Metrotech 9800XT SFL2 Series User manual

9800XT™ SFL2

SERVICE CENTER, SALES AND TECHNICAL SUPPORT INFORMATION

Corporate Headquarters Metrotech Eastern U.S. Service Center Metrotech European Service Center

3251 Olcott Street 1824 Murfreesboro Road, Ste. 104 Seba KMT

Santa Clara, CA 95054 Nashville, TN 37217 Dr. Herbert Iann St. 6

800-446-3392 800-624-6210 96148 Baunach, Germany

408-734-1400 Direct 615-366-7323 Direct +49 9544 680

408-734-1415 Fax 615-360-9855 Fax +49 9544 2273 Fax

www.metrotech.com nashville@metrotech.com service@sebakmt.com

sales@metrotech.com

Warranty: One year. Specifications Subject to change without notice, ISO 9001:2000 Certified. Copyright 2008. All Rights Reserved. Rev 12/01/07

OPERATIONS MANUAL

Sheath Fault Locator

2

ISO 9001 CERTIFIED

Metrotech has received ISO 9001 Quality Management System Certification.

Metrotech adheres to the quality standard guidelines of ISO 9001 and ensures

quality in its design/development, production, installation, and servicing

disciplines.

© Metrotech Corporation 2005-2008

Metrotech Corporation

3251 Olcott Street

Santa Clara, CA 95054

USA

Tel: 1.800.446.3392; 1.408.734.1400

Fax: 1.408.734.1415

Internet: www.metrotech.com

Revision C: 12/1/07

TABLE OF CONTENTS

List of Illustrations ………………………………………………………. .1

1 Introduction…….……..………………………….…………………………. 2

2 Safety Precautions………………………………………………………… ..3

3 9800XT SFL-2 Quick Start Guide for the Experienced User………. .4

4 9800XT SFL-2 Equipment………………………………………..….….. .10

4.1 Standard Equipment……………………………………….. .. .….….10

4.2 Optional Accessories…………………………………….. .. .…. . ….12

4.3 Technical Specifications…………………………………….. … …...13

4.4 Transmitter Controls and Indicators…………………………….……16

4.5 Transmitter Features………………………………………………….18

4.6 A-Frame Receiver Controls and Indicators…………………………..20

4.7 Additional A-Frame Receiver Features………………………………21

5 Principles of Operation…………………………………………………….22

5.1 Functional Theory…………………………………………………...22

5.1.1 Earth Voltage Gradient…………………. …………………………24

5.1.2 Equipotentials……………..………………………………………..24

5.1.3 Multiple Fault Patterns………………………………………..……26

5.1.4 Distortion Due to Adjacent Conductors……………………………26

6 Checkout Procedure……..…….. . ………………………. … .. .…. … ... 27

7 Operation…….…..…………………………………………………….…....29

7.1 Check the Batteries Prior to Going into the Field…… . . . . . . . . . …29

7.2 Ensure all conductors are de-energized.…………… . . . . . . .. .……29

7.3 Lift the Grounds………………. . . . .……………………………. ..29

7.4 Attach the Transmitter to the Conductor-Check Fault Resistance . . 29

7.5 Synchronize the A-Frame Receiver…. .…………………………….30

7.6 Confirm that a Fault Exists…………. . . . . .………………………..32

7.7 Trace the Cable with the 9800 Receiver…. . . . . . . .………………..32

7.8 Pinpoint the Fault…………….. …………………………. .……….32

7.9 Verify the Fault……………. . . .……. .. ..……………………….…32

8 Advanced Techniques…...….………………………………….…...……..33

8.1 Faults Under Inaccessible Surfaces…. . . . .………………………...33

8.1.1 Perpendicular Method………………………………………..……..33

8.1.2 Triangulation Method………….. .………………………… ………34

8.2 Faults Under Pavement…. ...……………………………… ……..35

8.3 Long Distance Tracing……. . . . . . .………… .. …… ……………35

8.4 High and Low Impedance Faults…. . . . . . . . . . . . . . ……………..36

8.5 Multiple Faults……. . . . . . . . .…………………………………. . .36

9 Maintenance…………………………………………………………… … ...37

9.1 Receiver Battery Replacement……… .. . . . . . . . . . . . . .. . ………37

9.2 Service Center………………………………… . . . . . . . . . .. .. ….38

Appendix ………………………………………………………………….. . ....39

Copyright…………………………………………………………………… ....40

Warranty……………………………………………………………….. .. … ...41

1

LIST OF ILLUSTRATIONS

Figure 3-1: Fault Resistance Scale.. . . . . .. . . . . . . . . . . . . . . . . . . . . .. . . . . . ..4

Figure 3-2: Clamping Black Lead to Ground Rod…..…….. ………………...5

Figure 3-3: Clamping Red Lead to Targeted Cable.………………………. ...5

Figure 3-4: Locating the Targeted Cable…………..………………. .… …… 5

Figure 3-5: Positioning of A-Frame Receiver for Synchronization………….6

Figure 3-6: Locating the Cable Fault with A-Frame Receiver…….………. .7

Figure 4-1: Standard Equipment and Accessories. . …… . . . . . . . . . . . . . . .. 11

Figure 4-2: Transmitter Controls Panel….……..…………… ……………….16

Figure 4-3: A-Frame Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 5-1: Typical SFL-2 Transmitter Connection………………………… 23

Figure 5-2: Signal Pattern Around Fault and Ground Point……………..… 24

Figure 5-3: Multiple Fault Signal Patterns………………………………….. 26

Figure 6-1: Checkout Test Set-Up…………………………………….……… 27

Figure 7-1: Synchronizing the A-frame……………………………………….30

Figure 7-2: Fault Confirmation………………………………………………. 31

Figure 8-1: Perpendicular Method…………………………………………… 33

Figure 8-2: Triangulation Method…………………………………………… 34

Figure 8-3: Locating an Equipotential Circle……………………………….. 34

Figure 8-4: Fault Location Using Extension Cable for

Increased Sensitivity…………………………………………….. 35

Figure 9-1: Receiver Battery Replacement………………………………….. 37

2

1INTRODUCTION

The Metrotech 9800SFL Sheath Fault Locator system is designed to detect and pinpoint

sheath and other conductor faults that are in direct contact with the earth.

The 9800SFL offers these unique features:

♦ Fault level measurement at the Transmitter

♦ Simultaneous fault finding and line tracing.

♦ Signal strength LCD on the A-Frame for judging proximity to

faults, comparing multiple faults, and detecting pinholes and

“trees” in power cable.

♦ Detection of low and high resistance faults.

♦ Automatic battery checking and low battery warning

♦ Non-polarized A-Frame.

♦ Single-handed operation. No need to carry locator receiver as well

as A-frame.

Operation of the unit is completely automatic; there are no operator adjustments required.

Both the Transmitter and Receiver are water resistant and built to withstand the rigors of

field use.

3

2 SAFETY PRECAUTIONS

1 Metrotech Utility Line and Sheath Fault Locators are intended for use by utility

and contractor professionals. Safety hazards for underground utility access

areas include electrical shock, explosive gases, and toxic fumes as well as

potential influence on communications and control systems such as traffic control

and railroad crossings.

2 Familiarize yourself with all required safety practices of the local utility company,

or other owner of the plant before entering an access area or connecting a

Metrotech transmitter.

3 Before connecting transmitter directly to any conductor, make sure that the

line is de-energized and out of service. Never make a direct connection to a

live power cable.

4 If you use the Metroclamp on energized electrical or control lines follow

appropriate safety procedures to avoid the risk of injury.

5 Pay special attention when using a locator in high traffic areas.

4

3 9800XT SFL-2 SHEATH FAULT LOCATOR QUICK START

FOR THE EXPERIENCED USER

1 Check Batteries Prior to Departing for the Field

Check the batteries in the Transmitter, Receiver, and A-Frame.

Replace/recharge if necessary. Turn the instruments off.

2 Ensure all conductors are de-energized

3 Lift Grounds

Lift Grounds (of all conductors in the circuit) at both ends of the faulted cable

section.

WARNING

When the Transmitter is set to “SFL”, the external OUTPUT JACKS produce

High Voltage. Do not touch these jacks, electrical shock will result!

4 Attach Transmitter to Conductor – Check Fault Resistance

1 Turn Transmitter “OFF.”

2 Plug Black and Red leads into the Transmitter.

3 Stretch Black-lead 180 degrees away from conductor.

4 Push grounding rod into earth and clamp black lead to grounding rod.

Establish the best ground possible. See figure 3-2

5 Clamp Red lead to target conductor sheath. See Figure 3-3

6 Turn Transmitter power knob to “SFL” position.

Check fault resistance scale: See Figure 3-1

0-100k ohms – Severe Fault

100k – 500k ohms – Medium Fault

1 Megohm and above – Light Faults

Note: Read the number below the oscillating

bar to check the quality of the targeted

cable. The fault resistance on

Figure 3-1 is 10K ohms (Severe Fault).

Figure 3-1: Fault Resistance Scale

5

Figure 3-2: Clamping Black Lead to Ground Rod

Figure 3-3: Clamping Red Lead to Conductor

5 Use the 9800XT Line Locator Receiver to Trace the Cable

Trace and mark the cable as you proceed towards the fault.

Figure 3-4: Locating the Targeted Cable

6

5 Synchronize the A-Frame Receiver and establish reference value of fault

(A-Frame receiver has a one-color band above each spike (Black or White)

1 Hold the A-Frame Receiver so the spike with the black band is about 2 steps

away from the ground rod and the spike with the white band is in-line with the

targeted cable. The A-frame receiver must be placed as shown in figure 3-5

for synchronization and for unit to operate correctly. Push the A-Frame spikes

into the ground. Switch the Receiver “ON” wait until arrow flashes.

Figure 3-5: Positioning of A-Frame Receiver for Synchronization

2 Monitor bar-graph LCD display for arrow direction. If the arrow points

away from the ground rod, there is a fault.

3 If the arrow points towards the ground rod, there is no fault, and

grounds and connections need to be rechecked

4 The number of bars on the LCD indicates the potential gradient

associated with the fault at the synchronization location.

5 The number of bars will decrease when you move away from the

synchronization location and will increase when you get closer to the

targeted fault. See Figure 3-6.

7

Figure 3-6 : Locating the Cable Fault with A-Frame Receiver

8

6 Pinpoint the Fault

1 Keep the A-Frame parallel to the target cable.

2 Insert the A-Frame every 10-20 ft. Follow the arrow.

3 When the arrow changes direction, backtrack. Look at the number of bars

activated and compare them to number of bars you read at synchronization

point. If the number of bars is similar to the number of bars at

synchronization point, you have located the main fault.

4 Insert the A-Frame every two feet until the arrow changes direction again.

5 Move the A-Frame across the cable until a slight movement causes the

arrow to change direction. The fault is located at the center of the A-

Frame.

6 Check entire cable for multiple faults. If more faults are present, check the

active number at each fault site and compare it to the reference number.

The higher the active number the larger the fault.

If you have difficulty with your Metrotech SFL-2 Sheath Fault Locator, check the manual

for additional tips. For Assistance, call us at 1-800-446-3392.

9

NOTE: This equipment has been tested and found to comply within limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in residential installations. This

equipment generates, uses, and can radiate radio frequency energy. If not installed and

used in accordance with the instructions, it may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause interference to radio or television

reception (Which can be determined by turning to the locating equipment off and on). We

suggest the user try to eliminate the interference by one or more of the following

measures:

♦ Reorient or relocate the receiving antenna.

♦ Move the equipment away from the Receiver.

♦ Plug the equipment into an outlet on a circuit different from

that to which the Receiver powered. If necessary, the user

should consult the dealer or an experienced radio/television

technician for additional suggestions.

CAUTION: Only equipment certified to comply with Class B (computer input/output

devices, terminals, printers, etc.) should be attached to this equipment. Finally, any

changes or modifications to the equipment by the user not expressly approved by the

guarantor or manufacturer could void the users authority to operate such equipment.

10

4 MODEL 9800XT SFL EQUIPMENT

4.1 Standard Equipment

The SFL transmitter is an option to the 9860XT and 9890XT Locator System and is

designated by the ‘F’ in the Part Number. When the SFL option is selected, the standard

equipment may include:

Part Model # Description Remarks

9860XT_FXT 4.8 Hz, 9.82kHz, 82 kHz Transmitter

9890XT_FXT 4.8Hz, 982 Hz, 9.8 kHz, 82 kHz Transmitter

9860XT_FXT 9.82kHz, 82 kHz, 50/60 Hz, Receiver

14-22 kHz

9890XT_FXT 982 Hz, 9.8 kHz, 82 kHz Receiver

50/60 Hz, 14-22 kHz

10498 4.8Hz A-Frame Receiver

400B196-1 Red Test Cable

400B196-2 Black Test Cable

600A113 Operating Manual

500B353 Foam pads

11

Figure 4-1: Standard Equipment and Accessories

Standard:

1. 9800XT Receiver

2. 9800XT Transmitter

3. Conductive Attachments

4. Ground Rod

5. Carrying Case

6. SFL – 2 Receiver

7. Operation Manual

Accessories:

8. MetroClamp

9. Flex-Sonde

10. High Power Sonde

11. Standard Power Sonde

12

4.2 Optional Accessories

Optional accessories available for the 9800XT Sheath Fault Locator are listed below:

Part/Model # Description Remarks

4290 2” Metroclamp and For Inductive

jumper cable Coupling or

CableID

4490 4” Metroclamp and For Inductive

jumper cable Coupling or

CableID

4890 8” Metroclamp and For Inductive

jumper cable Coupling or

CableID

400B246 Conductive Attachment Telephone style Clips

400A132 100’ Ground Lead Extension

400B252 Vehicle Mount Charger For use with rechargeable

transmitter batteries

500D082 A-Frame Carrying Case

183048 Head Phones For use in

high noise

levelareas

10126 Live Power Connector Use at 9.8kHz

158084 Search Coil For Cable and pair ID

13

4.3 Technical Specifications

TRANSMITTER

Output Frequencies: Model Frequencies

9860XT* 4.8Hz, 9.82kHz, 82kHz

9890XT* 4.8Hz, 982Hz, 9.82kHz, 82kHz

Audio Output: Pulsing tone to indicate Transmitter output is active.

Line Tracing Ohmmeter: 0-2 kOhm

Fault Metering: Continuous fault resistance monitoring 0 to 10M Ohm.

Automatic ”Best” Frequency Selection

Nominal Output Power

Conductive Mode: Model Watts

9860XT 3*

9890XT 3*

* Output power limited to

.7W at 82kHz

Power Settings: Low and High (all models)

Battery Type: Ten D Cells

Optional Rechargeable NiCd

Battery Life: Alkaline 28-70 hours

NiCd 9-22 hours Continuous use,

depending on power and Frequency selection.

Battery Check: Automatic at start up

Operation

Temperature: -4º to +122º F (-20º to +50º C)

Dimensions: 14.25”L x 9.25”W x 5.25”H

(36.2 cm x 23.5 cm x 13.3 cm)

Weight: 8.9 lbs. (4 kg)

14

Technical Specifications (4.3 cont’d)

A-FRAME RECEIVER

Frequency: 4.8 Hz Crystal Controlled

Input Sensitivity: 5 MV

Sensitivity Control: Automatic

Dynamic Range:

Bargraph 72 dB

Output Indication:

Bargraph LCD Flashing LCD arrows point to fault 12 segment LCD bar

graph indicates signal level, each bar = 6dB.

Battery: 9 V NEDA 1604 or equivalent.

Battery Life: 100 hours continuous use.

Battery Test. Automatic at power on

Weight: 4.4 lb (2.0 kg)

Dimensions: 32 in. H x 22 in. W x 1 in.

(81 cm x 56 cm x 2.5 cm)

Operational Temp: -4 to + 120 degrees F

15

Technical Specifications (4.3 cont’d)

9800XT Receiver

Frequencies: Model Frequencies

9860XT Active - 9.82kHz, 82kHz

Passive - 50/60Hz, 14-22kHz

9890XT Active - 982Hz, 9.82kHz, 82kHz

Passive - 50/60Hz, 14-22kHz

Depth

Readout

Accuracy: Passive-+(5% + 2”) under normal conditions

Active-+(5% + 2”) under normal conditions

Distance Sensitive Left/Right GuidanceTM

Real-Time Continuous Gain AdjustmentTM and Manual Gain Control

Simultaneous Peak and Null DisplayTM

Current Measurement

Backlighting: Standard on all 9800XT receivers

Serial link: RS232

Battery Type: Six AA Cells

Battery Life: 30 hours continuous use

24 hours continuous backlit use

Battery Check: Continuous Automatic Operation

Temperature: -4º to +122º F (-20º to +50º C)

Dimensions: 27”L x 7”W x 9”H

(68.6 cm x 17.8 cm x 22.9 cm)

Weight: 5.4 lbs. (2.35 kg)

16

4.4 Transmitter: Controls and Indicators

WARNING

When the Transmitter is set to “SFL”, the external OUTPUT JACKS produce

high voltage. Do not touch these jacks, electrical shock will result!

See Figure 4-2 for location of Transmitter controls and indicators described below:

Figure 4-2: Transmitter Control Panel

1 Output Clamp Jack

2 Conductor Arrow

3 Charge Jack

4 Frequency Knob

5 LCD Display

6 Power Knob

7 Battery Access Caps

8 SFL Conductive Attachment Output Jack

This manual suits for next models

2

Table of contents

Other Metrotech Security Sensor manuals

Popular Security Sensor manuals by other brands

Vertiv

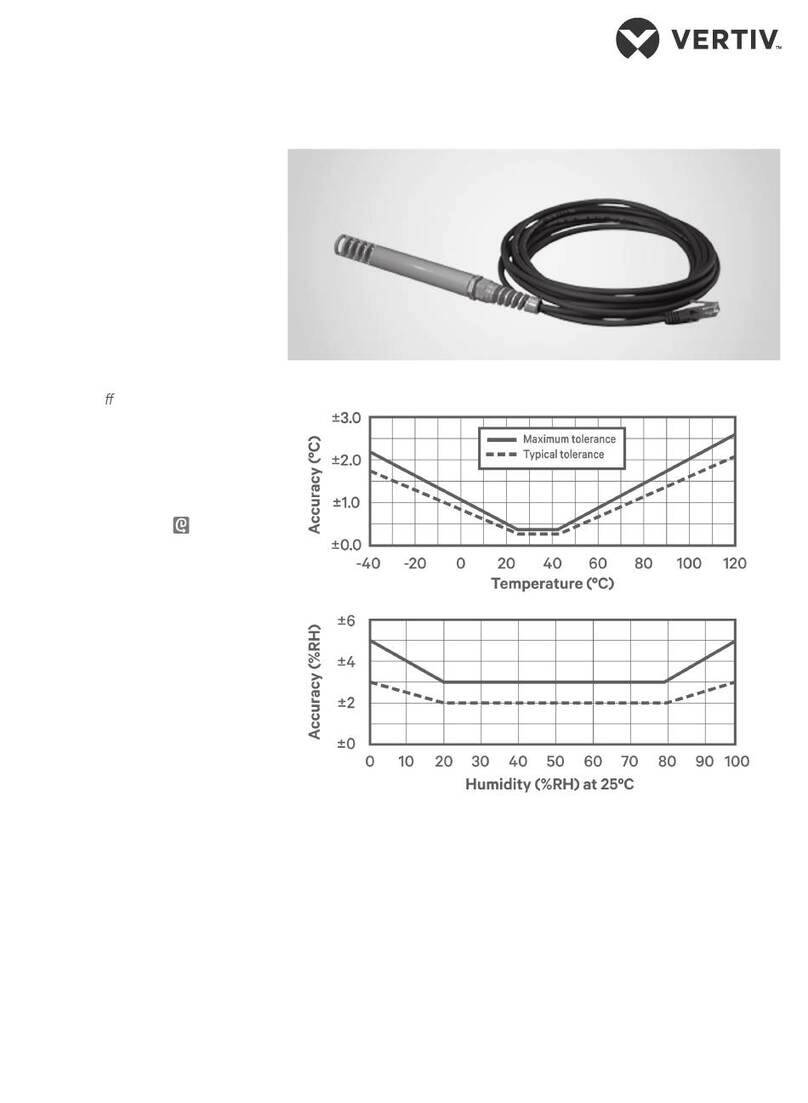

Vertiv GEIST RTAFHD3 Quick installation manual

Extech Instruments

Extech Instruments DV40 manual

Honeywell

Honeywell Miller Titan TR50 user guide

ComSonics

ComSonics QAM Sniffer Quick reference guide

Crowcon

Crowcon Xgard IR Installation, operating and maintenance instructions

Dilo

Dilo SF6-LeakPointer operating manual