Operating Instructions

Meyer Sound Laboratories, Inc.

2832 San Pablo Avenue

Berkeley, CA 94702

UM-1C

UltraMonitorTM

■Standing in front of the loudspeaker, position the

analyzer microphone directly between the horn and

the 12-inch driver, at right angles to the cabinet face,

and about 20 inches in front of the UM-1C.

■If polarity of the horn driver is reversed, a trough will

appear in the response curve, centered near 1600 Hz.

If in doubt, reverse the polarity of the Hi amplifier output

while you watch the analyzer display.

2. Multiple cabinets.

Each cabinet should first be tested as above.

■Connect one loudspeaker and advance the pink noise

to a convenient measuring level. Position the measuring

microphone between two adjacent loudspeakers, and

about six feet distant. Note the frequency response and

overall level.

■Leaving the first loudspeaker connected, connect the

adjacent one and observe the analyzer display.The

entire curve should jump up in level, indicating correct

addition between the loudspeakers. If the loudspeakers

are adjacent, a polarity reversal between them will show

up as severe broadband cancellation. As the loudspeak-

ers are moved apart, the cancellation will become less

apparent at high frequencies. For this reason, polarity

testing should be done with cabinets adjacent.

All Meyer Sound loudspeakers are thoroughly tested

in all stages of manufacture and correct polarity of indi-

vidual cabinets is assured. However, accidental polarity

reversal is possible when there are multiple amplifier

connections. A cabinet which is out of polarity with the

rest of the system will cause severe cancellation, result-

ing in a noticeable decrease in SPL and possible compo-

nent damage.

Because of the extensive signal processing circuitry of

the M-1A Control Electronics Unit, the “phase-popper”

type of speaker phase checkers cannot reliably be used

to test for correct polarity of the low and high drivers of

the UM-1C. However, because the UM-1C is phase

corrected through crossover, any of the portable spectrum

analyzers can be used, with a pink noise source, to test

for driver polarity as follows:

1. Single cabinets.

First, verify polarity of the woofer by connecting a 9 volt

battery at the end of the loudspeaker cable.

Cannon connector Battery

Pin 1 + terminal

Pin 2 – terminal

■The woofer cone should move outward toward the

listener. Connect the speaker cable to the amplifier.

■Input the pink noise source to the M-1A and advance

the M-1A input Level

control to a convenient measuring level.

Verifying System Polarity

Note. If you are using standard Meyer Sound loudspeaker

cables and adapters, simply connect the female end of

the loudspeaker cable to the UM-1C, the male end of the

cable to the Meyer Sound pigtail adapter, and the banana

connectors of the adapter to your amplifier outputs. In

making connections between the UM-1C and the amplifier,

be sure to connect the 12-inch driver to the Lo channel,

and the horn driver to the Hi channel.

The adapter banana plugs are color-coded as follows:

Red — Low frequency driver

Black — High frequency driver

For connections between the M-1A and the power ampli-

fier, refer to the M-1A Operating Instructions.

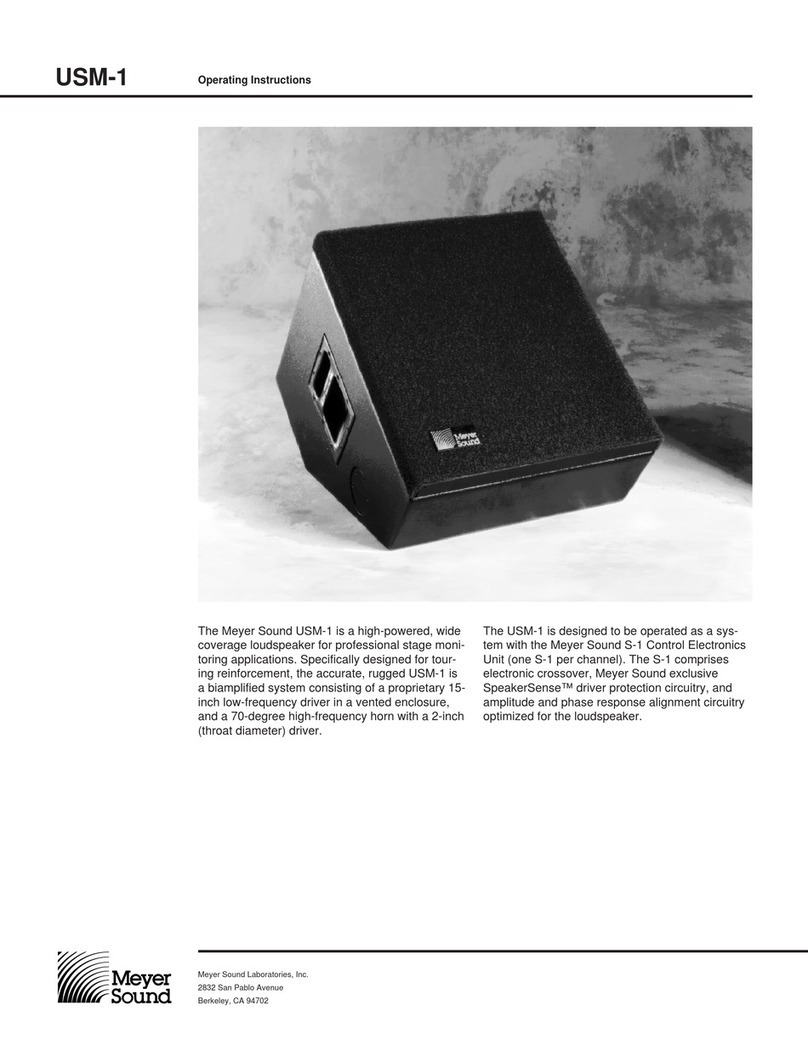

The UM-1C is a biamplified system and must be used

with the M-1A Control Electronics Unit. The M-1A

functions as an active crossover, dividing the input signal

into high and low frequency components.

The connection terminals of the low and high frequency

drivers appear on a single Cannon P-type 4-pin connec-

tor located on the rear of the UM-1C cabinet. The pin

assignments for this connector are:

Pin 1 — 12-inch driver, hot

Pin 2 — 12-inch driver, common

Pin 3 — horn driver, common

Pin 4 — horn driver, hot

(When the cabinet is fitted with a Cannon EP-5

connector, Pin 5 is unconnected.)

The minimum wire size for connections between the

UM-1C and the power amplifier should be 14 gauge.

Connections

Amplifier Requirements The UM-1C requires a professional quality two-channel

power amplifier rated at 200-300 watts per channel

continuous into 8 ohms. (If two UM-1Cs are to be oper-

ated in parallel from the amplifier, it should be capable

of driving 4 ohms.) Use of amplifiers of lower power will

not allow the full power and headroomofthe UM-1C

system to be realized (though this may be acceptable in

applications where high pressure levels are not required).

Conversely, use of amplifiers rated at significantly more

than 300 watts per channel may endanger the loud-

speaker, and is not recommended.

For further information on power amplifiers, please refer

to Choosing a Power Amplifier, a Meyer Sound Techni-

cal Note available from your dealer.