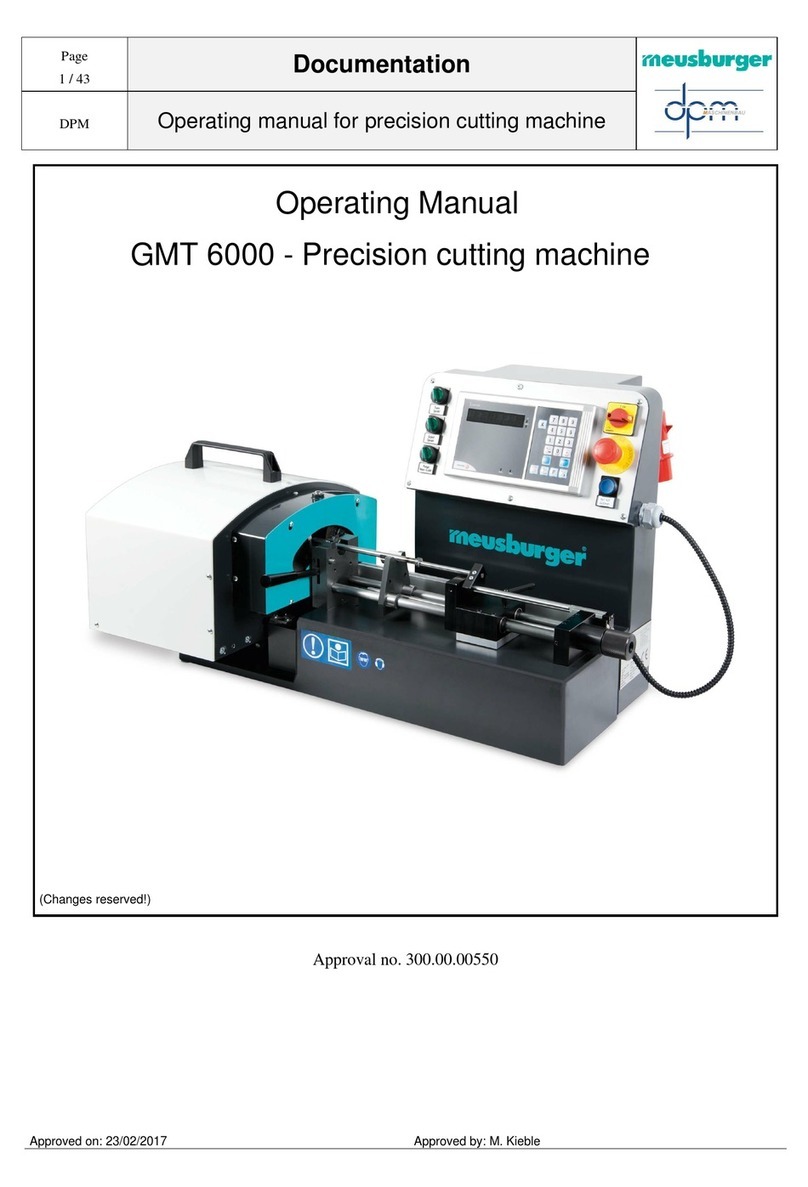

Meusburger GMT 6000 User manual

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.22

Operating Manual GMT 6000

- Precision cutting machine

Changes reserved! No. 300.00.00550

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 2

Preface

The information contained in this manual ensures that the dpm

ejector cutting unit is operated safely, properly and efficiently.

Following the explanations, notices and regulations:

prevents hazards and faults,

reduces repair costs and downtimes

increases reliability and the service life

of the machine. The operator must ensure that persons tasked

with using, maintaining and repairing the dpm ejector cutting

unit read the manual. The manual must be kept at hand in the

place where the machine is used.

Not being familiar with or not observing this manual can

give rise to hazards to persons!

This manual must be read carefully before the ejector

cutting unit is commissioned. The instructions, particularly

the safety instructions, must be followed!

This manual applies only to the "ejector cutting unit“ indicated

on the cover page and specified in the section on "Suitability".

Before it is used outside its described field of application, it is

essential to consult

dpm Daum + Partner Maschinenbau GmbH

Am Lauerbühl 2

D - 88317 Aichstetten, Germany

Tel. +49 7565 94080 Fax. +49 7565 940850

Otherwise any warranty, liability and accessory liability claims

shall be void.

Copyright © 09 February 2018 by dpm Daum + Partner

Maschinenbau GmbH Realisation: dpm Daum + Partner

Maschinenbau GmbH

All rights to this manual are reserved, particularly the right of

reproduction and distribution as well as translation. No part of

the manual may be reproduced or electronically processed,

copied or distributed in any form (by copying, on microfilm or by

another means) without the prior written permission of Daum +

Partner.

Issue: 09 February 2018 Author: W. Ertel

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 3

Contents

1Notes about the operating manual...................................................................................4

1.1 Note, terms, symbols................................................................................................4

1.2 Pictograms...............................................................................................................5

2Correct use in accordance to the instructions (intended use) ..........................................6

2.1 Use of the machine ..................................................................................................6

3Safety..............................................................................................................................7

3.1 Safety directives and regulations..............................................................................7

3.2 Safety hazards.........................................................................................................7

3.3 Safety symbols and safety markings of the ejector cutting unit.................................9

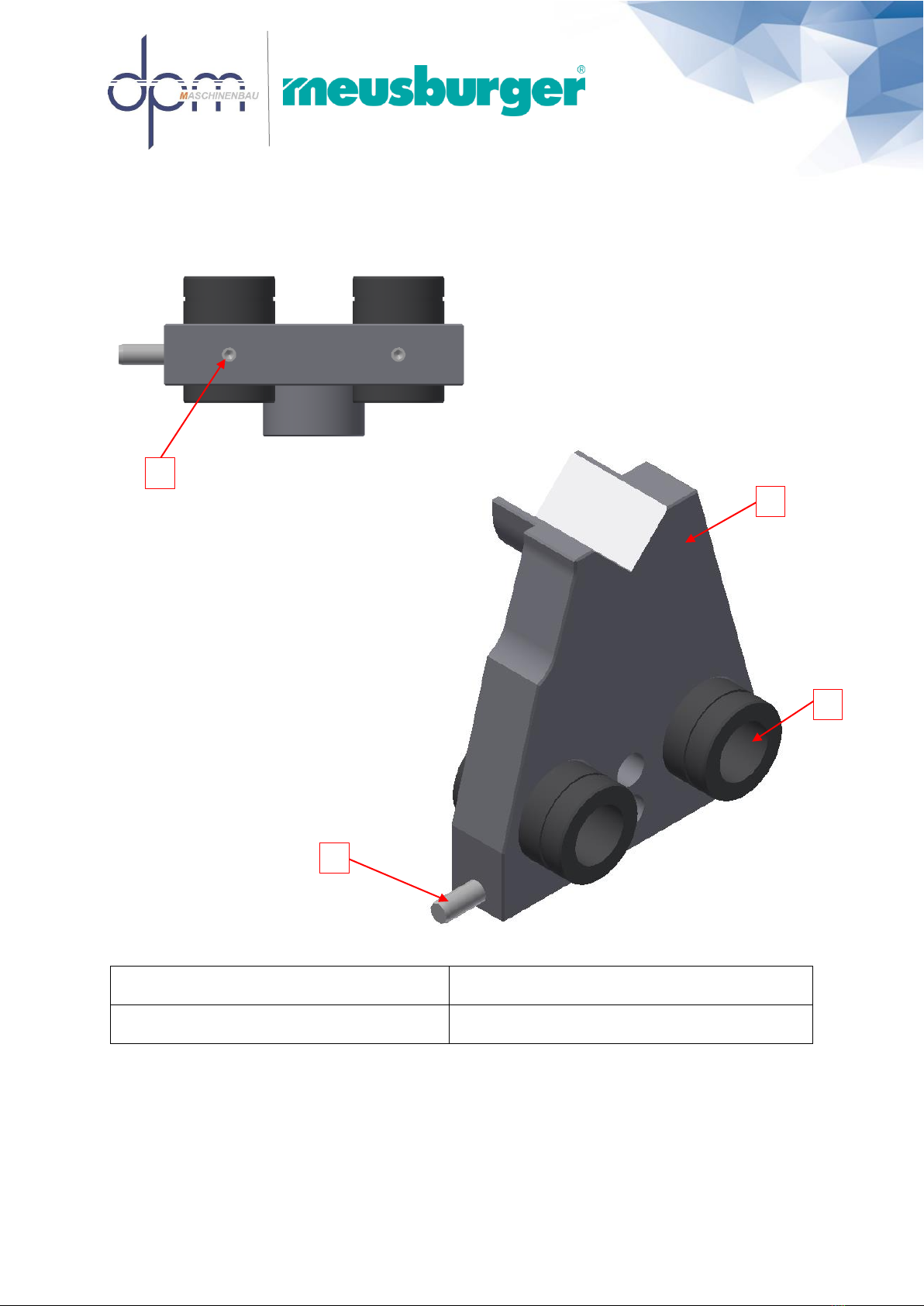

4Overall view...................................................................................................................10

4.1 Complete control unit .............................................................................................12

.........................................................................................................................................12

.........................................................................................................................................12

4.2 Complete linear unit –300.00.00403......................................................................13

4.3 Clamping prism –300.00.00382.............................................................................14

4.4 Support prism –300.00.00401...............................................................................15

4.5 Auflageprisma........................................................................................................15

4.5 Length adjustment –300.00.00174........................................................................16

4.6 Pivoting motor base................................................................................................17

.........................................................................................................................................17

.........................................................................................................................................17

4.7 Grinding spindle / cutting wheel –300.00.00409....................................................19

4.8 Grinding spindle / cup wheel –300.00.00407.........................................................20

4.9 Rocker bearing.......................................................................................................21

4.10 Spindle bearing –300.00.00359.............................................................................22

4.11 Technical Data.......................................................................................................23

5Operation......................................................................................................................24

5.1 Setting up the machine...........................................................................................24

5.2 Machine connections..............................................................................................25

5.3 Controls and displays.............................................................................................26

5.4Switching on...........................................................................................................29

5.5 Switching off...........................................................................................................29

5.6 Dressing the grinding wheel...................................................................................29

5.7 Inserting a workpiece .............................................................................................29

5.8Referencing "obtaining zero position".....................................................................30

5.9 Cut-off grinding.......................................................................................................30

5.10 Surface grinding.....................................................................................................30

5.11 Emergency stop.....................................................................................................31

5.12 Acknowledge the emergency stop..........................................................................31

6Care and maintenance..................................................................................................32

7Spare parts list..............................................................................................................36

8Zubehör.........................................................................................................................39

9Declaration of Conformity..............................................................................................40

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 4

10 Fault report fax..............................................................................................................41

1 Notes about the operating manual

1.1 Note, terms, symbols

Safety Safety regulations for safe, risk-free use of the ejector

cutting unit

Operation Information about the suitability, use, function, operation,

variants and accessories

Commissioning Information on the operation of the machine

Control Explanation of the control elements, description of

handling

Maintenance Work that must be done for the purpose of safe operation,

to maintain functional capability and to avoid hazards or

faults

Faults Explanation of the causes of faults and how to remedy

them

Appendix Illustrations, standard maintenance instruction, sample of

an inspection report in accordance with the directives of

the employer's liability insurance association

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 5

1.2 Pictograms

The machine and this manual carry labels that warn of hazards, stipulate or command

particular actions and point out special information. It is essential to follow the notices and

regulations that these highlight!

Danger!

Warning about a dangerous situation. There is a direct risk of a

serious accident is the regulations and instructions are not

observed!

Warning!

Warning about a possibly dangerous situation! Not following the

instruction can give rise to accident risks!

Caution!

Warning about a possibly dangerous situation or damage. Not

following the instructions can give rise to accident risks or damage

to the ejector cutting unit.

Command!

A particular action is stipulated! Not following the command can give

rise to a dangerous situation or damage!

Note!

Supplementary information about particular circumstances,

explanations, descriptions, cross references, explanations of special

activities or functional processes. Not following the instruction can

give rise to damage. There is no accident risk.

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 6

2 Correct use in accordance to the instructions (intended use)

2.1 Use of the machine

Machine tool for cutting and surface grinding of cylindrical and stepped ejector pins, flat

ejectors, profile stamps, punching dies, ejector bushes etc. The grinding wheels are driven

by two three-phase asynchronous motors with squirrel-cage rotors by a toothed belt drive.

The force exerted by the workpiece on the grinding wheel is always radial. The cup wheel

can be aligned by a puller diamond and set with an adjusting screw until the wear limit is

reached. The workpiece is held in place by a spring clamping prism and positioned with a

stop. A linear unit with screw spindle adjustment and visual digital output facilitates the exact

(0.01 mm) positioning/advance of the workpiece before cutting (separation) and subsequent

surface grinding.

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 7

3 Safety

3.1 Safety directives and regulations

The following general safety regulations must be followed:

Commissioning, operation and maintenance only after briefing and

instruction by the owner and knowledge of the operating

manual.

Commissioning, operation and maintenance only by trained and

qualified personnel (protective goggles and safety shoes are

mandatory)

When switching on the machine, the direction of rotation of the cup

wheel must be clockwise and that of the cutting wheel must be

counter-clockwise, see also instructions under 5.2 Connections of

the machine

Only switch on once you have checked the safety devices function

correctly.

Do not tamper with any safety devices or bypass, deactivate or

remove them.

The accident prevention regulations must be observed, and all

working methods that can jeopardise work safety are prohibited.

3.2 Safety hazards

Potential hazards if the operating manual is not followed:

If the machine is not operated, maintained or repaired in accordance

with the safety regulations, or if it is operated improperly or misused,

the result is

Hazards to the health of operating personnel

Hazards to the machine and other property belonging to the

operator

Impairment of the machine's efficient functioning.

If the regulations laid down in the operating manual are not observed,

the manufacturers shall not be liable for the resulting damage and

consequential losses!

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 8

Safety hazards can occur from:

Working at the machine without a protective cover on the

grinding wheel, (unauthorized changes to the safety devices

are not permitted).

The two grinding wheels rotating in the incorrect direction

The rotating grinding wheels when working at the machine

(there is a risk of clothes, long hair or gloves being pulled into

the machine).

Force applied to the grinding wheels in the axial direction.

(There is a risk of breakage of the grinding wheels).

Operating the rocker mechanism (there is a risk of crushing

between the rocker and its base).

Working on the machine without protective goggles (danger

from flying metal chips and grinding dust).

Removing the cut-off workpiece parts (risk of burning)

Parts can be thrown out if the grinding wheels are defective.

(risk of injury).

Inserting the shaft into the spring prism (risk of crushing

fingers).

Risk from electrostatic charging of components, personnel

touching contact charged parts.

Working at the electronic box or motor housing by touching

live parts during operation. Risk from damaged lines or

cables. Only trained electricians may carry out such work.

Do not operate the machine in hazardous areas.

Switching on the machine with the workpiece inserted

Transportation of the machine - personal safety measures

appropriate to the total weight of the machine must be taken.

Additionally, the personnel must be informed about any loose

or moving parts of the machine before transport. (Only

trained and instructed personnel are permitted to transport the

machine).

The main switch must be switched off for maintenance,

inspection or cleaning of the machine.

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 9

3.3 Safety symbols and safety markings of the ejector cutting unit

1

Mandatory

instruction

Disconnect first, then work on the electrical

installation.

2

Mandatory

instruction

Wear ear protection, Wear protective goggles, First

read the operating manual, then activate!

4

Warning

There is a risk of electric shock

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 10

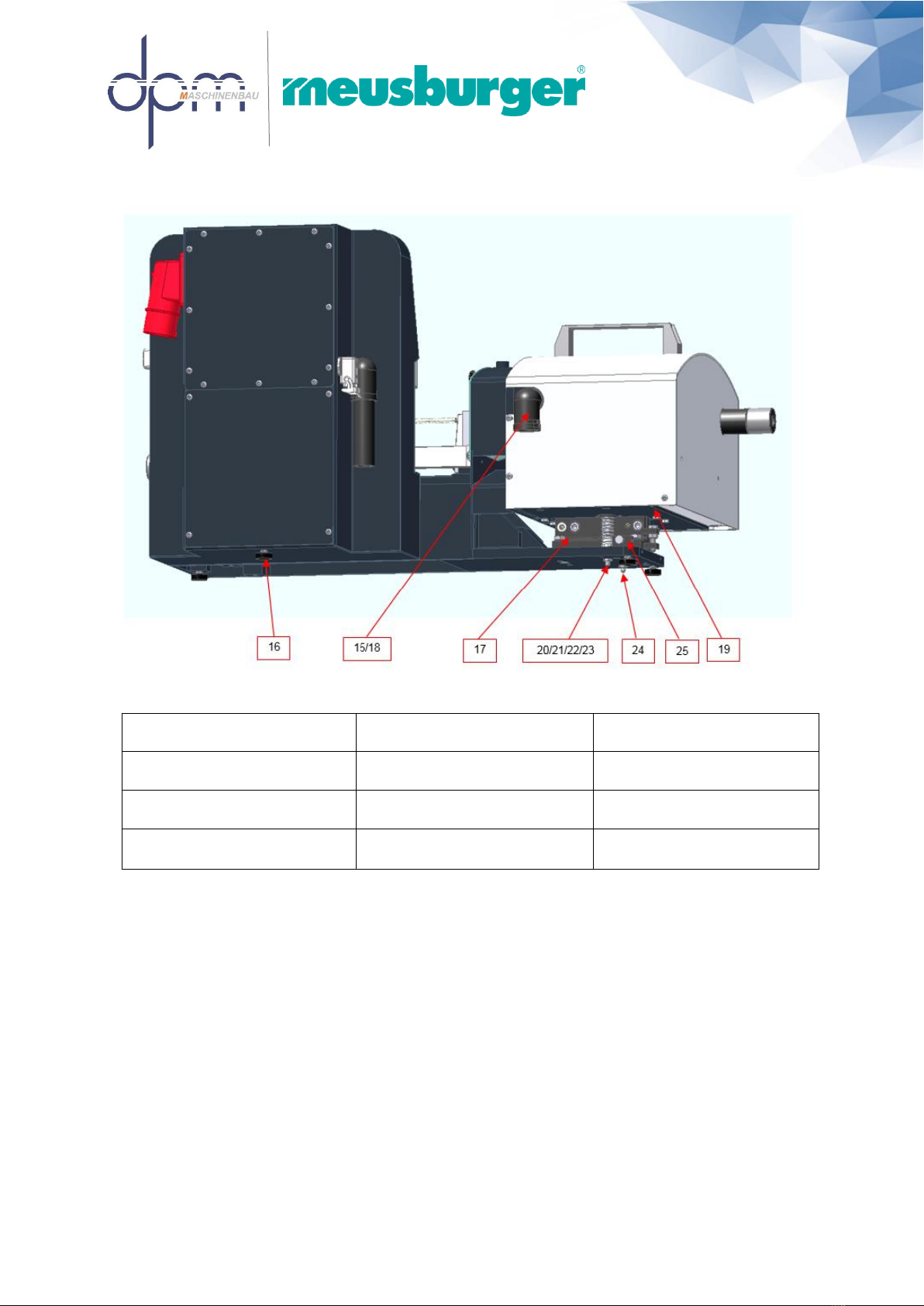

4 Overall view

1) 300.00.00398 (1x)

Base

5) 060.30.905 (1x)

Glass scale MKT 37

9) 300.00.00392 (1x)

Disc cover

13) 050.01.2971

Cup wheel

2) 300.00.00370 (1x)

Complete control cabinet

6) 300.00.00174 (1x)

Longitudinal adjustment

(cup wheel)

10) 300.00.00392 (1x)

Disc cover

14) 050.01.2972

Cutting wheel

3) 300.00.00403 (1x)

Linear unit

7) 050.01.2744 (1x)

Handle

11) 300.00.00387 (1x)

Holding rail for handle

4) 300.00.00462 (1x)

Cover

8) 300.00.00390 (1x)

Cover for complete

grinding wheel

12) 050.01.2953

Insulation for cover

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 11

15) 050.01.2750 (1x)

Corrugated pipe fitting 90°

19)300.00.00433 (1x)

Complete drive console

23) 300.00.00437 (2x)

Bracket

16) 050.01.2886 (4x)

Rubber-metal stop

20) 300.00.00452 (1x)

Spring retainer, long

24) 300.00.00451 (1x)

Spring retainer, short

17) 300.00.00359 (1x)

Adjustable spindle mount

21) 050.01.2928 (2x)

Pressure spring

25) 300.00.00372 (2x)

Adjusting block

18) 060.80.279 (1x)

Counter nut M32x1.5

22) 300.00.00436 (2x)

Spring bearing

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 12

6

11

14

15

12

17

18

19

20

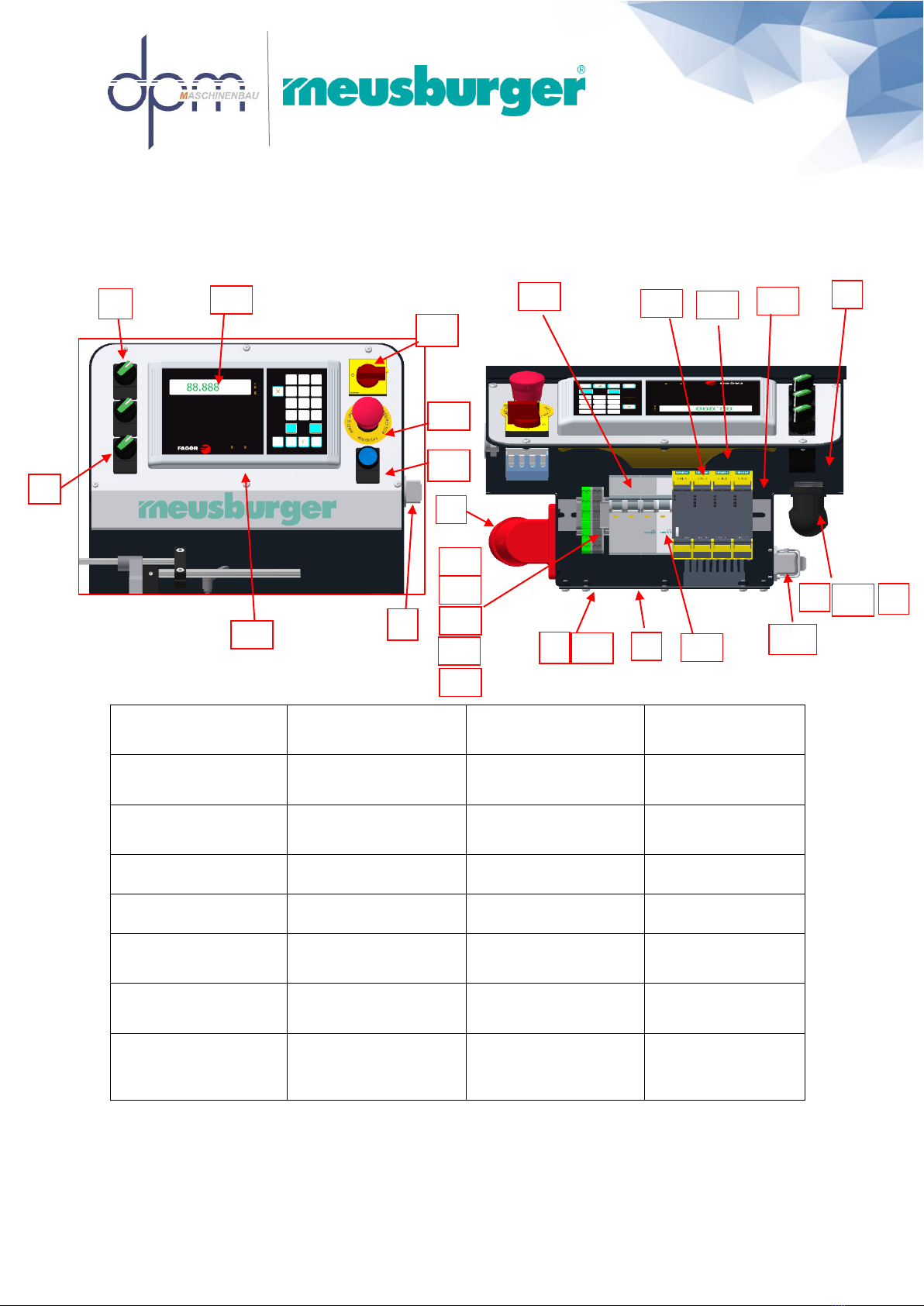

4.1 Complete control unit

1) 300.00.00355 (1x)

Bottom cover

9) 300.00.00360 (1x)

Control cabinet housing

17) 060.80.008-200 (1x)

DIN rail 35x7.5

25) E061.03.00160 (2x)

Battle plate, grey

2) 300.00.00367 (1x)

Electrics box cover

10) E061.04.00001 (1x)

Mounting case, angled

18) E061.12.00303 (1x)

3-pin circuit breaker

26) E061.03.00150 (2x)

4-wire circuit terminal

2,5mm²

3) 050.01.2750 (1x)

Corrugated pipe fitting

90°

11) 061.13.00262 (1x)

Emergency stop

pushbutton

19) E061.24.14000 (1x)

Safety relay

27) E061.03.09050 (1x)

Group tag holder

4) 061.13.00384 (3x)

Iluminated toggle switch

12) 060.30.904 (1x)

Innova Display

20) E061.24.14001 (3x)

Sirius motor starter

5) 061.51.12111 (1x)

Cable gland

13) 300.00.00368 (1x)

Dichtung El.-Box

21) E061.12.00002 (1x)

1.pin circuit breaker

6) E061.04.70000 (1x)

CEE-plug

14) E061.09.00003 (1x)

Main / emergency-stop

switch

22) 300.00.00426 (1x)

Operating Panel, angled

7) 050.01.2751 (1x)

Corrugated pipe

PUR NW 29

15) 061.13.01024 (1x)

Illuminated pushbutton,

blue

23) E061.03.09000 (2x)

End clamp TS 35

8) 061.52.02040 (4x)

Tag labelling

16) 060.80.279 (1x)

Counter Nut M32x1.5

24) E061.03.00154 (2x)

4-wire circuit terminal

2,5mm²

1

2

3

5

7

8

10

13

16

21

22

23

24

25

26

27

4

9

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 13

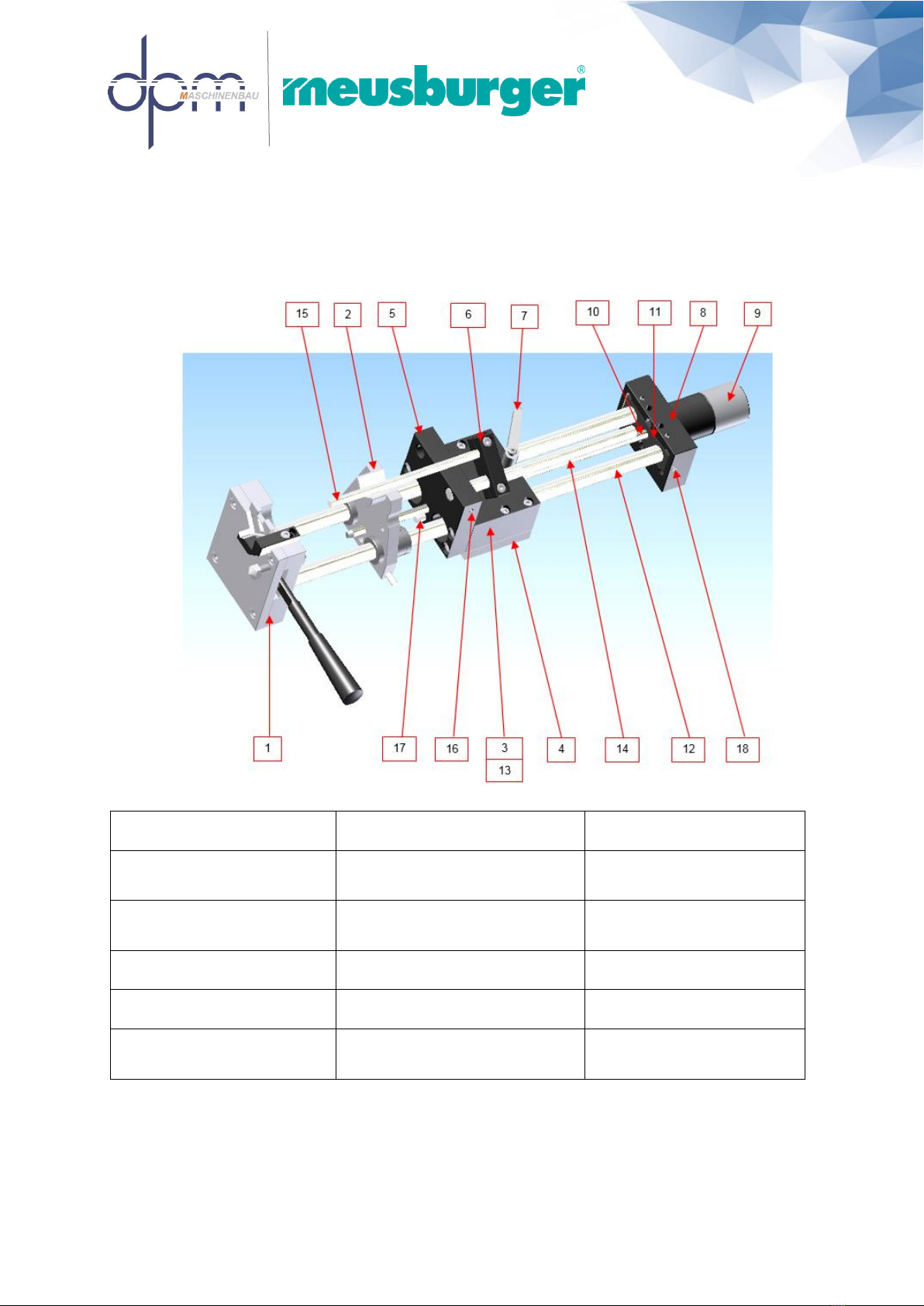

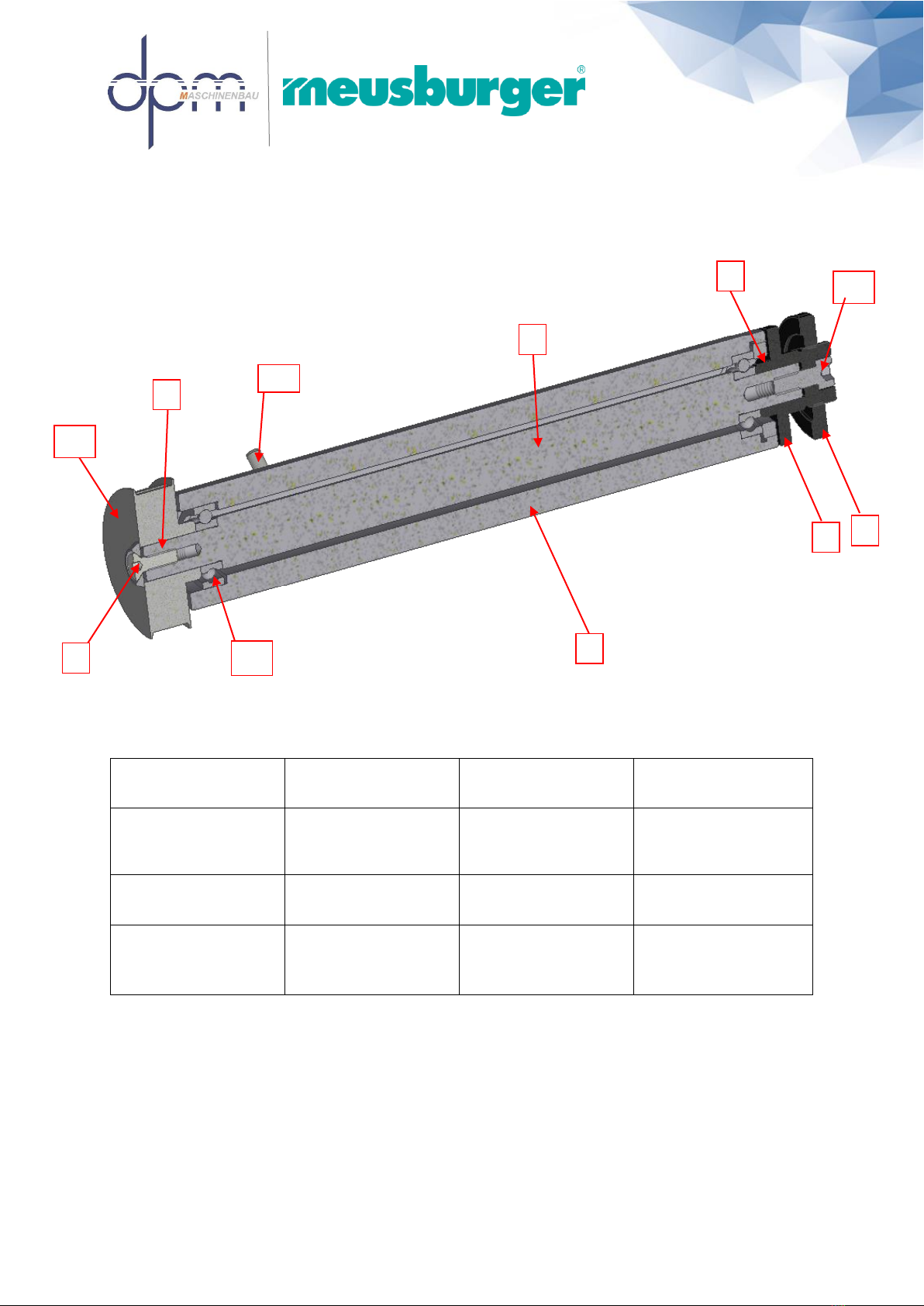

4.2 Complete linear unit –300.00.00403

1) 300.00.00382 (1x)

Clamping prism

7) 050.01.2713 (1x)

Clamping lever

13) 050.01.2718 (4x)

Ball lining Ø16

2) 300.00.00401 (1x)

Support prism

8) 300.00.00379 (1x)

Carriage guide bracket, outer part

14) 050.01.2715 (1x)

Hardened precision shaft

Ø12h6

3) 300.00.00173 (1x)

Carriage base

9) 300.00.00174 (1x)

Length adjustment

15) 050.01.2716 (1x)

Hardened precision shaft

Ø8h6

4) 300.00.00386 (1x)

Monitoring car holder

10) 300.00.00466 (1x)

Shaft for length adjustment

16) Threaded pin (1x)

ISO 4026-M6x16

5) 300.00.00166 (1x)

Carriage face plate

11) 300.00.00009 (1x)

Carriage guide bracket, inner part

17) Hardened cylinder pin (1x)

ISO 8734-8x50

6) 300.00.0456 (1x)

Stop part

12) 050.01.2714 (2x)

Hardened precision shaft

Ø16h6

18) Threaded pin (6x)

ISO 4026-M6x8

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 14

4.3 Clamping prism –300.00.00382

1) 300.00.00380 (1x)

Clamping prism base plate

5) 050.01.2770 (1x)

Dressing diamond

9) Hardened cylinder pin (2x)

ISO 8734-5x24

2) 300.00.00162 (1x)

Push-pull device guide

6) 050.01.2712 (1x)

Cone handle

10) Hardened cylinder pin (1x)

ISO 8734-5x10

3) 300.00.00161 (1x)

Push-pull device

7) 300.00.00036 (1x)

Lever

11) Threaded pin (1x)

ISO 4026-M5x16

4) 300.00.00163 (1x)

Support

8) 050.01.2892 (1x)

Control spring Ø10x35.3xØ1.4

12) Threaded pin (1x)

ISO 4026-M5x16

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 15

4.4 Support prism –300.00.00401

4.5 Auflageprisma

1) 300.00.00402 (1x)

Support prism plate

3) Hardened cylinder pin (1x)

ISO 8734-6x20

2) 050.01.2718 (2x)

Bushing

4) Hexagon socket set screw with truncated cone (2x)

ISO 4026 M5x8 –45 H 2x

2

3

1

4

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 16

4.5 Length adjustment –300.00.00174

1) 300.00.00175 (1x)

Adjustment bush

5) Retaining ring (1x)

DIN 471 - 15x1

9) Retaining ring (1x)

DIN 472 - 15x1

2) 300.00.00011 (1x)

Support

6) Axial deep groove ball bearings (2x)

050.31.910 (Ø15 x Ø28 x 9)

3) 300.00.00014 (1x)

Washer disc

7) 050.01.2899 adjusting washer (1x)

Ø15 x Ø28 x 1

4) 300.00.00396 (1X)

Washer

8) Threaded pin (3x)

ISO 4026-M4x4

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 17

4.6 Pivoting motor base

1) 300.00.00409 (1x)

Cutting wheel grinding spindle

7) 300.00.00194 (1x)

Pulley T5/Z72

13) 300.00.00352 (1x)

angel f. adjustment

2) 300.00.00407 (1x)

Cup wheel grinding spindle

8) 300.00.00186 (1x)

Pulley T5/Z48

14) 300.00.00412 (1x)

Stop ring

3) 060.07.051 (1x)

Three-phase asynchronous motor

0.75 kW

9) 300.00.00427 (1x)

Mounting flange f. motor kl.

15) 300.00.00423 (1x)

Perforated sheet

4) 060.07.050 (1x)

Three-phase asynchronous motor

0,37 kW

10) 300.00.00428 (1x)

Mounting flange f. motor gr.

16) 300.00.00063 (1x)

Delivery agent

5) 050.01.2747 (1x)

Toothed belt T5 Z78

11) 300.00.00195 (1x)

Connecting washer

17) 300.00.00235 (1x)

Engine cover

6) 050.01.2746 (1x)

Toothed belt T5 Z90

12) 300.00.00187 (1x)

Connecting washer

18) 050.01.2748 (2x)

Scraper Ø40xØ48,6x7

19) 300.00.00094 (1x)

Scraper Ø14 x 1 x 160

2

14

1

3

4

5

6

7

10

11

13

15

17

16

8

9

12

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 18

Info! M6 bolts glued with VBA 2M70 (Meusburger)!

Cylinder head screw M6 14Nm tightening torque!

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 19

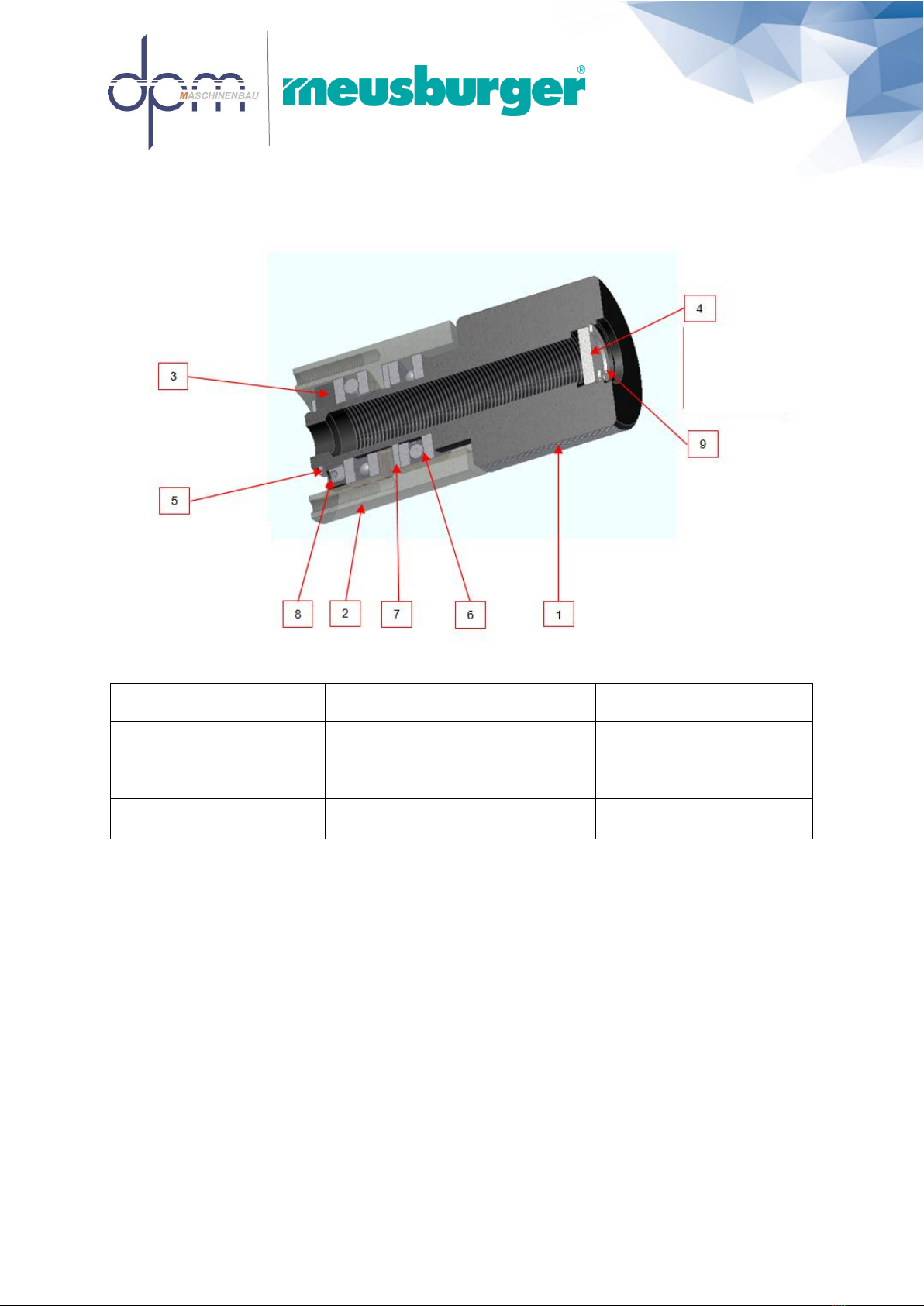

4.7 Grinding spindle / cutting wheel –300.00.00409

1) 300.00.00408 (1x)

Grinding spindle sleeve

5) 300.00.00055 (1x)

Washer

9) 300.00.00182 (1x)

Toothed belt pulley T5 Z19

2) 300.00.00048 (1x)

Grinding spindle shaft

6) Fitting key (1x)

DIN 6885 A4x4x18

10) Cylinder head bolt

ISO 4762 M6x16-12.9 (1x)

3) 300.00.00393 (1x)

Clamping nut

7) 050.31.015 (2x) deep groove ball

bearings

DIN 625 SKF 6001-2RS1

11) stop ring (1x)

300.00.00412

4) 300.00.00050 (1x)

Disc flange, inside

8) 300.00.00052 (1x)

Threaded ring

5

6

7

11

1

8

10

3

4

9

2

dpm Daum + Partner Maschinenbau GmbH · Am Lauerbühl 2 · D-88317 Aichstetten - 01.11.2022 20

4.8 Grinding spindle / cup wheel –300.00.00407

1) 300.00.00045 (1x)

Grinding spindle sleeve

5) 300.00.00052 (1x)

Threaded ring

9) 300.00.00185 (1x)

Toothed belt pulley

T5 Z30

2) 300.00.00406 (1x)

Grinding spindle shaft

. 6) 300.00.00055 (1x)

Washer

10) Cylindrical pin

hardened

(ISO 8734-5x16) (1x)

3) 300.00.00223 (1x)

Disc flange inside,

Left-handed

7) Adjusting spring (1x)

DIN 6885 A4x4x18

11) 050.01.2887 (1x)

ISO 4762 M6x16-12.9

Left-hand thread

4) 300.00.00394 (1x)

Clamping nut,

left-hand thread.

8) 050.31.015 (2x)

Deep groove ball

bearings DIN 625

SKF 6001-2RS1

1

2

3

4

5

6

11

7

8

9

10

Other manuals for GMT 6000

1

Table of contents

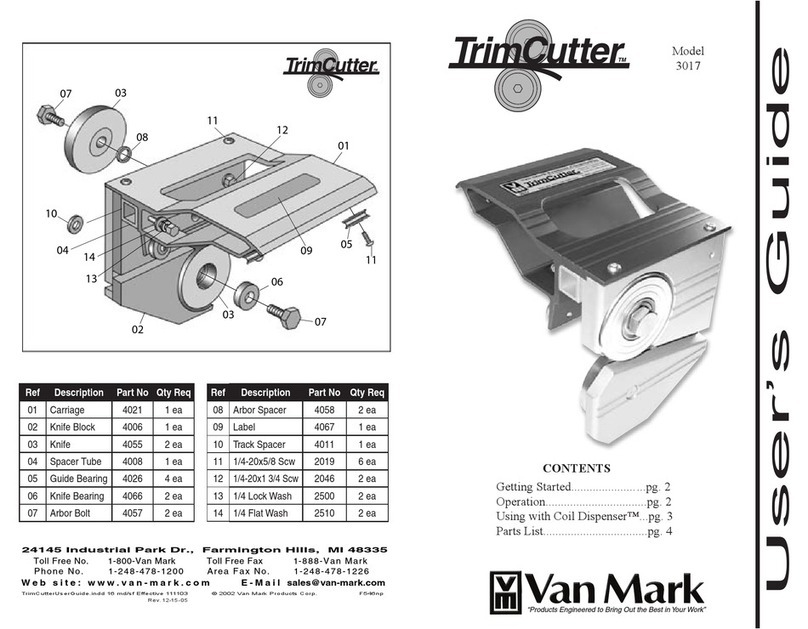

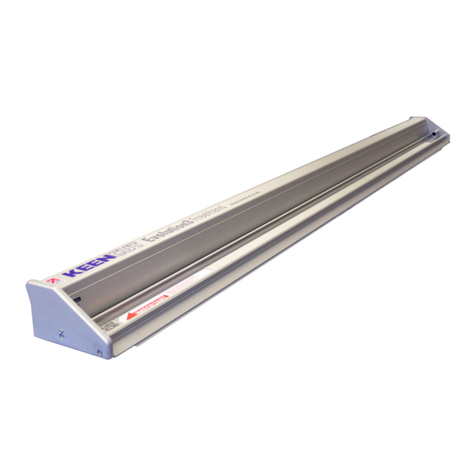

Other Meusburger Cutter manuals

Popular Cutter manuals by other brands

Stryker

Stryker 0940-000-000 Instructions for use

KEENCUT

KEENCUT Evolution3 FreeHand user guide

Current Tools

Current Tools 754 Operating, Maintenance, Safety and Parts Manual

Makita

Makita DCS553 instruction manual

EINHELL

EINHELL 43.012.50 operating instructions

Xyron

Xyron Personal Cutting System None user manual