Cedima • Technical Documentation • Joint Cutter CF •1020 B • Issue date: 21/09/2021

4

Machine Overview..........................................................................................................................29

4.1

Proper Use....................................................................................................................................................... 29

4.2

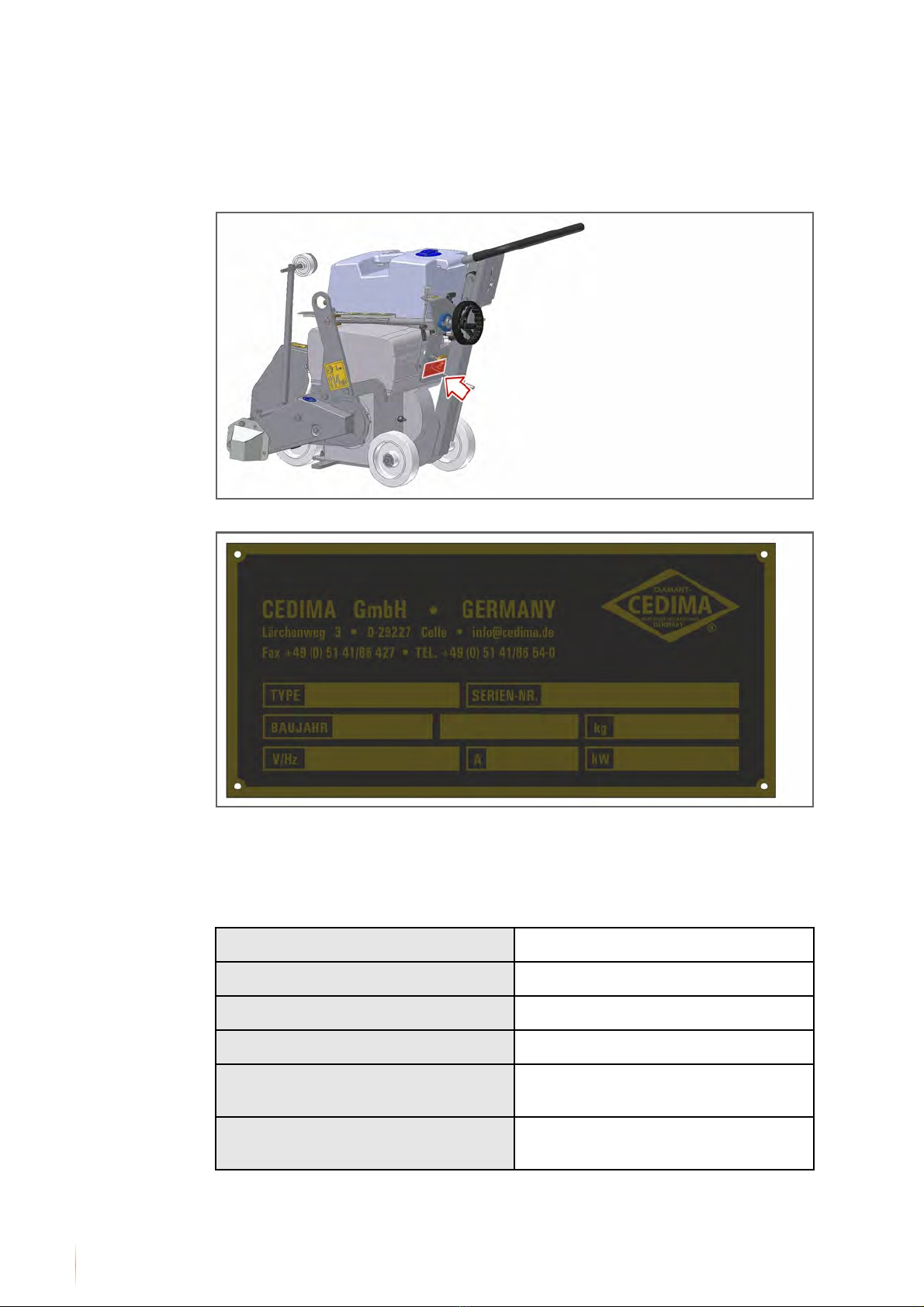

Parts of the Machine .................................................................................................................................... 29

4.2.1

Overview................................................................................................................................. 30

4.2.2

Removable Water Tank...................................................................................................... 31

4.2.3

Motor........................................................................................................................................ 32

4.2.4

Cutting Shaft Protective Cover........................................................................................ 36

4.2.5

Blade Guard ........................................................................................................................... 37

4.2.6

Parking Brake......................................................................................................................... 39

4.2.7

Height-Adjustable Handle ................................................................................................ 40

4.2.8

Cutting Depth Adjustment............................................................................................... 41

4.2.9

Cutting Shaft Swivelling Unit........................................................................................... 42

4.2.10

Flushing Water Connection.............................................................................................. 44

4.2.11

Visor Device ........................................................................................................................... 46

4.3

Working and Danger Areas ....................................................................................................................... 47

4.4

Operating Description................................................................................................................................. 47

4.5

Operating Modes.......................................................................................................................................... 47

5

Transportation and Setup .............................................................................................................48

5.1

Transportation ............................................................................................................................................... 48

5.2

Unpacking....................................................................................................................................................... 49

5.3

Requirements for the Environment........................................................................................................ 49

5.4

Lifting and Setting Down the Machine ................................................................................................. 49

6

Setup................................................................................................................................ 51

6.1

Readying the Machine for Operation..................................................................................................... 51

6.2

Moving the Cutting Shaft........................................................................................................................... 53

6.3

Fitting and Removing the Diamond Saw Blade ................................................................................. 54

6.3.1

Requirements for the Diamond Saw Blade................................................................. 54

6.3.2

Fitting the Diamond Saw Blade ...................................................................................... 55

6.3.3

Removing the Diamond Saw Blade ............................................................................... 57

6.4

Removing and Fitting the Blade Guard................................................................................................. 57

6.4.1

Removing the Blade Guard............................................................................................... 58

6.4.2

Fitting the Blade Guard...................................................................................................... 59

6.5

Converting the Machine............................................................................................................................. 60

6.6

Commissioning.............................................................................................................................................. 61

6.6.1

Information ............................................................................................................................ 61

6.6.2

Commissioning the Machine ........................................................................................... 62

7

Operation ......................................................................................................................... 65

7.1

Operating the Machine............................................................................................................................... 65

7.2

Daily Start-Up ................................................................................................................................................. 65

7.2.1

Prerequisites.......................................................................................................................... 65

7.2.2

Preparing the Machine for Operation........................................................................... 66

7.2.3

Switching on Machine........................................................................................................ 67

7.3

Carrying out the Cutting Process ............................................................................................................ 70

7.4

Eliminating Disruptions in Operation .................................................................................................... 74

7.5

Switching off Machine ................................................................................................................................ 75

7.6

Daily Shut-Down ........................................................................................................................................... 75