Metronic 5200BF User manual

BULLETIN

O-2400

JUNE 1989

METRONIC 5200BF

ELECTROLYTIC RECOVERY SYSTEM

FOR COLOR PHOTO PROCESSING

TABLE OF CONTENTS

Statement of Warranty and Liability.

Introduction

Specifications

Installation

Bill of Materials

Operating Procedures

Trouble Shooting Guide

Silver Stripping Procedures

Silver Flake Refining

Dwg #A-1442 - Diagram, Chemical Interconnection

Swg #A-1445 - Chamber Components

Fig A - 5200 BF

Fig B - Interconnections

Fig C - Float Assembly & Drain Hose

Fig D - Plating Chamber & Connections

Fig E - Pump Locations

Fig F - Front view with cover removed

Fig G - Rear view of E.M.P. Locking Latch

Fig H - E.M.P Assembly

Fig J - E.M.P. Assembly showing timing switches

damage outside the control of SERFILCO are not covered

by this warranty. Under no circumstances shall SERFILCO

be responsible for any damage, loss or liability of any nature

arising out of the installation or use of the materials or

equipment furnished.

No other warranties, expressed or implied, except as

stated above, shall apply. This warranty becomes null and

void if any device or accessories other than those distributed

or officially recommended by SERFILCO is installed, or

attached to this equipment.

INTRODUCTION

The Metronic 5200 BF is an electrolytic recovery system

intended to recover silver from fixer and bleach fix. This is

a closed loop recirculating recovery system that continu-

ously passes the spent fixer and bleach fix solution from the

10 gallon desilvering tank through the plating chamber. The

silver is deposited on a cathode inside the electrolytic

chamber. The unit turns on automatically when the 10 gallon

desilvering tank reaches the 3.5 gallon level.

The unit will run in the recirculating mode until the

maximum amount of silver has been recovered.

At the end of the recirculating cycle, which varies with

silver concentration, the unit will go into a drain mode until

all the chemistry is out of the holding tank and plating

chamber. It will then automatically turn off and wait for the

next batch of chemistry.

1.

2.

3.

Electrolytic Chamber (SPU) (See Fig. B)

This chamber is equipped with one (1) round 5" anode,

one (1) 8" cathode, one(1) circulation pump, and one(1)

discharge pump.

Rectifier (EMP) (See Fig. H)

The rectifier is equipped with digital current readout, level

control, and power switch.

Desilvering Tank (See Fig. F)

The desivlering tank is a 10 gallon holding tank with High/

Low level controls set to start at about 3.5 gallons.

The Metronic 5200 BF consists of:

SAFETY PRECAUTIONS

BEORE STARTING PUMP

Read operating instructions and instructions supplied

with chemicals to be used.

Refer to Chemical Resistance Data Chart for compati-

bility of materials in pump with solutions to be used.

Note temperature and pressure limitations.

Personnel operating pump should always wear suitable

protective clothing: face mask or goggles, apron and

gloves.

All piping must be supported and aligned independently

of the pump.

Always close valves slowly to avoid hydraulic shock.

Ensure that all fittings and connections are properly

tightened.

1.

2.

3.

4.

5.

6.

7.

BEFORE CHANGING APPLICATION OR

PERFORMING MAINTENANCE

Wear protective clothing as described in item 4 above.

Flush pump thoroughly with a neutralizing solution to

prevent possible harm to personnel.

Verify compatibility of materials as stated in item 2

above.

1.

2.

3.

STATEMENT OF WARRANTY AND LIABILITY

SERFILCO warranties its equipment against defects in

material and workmanship for six months from the date of

installation. Any claimed defects must be reported, and the

material or equipment returned, freight prepaid, to our plant

within the warranty period. Our liability is limited to replacing

or repairing, at our option, any material or equipment, at no

cost to the purchaser, Damages or loss during shipment are

not covered by this warranty, but are the responsibility of the

carrier(s). Please report all shipping damage to the carrier(s)

immediately.

All material and /or equipment supplied by vendors other

thanSERFILCO,shallcarrynowarrantyexceptsaidsupplier's

warranty as to materials and workmanship. Transportation

handling damage, wear and tear, and other causes of

1

1

2

2

3

2

4

5

5

INSTALLATION

Install the Metronic 5200BF near the processor drain line.

A. NEW LAB INSTALLATION

There are two fittings to be installed on tank (see Fig. F)

One for Fix, Bleach Fix "IN" and one for overflow to drain.

These may be interchanged.

a. The Fix, Bleach Fix hose from the processor and

printer is connected to the desilvering tank.(see Fig.

F)

b. The overflow drain fitting which goes to drain. (see

Fig. F) This allows some protection in case of equip-

ment failure.

Put system on top of black base.

Attach (3) 3/4" hoses to tank with hose clamps on each

fitting. (see Fig.C)

Install rectifier (EMP) in shelf with black connector "D"

to SPU chamber, gray cable "C" to the float switch cable

on the desilvering tank, and AC power cord "A" to wall

receptacle. (see Fig. B) Be sure to check and insure that

the retaining strap on the rear of the unit is set to hold the

EMP inside the cabinet. (see Fig. G)

Connect the Metronic 5200BF 1/2" I.D . drain hose to the

nearest drain. (see Fig. C)

Turn on AC power. (AC power should be left on at all

times, as system will be in stand-by mode until tank is

filled).

Check system for leaks by filling tank with water until

system turns on. The system will run for approximately

7 minutes, then go to drain mode.

SPECIFICATIONS

B. EXISTING LABS

Connect hoses as indicated on the previous page.

1

.

1.

2.

3.

4.

5.

6.

7.

OPERATING PROCEDURES

After completion of installation, turn on power.

The "IN" hose to the desilvering tank will only allow fix

and bleach fix into the tank.

When changing chemistry, Bleach Fix and Fixer will drain

to tank. When tank is filled to level of high float, unit will

turn on and run until the maximum amount of silver has

been recovered.

1.

2.

3.

When cleaning out your processors, avoid getting any

water or cleaners in the desilvering tank. This will cause

the 5200 BF to not plate.

4.

For Labs where Fix and Bleach are automatically replen-

ished, the 5200 BF will be on stand-by until upper float switch

is activated to turn recirculating pump and desilvering cycle

on. This is automatic. Always keep the unit in the "ON"

mode.

Dimensions: 22"x9-1/2"x21-3/4"

(55.9 cm x 21.1cm x 55.2 cm)

Recovery Rate: 1.25 troy ounces per hour

(40 grams per hour)

Silver Capacity: 394 troy ounces

(12 kg)

Cathode Dimensions: 8" diameter (20.3 cm)

6" height (15.2 cm)

Drain Systems:

Power Requirements:

Pump - 2-4 liters per minute

110/120 VAC (US)

220 V (Europe)

Major Component Listing

A. Cabinet

b. EMP

C. SPU

D. Desilvering tank

BILL OF MATERIALS

DESCRIPTION QUANTITY/UNIT

Nut, 1/2 12 UNC

Washer, 1/2"

SPU cover

Barb

"O" ring, B-1203

Anode, 5"

Stud Assy

Nut, B-1205

Seal

"O" ring B-1205

Cathode, 8" SS

"O" ring C-1202

Anode Rod PVC

SPU Chamber

Barb

Plate

Bracket, Mtg. Chamber

Pump G/R

Connector assy

SPU cabinet

Cabinet base

Cover

Jack, banana red

Jack, banana black

Block, mounting

Wire #14 black

Wire #14 red

Lug, ring #10 18/14

Gasket, plating chamber

Lug ring, 14 AWG wire

2

2

1

1

1

1

4

4

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12"

12"

2

1

2

SPU

HOLDING TANK

DESCRIPTION

Transistor 2N6057

Lug, ring #6 (22-18)

Lug, ring #10 (16-14)

Tie, cable 7-1/4"

Tie, cable 3-3/4"

Transformer 24-12

Rectifier, bridge 25A

Capacitor, 1900 UF 25V

Terminal, block 2 pos.

Cabinet, EMP

Clamp, capacitor

Fan, cooling

Washer, #6 lock SS

Washer, #8 lock SS

Washer, #6 flat SS

Washer, #8 flat SS

Nut, 6-32 SS

Nut, 8-32 SS

Screw. 6-32 x 5/8 P.H. SS

Screw, 6-32 x 1/2 P.H. SS

Screw, 6-32 x 3.8 SS

Heatsink 4"

Spacer, Hex 1-1/4"

Cord, Power 3 cond. 6

Cable, 5 cond. (SPU)

Assy, PCB w/harness

Assy, front panel

Relay, 8 pin octal

Relay, FRP 104 (alco)

Socket, relay octal

Socket, transistor

Molex, connector (male)

Molex, connector (female)

Wire, 20awg 3 cond

Pin, female

2

1

2

3

12"

1

1

1

1

1

1

1

14

1

14

1

14

1

2

4

3

1

3

1

1

1

1

1

1

2

2

5

3

6

24

QUANTITY/UNIT

EMP

Tank 12 x 12 x 18

Fitting, bulkhead 3/4"

Switch, float

Tee, 1/4"

Elbow, 1/4"

3-way Ball valves

3/4" MPT x barb

3/4" MPT x barb elbow 90

3/4" Tee FPT

3/4" Nipple, long 3"

1

3

2

2

2

1

3

2

1

1

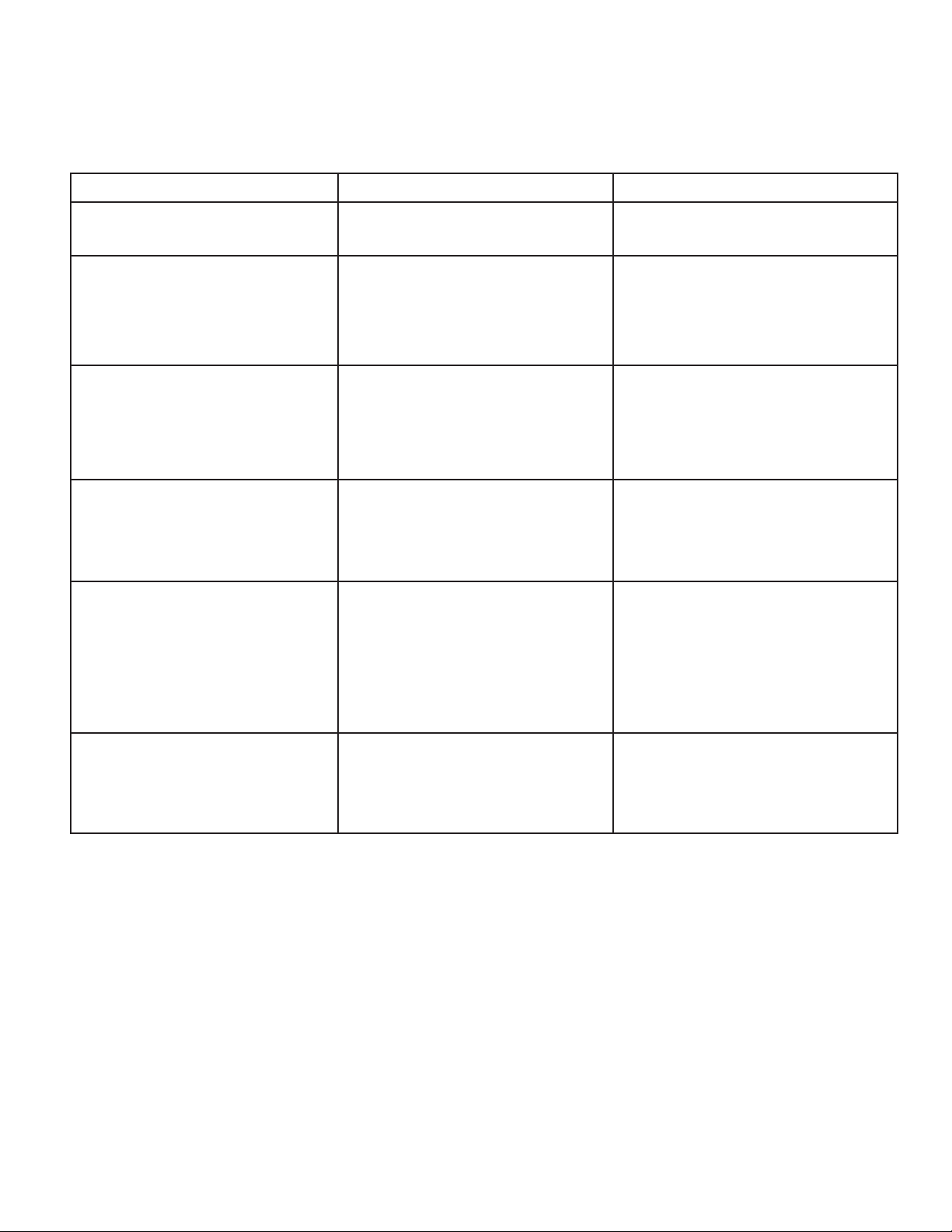

TROUBLE SHOOTING GUIDE

CORRECTIVE ACTIONPROBABLE CAUSESYMPTON

Power light ON, desilvering light ON,

no amp reading on digital meter

No apparent silver plating on

cathode

1. Blown fuse

2. Unit not plugged in

3. Faulty EMP

1. Insure tank is filled to top float switch

2. a. Lift switch up to close position, to

start desilvering cycle.

b. Clean and unclog switch with

water.

c. If (b) does not work, call for

service.

1. Replace fuse

2. Plug in unit

3. Call for service if (1) or (2) does not

correct symptom

1. Call for service

1. Call for service

2. Call for service

3. Reroute developer to drain and

clean out the desilvering tank and

plating chamber with water.

1. Check if fitting is loose, If so, tighten.

2. If fitting is too tight, loosen slightly

so as not to distort gasket. If leak

persists, disconnect fitting and

check gasket for damage.

1. Fittings either too tight or not tight

enough

2. Flashing around fitting hole.

1. Defective EMP

1. Desilvering time too short

2. No amps on digital meter

3. Developer mixed with Fix and

Bleach Fix

Leaking from tank fittings

Switch "ON" light will not light

1. Add solution with silver

2. Call for service

1. No silver in the solution

2. Faulty EMP

Unit goes into main mode after

seven minutes

1. Tank not filled to top float switch

2. Float switch stuck open

Desilvering cycle will not start,

Switch "ON" light is lit

SILVER STRIPPING PROCEDURES

Check for silver after one month. Refer to A-1486 for plating

chamber components.

Before starting the stripping of the Metronic 5200 BF unit, it

is advisable to perform a quick operational check and visual

inspection. The operational check will tell you if there is a

reason, other than adjustments, for the metal not to plate

properly. The visual inspection will help identify the source

of any leaks.

Remove the silver from the cathode by gently flexing the

cathode. It would be best to leave the silver on until you

have accumulated about 1/8" thickness, which will make

it easier to remove.

Clean the anode (Item 6) of any build up of residue on the

surface by washing it with a wet sponge and warm water.

If the anode is damaged or does not go back to a fine grey

color, it will have to be replaced.

DO NOT USE ABRASIVES ON THE ANODE!

Clean the metal that may be present from the bottom of

the chamber. Dry it out and send out with the silver flake

for refining.

Inspect the anode "O" ring and chamber gasket for

cracks from the chamber wall. Replace if necessary.

Reassemble the cathode and chamber top. (see Dwg #A-

1445) Make sure that the long end of the cathode is on

the inside. Clean the inside of the cathode with alcohol or

acetone to remove any oil left by your hands. Gently slide

the cathode and chamber top into the chamber.

Clean the bottom of the SPU case to remove any solution

that may have been spilled.

Check all the clamps on the unit to ensure they are tight.

Occasionally check the cathode and anode nuts for

leakage. Replace "O" rings and /or spacers if required.

10.

11.

12.

SILVER FLAKE REFINING

There are numerous silver flake buyers and refiners in your

area. In the event that you would like a listing of available

refiners, call our service department and an updated listing

will be make available to you.

Occasionally check the cathode and anode nuts for

leakage. Replace "O" ring and /or spacers if required.

When re-assembling the chamber top put on two or

three turns of teflon pipe tape on all the threads of the

studs to prevent leaking.

13.

14.

6.

7.

8.

9.

Turn the power switch OFF on the Metronic 5200 BF unit.

Disconnect the S.P.U. power cable and float cable.

Remove the top cover with the rectifier.

Loosen the clamp that holds the hose at the chamber

outlet (top) and slide the connecting hose off fitting (4)

(see A1486)

Disconnect the Red & Black wires from the chamber top.

(see Dwg # A-1445)

Remove the chamber top retaining nut (1) and washer (2).

Remove the chamber top and cathode assembly up and

out of the chamber. (Items 4, 5, 6, & 8) Remove cathode

nuts and "O" rings. Remove the cathode item 8 (see A-

1486)

NOTE: On occasion, due to unusual plating conditions,

1

.

2.

3.

4.

5.

you may find that the cathode is stuck in the chamber.

If you encounter this, Proceed as follows:

Remove the two cathode retaining nuts, black wire,

spacers, and "O" rings located on the chamber top.

Remove the chamber top leaving the cathode in

place

Pushing in on the cathode studs, pull the cathode up

and out of the chamber.

a.

b.

c.

NEVERTRYTOPRYTHECATHODEOUTWITHASCREW-

DRIVEROR OTHER TOOL. THIS WILL RESULT IN BREAK-

AGE OF THE CHAMBER.

STRIPPING - SCHEMATIC 1

Table of contents