resetable)

Transducers powered from device:

for modules DL7-IN6I(24V)

for modules DL7-IN6I

24 VDC ±15% / max 0.25mA

None

Galvanic separation from the other circuits

250 VAC; 1500 VAC for 1 minute

DL7, DL7L

19

Universal input module DL7-IN3

Number of inputs

3

Sensor type

0–20 mA; 4–20 mA (without loop supply

module)

±10 V / 0-10 V (2-10V, 0-5V, 1-5V)

Thermocouple (Table below); ±100mV

Resistance (Table below) 0 .. 4000 Ω

Maximum input voltage

±30 VDC

Galvanic separation from the other circuits

250 VAC; 1500 VAC for 1 minute

Galvanic separation between channels

None

The parameters for input type 0-20 mA, 4-20 mA

Galvanic separation between channels

None

WARNING:

In the DL7 device, it is posible to instal max 4 modules with power output 24V DC at the same time

(DL7-IN6I (24V)).

RTD inputs module measuring the temperature and the resistance DL7-IN6RTD (DL7-IN3RTD)

Number of inputs

for module DL7-IN6RTD

for module DL7-INRTD

6

3

Sensor type

Resistive (refer the table below)

Linear resistance

Sensor connection type

2-wire; 3-wire; 4-wire

Sensor current

200 A

Measuring range

0 .. 4000 Ω

Resolution

0.05 Ω

Wire resistance compensation

in the 3-wire connection

Automatic

Wire resistance compensation

in the 2-wire, 3-wire, 4-wire connection

Constant within the range of -99.99 Ω to

+99.99 Ω

Maximum resistance of wires supplying power to the

sensor

20

Maximum input voltage

±40 VDC

Galvanic separation from the other circuits

250 VAC; 1500 VAC for 1 minute

Galvanic separation between channels

None

Input module measuring the temperature and voltage mV DL7-IN6TC

Number of inputs

6

Sensor type

Thermocouple (refer the table below)

Linear voltage source

Measuring range

-140 .. +140 mV

Resolution

0.01 mV

Cold junction compensation

Any other temperature measuring channel

(in °C/°F) or a constant value for thermocouple

B –no compensation

Maximum input voltage

±40 VDC

Galvanic separation from the other circuits

250 VAC; 1500 VAC for 1 minute

Galvanic separation between channels

None

DL7, DL7L

20

Measuring range

0–20 mA; 4–20 mA;

(the actual range -22 .. 22 mA)

Resolution

0.001 mA

Measurement accuracy (Ta= +25° C)

< ±0.1% measuring range

(typically < ±0.05%)

Temperature drift

< ±0.02% /°C measuring range

Input resistance

12 ±10%

Input protection

Polymer fuse 50 mA (resetable)

Parameters for type ± 10 V / 0-10 V

Measuring range

-10 .. +10 VDC (or sub-range)

(the actual range-11 .. +11 VDC)

Resolution

0.0001 V

Measuring range (Ta= +25° C)

< ±0.1% measuring range

(typically < ±0.05%)

Temperature drift

< ±0.02% /°C measuring range

Input resistance

>100 kΩ

Parameters for type TC

Measuring range

-140 .. +140 mV

Resolution

0.01 mV

Cold junction compensation

Any other temperature measuring channel

(in °C/°F) or a constant value for thermocouple

B –no compensation

Parameters for type RTD

Sensor connection type

2-wire; 3-wire; 4-wire

Sensor current

200 A

Measuring range

0 .. 4000 Ω

Resolution

0.05 Ω

Wire resistance compensation

in the 3-wire connection

Automatic

Wire resistance compensation

in the 2-wire, 3-wire, 4-wire connection

Constant within the range of -99.99 Ω to

+99.99 Ω

Maximum resistance of wires supplying power to the

sensor

20

Voltage input module DL7-IN6V

Number of inputs

6

Sensor type

0-10 V (2-10V, 0-5V, 1-5V)

Linear voltage source

Measuring range

-10 .. +10 VDC (or sub-range)

(the actual range-11 .. +11 VDC)

Resolution

0.0001 V

Measuring range (Ta= +25° C)

< ±0.1% measuring range

(typically < ±0.05%)

Temperature drift

< ±0.02% /°C measuring range

Input resistance

>100 kΩ

Maximum input voltage

± 40 VDC

Galvanic separation from the other circuits

250 VAC; 1500 VAC for 1 minute

Galvanic separation between channels

None

Other manuals for DL7 Series

1

This manual suits for next models

10

Table of contents

Other Metronic Data Logger manuals