Meyer Burger GB User manual

Installation Guide MB

Solar Modules

Applications

The modules are suitable for the following applications:

• Ambient operating temperature: –40°C to +40°C

• Maximum compression load 5400 Pa, maximum tensile load

2400 Pa

(includes a safety factor of 1.5)

•

Installation on a substructure for solar panels

•

All modules will be tested and approved according to IEC

61215-2016 and IEC 61730-2016 (Certification pending)

• Installation must comply strictly with all country-specific

electrical and structural safety standards.

Handling

• Wear gloves when handling the module frame

• When unstacking the modules, protect the front side against

scratching, etc.

• Never short-circuit the cables of the solar modules, i.e., do

not connect them together

• Cables and sockets must not be used for handling or transport

• Do not walk on the modules and avoid other kinds of point

load because these could result in irreparable damage

Installation location

The installation location should be chosen bearing the following

aspects in mind:

• The modules must not be installed:

· In an enclosed area

· At an altitude of more than 2000 m above sea level*

· On a water surface*

· In places where water can accumulate (e.g., due to flooding)

· In the vicinity of highly flammable gases or vapors (e.g., near

gas tanks or filling stations)

· Directly adjacent to air conditioning or ventilation systems

• The modules must not be used as a substitute for roofing

or facades

• If the modules are installed less than 500 m from the sea,

special precautions are necessary with regard to grounding,

maintenance and cleaning

• Avoid contact between chemical substances (e.g., oil or

solvents) and parts of the modules.

Orientation

• The modules can be mounted in either portrait or landscape

orientation

• Make sure no water can accumulate. Rain or melt water must

be able to drain off freely.

• The drainage holes in the module frame must not be closed

or obscured

• Minimum tilt: 5°

•

The maximum tilt should be determined based on local

regulations

•

Self-cleaning is improved if the modules are tilted by more

than 20°.

Shading

Optimum sunlight results in maximum energy yield:

• Install the modules so that they are facing the sun

• Avoid total or partial shading (e.g., due to trees, chimneys,

buildings, dirt, snow, overhead power lines)

• Shading of the glass-glass modules on the rear side should be

avoided.

Substructure

The substructure must meet the following requirements:

• The substructure must provide the required structural strength

and be designed to withstand local snow and wind loads

• Uneven snow coverings (e.g., snow banks or dris) could result

in significantly higher, localized loads and must be removed or

avoided with the help of technical measures

* Please ask the manufacturer for advice if you wish to install the modules at an altitude of more than 2000 m above sea level or on a water surface.

• The substructure must not cause any other forces to act on

the modules in addition to wind and snow loads

• The substructure must be correctly attached to the roof or

the floor

• All forces acting on the modules must be transmitted to the

substructure

• There must be no objects on the back side which will

cause concentrations of pressure if the modules bend in

the middle

• The substructure must ensure adequate cooling of the

modules by rear ventilation

• Stress-free attachment of the substructure is essential to

enable thermal expansion

• Avoid additional stresses or torques at the mounting positions

• The clamps must match the rails

• Make sure that clamps, slide-in profiles, etc., likewise do not

touch the glass, including under load

• You should also make sure that the substructure does not

touch the socket, including under load

• With glass-glass modules, the substructure must not cause any

additional shading behind the modules (i.e., there should be

no rails underneath them)

• Make sure that the connecting cables to the socket do not run

between the laminate and the mounting rails

• Avoid contact between different metallic materials (contact

corrosion; refer to the electrochemical series)

• Use corrosion-resistant screws and M8 washers

(diameter ≥ 15.8 mm) for mounting. The fastening screws

and washers should have the same material properties.

Clamp system

Use clamps which meet the following requirements:

• Minimum clamp width: 40 mm

• Clamp height for 35 mm module height

• Clamp depth: 7–11 mm

• The clamps must not touch the front glass

• No cells must be shaded as a result of the clamps

• The clamps must not damage the module frame

• The clamps must provide the required structural strength at

the installation location

• Use clamps which guarantee long-term stability and secure

attachment of the modules to the substructure

• The clamps must be installed in accordance with the manufac-

turer’s instructions, including any specific hardware and torque

requirements. Do not exceed a maximum torque of 20 Nm.

Maintenance and cleaning

• Regular cleaning (once or twice a year) will improve the

energy efficiency of the modules

• Use cleaners containing alcohol (ethanol, isopropyl alcohol)

for manual cleaning or hand washing. Cleaners that are highly

acidic or strongly alkaline must not be used. The modules can

also be cleaned using a soap and water solution.

• Do not use abrasive cleaning agents such as abrasive powder,

steel wool, cleaning pads or scrapers

• Do not use high-pressure cleaners for cleaning

• Remove heavy soiling using plenty of water before wiping the

glass surface. Leave stubborn dirt to soak where necessary

• Never touch the glass with your bare hands because you

could leave fingerprints.

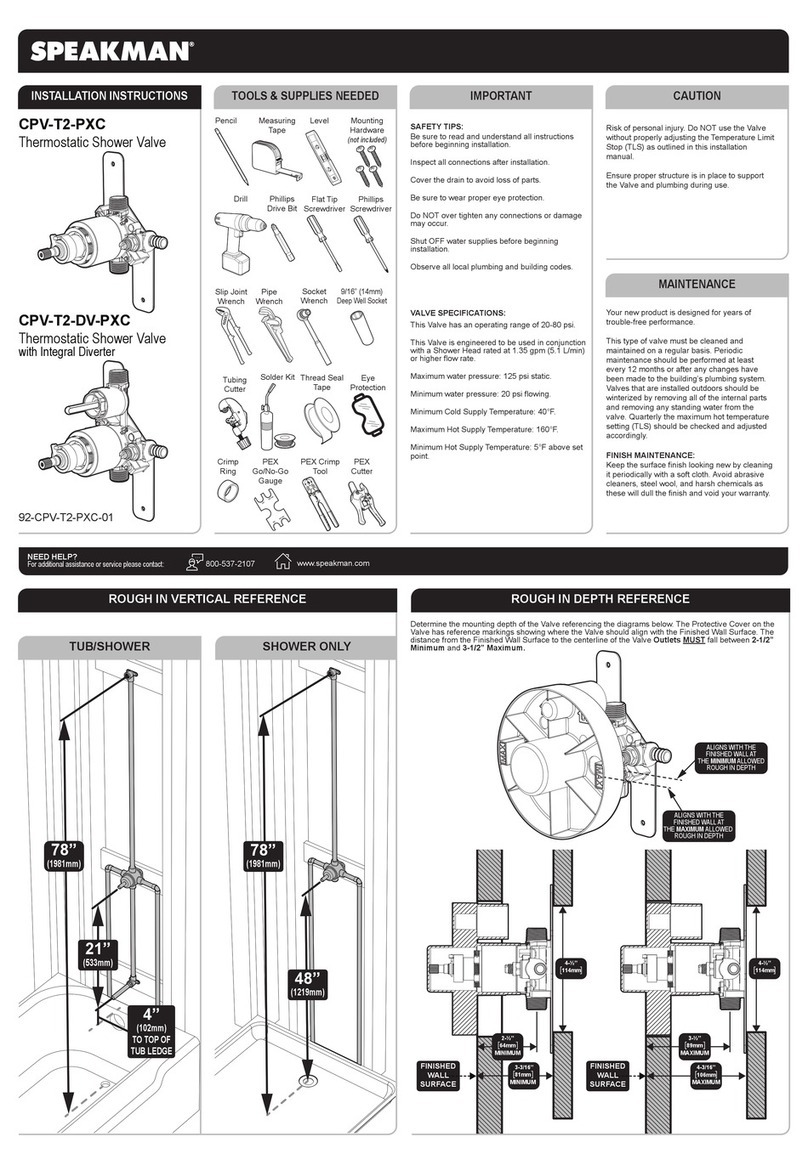

Installation with clamps

Point mounting

Line mounting

CL2

L

CP1

CL1

L

B

CP2

B

Module type Mounting method Clamp range [mm] Test load (includes a safety factor of 1.5), compression/tensile [Pa]

GB CP1/CL1

MP1/MP2

IP1

L = 200–450

L = 320

-

5,400/2,400

CP1

CP2/CL2

IP2

L = 0–200 & 450–550

B = 0–300

-

2,400/2,400

GG CL1

IP1

L = 200–450

-

5,400/2,400

CP2/CL2

IP2

B = 0–300

-

2,400/2,400

Please ask Meyer Burger for advice on non-specified mounting methods or higher loads; in this case, suitable alternative attachment options can be developed.

Legend: CP: Klemmpunkt (Clamp point), CL: Clamp line, MP: Mounting point, IP: Installation profile

Installation at the attachment points

Installation with slide-in rails

Point mounting

Line mounting

Line mounting

IP1 IP2

MP1

L

4 x attachment

points

MP2

L

4 x attachment

points

Meyer Burger (Industries) GmbH

An der Baumschule 6–8

09337 Hohenstein-Ernstthal

Germany

www.meyerburger.com

This manual suits for next models

1

Popular Control Unit manuals by other brands

IME

IME Nemo 96HDLe Mounting instructions

Siemens

Siemens SIMATIC NET CP 1628 operating instructions

Quantum Rehab

Quantum Rehab DX Basic operation instructions

Elvox

Elvox 732E Wiring instructions

Bandini Industrie

Bandini Industrie GiBiDi CB24 Instructions for installations

Kohler

Kohler K-10949 installation guide