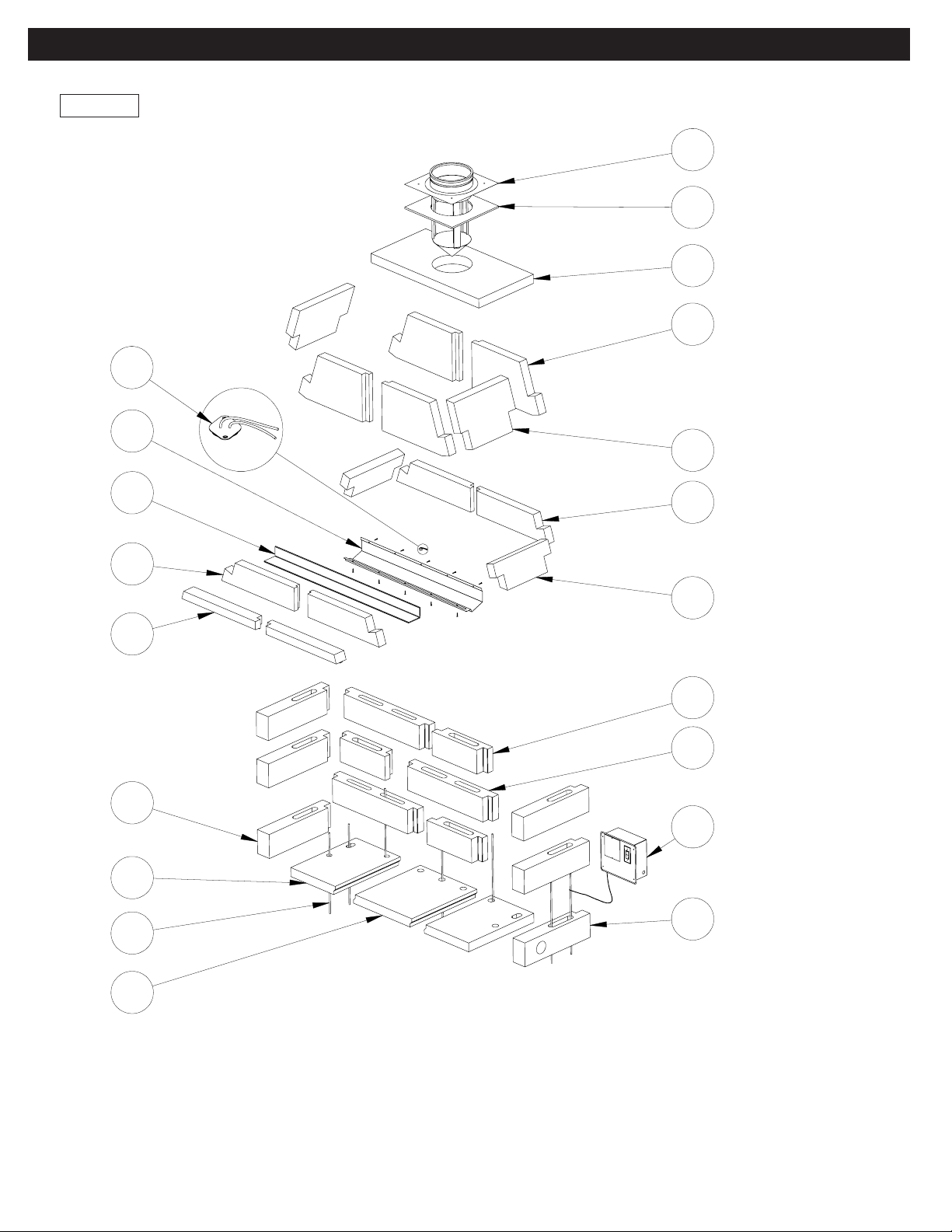

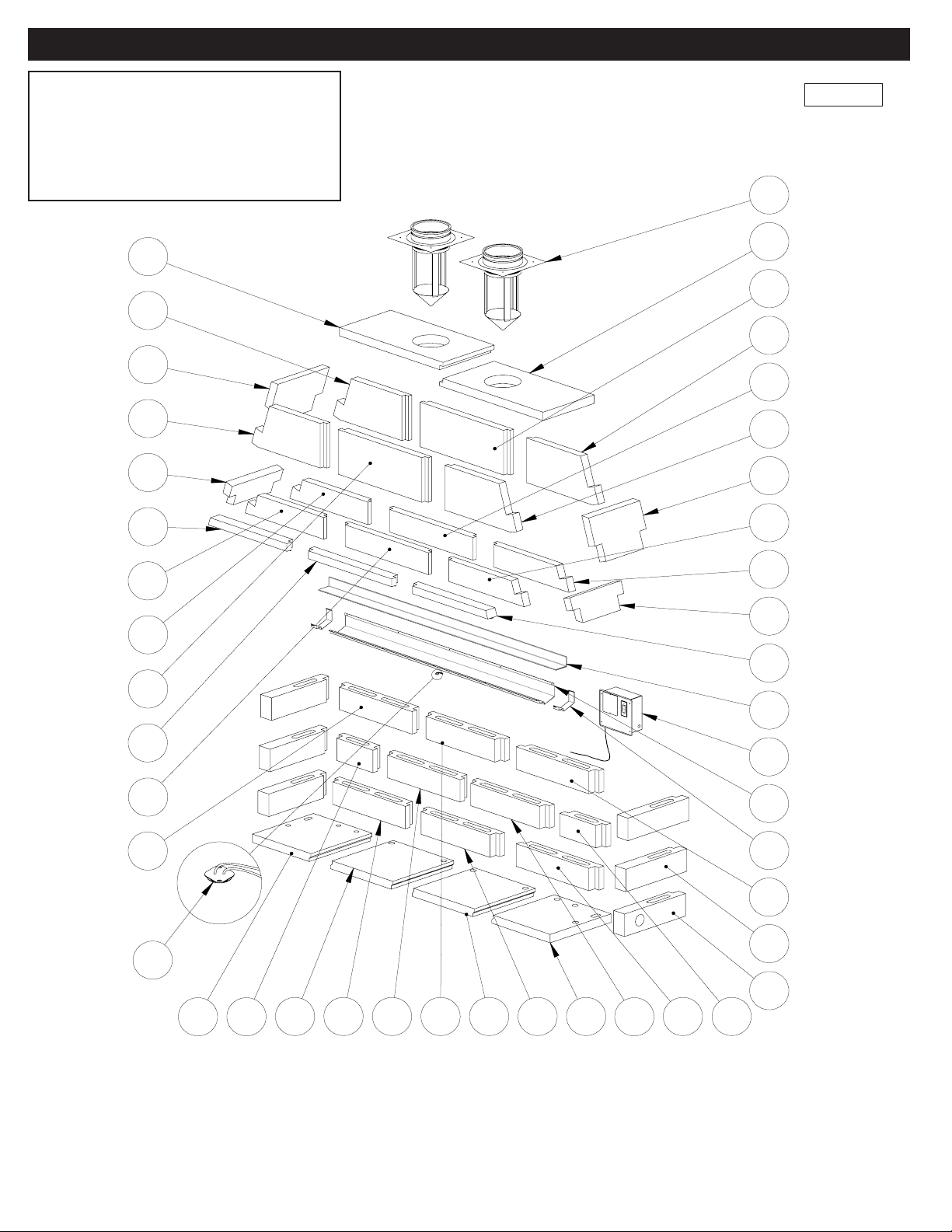

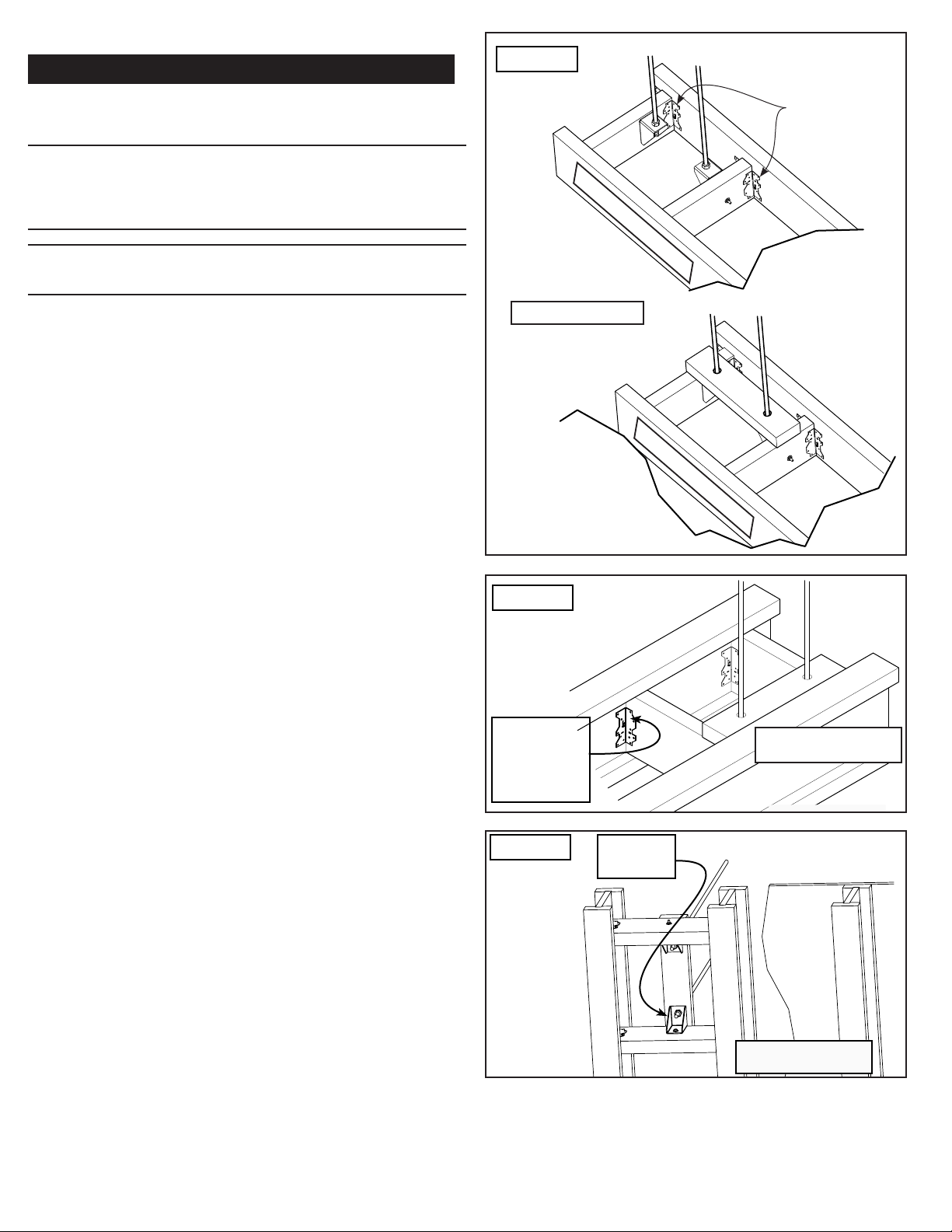

17

What You Will Need

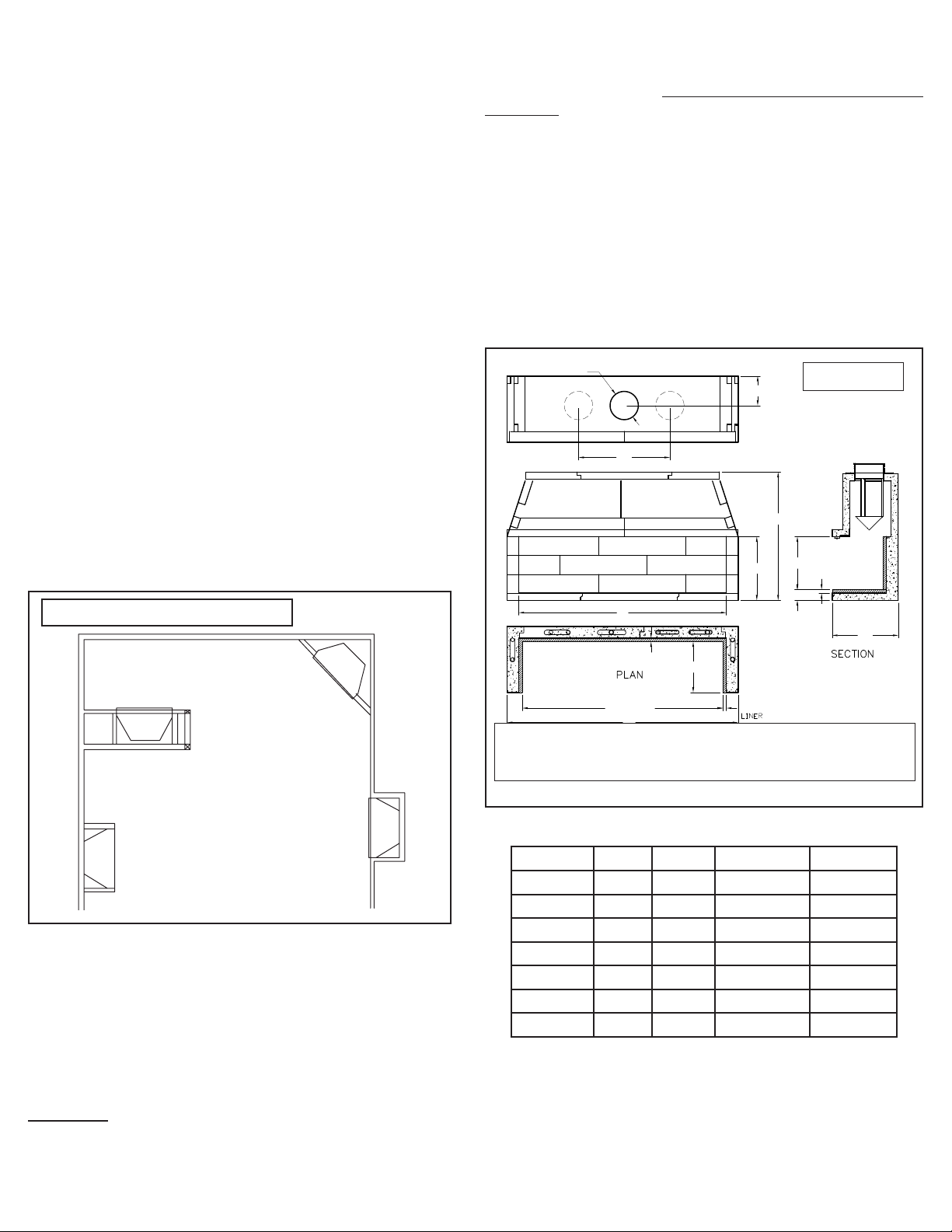

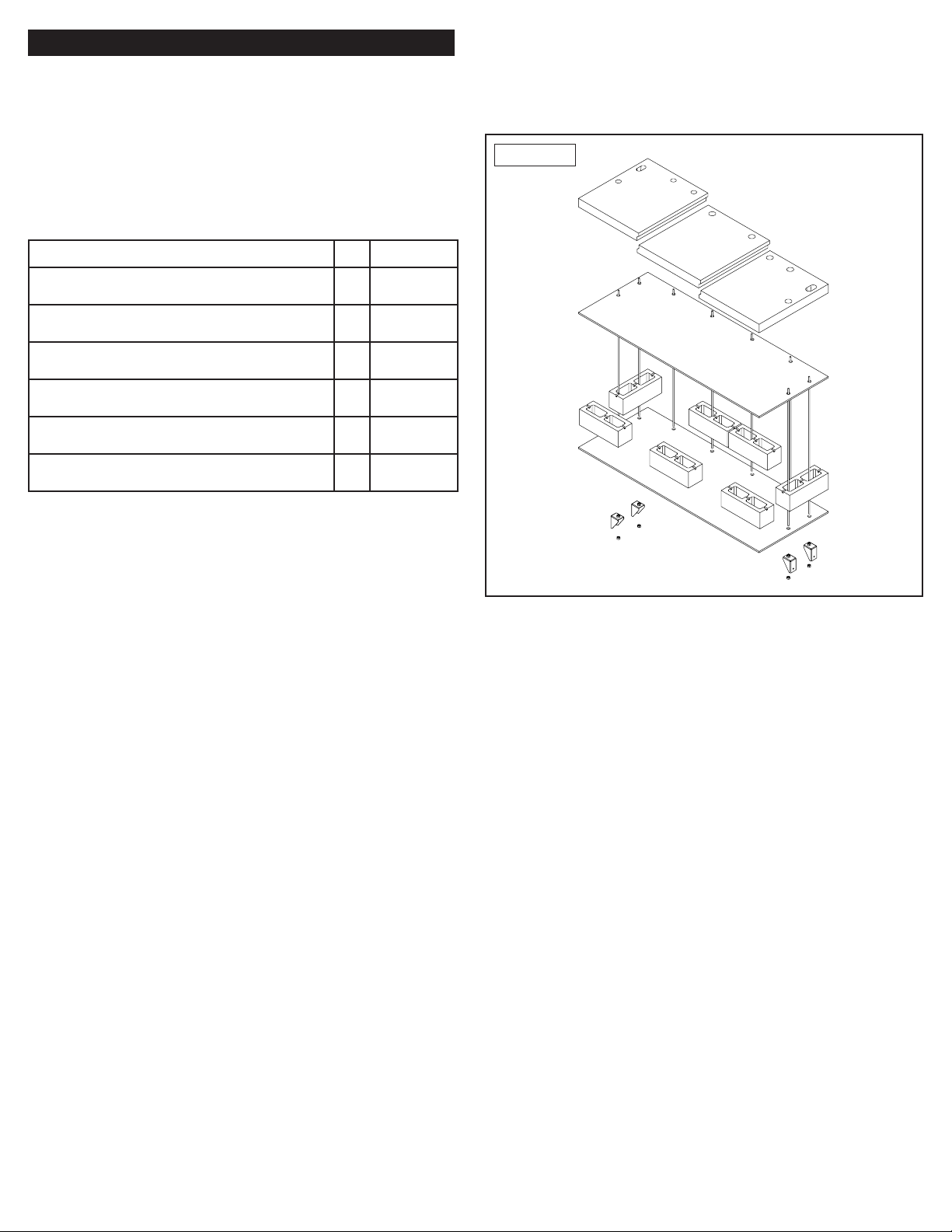

You will nd that the Mason-Lite B-vented Gas Appliance is

designed to be completely assembled on-site, consisting of

interlocking precast parts. The parts of the appliance are made

of Mason-Lite’s incredibly strong blend of specialty cement and

a light weight aggregate.

IMPORTANT! When applying mortar, it is imperative that the

concrete blocks be maintained moist (not soaking) so they don’t

absorb the water out of the mortar and cause adhesion to fail.

Frequently run a damp sponge to the parts before mortar is

applied!

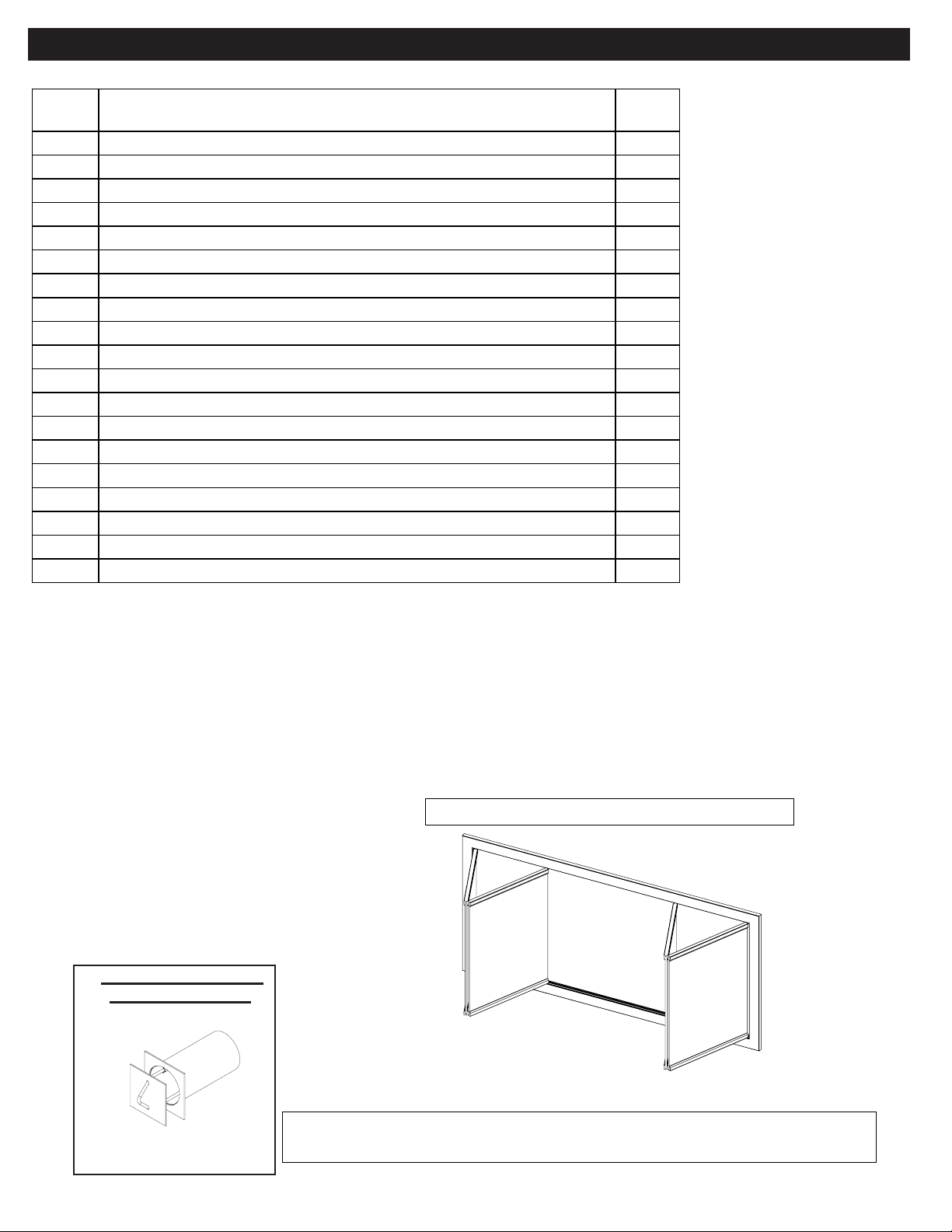

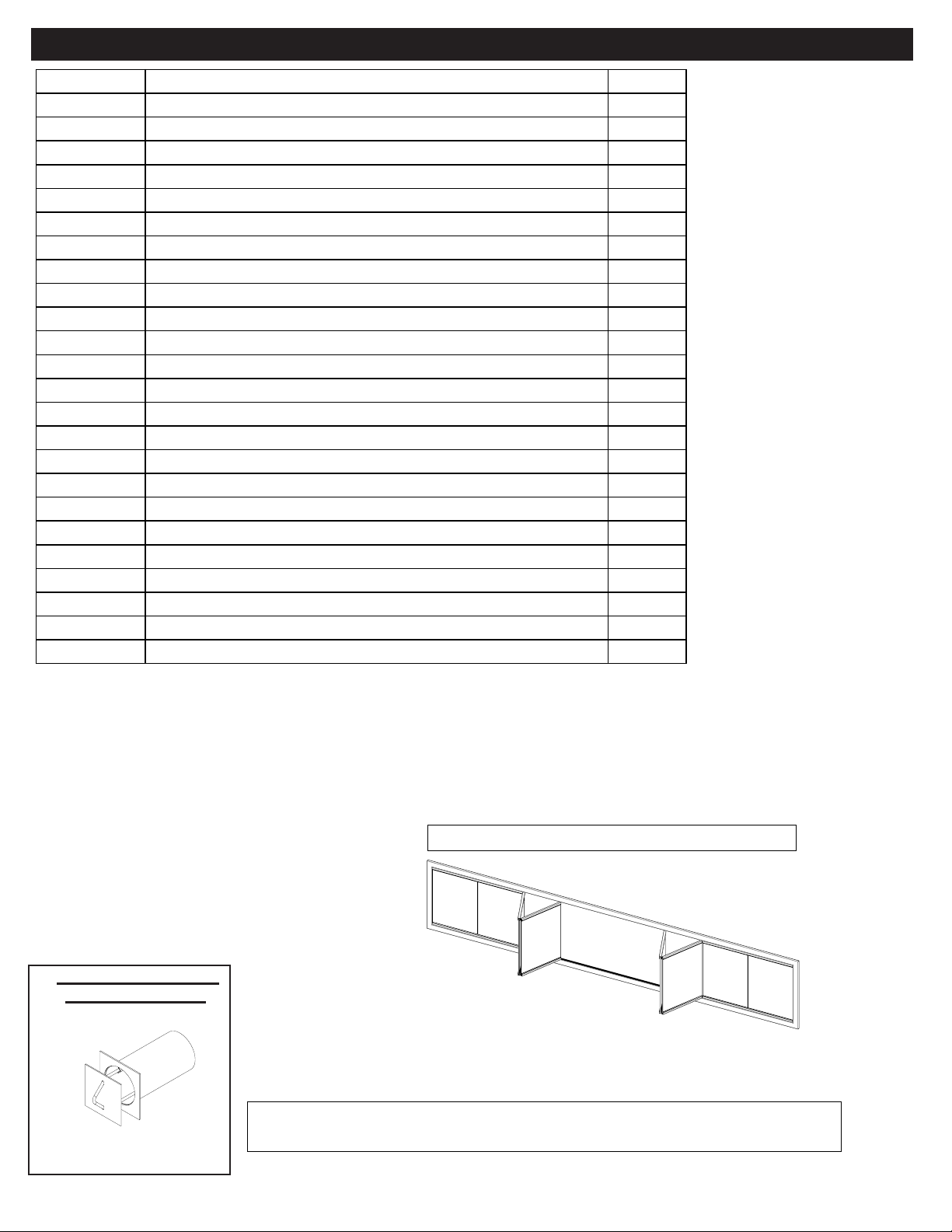

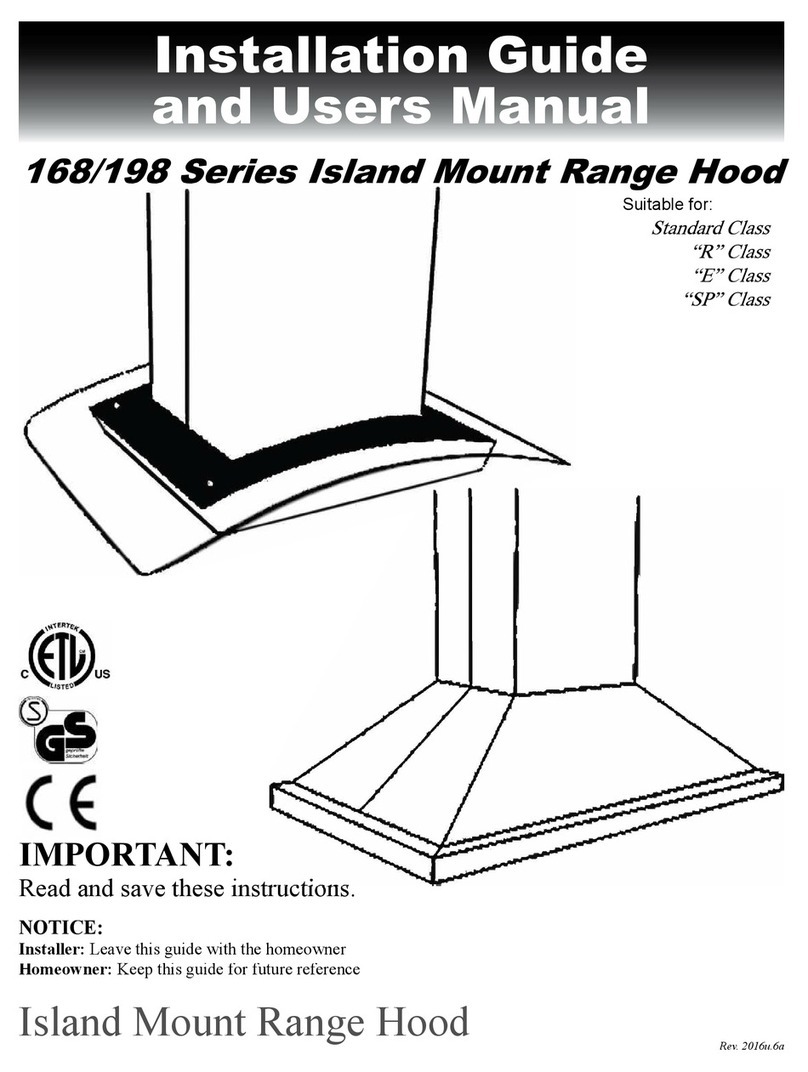

The installation of an anchor plate/damper is required but not

supplied. You may purchase it from any chimney manufacturer

or Masonry Fireplace Industries. Also, an optional combustion

air inlet MFPST-4AK can be obtained from Masonry Fireplace

Industries.

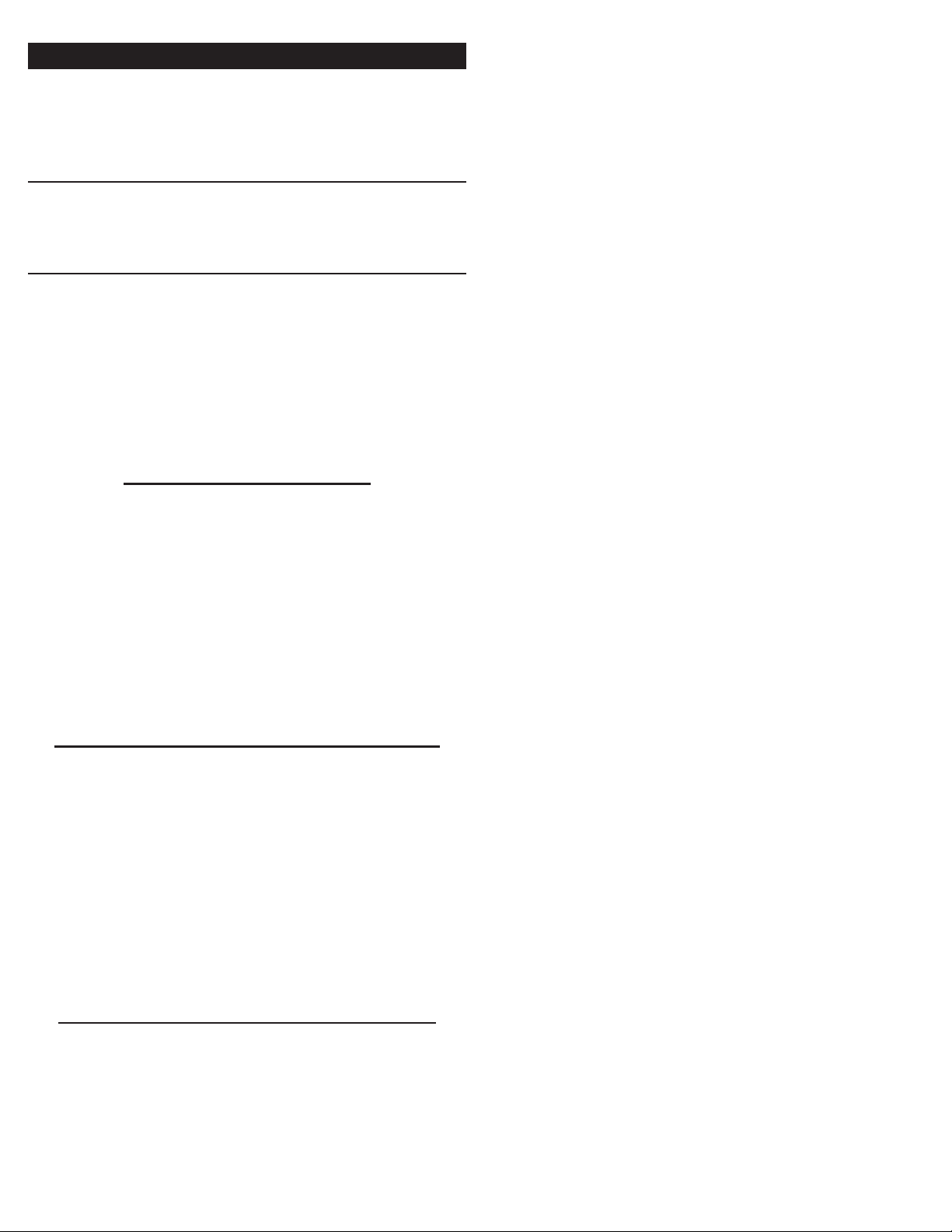

Refractory Firebrick Lining is required. Side and rear wall

rebrick should be a minimum of 1-1/2” thick. Hearth lining

should be a minimum of 2” thick. For more information see

page 21.

Tools needed for installations:

●One 4’ level

●Roto-hammer with ½” drill bit (needed for concrete slab

install only)

●Drill motor with mixer blade (to mix Mason-Lite Mortar)

●Two empty 5 gallon buckets (to mix Mason-Lite Mortar)

●One wheelbarrow and shovel to mix concrete.

●Grout bag

●Triangular masonry trowel

●Rubber hammer

●Sponge and water bucket to wipe down and moisten parts

prior to applying mortar.

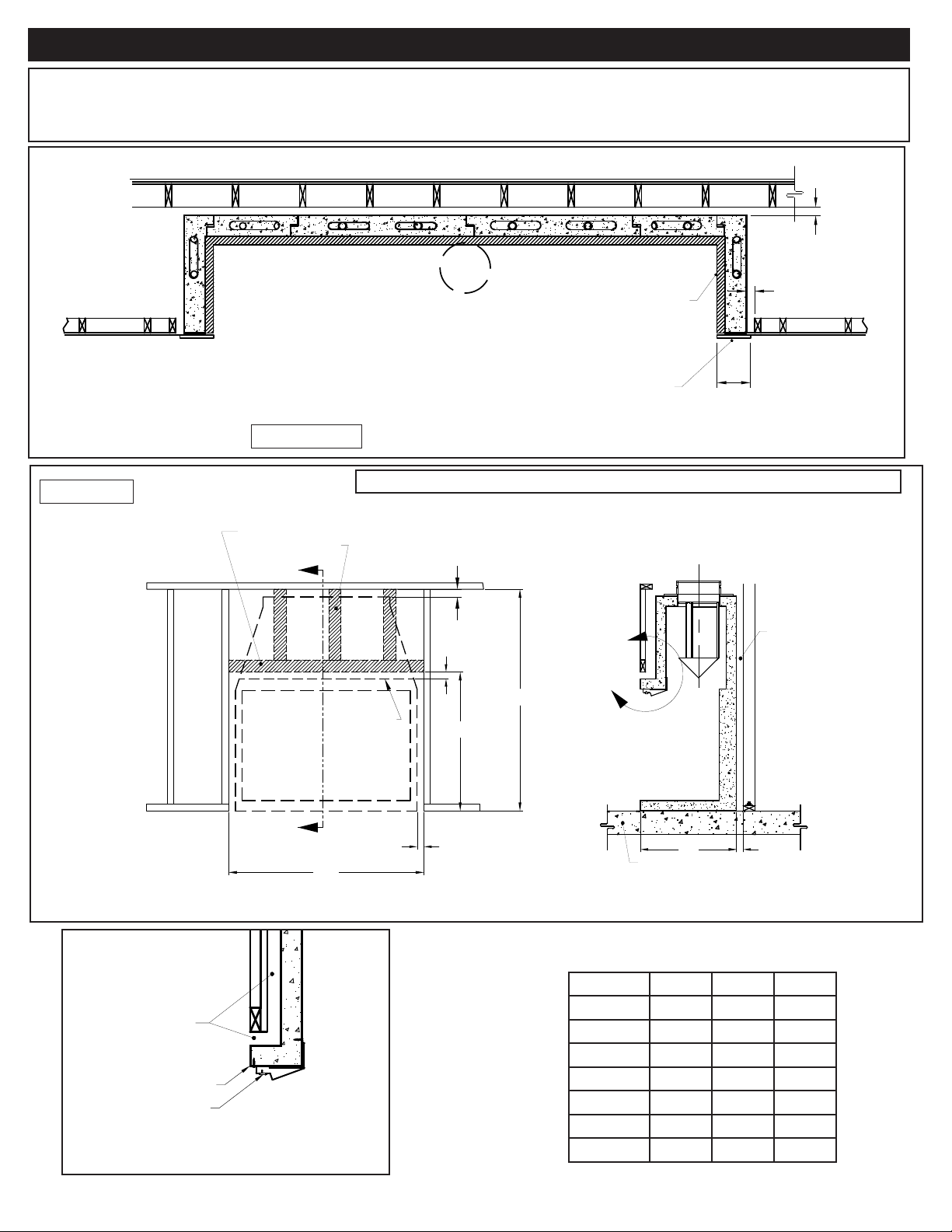

Materials needed for concrete slab installations

LMFP48/60/72:

Six (6) pieces 3/8” rebar x 36” long (included with unit)

Six (6) pieces of rebar x 12” long (included with unit)

LMFP84/96/108/120:

Eight (8) pieces 3/8” rebar x 36” long (included with unit)

Eight (8) pieces of rebar x 12” long (included with unit)

ALL UNITS:

●Epoxy for securing rebar in footing / foundation.

●Three (3) - 90 lb. bags of Ready-Mix Concrete with 1/4” or

smaller aggregate.

Materials needed for wood floor installations

LMFP48/60/72:

Six (6) pieces 3/8” rebar x 36” long (included with unit)

Six (6) ea. All-thread x 12” long (with nuts and washers)

LMFP84/96/108/120:

Eight (8) pieces 3/8” rebar x 36” long (included with unit)

Eight (8) ea. All-thread x 12” long (with nuts and washers)

ALL UNITS:

Three (3) - 90 lb. bags of ready mix concrete with 1/4” or smaller

aggregate.

6” Structural Metal Base to allow 6 inch airspace below the unit

(required for combustible floor systems)

SURFACE CRACKS - The Mason-Lite Appliances are

manufactured using high quality materials. During the

drying process, surface cracking may occur. These small

cracks (under 1/16” will not aect the appliance safety or

performance). During the assembly process, ll surface

cracks with thin-set mortar and brush when drying for a

smooth surface nish.

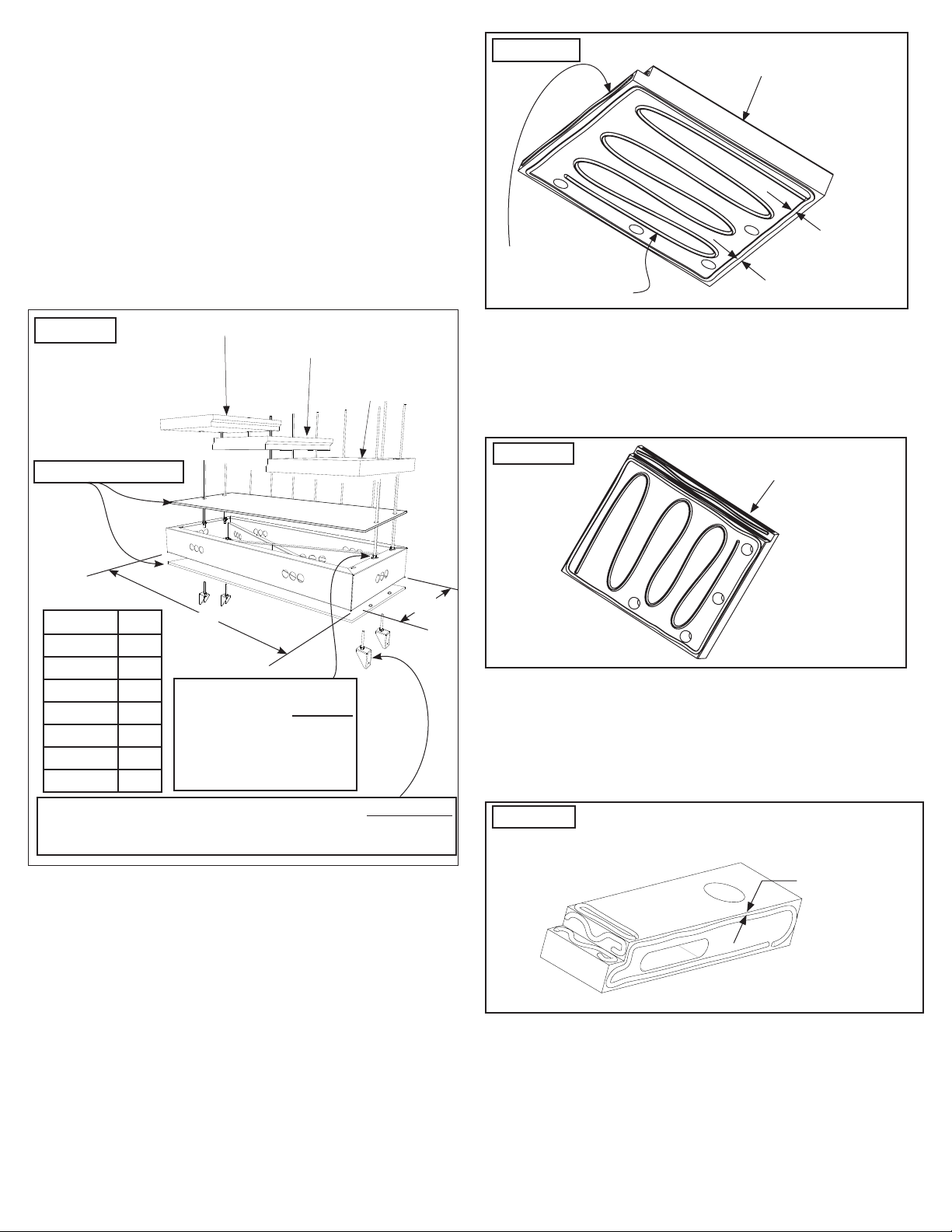

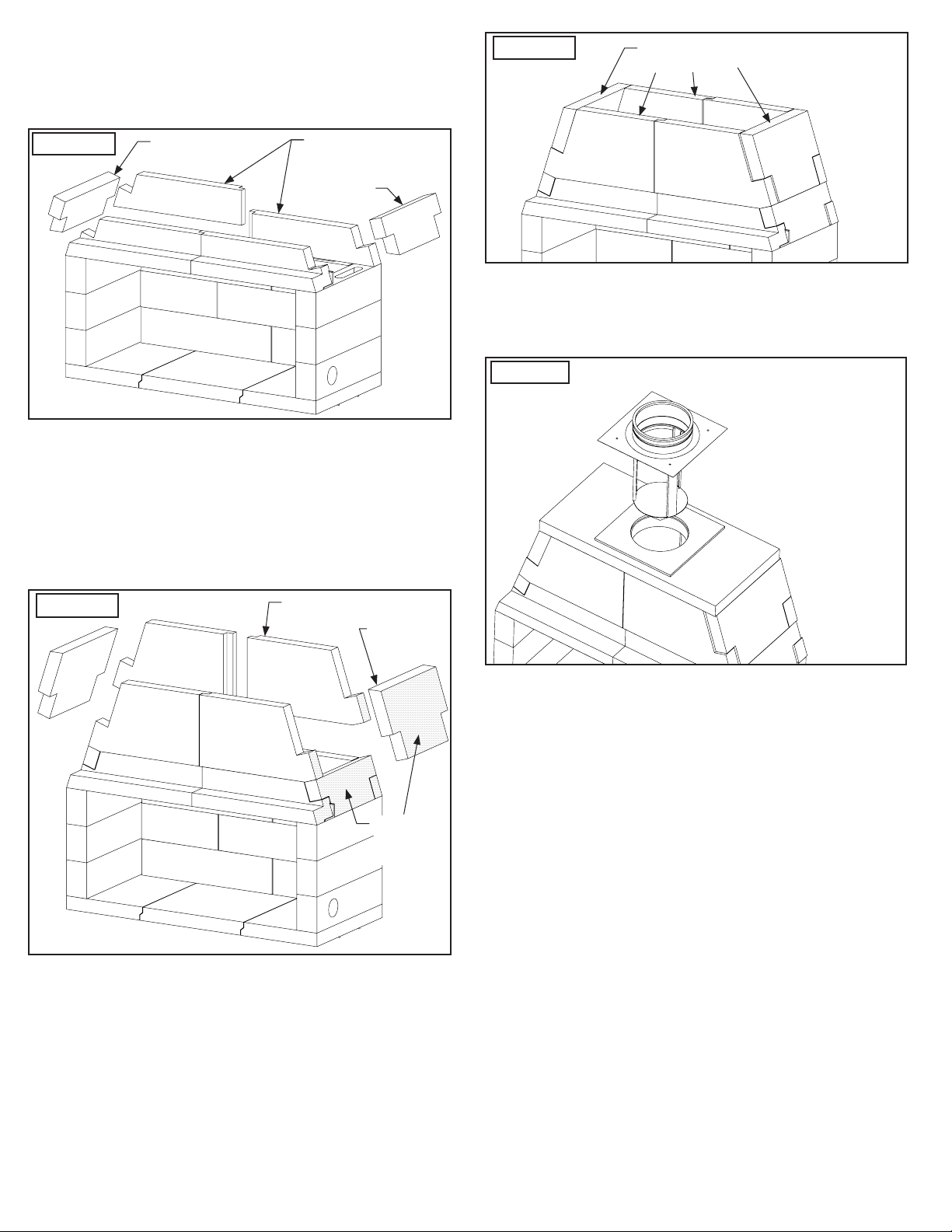

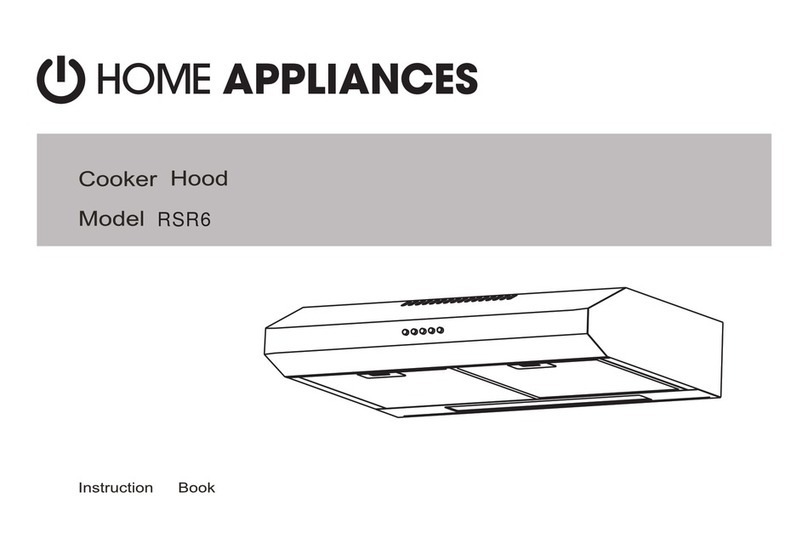

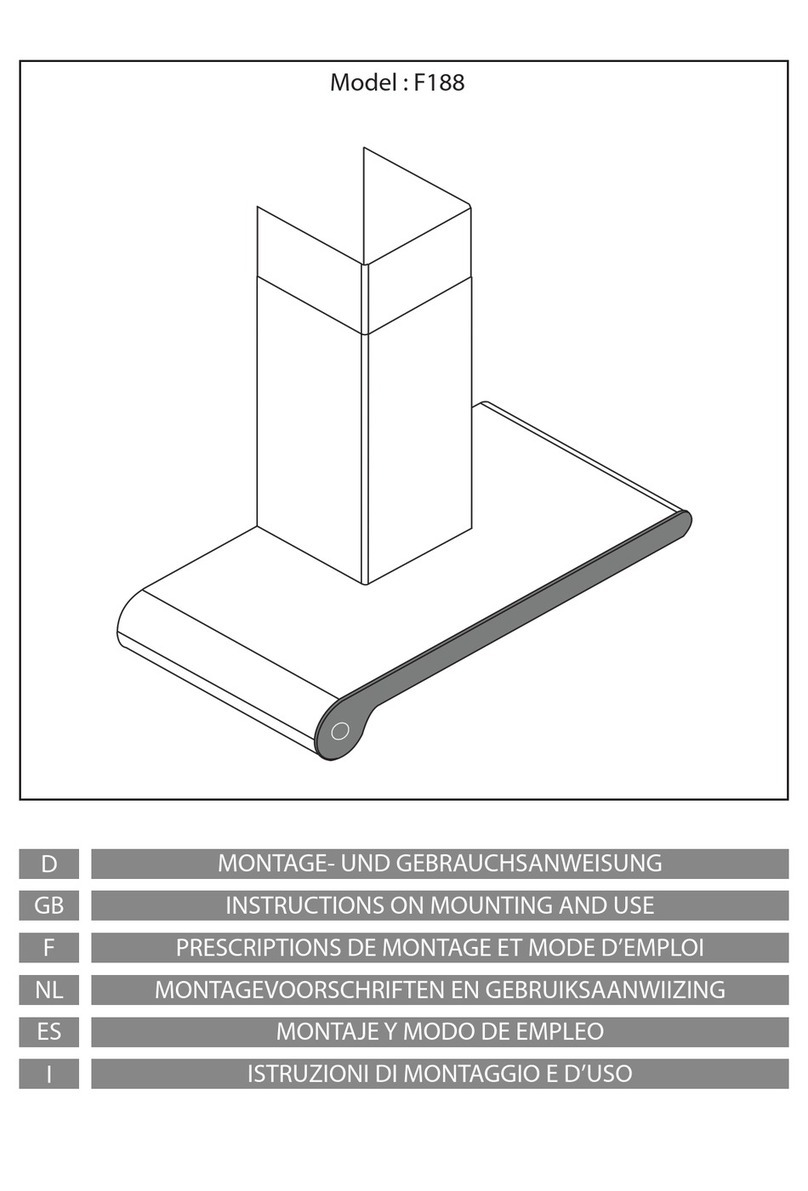

Field Assembly Procedures

a) Mixing the Mason-Lite mortar – The mortar comes premixed

and should be dry. Be sure to use clean water and work it

up into a mixture that is pasty but not lumpy. If it’s too thin

and the surfaces don’t stay moist, the components will not

adhere. Load the mixture into a standard grout bag.

b) Apply about ½” (one-half inch) thread of mortar. The mortar

bead should be approximately ½” (one-half inch) away from

all edges. The mortar has a considerable amount of holding

power so do not overload the components with too much

mortar. Keep the components moist at all times!

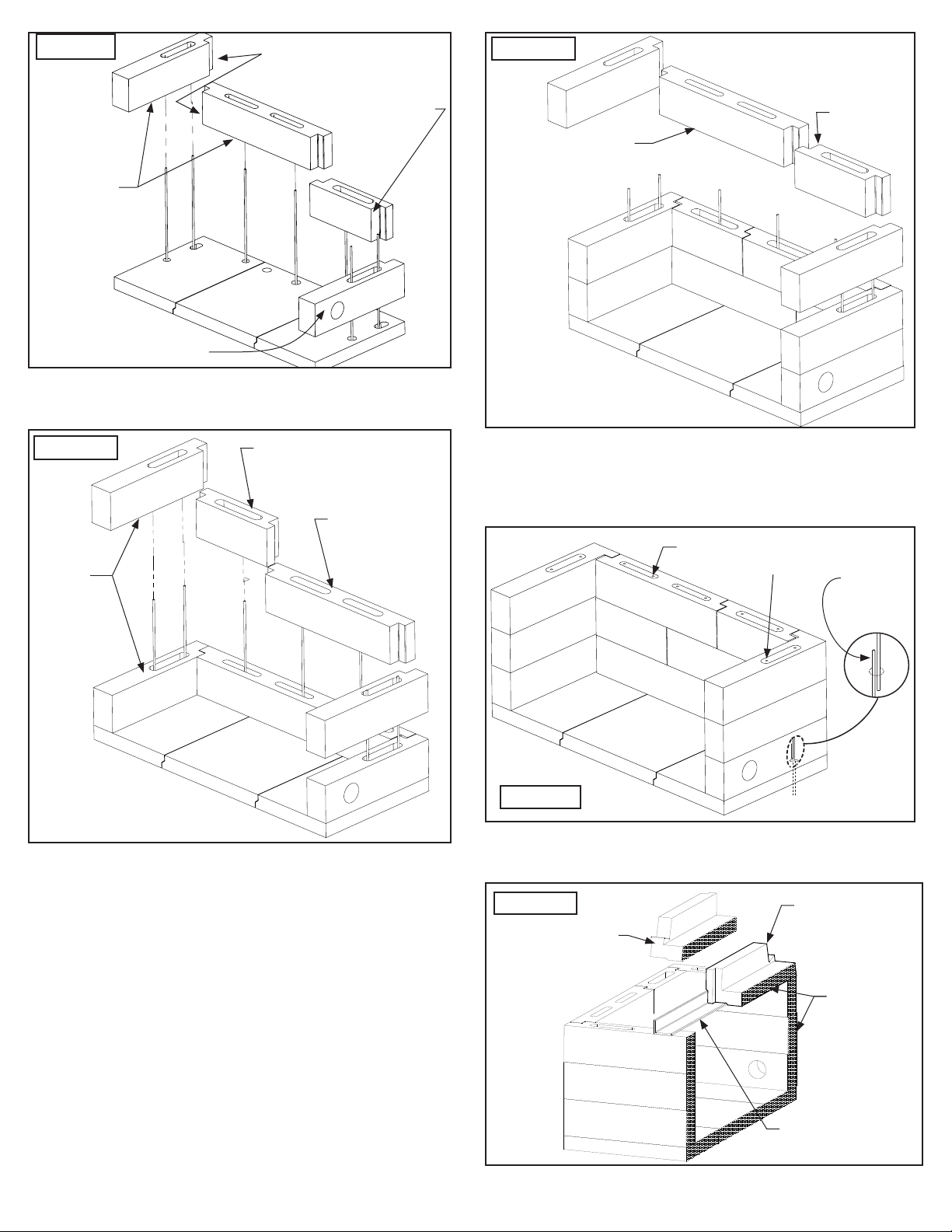

c) Some mortar will “ooze out” when placing components

together, this is normal. Wipe excess away with a trowel. Do

not cover component surfaces completely with mortar. Do

not apply the mortar in thick bands even if the component

you are working with is larger than the rest. You will want to

apply “stripes” of mortar in these situations.

d) Make sure components are level. It’s extremely important

that you pay careful attention to how you are assembling

the Mason-Lite Appliance since every component builds on

the next. If you have to make any kind of an adjustment, do

not try to do it “by loading an opening” with mortar, this will

only result in an appliance that will not be plumb or level.

Use wood shims instead. You will nd these small wood

shims supplied with the Mason-Lite Appliance and

you can nudge them in between openings to achieve the

precision you need in making component adjustments.

Once you have removed any shims, you will want to cover

any gaps that may have resulted with the mortar.