Metso LCP9H Series Operating and maintenance manual

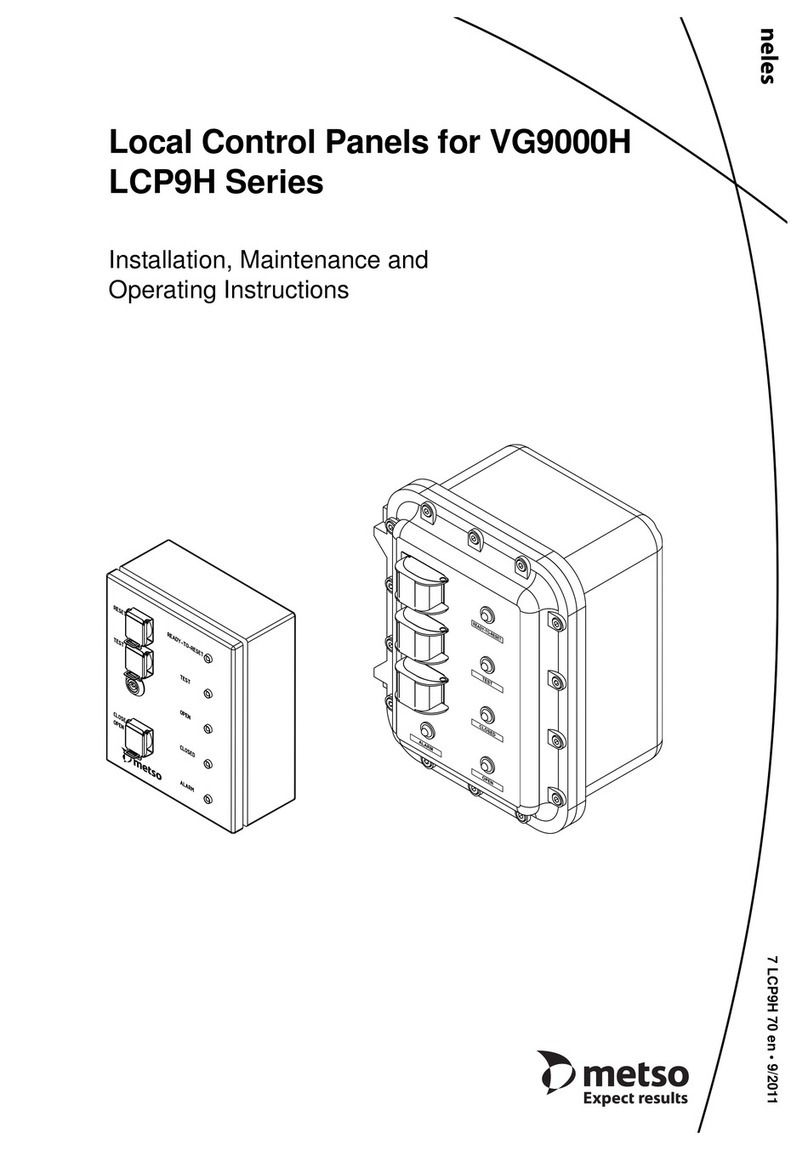

Local Control Panels for VG9000H

LCP9H Series

Installation, Maintenance and

Operating Instructions

NOTE: Special version for Liwa-project

7 LCP9H 70 en Liwa • 5/2018

27 LCP9H 70 en Liwa

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the device.

If you require additional assistance, please contact the manufacturer or manufacturer's representative.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

Table of Contents

1 LCP9H Local Control Panels for VG9000H .........3

1.1 General .....................................................................3

1.2 Technical description ..........................................3

1.3 System architecture .............................................3

1.4 Markings ..................................................................4

1.5 Technical specifications .....................................4

1.6 Recycling and disposal .......................................6

1.7 Safety precautions ...............................................6

2 TRANSPORTATION, RECEPTION AND

STORAGE ..............................................................6

3 MOUNTING ..........................................................7

3.1 Electrical connections .........................................7

4 LCP9H LAYOUT AND FUNCTIONALITY ..............7

4.1 Functionality ..........................................................8

5 MAINTENANCE .................................................... 9

5.1 LED test ....................................................................9

6 TROUBLE SHOOTING ...........................................9

7 TOOLS ...................................................................9

8 SPARE PARTS....................................................... 9

9 DIMENSIONS ......................................................10

10 EC DECLARATION OF CONFORMITY ................11

11 TYPE CODING .....................................................12

7 LCP9H 70 en Liwa 3

1 LCP9H Local Control Panels for

VG9000H

1.1 General

The Local Control Panels LCP9H-series are designed to be

used together with the VG9000H intelligent safety solenoid.

Later on in this manual LCP9H name is used when all device

versions are in question. LCP9HL name is used when loop

powered versions are in question.

Different versions of LCP9H are following:

LCP9H, LCP9HW

Externally powered with ATEX and IECEx Ex i and Ex e

approvals

Use with VG9000H_L2

LCP9HL, LCP9HWL

Loop powered with ATEX and IECEx Ex i and Ex e

approvals

Use with VG9000H_L3

LCP9HE, LCP9HEW

Externally powered with ATEX and IECEx Ex d and tb

approvals

Use with VG9000H_L2

LCP9HEL, LCP9HEWL

Loop powered with ATEX and IECEx Ex d and tb

approvals

Use with VG9000H_L3

See the details of different types of LCP9H in the type cod-

ing at the end of this document.

This manual only describes the Local Control Panel wiring,

configurations and functions. See the VG9000H manual

(7VG92H70en) for detailed information, functionality and

wiring connections and options for the VG9000H.

1.2 Technical description

LCP9H permits the emergency isolation valve to be closed

(or opened) locally (close/open functionality, see 4.1.1 for

details). LCP9H permits the valve to be returned to the nor-

mal operating position when the trip initiators are normal

(manual reset functionality, see 4.1.2 for details). There is

also the option for functional testing (PST) of the emer-

gency isolation valve (test functionality, see 4.1.3 for

details).

Trip-functionality is removed in the W versions of the

LCP9H.

See the details of different types of LCP9H in the type cod-

ing at the end of this document.

LCP9H has also indicators (LEDs) for the valve position

(open/close), ready to reset, testing and alarm status (see

4.1.4-7 for LED details).

All the buttons are lockable with e.g. padlock (max. shackle

dia. 5 mm).

1.3 System architecture

The Local Control Panel LCP9H is connected to the

VG9000H with a dual pair cable. Communication between

the devices is handled by a current loop. The LCP9H needs

also a supply power. For the loop powered LCP9H versions

(LCP9H_L) the supply power is taken from the input loop for

the VG9000H, which needs to be 8 mA or more. For the

other LCP9H versions the power supply is external 24 VDC.

Refer to the general wiring of the LCP9H versions in Fig. 1 &

2. See detailed wiring information in Section 3.2.

If the LCP9H is used in intrinsically safe installations, an iso-

lator will be needed for the 24 V DC power supply, see Sec-

tion 1.5 for compatible isolators.

Fig. 1 General wiring of LCP9H / VG9000H_L2

Air supply

1. ValvGuard VG9000H_L2

2. Pneumatic actuator

3. Local Control Panel LCP9H

AO (mA)

from safety system (or from RCI9H)

24 V DC supply

(via isolator if required)

Serial

communication

47 LCP9H 70 en Liwa

1.4 Markings

The Local Control Panel is equipped with an identification

plate (Fig. 2 or 3).

1.5 Technical specifications

VG9000H compatibility

LCP9H 24 VDC powered versions are compatible with

VG9_H_L2_ versions. LCP9H loop powered versions

(LCP9H_L) are compatible with VG9_H_L3_ versions.

See the LCP9H type coding for further details of different

LCP9H versions.

See the VG9000H type coding for further details of different

VG9000H versions.

Temperature range

-20° to 85 °C (Ex ia, ic)

-20° to 65 °C (Ex d, e)

Electronics

Electrical connection: max. 2.5 mm2

LCP9H 2 pcs. conduit entry, dia. 21 mm, cable

glands for cable with with ext. dia. 8-

12 mm included

LCP9HE 2 pcs. conduit entry, M20x1.5

Power consumption: 400 mW

Power supply: Externally powered versions; 11–

24 V DC, 50 mA. Short circuit

protected. Maximum distance

1200 m

Loop powered versions: power taken from VG9000H input

signal, minimum 8 mA.

Interface values for externally powered versions:

Ex ia IIC T4/T5/T6 Gb

Input values for the power supply:

Ui ≤25.2 V

Ii ≤150 mA

Pi ≤650 mW

Ci ≤30 nF

Li ≤252 µH

Output values for the communication interface:

Uo ≤9.8 V

Io ≤47 mA

Po ≤120 mW

Co ≤3.3 µF

Lo ≤15 mH

Fig. 2 General wiring of LCP9H_L / VG9000H_L3

Fig. 3 Example of identification plate, LCP9H

Fig. 4 Example of identification plate, LCP9HE

7 LCP9H 70 en Liwa 5

Ex ic IIC T4/T5/T6

Input values for the power supply:

Ui ≤25.2 V

Ii ≤150 mA

Pi ≤650 mW

Ci ≤25 nF

Li ≤201 µH

Output values for the communication interface:

Uo ≤8.8 V

Io ≤42 mA

Po ≤93 mW

Co ≤45 µF

Lo ≤45 mH

Interface values for externally and loop powered versions:

Ex eb mb [ib] IIC T6...T4

Maximum input value for the power supply:

U = 24 V

The Intrinsically Safe parameters of the current loop

communication interface are:

Uo = 9,8 V

Io = 47 mA

Po = 120 mW

Co = 3,3 F

Lo = 15 mH

Ex d IIB+H2 T6 Gb

Ex tb IIIC T85 °C Db

Input values for the power supply:

Ui ≤25.2 V DC

Ii ≤50 mA

Pi ≤1.26 W

Output values for the communication interface:

Uo ≤8.8 V DC

Io ≤42 mA

Po ≤0.37 W

Interface values for loop powered versions:

Ex ia IIC T6...T4 Gb

Input values for the power supply:

Ui ≤ 28 V

Ii ≤ 120 mA

Pi ≤ 1 W

Li ≤ 313 H

Ci ≤ 33 nF

Output values for the communication interface:

Tx: Uo ≤ 8.3 V

Io ≤ 5.8 mA

Po ≤ 12 mW

Lo ≤ 50 mH

Co ≤ 3.6 F

Rx: Uo ≤ 8.3 V

Io ≤ 12.7 mA

Po ≤ 26 mW

Lo ≤ 50 mH

Co ≤ 3.6 F

Ex ic IIC T6...T4 Gc

Input values for the power supply:

Ui ≤ 28 V

Ii ≤ 120 mA

Pi ≤ 1 W

Li ≤ 313 H

Ci ≤ 27.5 nF

Output values for the communication interface:

Tx: Uo ≤ 8.3 V

Io ≤ 5.8 mA

Po ≤ 12 mW

Lo ≤ 50 mH

Co ≤ 3.6 F

Rx: Uo ≤ 6.5 V

Io ≤ 1.8 mA

Po ≤ 3 mW

Lo ≤ 50 mH

Co ≤ 152 F

ATEX and IECEx approvals are valid under these conditions.

Compatible isolators for the power supply (not loop pow-

ered models)

MTL 5021

P&F KFD0-SD2-Ex1.1045

STAHL 9176/.0-14-0

ABB V17132-520

Communication cable

The communication cable between LCP9H and VG9000H

must be a shielded, twisted pair, 4-wire cable. The shield

must be connected to housings in both ends. The maxi-

mum recommended distance between VG9000H and

LCP9H is 60 m.

Cable requirements:

Signals and corresponding ground

wires twisted

Wire thickness min. 0.8 mm

Shield coverage > 85 %

Test voltage > 1500 V

Ex requirement)

Resistance < 50 Ω/km

Capacitance < 50 pF/m

Material and weight

LCP9H 316L stainless steel, 2.8 kg

LCP9HE Copper-free aluminium alloy with

epoxy coating, 14.6 kg

Dimensions

LCP9H

With buttons and cable glands (approx.):

270 mm x 200 mm x 137 mm

(h x w x d)

LCP9HE

With buttons: 364 mm x 317 mm x 252 mm

(h x w x d)

67 LCP9H 70 en Liwa

APPROVALS

Intrinsically safe

IECEx Ex ia IIC T6...T4 Gb

Ex ic IIC T6...T4 Gc

Ex eb mb [ib] IIC T6...T4 Gb

IEC 60079-0: 2011

IEC 60079-11: 2011

IEC 60079-18: 2014

IEC 60079-7: 2015

ATEX II 2G Ex ia IIC T6...T4 Gb

II 3G Ex ic IIC T6...T4 Gc

II 2G Ex eb mb [ib] IIC T6...T4 Gb

EN 60079-0: 2012,

EN 60079-7: 2015,

EN 60079-11: 2012,

EN 60079-18: 2015

INMETRO

Ex ia IIC T6...T4 Gb

Ex ic IIC T6...T4 Gc

ABNT NBR IEC 60079-0:2013

ABNT NBR IEC 60079-11:2009

Flameproof and explosion proof

IECEx Ex d IIB+H2T6 Gb

Ex tb IIIC T85 °C Db IP66

IEC 60079-0: 2007,

IEC 60079-1: 2007,

IEC 60079-31: 2008

ATEX II 2GD

Ex d IIB + H2 T6 Gb

Ex tb IIIC T85°C Db IP66

EN 60079-0: 2009-10,

EN 60079-1: 2007-04,

EN 60079-31: 2009

INMETRO

Ex d IIB+H2 T6 Gb

Ex tb IIIC T85 °C Db IP65

ABNT NBR IEC 60079-0:2008 versão

corrigida 2011

ABNT NBR IEC 60079-1:2009 versão

corrigida 2011

ABNT NBR IEC 60079-31:2011

ABNT NBR IEC 60529:2009

Electromagnetic protection

Electromagnetic compatibility

Emission acc. to EN 61000-6-4: 2007

Immunity acc. to EN 61000-6-2: 2005

1.6 Recycling and disposal

Most local control panel parts can be recycled if sorted

according to material. Most parts have material marking. In

addition, separate recycling and disposal instructions are

available from the manufacturer.

The Local Control Panel may also be returned to the manufac-

turer for recycling and disposal. There will be a charge for this.

1.7 Safety precautions

2 TRANSPORTATION, RECEPTION AND

STORAGE

The Local Control Panel is a sophisticated instrument, han-

dle it with care.

Check the Local Control Panel for any damage that

may have occurred during transportation.

Store the Local Control Panel preferably indoors and

keep it away from rain and dust.

CAUTION:

Do not exceed the permitted values!

Exceeding the permitted values may cause damage to

the local control panel and to equipment attached to

the panel.

Damage to the equipment and personal injury may

result.

CAUTION:

During maintenance or commissioning when the

device cover is open, ensure that water does not go

inside the enclosure.

CAUTION:

Do not operate the device with the cover open or

removed!

Electromagnetic immunity is reduced.

Ex d WARNING:

Do not open the cover when an explosive atmosphere

may be present!

Ex d and Ex tb WARNING:

Use a cable gland with suitable Ex d IIC and Ex tb IIIC

certification. Use cable gland suitable for at least

-20 °C to 70 °C.

Ex d NOTE:

Only persons familiar with Ex d explosion protection are

allowed to work with the device. Special attention has to

be paid to careful handling and closing of the cover.

NOTE:

Avoid earthing a welding machine in close proximity to

the LCP9H.

Damage to the equipment may result.

7 LCP9H 70 en Liwa 7

3 MOUNTING

3.1 Electrical connections

There are two terminal blocks located in the circuit board

inside the LCP9H (see Fig. 4). LOOP terminals are for connec-

tion to the VG9000H and PWR terminals are for the 24 V DC

power supply or for the loop power.

NOTE: The VG9000H version to be used with LCP9H prod-

ucts needs to have type code option L2. The VG9000H ver-

sion to be used with LCP9H_L products needs to have type

code option L3.

In VG9000H the LCP connection terminals are located in the

upper housing.

See the VG9000H manual 7VG9H70EN for detailed electrical

connections in the VG9000H.

4 LCP9H LAYOUT AND FUNCTIONALITY

The LCP9H front panel layouts with push buttons and LEDs

can be seen in Fig. 5–8.

The push buttons (described in the Section 4.1) are as follows:

Open

PST

Close (not available in W version)

The LEDs (described in the Section 4.1) are as follows:

Ready-To-Open(amber)

PST (amber)

Open (green)

Closed (red)

FAULT (white)

NOTE:

The tightening torque for the cover screws of LCP9HE_

versions is 16 Nm.

NOTE:

The enclosure of the LCP9H meets the IP66 protection

class according to EN 60529 in any position when the

cable entries are plugged according to IP66.

Based on good mounting practice, the recommended

mounting position is with electrical connections placed

downwards. If these requirements are not met, and the

cable glands are leaking and the leakage is damaging the

LCP9H electronics, our warranty is not valid.

Fig. 5 LCP9H_ electrical connections

Fig. 6 LCP9H_L electrical connections

VG9000H_L2LCP9H_

LOOP_CHGND

LOOP_B-

LOOP_B+

LOOP_A-

LOOP_A+

PWR_IN_CHGND

PWR_IN-

PWR_IN+

24 V DC

supply

ground

ground

NOTE:

When installing the LCP9H, standard IEC 60079-14/12.2.4

should be considered. The circuits of the apparatus are

assumed to be earthed.

Fig. 7 LCP9H and LCP9HL front panel

Fig. 8 LCP9HW and LCP9HWL front panel

OPEN

PST

READY TO OPEN

CLOSE

FAULT

PST

CLOSED

OPEN

OPEN

PST

READY TO OPEN

FAULT

PST

CLOSED

OPEN

87 LCP9H 70 en Liwa

4.1 Functionality

The functionality of the LCP9H push buttons and purpose

of the LEDs are described below in 4.1.1-7.

Functionality of the LCP9H is lost in the following cases:

If the supply power (external 24 VDC or loop pow-

ered from VG) is disconnected.

If there is no communication between the LCP9H

and the VG9000H, e.g. the cable is broken or discon-

nected.

If the polarity of wires is incorrect.

If the Loop A (7, 8) and Loop B (9, 10) wires are mixed

in the VG9000H.

These above-mentioned cases do not affect the valve posi-

tion. Alarm LED is blinking in those cases.

The buttons need to be pushed (0.2–10 seconds) and

released to perform the desired function.

4.1.1 Close button

This functionality is only available in LCP9H and

LCP9HE. LCP9HW and LCP9HEW do not have the

valve closing functionality.

The purpose of the Close button is to manually close

or open the valve depending on the assembly and

configuration of the valve. It means that this will

drive the valve to safety position.

4.1.2 Open button

The purpose of the Open push button is to return

the valve to the normal operating position after the

emergency trip.

The Open button is operational only when the mA

signal from the safety system to VG9000H is in 12.0-

15.0 mA.

The Ready-to-Open LED is lit when mA signal from

the safety system is 12.0 - 15.0 mA. The Open button

is then operational.

Push and release the Reset button to return the valve

to the normal operating position.

4.1.3 PST button

The purpose of the PST button is to start the partial

stroke test (PST) manually or to cancel the manual

partial stroke test of the emergency isolation valve.

The stroke size of the test can be set via HART (DTM,

EDD) or from the LUI (Local User Interface) of the

VG9000H. See VG9000H manual 7VG970en for details.

The manual test via LCP9H uses the same stroke size

than manual PST programmed into VG9000H itself.

To start the PST test, press and release the PST button

and the PST LED will be illuminated.

To stop the ongoing manual PST test, press and

release the PST button and the manual PST test will be

cancelled. The valve will return to its normal operating

position.

It is also possible to cancel the manual PST test with

this PST button even if the test is started via HART or

LUI.

4.1.4 Ready-To-Open LED

The Ready-To-Open LED is turned on when mA sig-

nal from the safety system to the VG9000H is 12.0-

15.0 mA and the Open button has not yet been

pushed. It indicates that the Open button can be

used.

Fig. 9 LCP9HE and LCP9HEL front panel

Fig. 10 LCP9HEW and LCP9HEWL front panel

NOTE:

When the button is pushed and released, the valve will be

driven to the safety position; i.e. it will close the valve if it is

the emergency shutdown valve and it will open the valve

when it is the emergency blowdown (venting) valve.

NOTE:

When LCP is used with VG9PST version the trip-functiona-

lity needs to be enabled in VG. It is disabled as default.

NOTE:

When the button is pushed and released, the valve will be

driven to the normal operating position; i.e. it will open the

valve if it is the emergency shutdown valve and it will close

the valve when it is the emergency blowdown (venting)

valve.

NOTE:

Make sure to push the Reset button only when it is safe to

return the valve to the normal operating position.

NOTE:

Make sure to push the Ready-To-Open button only when it

is safe to return the valve to the normal operating position.

7 LCP9H 70 en Liwa 9

4.1.5 Open and Closed LEDs

Open and Closed LEDs indicate the valve position

and whether the emergency isolation valve is open

or closed.

If the valve is in the intermediate state both LEDs are

turned off.

The position information is taken from the position

information of the VG9000H safety valve controller

and the triggering limits are user selectable. The limits

can only be seen and changed via HART (DTM, EDD).

4.1.6 PST LED

The function of the PST LED is to indicate when the

PST button is pushed and the PST test with VG9000H

has started. See Section 4.1.3. for the PST button

functionality.

The PST LED will be turned on when the PST button

is pushed and released. It will be on also during the

Test Warning Time. The Test Warning Time is the

VG9000H parameter and can only be seen and

changed via HART (DTM, EDD).

The PST LED will also be turned on during other

tests: pneumatics test, automatic or manual PST and

ETT. See the VG9000H manual for other test details.

The LED will blink few times if the test starting fails.

4.1.7 FAULT LED

The Fault LED indicates the alarm state in the

VG9000H.

If the Fault LED is turned on, it means that the Alarm

status is activated in the VG9000H.

The Fault LED will blink, if the communication

between the LCP9H and the VG9000H is discon-

nected or not functional, or if the External Devices -

parameter "LCP" in the VG9000H DTM (Metso Valve

ManagerTM) is not selected or it is disabled (diS) in

the VG9000H LUI. That parameter can only be

changed via HART or LUI.

5 MAINTENANCE

Under normal service conditions there is no requirement

for regular maintenance.

5.1 LED test

Push the PST button for more than 10 seconds. All the LEDs

will then be turned on and off after one another in the fol-

lowing sequence: open, closed, ready to open, PST, fault.

After the LED test, the LEDs which were turned on prior to

this testing will be turned on.

6 TROUBLE SHOOTING

If the LCP9H does not work, check the following:

Check the LCP parameter in the VG9000H:

The LCP parameter in the VG9000H needs to be ena-

bled. Go to the parameters menu in the VG9000H LUI

and check that LCP is enabled. For details see the

VG9000H IMO.

This can also be checked in Assembly Related view in

the VG9000H DTM. Check that LCP is selected in the

External Devices parameter. For details see the

VG9000H DTM help file.

Wiring:

Check that the wiring between the LCP9H and the

VG9000H is done according to the instructions in

this manual and/or in the VG9000H IMO.

Power supply:

Check that the power supply or the loop power for

the LCP9H is connected according to the instruc-

tions in this manual and it is turned on.

VG9000H:

Check that the VG9000H installation and setup is

done according to the instructions in the VG9000H

IMO.

If starting the PST fails:

Check that there are no alarms/warnings in the

VG9000H. See the VG9000H IMO (7VG9H70en) and/

or DTM help file for details.

The push of the PST button may be too short or too

long. You need to push the PST button for 0.2–10

seconds and then release.

If the reset function does not work:

Check that the mA signal to VG9000H is above

12 mA. See the VG9000H IMO (7VG9H70en) for

details.

Check that supply pressure to the VG9000H is turned

on and in the correct range.

The push of the PST button may be too short or too

long. You need to push the PST button for 0.2–10

seconds and then release.

If the trip function does not work:

Check that the mA signal to VG9_P is 20 mA and the

functionality is enabled in VG. See the VG9000H IMO

(7VG9H70en) for details.

7 TOOLS

Use the provided key for opening and locking the cover in

LCP9H_ versions. No other special tools are required.

Use 8 mm hex key for the cover screws in the LCP9HE_

versions.

8 SPARE PARTS

The following spare parts are available:

printed circuit board

push buttons

button covers

Contact the local Metso Flow Control office for ordering

spare parts.

NOTE:

LCP9H maintenance must only be carried out by Metso

certified service personnel.

10 7 LCP9H 70 en Liwa

9 DIMENSIONS

LCP9H, LCP9HW, LCP9HL, LCP9HWL

LCP9HE, LCP9HEL, LCP9HEW, LCP9HWL

OPEN

PST

READY TO OPEN

CLOSE

FAULT

PST

CLOSED

OPEN

Note: This button is only available in LCP9H or LCP9HL.

LCP9HW or LCP9HWL does not have this button.

Note: This button is only available in LCP9HE and LCP9HEL.

LCP9HEW or LCP9HEWL does not have this button.

Note: The tightening torque for

the cover screws is 16 Nm

7 LCP9H 70 en Liwa 11

10 EC DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

Manufacturer:

Metso Flow Contro l Oy

01301 Vantaa

Finland

Product: Local Control Panel LCP9H_-series

As the products within our sole responsibility of design and manufacture may be used as parts or components in machinery and are not alone

performing functions as described in Article 6(2) in the Machinery Directive (2006/42/EC), we declare that our product(s) to which this Declaration of

Conformity relates must NOT be put into service until the relevant machinery into which it is to be incorporated has been declared in conformity

with the provisions of the Machinery Directive.

The product above is manufactured in compliance with the applicable European directives and technical specications/standards.

Protection from e.g. static electricity caused by the process or connected equipment must be considered by the user ( EN 60079-14 §6 ).

The product do not possess any residual risk according to hazard analyses made under the applicable directives providing that the procedures

stated by the Installation, Operation and Maintenance manual are followed and the product is used under conditions mentioned in the technical

specications.

Vantaa 16th F ebruary 2017

Ralf Liljestran d, Quality Manage r

Authorized person of the manufa cturer within the Europe an Com munity

Applicable directives:

EMC 2004/108/EC Electrical

ATEX 2014/34/EU

Approved and Ex marked types

ATEX Notied Bodies for EC Type Examination Certicate:

SIRA (Notied body number 0518)

Sira Certication Service

Rake Lane, Eccleston,

Chester, CH4 9JN

England

VTT (Notied body number 0537)

VTT, Expert Services

Otakaari 7B, Espoo

P.O.Box 1000, FI-02044 VTT

Finland

ATEX Notied Body for Quality Assurance:

ISO 9001:2008 Certicate No: 73538-2010-AQ-FIN-FINAS

ATEX 94/9/EC Annex IV Certicate No: DNV-2006-OSL-ATEX-0260Q

Det Norske Veritas AS (Notied body number 0575)

Veritasveien 1

1322 Høvik, Oslo

Norway

Type Product Approval EC Type examination Certicate

Ex i

LCP9H, LCP9HW

ATEX II 2G Ex ia IIC T6...T4 Gb VTT 09 ATEX 047X, Issue 5

EN 60079-0: 2012, EN 60079-11: 2012

ATEX II 3G Ex ic IIC T6...T4 Gc VTT 11 ATEX 048X , Issue 5

EN 60079-0: 2012, EN 60079-11: 2012

LCP9HL, LCP9HWL

ATEX II 2G Ex ia IIC T6...T4 Gb VTT 16 ATEX 057X

EN 60079-0: 2012, EN 60079-11: 2012

ATEX II 3G Ex ic IIC T6...T4 Gc VTT 16 ATEX 058X

EN 60079-0: 2012, EN 60079-11: 2012

Ex m

LCP9H, LCP9HW, ATEX II 2G Ex eb mb [ib] IIC T6...T4 Gb VTT 16 ATEX 043X

LCP9HL, LCP9HWL

EN 60079-0: 2012, EN 60079-7: 2015

EN 60079-11: 2012, EN 60079-18: 2015

Ex d

LCP9HE, LCP9HEW, ATEX 2 IIG Ex d IIB+H2 T6 Gb SIRA 11 ATEX 1170 , Issue 3

LCP9HEL, LCP9HEWL ATEX 2 IID Ex tb IIIC T85°C Db IP66 EN 60079-0: 2009, EN 60079-1: 2007,

Ta -20° to +65 °C EN 60079-31: 2009

EMC LCP9H, LCP9HW (EMC 2004/108/EC) EN 61000-6-2 (2005), NEMKO 135608

EN 61000-6-4 (2007)

LCP9H_L (EMC 2004/108/EC) EN 61000-6-2 (2005), SGS 285215-1

EN 61000-6-4 (2007)

Metso Flow Control Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, M A 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 2102 9700. Fax +55 15 2102 9748

Asia Pacic, 238B Thomson Road, #17-01 Novena Square Tower B, Singapore 307685. Tel. +65 6511 1011. Fax +65 6250 0830

China, 11/F, China Youth Plaza, No.19 North Rd of East 3rd Ring Rd, Chaoyang District, Beijing 100020, China. Tel. +86 10 6566 6600. Fax +86 10 6566 2583

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/valves

12 7 LCP9H 70 en Liwa

11 TYPE CODING

OPTIONAL DEVICE FOR VG9000H

LCP9H_

Externally powered Local Control Panel (LCP)

Versions for Ex i/e: LCP9H, LCP9HW.

Stainless steel 316L, IP66.

Versions for Ex d: LCP9HE, LCP9HEW.

Anodized aluminum, IP66

All versions include LEDs, Manual Reset and PST buttons.

Trip button removed in W versions. Buttons are lockable in

all versions.

Power consumption 400 mW. Power supply 11-30 V DC,

50 mA

ATEX and IECEx certifications:

LCP9H, LCP9HW:

II 2 G Ex ia IIC T6...T4 Gb

Temperature range: T4; -20° to +85 °C, T5; -20° to +80 °C,

T6; -20° to +65 °C.

II 3 G Ex ic IIC T6...T4 Gc

Temperature range: T4; -20° to +85 °C, T5; -20° to +80 °C,

T6; -20° to +85 °C.

II 2G Ex eb mb [ib] IIC T6...T4 Gb

Temperature range: T4; -20° to +65 °C, T5; < +65 °C,

T6; < +60 °C.

LCP9HE, LCP9HEW:

II 2 GD

Ex d IIB+H2T6 Gb

Ex tb IIIC T85°C Db IP66

Ta -20° to +65 °C.

INMETRO certifications:

LCP9H, LCP9HW:

Ex ia IIC T6...T4 Gb

Tamb: T6; -20 ... +50 °C, T5; -20 ... +65 °C, T4; -20 ... +65 °C

Ex ic IIC T6...T4 Gc

Tamb: T6; -20 ... +60 °C, T5; -20 ... +65 °C, T4; -20 ... +65 °C

LCP9HE, LCP9HEW:

Ex d IIB+H2T6 Gb

Ex tb IIIC T85°C Db IP65

Ta -20° to +65 °C

NOTE: 7. sign "L2" in VG9000H type coding needs to be

selected for additional conduit entries and terminal strip.

NOTE: See manual 7VG9H70en for further VG9000H details.

OPTIONAL DEVICE FOR VG9000H

LCP9H_L

LOOP POWERED Local Control Panel (LCP)

Versions for Ex i/e: LCP9HL, LCP9HWL.

Stainless steel 316L, IP66.

Versions for Ex d: LCP9HEL, LCP9HEWL.

Anodized aluminum, IP66.

All versions include LEDs, Manual Reset and PST buttons.

Trip button removed in W versions. Buttons are lockable in

all versions.

Power taken from VG input signal (min 8mA).

ATEX and IECEx certifications:

LCP9HL, LCP9HWL

II 2 G Ex ia IIC T6...T4 Gb

Temperature range: T4; -20° to +65 °C, T5; -20° to +65 °C,

T6; -20° to +50 °C.

II 3 G Ex ic IIC T6...T4 Gc

Temperature range: T4; -20° to +65 °C, T5; -20° to +65 °C,

T6; -20° to +60 °C.

II 2G Ex eb mb [ib] IIC T6...T4 Gb

Temperature range: T4; -20° to +65 °C, T5; -20° to +63 °C,

T6; -20° to +48 °C.

LCP9EHL, LCP9HEWL:

II 2GD

Ex d IIB+H2 T6 Gb

Ex tb IIIC T85°C Db IP66

Ta -20°C to +65°C

NOTE: 7. sign "L3" needs to be selected in VG9000H type

coding for additional conduit entries and terminal strip.

NOTE: Minimum input signal for VG9000H is 8 mA.

Other manuals for LCP9H Series

3

This manual suits for next models

7

Table of contents

Other Metso Control Panel manuals

Popular Control Panel manuals by other brands

Velocity

Velocity MMP Operation and maintenance manual

United Spa Controls

United Spa Controls T8-X Topside Installation manual & users guide

CPflight

CPflight B737 Series manual

Eaton

Eaton MEMSHIELD 4 installation instructions

Aritech

Aritech 1X-F Series Quick installation guide

HWH

HWH 325 SERIES Operator's manual

Zooper

Zooper OPT1/4 installation manual

Grasslin

Grasslin talento 800 Series operating instructions

Zehnder Rittling

Zehnder Rittling ComfoTouch XL QuickGuide Installation

Seav

Seav LRX 2271 manual

Mitsubishi Electric

Mitsubishi Electric GT1155-QTBD instructions

Danfoss

Danfoss VLT FC Series installation guide