METVISA BIMG FP 12 Series User manual

1

2

ÍNDICE

1. Safety Information......................................................................................................................... 3

1.1 General Warnings...................................................................................................................... 3

2. Technical Characteristics............................................................................................................. 4

2.1 Main Components...................................................................................................................... 4

2.2 Technical Data........................................................................................................................... 5

3. Installation..................................................................................................................................... 5

3.1 Equipment Layout...................................................................................................................... 5

3.2 Electrical Connection................................................................................................................. 6

4. Equipment Use.............................................................................................................................. 7

4.1 Utility.......................................................................................................................................... 7

4.2 Commands................................................................................................................................ 7

4.3 Operating Procedures................................................................................................................ 8

5. Cleaning and Maintenance ......................................................................................................... 10

5.1 Cleaning Procedures and Products Used ................................................................................ 10

5.2 Maintenance and Procedures in Case of Breakdowns............................................................. 11

6. ANNEXES..................................................................................................................................... 12

Electrical Schematic –110 V or 220 V - 60 Hz............................................................................... 12

Electrical Schematic –220 V –50 Hz........................................................................................... 13

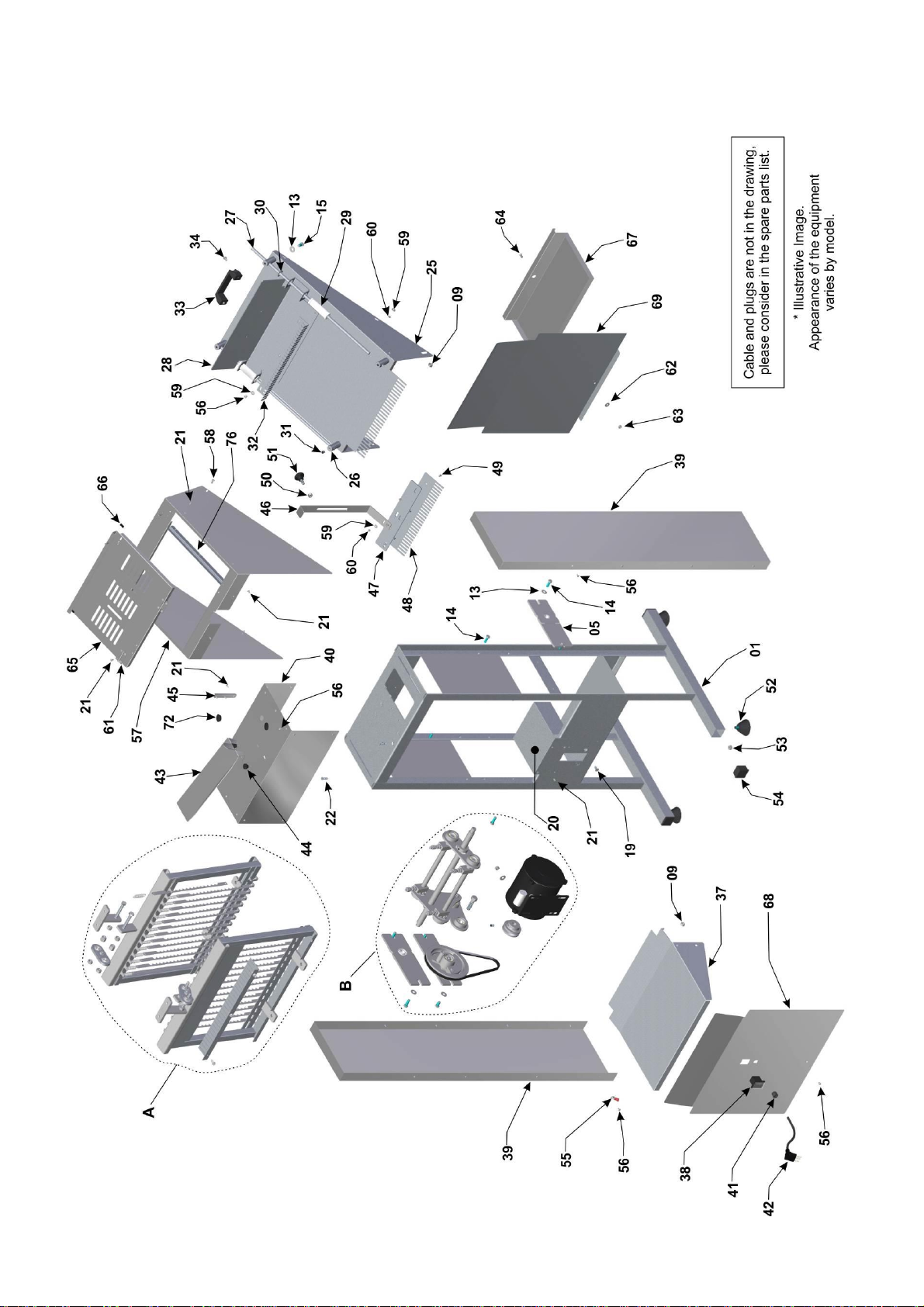

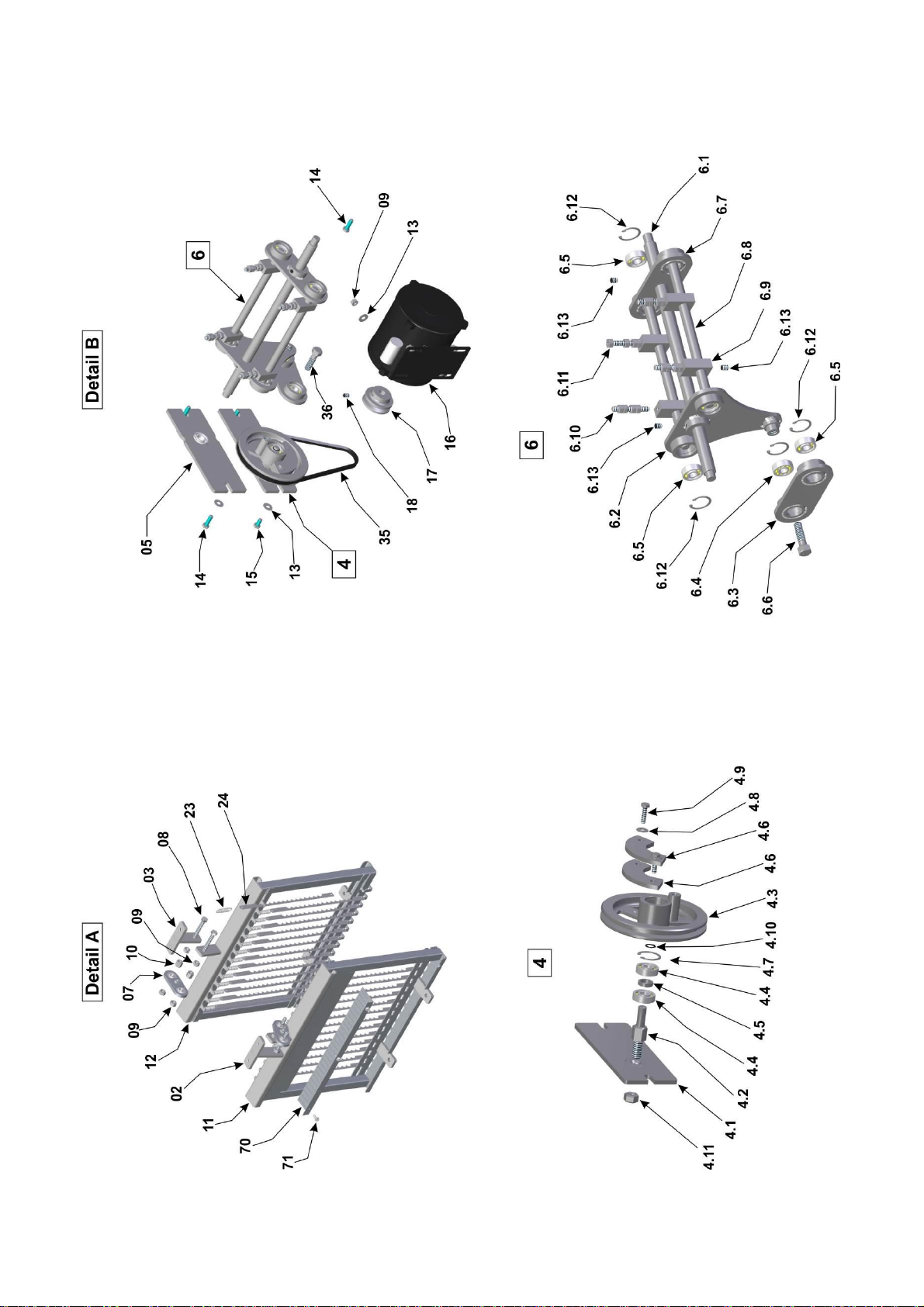

Exploded View............................................................................................................................... 14

Spare Parts ................................................................................................................................... 16

ATTENTION!

The characteristics, pictures and figures presented in this manual should be considered for

information. IMG BRASIL reserves the right to make such modifications as may be deemed

necessary without prior notice.

3

1. Safety Information

1.1 General Warnings

• Cautions / precautions must be observed when installing, using, maintaining and discontinuing use

of this equipment;

• Before carrying out any operation (assembly, use, maintenance and reuse after prolonged non-use

of the equipment), read the manual carefully;

• The equipment must be used by trained people familiar with the use and safety regulations

described in this manual;

• This equipment is not intended for use by people (including children) with reduced physical, sensory

or mental capacities, or people with lack of experience and knowledge, unless they have received

instructions regarding the use of the equipment or are under the supervision of a person responsible

for their safety.

• It is recommended that children be supervised to ensure that they are not playing with the

equipment;

• In case of rotation of the people that will work with the equipment, the new operator must be

educated about the standards and the operation of the equipment;

• The operator must use the Adequate PPE (personal protective equipment). As for example: use

hair caps, preventing them from locking in the equipment's moving parts

• The operator must always be aware of situations that can cause a risk of accidents and avoid them.

For example: avoid working with loose uniform sleeves, where they can lock in moving parts, causing

accidents;

• After reading and clarifying all doubts, this manual should be carefully stored in an easily accessible

location, known to all people who will operate the equipment and make it available to those who will

carry out maintenance for any inquiries. Whenever any questions arise, be sure to check the manual.

Do not operate the equipment in any way with doubts;

• In the installation, it is essential to make this manual available to the professionals who will do the

work.

• Never put hands, fingers or objects (such as spoons and knives) on or near the blades and moving

parts with the equipment turned on;

• Before starting cleaning and any type of maintenance, it is essential to disconnect the equipment

from the power supply;

• Periodically check the condition of cables and electrical parts;

• Do not leave the equipment turned on unattended.

ATTENTION!

Do not perform repairs on your own. Go to a service center authorized by the manufacturer.

Use only original parts in your equipment.

4

2. Technical Characteristics

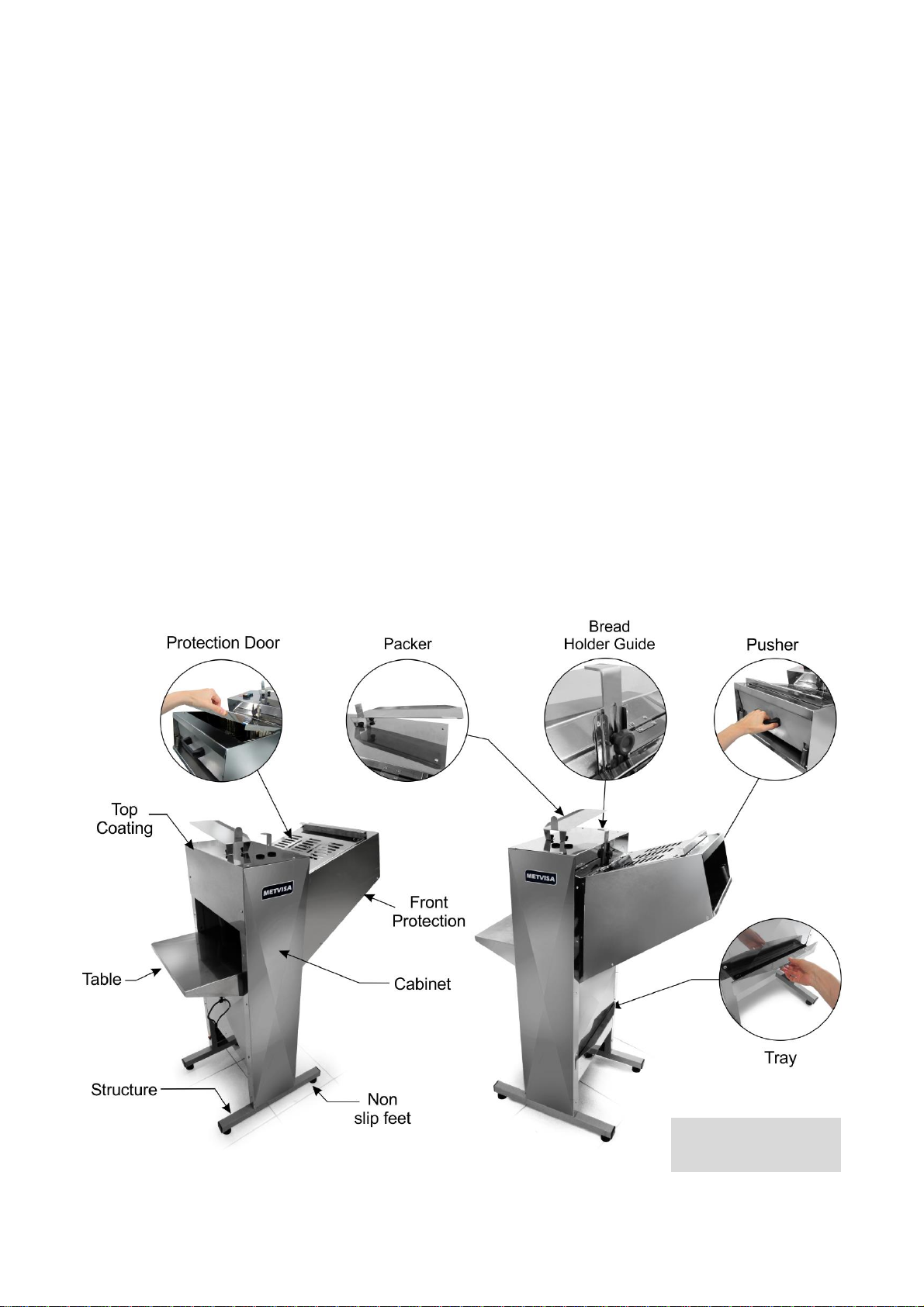

2.1 Main Components

For the equipment described in this manual, safety in use, cleaning, maintenance and

maximum hygiene are guaranteed by the project and special design of all parts and also by using

stainless steel and other materials suitable for contact with the bread.

The equipment was built with the following features:

• Protection door, front protection, top coating, structure, packer, table and tray are made of stainless

steel, which has superior corrosion resistance than other steels. It is a material resistant to the attack

of several corrosive agents;

• The blades are made of special steel, undergoing surface treatment that increases the material's

hardness and its resistance to wear. Its design and production guarantee perfect cutting precision;

• The structure and the pusher are made of SAE 1010/1020 carbon steel with electrostatic epoxy

paint, an excellent anti-corrosion protection that facilitates cleaning.

See the main components of the equipment below:

Note: For exploded view

with spare parts list, see

the annexes.

5

2.2 Technical Data

Model

Standard Measures

Length.xHt.xWidth

(mm)

Net weight

(kg)

Voltage

(V)

Rate

(A)

Useful Area

LengthxWidth

(mm)

FP12110M604

521x1365x915

72

110

3.7

360x150

FP12220M501

521x1365x915

72

220

2.2

360x150

FP12220M502

521x1365x915

72

220

2.2

360x150

FP12220M504

521x1365x915

72

220

2.2

360x150

FP12220M507

521x1365x915

72

220

2.2

360x150

FP12220M604

521x1365x915

72

220

2.1

360x150

Noise level (equipment with bread): 68 dB.

ATTENTION!

Characteristics like: model, serial number and voltage of the equipment are provided on the

label (figure below). Before installation, check that the power supply voltage of the

equipment corresponds to that of the mains

3. Installation

3.1 Equipment Layout

Connection to the electrical network and setup for operation must be carried out by a

qualified professional. Check if the equipment voltage is in accordance with the electrical network.

During installation, it is essential to make this manual available to the professionals who will

carry out the installation.

To ensure correct operation and safety, the equipment must be positioned in a sufficiently

large area, with a well level, dry and stable floor, away from heat sources and water taps, and in a

place where there is no heavy traffic of people. Install your equipment leaving a distance of at least 80

cm around it so that it has enough space for inspection, maintenance, cleaning and use.

6

ATTENTION!

The installation and the place where the equipment will be disposed must comply with the

norms of risk prevention and safety at work (regulatory norm in force in your country).

The manufacturer does not take responsibility for any direct or indirect damages caused by

non-compliance with these rules and other instructions presented in this manual.

3.2 Electrical Connection

The equipment is supplied with a power cord to plug into an electrical outlet. If the power

cord is damaged, it must be replaced with a new one. The exchange must be carried out by the

manufacturer, authorized agent or qualified person, in order to avoid risks.

The type of plug on the power cord varies by country. The installation of the equipment must

be carried out by a technician qualified for this function and observing the current regulations in the

country, especially with regard to grounding connection (if applicable).

Also included with the equipment is an equipotential grounding terminal, located at the rear

of the structure near the foot of the equipment.

The terminal identified in the figure aside is an additional protection to the

grounding that is provided for in the electrical network, it must be connected

to a grounding terminals, regardless of the connection to the electrical

network, and the other products that have accessible metallic parts, and that are stationary,

must also be connected to this bus as well as the service bench itself, if it is made of

metallic material. In this way, all these products will be under the same electrical potential,

avoiding undesirable leakage currents.

The equipment described in this manual is single-phase and single voltage, 110 V or 220 V.

If you need to change the voltage of your equipment, please contact the manufacturer or authorized

dealer.

ATTENTION!

Before turning on your equipment, always check that the mains supply voltage is the same

as the equipment's voltage.

The supply voltage of the equipment is 110 V or 220 V single-phase, as can be seen on the

voltage label affixed to the power cable or as indicated on the nameplate data label located

on the back of the equipment (see figure of this label in item 2.2 of this manual).

Make sure that the voltage of the electrical network where the equipment will be installed is

compatible with the voltage indicated on these labels.

For more details on the rest of the electrical part of the equipment, refer to the electrical

diagram in the manual annexes.

7

IMPORTANTE

The manufacturer does not take responsibility for any direct or indirect damages caused by

non-compliance with these rules and other instructions presented in this manual.

4. Equipment Use

4.1 Utility

This equipment is exclusively intended for slicing breads.

4.2 Commands

The equipment has an on/off button and a guide with a bread holder.

The power switch is located on the rear of the equipment, near the power cord. The guide

and the bread holder, on the other hand, are between the protection door and the upper covering.

See the description of each command below:

• On/Off Button –used to turn the equipment on and off. In position “1” it turns on, in position “0” it

turns off.

8

• Guide with Bread Holder –The guide slides up and down moving the bread holder, making it

possible to adjust the distance between the holder and the bread. So, the bread does not move from

the correct position during the process. To move the holder, follow the instructions below:

4.3 Operating Procedures

Before operating your equipment, make the perfect sanitation, especially of the components

that will come in contact with the bread. Do the cleaning with the equipment disconnected from the

mains. Follow the cleaning instructions in item 5 of this manual (below).

• Operation: The equipment can only be operated after verifying that the equipment voltage is in

accordance with the power supply network, if the equipment is positioned in an ideal location

(according to the guidelines in item 3.1), and if the tray is closed and locked, snapping the cutout

under the tray behind the screw.

Check the operating processes described below:

• Connect the power cord to the electrical network;

9

•After completing the process, turn off the equipment by pressing the power button in the "0"

position (off).

IMPORTANTE

It is recommended to place more than one bread at a time to speed up the process.

Never slice the bread while it is hot or raw. Wait until the bread is at room temperature and

properly baked.

ATTENTION!

Constantly empty the tray, thus preventing excess bread residues from overflowing and

falling to the floor, which could cause accidents and compromise the hygiene of the

establishment.

ATTENTION!

Never place your hands, fingers or objects (such as spoons and knives) on the cutting blade

while the equipment is on as this may cause serious injury.

10

ATTENTION!

If you notice that the equipment cannot slice the bread or it is stopping slicing, do not slice

breads that are still hot and do not press the pusher against the blades, as this will affect the

speed and performance of the motor, and the service life of the equipment.

Failure to follow these guidelines will be considered an unsafe act and abusive use of the

equipment.

Any irregularities, contact the authorized technical assistance closest to you.

5. Cleaning and Maintenance

5.1 Cleaning Procedures and Products Used

Your equipment was built with first-line materials, so use it properly and you will get great

satisfaction. Keep your equipment always clean and well-cared for, which will make it much more

durable.

A daily cleaning of the equipment must be carried out for good operation and durability

ATTENTION!

Before performing maintenance or cleaning, make sure that the on/off button is in position

”0” off and that the plug is disconnected from the mains.

ATTENTION!

Do not use water jet to clean the equipment.

IMPORTANTE

This equipment is not intended to be immersed in water for cleaning.

The detachable part (only the tray) must be removed from the equipment and washed with

soap and water or neutral detergent. Clean corners well, eliminating bread residue.

The rest of the equipment should be cleaned as many times as possible to prevent food

residues from drying out and sticking to the parts. For cleaning, dilute the soap or neutral detergent in

warm water and apply with a soft cloth. With a cloth dampened with water, rinse and then dry the

parts with a soft, dry cloth.

Never use abrasive products or sponges and substances that contain acids or chlorine to

clean metal parts, as they can scratch or damage the surface of the parts, causing corrosion points.

Do not pour water on the motor and electrical parts for cleaning, otherwise, starting it may cause an

electric shock or even burn the equipment.

11

ATTENTION!

It is extremely important that products used in cleaning ensure maximum cleanliness and

are non-toxic.

Dry the blade thoroughly. Moisture compromises the life of the blade and yield of the

cutting process.

ATTENTION!

Take care when cleaning near the blade, it is extremely sharp. Handle with care because this

may cause accidents. The same attention is paid to any other cutting component of the

equipment.

5.2 Maintenance and Procedures in Case of Breakdowns

The operator must be instructed to perform routine inspections, making minor adjustments,

cleaning and observing signs of breaches that may occur. Examples include: checking for strange

noise; loss of equipment power; the non-execution by the equipment of the service to which it is

proposed; among others. Actions like these are indispensable to ensure a longer equipment life.

ATTENTION!

When servicing (even minor adjustments), always disconnect the equipment from the mains.

It is recommended to carry out preventive maintenance every 6 months, checking and

adjusting clearances, cleaning internal parts, wear and tightening (tensioning) of the motor belt, etc.

When detecting broken or weakened parts, replace with original parts.

By performing preventive maintenance, you eliminate the inconvenience of getting the

equipment stopped when you need it most, reducing the cost of maintenance and reducing the risk of

accidents.

ATTENTION!

Preventive maintenance requires a trained professional or authorized technical assistance.

Make sure that the equipment is disconnected from the mains.

Whenever any item regarding the safety of the equipment (such as cleaning or maintenance) is

removed, reset it and confirm that it is performing its function correctly.

When you experience any malfunction or non-compliance, refer your equipment to the

nearest service center. See technical assistance on our website: www.metvisa.com.br

12

6. ANNEXES

Electrical Schematic –110 V or 220 V - 60 Hz

ATTENTION:For electrical installation, observe the current regulations in the country, especially

with regard to the grounding connection (if applicable).

13

Electrical Schematic –220 V –50 Hz

NOTE: In the electric schematic above, the White wires are represented by the pink color.

ATTENTION:For electrical installation, observe the current regulations in the country, especially

with regard to the grounding connection (if applicable).

14

Exploded View

15

Exploded View

16

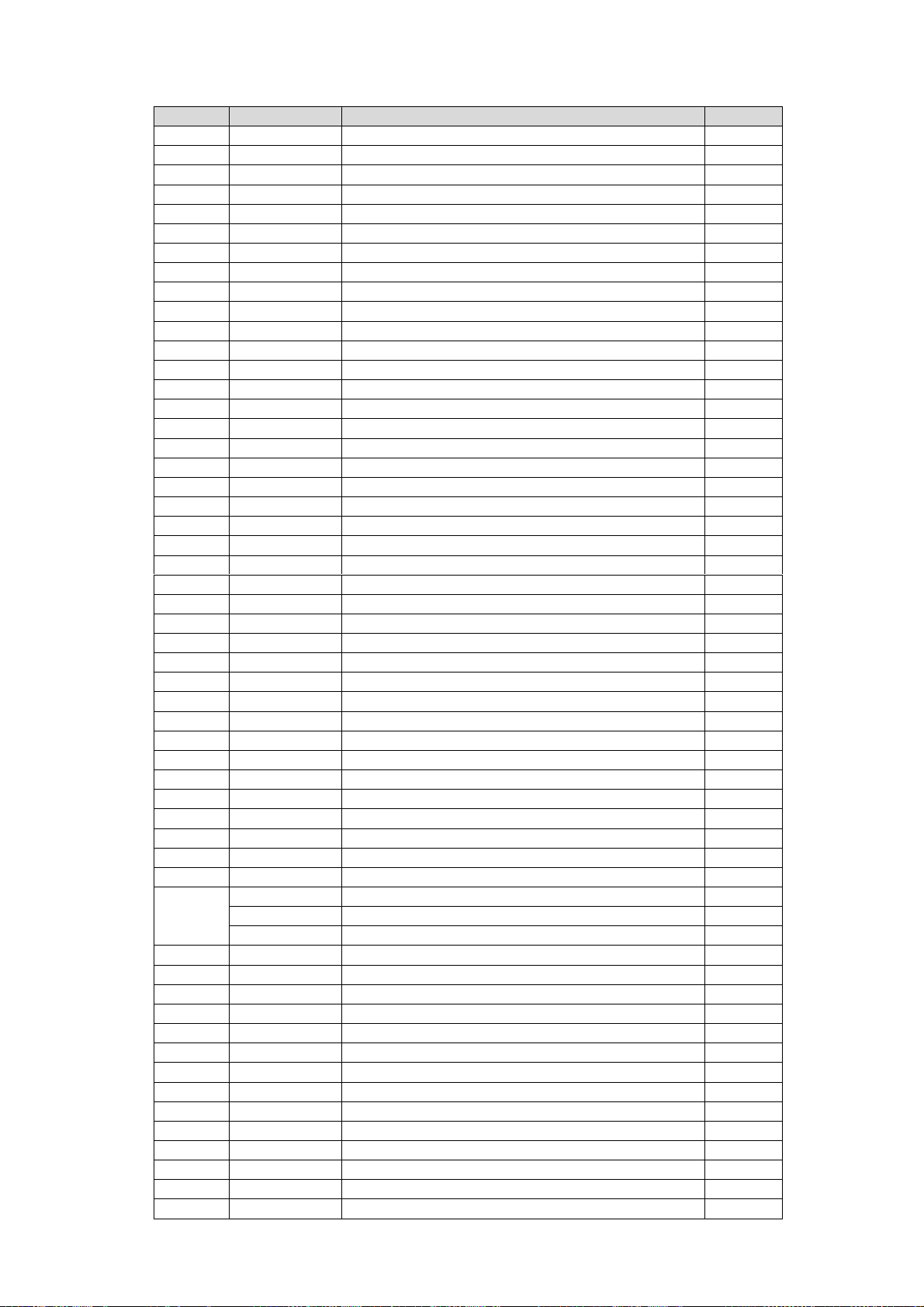

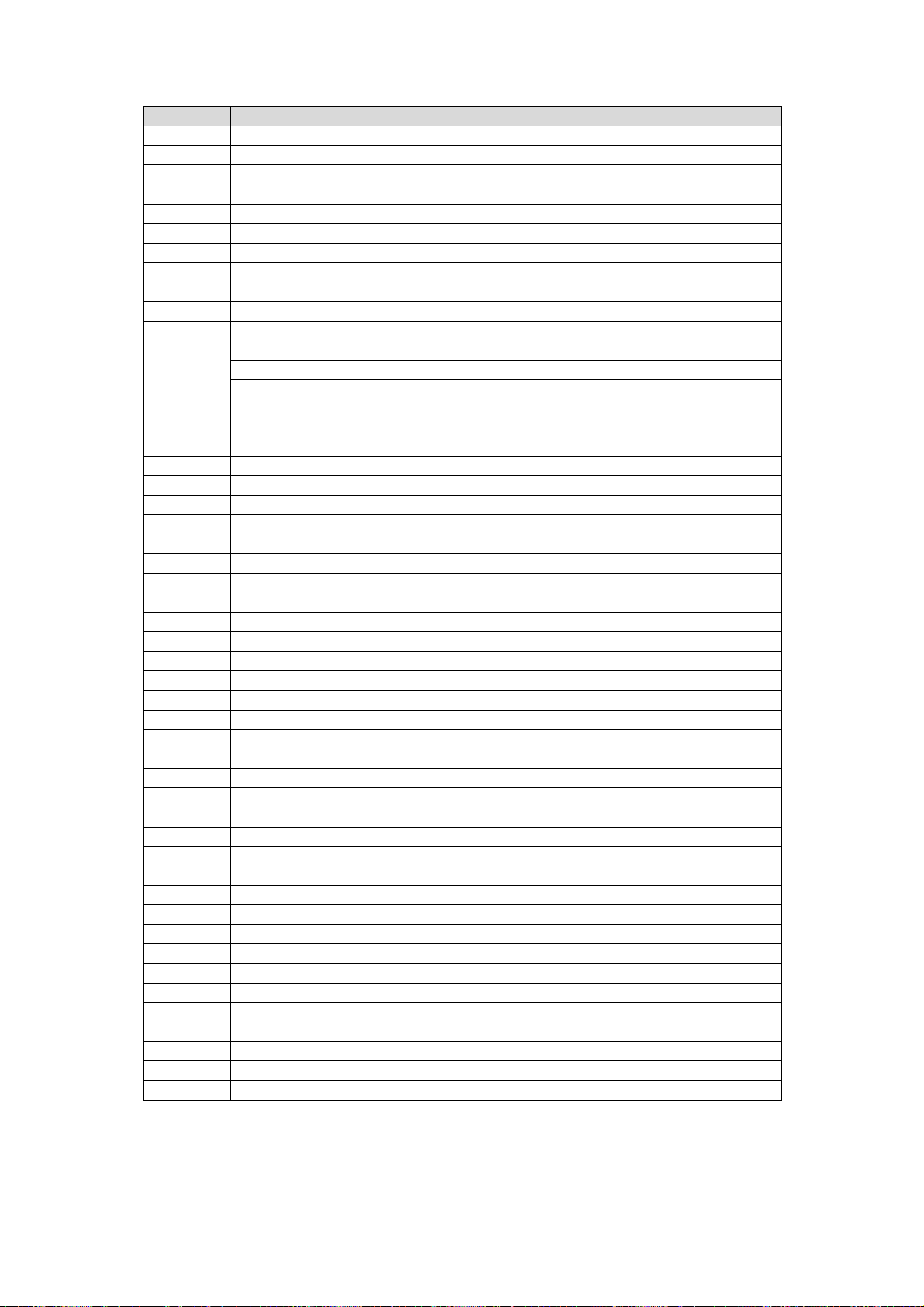

Spare Parts

Position

Code

Description

Quantity

1

ETR062

Complete Welded Structure

01

2

FXC002

Rear Articulator Fixer

01

3

FXC001

Front Articulator Fixer

01

4

CJT1057

Bearing and Pulley Set

01

4.1

MAC053

Pulley Bearing

01

4.2

EIX041

Pulley Shaft

01

4.3

POL017

Pulley

01

4.4

ROL003

Bearing ESF

02

4.5

SRO010

Bearing Separator

01

4.6

CTP003

Counterweight

02

4.7

APE001

Retaining Ring

01

4.8

ARL004

Flat Washer

02

4.9

PRS004

Hexagonal Screw

02

4.10

APE005

Retaining Ring

01

4.11

POS010

Hexagonal Nut

01

5

CJT1058

Bearing Side Assembly

02

6

CJT1059

Rod / Articulator / Axle Set

01

6.1

EIX207

Central Axis

01

6.2

BIL002

Double Rod

01

6.3

BIL003

Rod

01

6.4

ROL028

Bearing

01

6.5

ROL003

Bearing

05

6.6

EIX040

Rod Axle

01

6.7

ART003

Double Articulator

01

6.8

EIX042

Frame Axis

02

6.9

SBT382

Blade Frame Support

04

6.10

TRT009

Rod

04

6.11

POS004

Hexagonal Nut

16

6.12

APE001

Retaining Ring

06

6.13

PRN002

Allen Screw S/C

06

7

CJT700

Articulator Set

02

8

PRS012

Hexagonal Screw

04

9

POS004

Hexagonal Nut

20

10

POS014

Hexagonal Nut

04

11

CJT112

Rear Blade Frame

01

12

CJT111

Front Blade Frame

01

13

ARL003

Flat Washer

14

14

PRS006

Hexagonal Screw

08

15

PRS008

Hexagonal Screw

06

16

MTE214

Motor 1/4 HP 4P 127 V 60 Hz

01

MTE215

Motor 1/4 HP 4P 220 V 60 Hz

01

MTE035

Motor 1/4 HP 4P 220 V 50 Hz

01

17

PMT016

Pulley

01

18

PRN001

Allen Screw

01

19

PRC004

Flat Machine Screw

04

20

CRC061

Motor Protection

01

21

RBT004

Rivet

23

22

PRC003

Flat Machine Screw

04

23

MOL007

Blade Spring

28

24

LMT012

Blade

28

25

CLH002

Gutter

01

26

SBT266

Pusher Guide Support

04

27

GIA071

Pusher Guide

02

28

EPR011

Pusher

01

29

BGT050

Pusher Guide Bushing

02

30

APE004

Retaining Ring

02

17

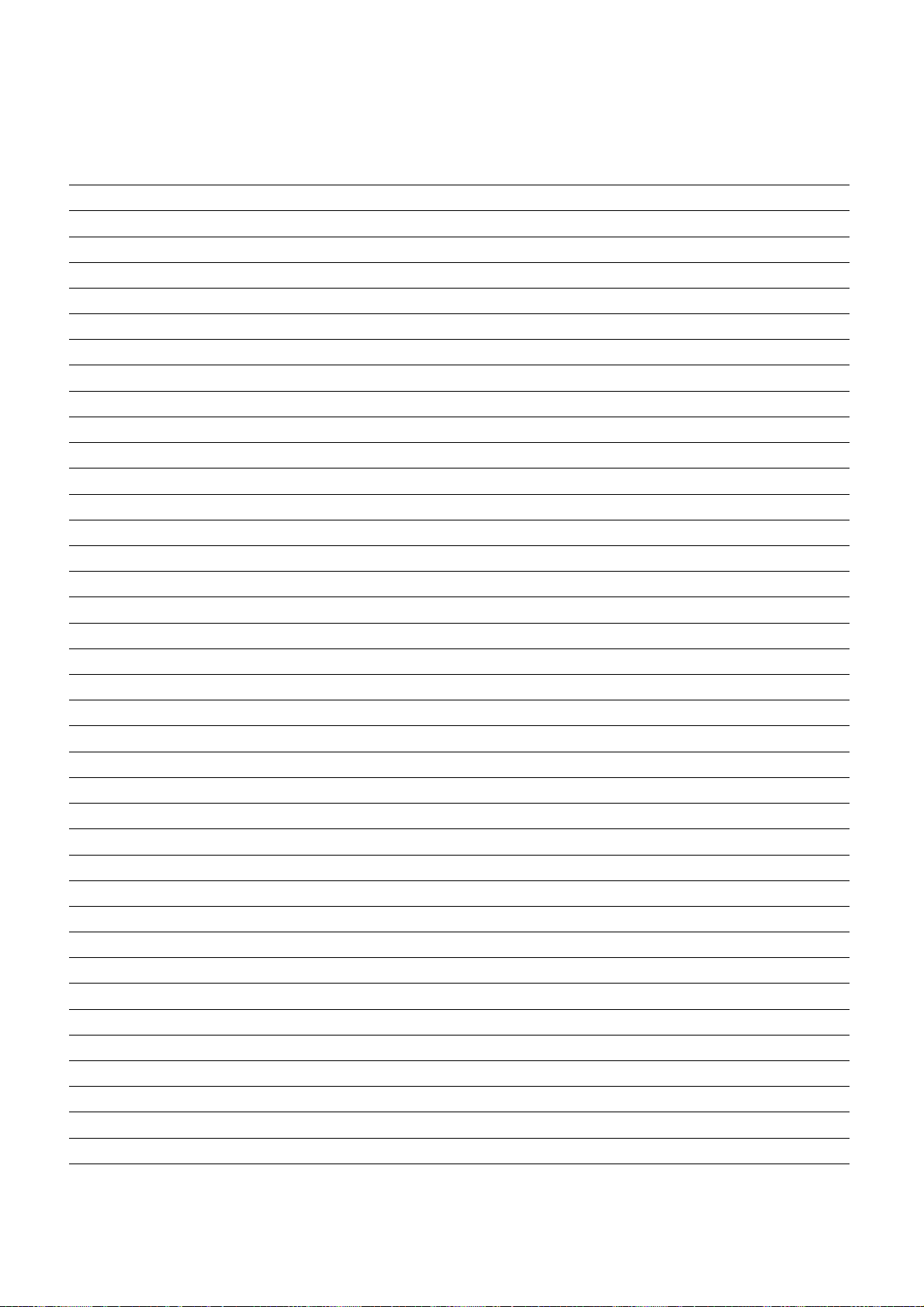

Spare Parts

Position

Code

Description

Quantity

31

PRN002

Allen Screw

04

32

CRC906

Pusher's Comb

01

33

ACA009

Handle

01

34

PRR021

Round Machine Screw

02

35

COR006

Belt

01

36

EIX040

Rod Shaft

01

37

CJT081

Table

01

38

CHE016

On/Off Button

01

39

CRC545

Right and Left Side Protection

02

40

CRC909

Top Coating

01

41

TCE073

Cable Gland

01

42

CBE023

Cable Type 1 - FP12220M501

01

CBE029

Cable Type 2 - FP12220M502

01

CBE030

Cable Type 4 - FP12110M604

FP12220M604

.FP12220M504

01

CBE179

Cable Type 7 - FP12220M507

01

43

BDJ020

Packer

01

44

MNL014

Handle

02

45

AMP052

Holder Guide Support

02

46

GIA072

Holder Bread Guide

01

47

SBT274

Holder Bread Guide Support

01

48

CUP022

Comb Holder Plate

01

49

PRC009

Flat Machine Screw

04

50

POS015

Stainless Steel Hexagonal Nut

01

51

MNL008

Handle

01

52

PEP002

PVC Feet

04

53

POS003

Hexagonal Nut

04

54

SPT001

Plastic Shoe

04

55

TCE023

Equipotential Terminal

01

56

PRR017

Stainless Steel Round Machine Screw

34

57

PTC097

Front Protection

01

58

PRS045

Stainless Steel Hexagonal Screw

04

59

ARL008

Stainless Steel Flat Washer

11

60

POS016

Stainless Steel Hexagonal Nut

08

61

DBC004

Stainless Steel Hinge

02

62

ARL004

Flat Washer

01

63

POS021

Stainless Steel Hexagonal Nut

01

64

PRC005

Flat Machine Screw

01

65

PTA009

Front Protection Door

01

66

PTC102

Front Protection Door Protection

02

67

BDJ024

Tray

01

68

GAB229

Rear Structure

01

69

GAB126

Frontal Structure

01

70

SPD048

Blades Stainless Steel Separator

01

71

PRA007

Stainless Steel Self-Drilling Hexagonal Screw

03

72

BCH036

Round Cap

02

73

CBE033

Black Splice Electric Cable

01

74

CBE092

Power Cable Splice 200 mm Grounding

01

75

TCE013

Female Terminal

01

18

Notes

19

20

IMG-BRASIL Gastronomy Machinery Industry Ltda.

CNPJ 11.193.347/0001-14 - CREA 131726-3

Road. Antônio Heil - KM 23 Nº 5825 - Neighborhood: Limoeiro

ZIP CODE 88352-502 - Brusque - SC - Brazil

Phone/fax. +55 47 3251-5555 - Web Site: www.metvisa.com.br

This manual suits for next models

6

Table of contents

Other METVISA Kitchen Appliance manuals