Meusburger H 4062 User manual

Meusburger Georg GmbH & Co KG | Kesselstr. 42 | 6960 Wolfurt | Austria

T +43 5574 6706-0 | sales@meusburger.com | www.meusburger.com

1. User instructions:

1.1. Purpose and validity of document:

This document contains the information that is necessary for the proper use of the products described therein. It is intended for

use by technically qualied personnel. Qualied personnel are persons who, by virtue of their training, experience and instruction,

in conjunction with their knowledge regarding the relevant standards, provisions, accident prevention regulations and operating

conditions, have been authorised by the Plant Safety Ocer to carry out the required activities in order to ensure that potential

hazards are recognized and avoided.

1.2. Visual representation of safety instructions:

Wear safety footwear:

Risk of crushing!

Trip hazard:

2. General safety instructions:

2.1. Intended use:

The assembly table is used in order to facilitate the installation and maintenance work on moulders moulds, die cast and

moulds and punching tools. It is only intended for moulds and tools that possess sucient stability by virtue of the ratio of their

footprint-to-height ratio. Proper use of the assembly table also includes compliance with the instructions regarding safety,

operation, maintenance and servicing which form part of this user manual.

2.2. Technical specications:

Description Unit H 4062/496/1156 H 4062/796/1496 H 4062/996/1846

Dimensions (w x l x h) [mm] 526 x 1186 x 860 826 x 1526 x 880 1026 x 1876 x 700

Unladen weight [kg] 320 700 1200

Maximum connection pressure [bar] 6 6 8

Maximum load on the table [kg] 3000 3000 5000

Maximum load on the moving plates (per plate) [kg] 2000 2000 2500

Maximum tool size [mm] Width 500

Height 1000

Width 800

Height 1000

Width 900

Height 1300

Maximum tool overhang over moving plates [mm] 80 on all sides 100 on all sides 50 on all sides

Attention

User manual – Assemby table H 4062

Meusburger Georg GmbH & Co KG | Kesselstr. 42 | 6960 Wolfurt | Austria

T +43 5574 6706-0 | sales@meusburger.com | www.meusburger.com

2.3. Foreseeable misuse:

If incorrectly assembled (in a non-horizontal position), stability is

not guaranteed under high load conditions (see 5). Large mould

halves which, as a result of their footprint-to-height ratio, do not

possess sucient stability, must be secured using the

anti-tipping brackets supplied (see 3.2). Make sure that the

underside of the mould or die half rests completely on the

support plate so that there is no point load. The maximum tool

size and the maximum weight must not be exceeded. The

maximum tool overhang must be adhered to, in order to prevent

the tool Support plate from tipping. The assembly table must

never be left unsupervised while switched on.

2.4. Residual risks:

Please be aware of the trip hazard caused by the protruding

feet of the assembly table with base frame. In users must be

aware of the risk that their ngers may be crushed by the raised

edges when the moving plates are in operation.

2.5. Duties of the operator:

The operator is obliged to instruct operating personnel with

regard to the safe and proper handling, maintenance, servicing

and appropriate operation of the assembly table. The operator

must prove that the assembly table has been erected in

accordance with the instructions.

2.6. Duties of the user:

Any person operating the assembly table must have read this

user manual. Proper protective clothing must be worn and the

safety instructions must be adhered to.

2.7. User qualications:

The assembly table must only be used by specialised personnel

qualied who have read the user manual. Trainees must

operate the assembly table under supervision only.

2.8. Personal protective equipment:

All users are obliged to wear protective gloves and class 2 or

higher safety footwear (non-slip soles and protective toecaps).

2.9. Safety and protection devices:

In order to prevent the slippage of the Support plate beyond the

edge of the table surface, raised edges have been tted around

the entire edge of the table. Checks should be carried out on a

regular basis to make sure these are still rmly attached.

Meusburger Georg GmbH & Co KG | Kesselstr. 42 | 6960 Wolfurt | Austria

T +43 5574 6706-0 | sales@meusburger.com | www.meusburger.com

3. Description of machine:

3.1. Versions

Mat.: 1.1730

n* max. kg* p* [bar] b1 l1 l2 h b l No.

23000 6 346 266 296 850 496 1156 H 4062/496/1156

2 596 346 396 796 1496 H 4062/796/1496

1 5000 8 796 466 496 660 996 1846 H 4062/996/1846

* n) number of drawers | max. kg) maximum load capacity | p) operating pressure

3.2. Sub-assemblies and components:

1. Base-plate tted

2. Base frame

3. Tool cabinet

4. Moveable plates

5. Anti-tilt brackets

6. Adjustable feet

7. Securing bolt for tool cabinet

h

n

bb1

l1

l2

l

7

4

5

3

2

6

1

Meusburger Georg GmbH & Co KG | Kesselstr. 42 | 6960 Wolfurt | Austria

T +43 5574 6706-0 | sales@meusburger.com | www.meusburger.com

3.3. Accessories:

4 eye bolts 2 xing brackets

2 xing brackets

Copper mallet

Multi oil VMM 4

Spirit level

4. Transportation:

The assembly table can be transported using a forklift truck,

as the base frame has been congured in such a way that the

forklift truck can drive underneath the table without hindrance.

The table can also be lifted by means of the eye bolts supplied.

Transportation by crane (eye bolts) must only take place if the

moveable plates have been removed.

5. Installation and commissioning:

The assembly table must be placed so that there is at least

0.5 m of free space on all sides. In order to guarantee the

stability of the table, it must be placed on a rm surface in a

horizontal position to be veried using the spirit level supplied.

The feet of the table can be adjusted for this purpose.

In order to avoid exceeding the maximum air pressure, a

pressure regulator (not included in the delivery) must be

installed upstream of the compressed air connector of the

assembly table, before commissioning. In order to ensure that

the compressed air supply can be shut o, a stop-cock (not

included in the delivery) must be tted upstream of the

compressed air connector of the assembly table.

5.1. Compressed air supply/pneumatics connection plan:

The connector to the assembly table is a coupler with d1:9.

shut-o valve

(main switch)

manual slide valves

on the table

support plates

(consumers)

H 4062 Assembly table

to be installed by the

operator

pressure regulator

with manometer

pneumatic source

Meusburger Georg GmbH & Co KG | Kesselstr. 42 | 6960 Wolfurt | Austria

T +43 5574 6706-0 | sales@meusburger.com | www.meusburger.com

6. Operation (Normal operation):

6.1. Operating and display elements:

Both support plates of the mould can be switched on and o

separately using the manual slide valves. In order to avoid any

undesirable movements, always activate only one support plate of

the mould and once the movement has been completed,

immediately switch it o again.

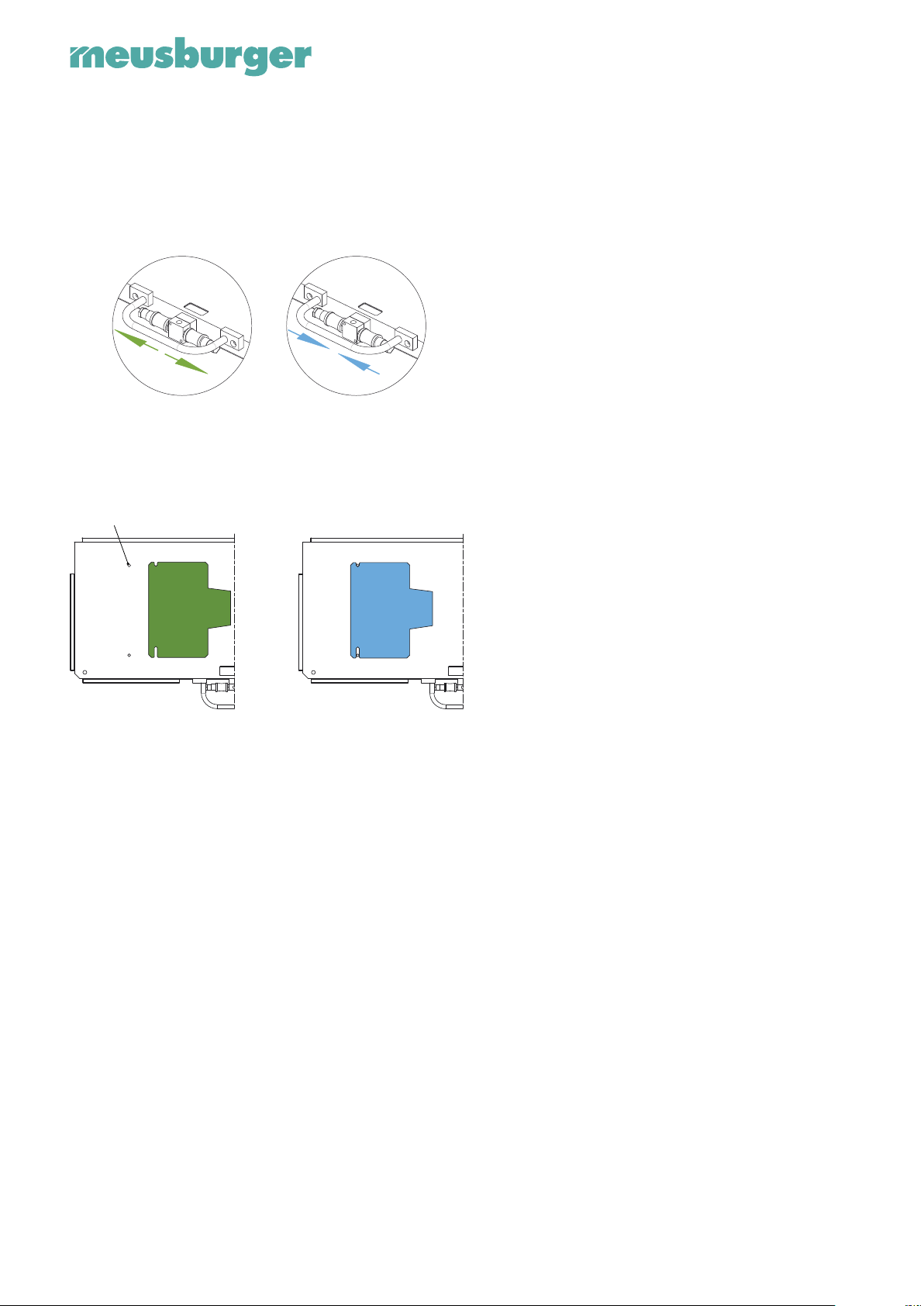

ON OFF

A support plate-half can be additionally secured by means of

two dowel pins incorporated into the table’s surface. Any mould

support plate that are not in use must always be secured.

Dowel pin E 1300

moveable fixed

6.2. Control and operation:

Positioning the mould:

The mould halves should be positioned as centrally as possible

on the support plates. This is the only way to ensure optimal air

ow so the plates move.

Switching the machine on:

In order to switch on the machine, rst of all, the shut-o valve

must be opened. The manual slide valves can then be used to

control each plate individually.

Switching the machine o:

In order to switch o the machine, both manual slide valves

must be closed and then the main switch turned o. This avoids

any unwanted untimely movement of the board caused by

turning the shut-o valve.

Emergency shut-down:

In an emergency, the shut-o valve must be turned o

immediately so as to cut o the compressed air supply to the

entire system.

7. Maintenance, cleaning, servicing:

Before each use it must be checked that the mechanical

operating equipment is in a proper and functional condition. The

schedule for these checks must be set in such a way that any

faults that arise can be detected in good time and any damage

immediately rectied. The air hoses must be checked daily for

possible damage. In addition, the table’s surface, raised edges

and support plate must be oiled regularly, otherwise they will be

subject to severe corrosion. The raised edges must be checked

regularly to make sure that they are rmly attached.

7.1. Auxiliaries and consumables:

Meusburger Multi oil VMM 4 for the regular oiling of corroding

parts.

7.2. Spare and wear parts:

Spare parts may simply be ordered from our sales department.

Compressed air hoses should be renewed after no more than 6

years.

8. Troubleshooting and fault correction:

In the event of damage to the compressed air circuit, the circuit

must be systematically checked from the pneumatic source

right through to the support plate.

9. Decommissioning:

In the event of temporary shutdown or storage, the entire

assembly table must be oiled, otherwise it will be subject to

severe corrosion. It should be stored in a dry place.

10. Disassembly, dismantling:

As the assembly table is made of iron and plastics only, it

may be disposed of via the conventional system of separated

rubbish disposal. Assembly tables that have reached the end of

their service life may be returned to Meusburger Georg GmbH

& Co KG for disposal, free of charge.

Meusburger Georg GmbH & Co KG | Kesselstr. 42 | 6960 Wolfurt | Austria

T +43 5574 6706-0 | sales@meusburger.com | www.meusburger.com

11. EC Declaration of Conformity:

As the manufacturers of this machine, we hereby declare that the machine described below complies with the

stated Directives and Standards.

Manufacturer: Meusburger Georg GmbH & Co KG

Kesselstr. 42 | 6960 Wolfurt | Austria

Authorised party in relation to Meusburger Georg GmbH & Co KG

the technical documentation: Meusburger Guntram

Kesselstr. 42 | 6960 Wolfurt | Austria

Designation of machine: Air-cushioned assembly table

(Commercial name)

Model, type: H 4062

Guidelines: 2006/42/EC Machinery Directive

Standards:

EN ISO 12100 Safety of machinery – General principles for design – Risk assessment

and risk reduction

EN ISO 4414 Pneumatic uid power – General rules and safety requirements

for systems and their components

EN ISO 13849-1 Safety of machinery – Safety-related parts of control systems

Part 1: General principles for design

EN ISO 13857 Safety of machinery – Safety distances to prevent hazard zones

being reached by upper and lower limb

ÖNORM EN 842 Safety of machinery – Visual danger signals – General requirements,

design and testing

Wolfurt, December 2022

Place, date Managing Director Meusburger Guntram

Other manuals for H 4062

1

This manual suits for next models

3

Table of contents

Other Meusburger Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual