12

Important Pre-installation Information

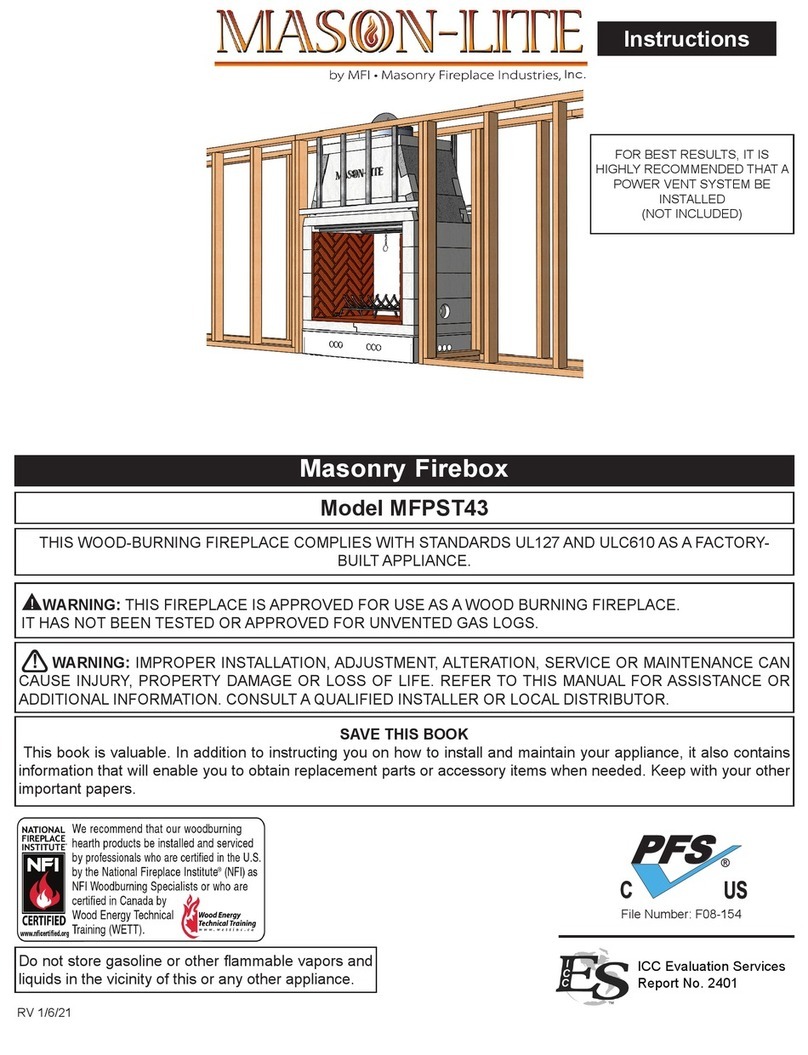

Overview

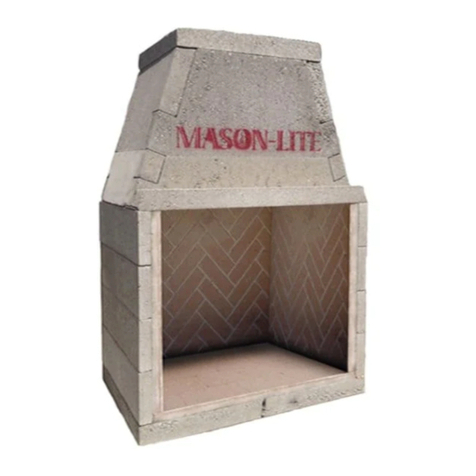

You will nd that the Mason-Lite Fireplace is designed for

complete assembly at your construction site with all necessary

items delivered consisting of interlocking precast parts, 50 lbs.

of Mason-Lite mortar and rebar.

The parts of the replace are made of Mason-Lite’s incredibly

strong blend of specialty cement and a lightweight aggregate.

The design of the replace calls for the installation of a refractory

re brick liner. This should be a minimum of 1-1/8” thick. The

liner will be applied within the walls of the rebox. Modular

rebrick panels are also available from MFI.

Additional Materials Required:

1) Ready-Mix concrete - 2 cu.ft.

SURFACE CRACKS - The MASON-LITE FIREPLACES are

manufactured using high quality materials. During the drying

process, surface cracking may occur. These small cracks

(under 1/16” will not aect the replace safety or performance).

During the assembly process, ll surface cracks with thin-set

mortar and brush when drying for a smooth surface nish.

Leveling and Aligning Components:

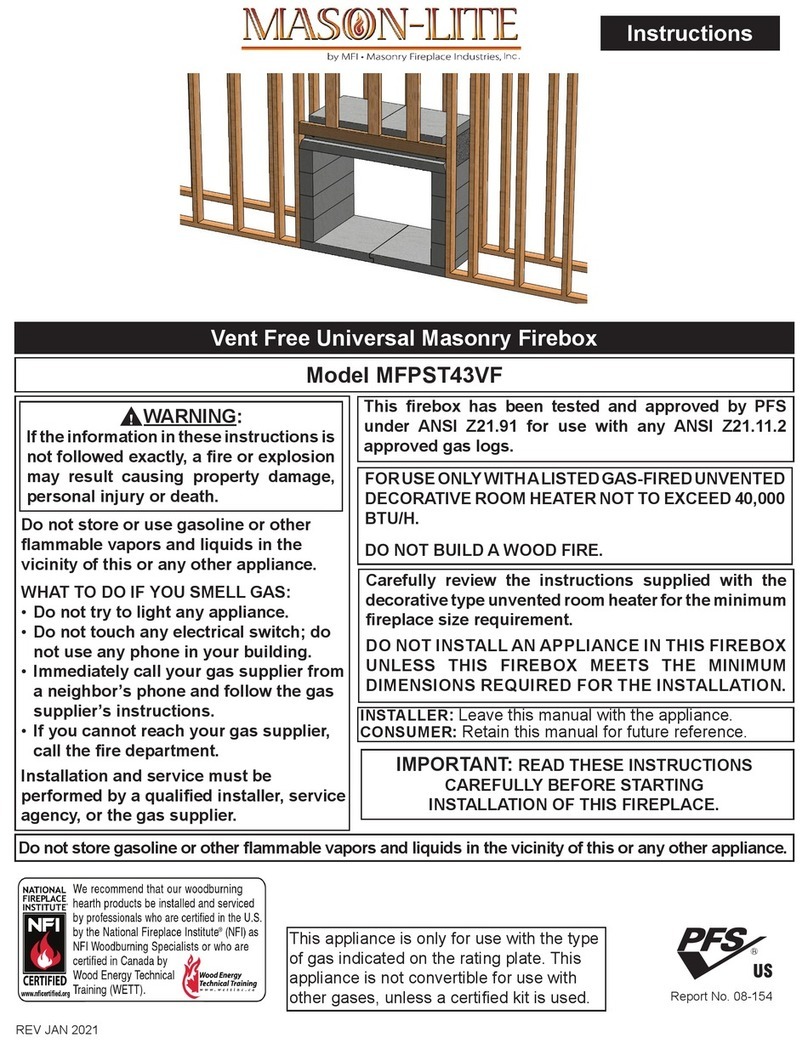

It is important to assemble all Vent-Free replace components

ush, level and square. Since it is not intended that mortar

be used to lay a mortar joint of any measurable thickness as

is typical when laying brick or concrete block, adjustments in

component height and level alignments are accomplished with

the use of small shims. These shims can be tapped into place

to level and align components. Once the Mason-Lite Mortar is

set, the shims must be removed completely.

Be sure to re-grout any and all gaps where shims have been

inserted and then removed or where contact surfaces have

been separated by shim leveling.

Field Assembly Procedures

1) Mixing the MASON-LITE mortar – You will require a 50 lb.

bucket of MASON-LITE mortar which will be more than

enough to adequately ax all the replace components,

one to the next. The mortar is premixed and dry and

is to be used to adhere all the replace components.

Be sure to use clean water and work it up into a mixture that

is pasty but not lumpy. If it is too thin, the components will

not adhere. Some trial and error may be necessary. You will

want to apply the mixture with a standard grout bag.

2) Moisten all surfaces which will have grout applied prior

to assembly. This will minimize shrinkage and cracks

developing in the joint areas. Best way to accomplish this is

with a bucket of water and a large sponge. Dip sponge into

water and apply a liberal amount of water to the grout joint

surface several minutes before the part is to be assembled.

The water will absorb into the surface allowing the grout to

properly cure.

3) Assembly of the Components – Once you have found the

proper consistency of the mixture, load it into the grout

bag and then place the components together applying

the mixture directly to the components where they come

together. As a rule, you can gure that you should lay down

about ½” (one-half inch) of a thread of mortar. The line of

mortar should be approximately ½” (one-half inch) away

from all the edges of each separate component.

The mortar has a considerable amount of holding power so

do not overload the components with too much mortar.

4) You will notice that some mortar will “ooze out” when you

place the next component on top of or next to the component

you previously place. This is to be expected – it means the

two pieces have properly bonded -- and you will want to

swipe the excess away with a trowel. It is never intended

that the surfaces of the MASON-LITE components are to be

completely covered with mortar.

5) Do not apply the mortar in thick bands even if the component

you are working with is larger than the rest. You will want to

apply “stripes” of mortar in these situations.

6) Making Sure Components Are Level – It is extremely

important that you pay careful attention to how you are

assembling the MASON-LITE. Since every component

builds on the next, it is critical, that from the beginning, you are

checking that the components are tting together to be level

and ush. If you have to make any kind of an adjustment, do

not try to do it “by loading an opening” with mortar. That is

completely unacceptable, resulting in a replace that will not

be plumb or level. What you are advised to do is make use

of shims. You will nd these supplied with the MASON-LITE

and you can nudge them in between openings to achieve

the precision you need in making component adjustments.

7) Once you have removed the shims, you will want to cover

any gaps that may have resulted with the grout.

Warning: All surfaces where grout is applied must

have water sponged on several minutes prior to

assembly. This will minimize cracking of grout joint

and provide maximum strength.