MFZ Ovitor TVR(FC) 5 Manual

OPERATING AND MAINTENANCE INSTRUCTIONS

DOOR OPERATOR TVR(FC) 5

OVITOR OY

SIENITIE 24

FIN‐00760 HELSINKI

FINLAND

Tel. +358 (0) 207 106 600

Fax. +358 (0) 207 106 601

ENG

2 ‐Door operator TVR(FC) 5 / Rev 1.41

1. CONTENT

2. KEY TO SYMBOLS

3. GENERAL INFORMATION

These operang instrucons are part of the door operator

delivery. Always store these instrucons in the vicinity of

the door operator, e.g. with other technical documents of

the door.

Anyone involved in installing, maintaining or repairing the

door operator must be familiar with this manual and ob‐

serve its regulaons and instrucons. The manufacturer will

not take responsibility for damage and operaonal errors

that occur if the regulaons and instrucons contained or

menoned in this manual are neglected.

The door operator described in these operang instrucons

is meant to open and close a door or similar. The door oper‐

ator is described here on the basis of its technical character‐

iscs at the me of prinng the manual.

The manufacturer reserved the right to modify separate

basic unit assembly groups and materials if these modifica‐

ons are considered appropriate for improving the capacity

and safety of the door operator.

The speed and travel of the door determine which gear and

limit transmission values should be used. Different possible

transmission raos are not explained in this manual. The

transmissions for each specific case can be found in the pro‐

ducon informaon, by the serial number.

Serial number:

Fig. 1.

1. Contents ................................................................ 2

2. Key to symbols ...................................................... 2

3. General informaon.............................................. 2

3.1 Safety instrucons ........................................... 3

3.2 Rang plate ..................................................... 3

4. Product range ....................................................... 4

4.1 Opons ............................................................ 4

5. Mechanical installaon ......................................... 4

6. Electrical installaon ............................................. 5

7. Set up .................................................................... 6

7.1 Adjustment of the slipping clutch .................... 6

7.2 Adjustment of the limits .................................. 6

7.3 Digital seng –AVE limits ............................... 7

8. Operaon .............................................................. 8

8.1 Disengagement clutch (not TVR‐type) ............ 8

9. Service and maintenance ...................................... 8

9.1 Changing the fricon lining of the

slipping clutch ....................................................... 9

9.2 Permied load ................................................. 9

9.2 Spare parts ...................................................... 9

9.3 Troubleshoong .............................................. 9

10. Declaraon of incorporaon of partly

completed machinery .........................................12

Danger of personal injury!

The safety instrucons must be

observed

Warning! Danger to property!

The safety instrucons must be

observed!

Informaon

Special informaon

Reference to other sources of

informaon

Door operator TVR(FC) 5 / Rev 1.41 ‐ 3

This door operator meets the requirements of 2006/42/EY,

EMC‐direcve 2004/108/EY, LVD 2006/108/EY and standard

EN 13241‐1 and is delivered in safe operaon mode. Self‐

made modificaons that could affect the operaonal safety

of the door operator are not allowed.

Observing the instrucons will improve your safety and that

of your operang environment. It also ensures the opera‐

onal safety of the door and its drive unit and prevents in‐

terrupons in use caused by faulty handling, along with bur‐

dens to the environment.

Observe occupaonal safety and environmental protecon

regulaons, when transporng, seng‐up, installing, oper‐

ang, maintaining and dismantling the door operator.

To ensure operaonal safety, only original components or

parts that have been specifically approved by the manufac‐

turer may be used in or connected to the door operator. All

components of the device have been selected, protected

and constructed so that they are durable and meet the envi‐

ronmental and operaonal requirements specified in this

manual.

Perform maintenance on the door and the door operator

only when the door is not moving. To prevent unintenonal

starng of the door operator, you must e.g. lock the main

switch of the door operator control system in the 0 posion.

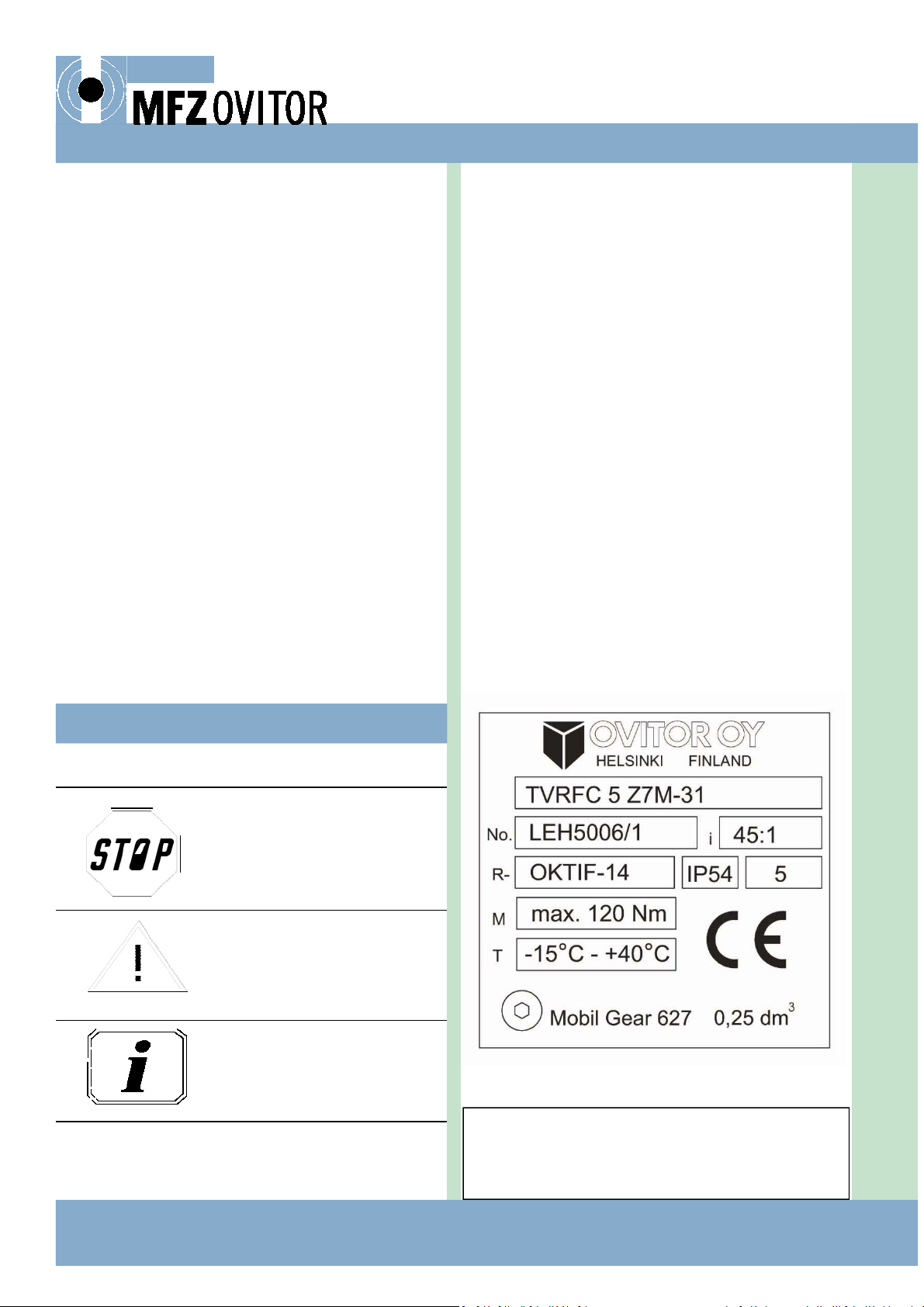

3.2 RATING PLATE

Every complete drive unit has two (2) rang plates, one on

the gear box and the other one on the electric motor (fig. 2).

The plate on the gear box shows (fig. 1), in addion to the

technical informaon, also the producon serial number

(e.g. MLN9878/1), on the basis of which all original produc‐

on informaon can be traced later.

Only authorised and properly trained

personnel may install, maintain or

repair the door operator. In cases of

more demanding repairs, always de‐

liver the door operator to the manu‐

facturer for maintenance.

Ensure that the persons responsible

for installaon, preparaon for uli‐

saon and maintenance of the door

operator have read this manual and

that they understand and observe the

regulaons and instrucons con‐

tained and menoned therein.

3.1 SAFETY INSTRUCTIONS In all quesons related to service, spare part deliveries or

claims it is extremely important to refer to the serial num‐

ber. With reference to this number it will be possible to

clear up in detail important maers related to producon,

quality control and deliveries. Record the serial number of

the GEAR box e.g. on the second page of this manual.

Fig. 2.

Rang plate of the

motor

Rang plate

of the gear

Mounng 4xM8—

dep. 20

4 ‐Door operator TVR(FC) 5 / Rev 1.41

4. PRODUCT RANGE

4.1 OPTIONS

TVR 5 door operator is delivered in following opons:

F = Disengagement clutch for manual operaon

C = Slipping clutch, dry, on the input sha between motor

and the gear box

Type of the mounng flange:

Z6 = flange IEC 63 B5

Z7 = Flange IEC 71 B5

Z8 = Flange IEC 80 B5

Z9 = Flange IEC 90 B5

X = Flange for Ovitor brake motor, not IEC standard

Type of motor:

M = 3~ electric motor

MY = 1~ electric motor

MD = Dahlander 2‐speed motor

MJ = Motor with built‐in magnec brake (Brake motor)

MDJ = Dahlander 2‐speed brake motor

MT = DC‐motor

E.g. TVRFC 5 Z7M

5. MECHANICAL INSTALLATION

Before installaon, inspect the drive unit visually for possi‐

ble damage sustained during transport. Addionally, the

drive unit must stand on each of its four sides for about one

minute to make sure that no damage to rotary sha seals or

the housing has been sustained during transport. No oil

leaks are allowed. If oil is leaking out, remove it immediately

with an oil‐absorbing substance. Installaon of a drive unit

with oil leaks is forbidden. Deliver a faulty unit to the manu‐

facturer for repair.

The drive unit must be mounted carefully on a solid and

even surface and bolted firmly to the base. If the drive unit

is to be mounted on a steel structure, make sure that this

structure will not bend. If the mounng base is not perfectly

even, the fixing lugs of the drive unit could break when the

fixing screws are ghtened. Do not bend gear when ghten‐

ing the fixing screws. Use fixing screws with a min. strength

class of 8.8. Install the drive unit so that no resonance vibra‐

on will occur and no vibraon can be transferred from ad‐

jacent structures. Do not perform welding on the drive unit

or connect it to welding circuit.

When mounng the drive unit, note the access required for

adjustment of the limit switches, as shown in the adjacent

fig. 2. The dimensions of the drive unit are shown in type

specific drawings 62XX/7XXX (e.g. 6225/7076).

If a chain transmission is used, sprockets should be perfectly

aligned. The fixing of the drive unit must be able to support

min. 5000 N chain tension.

Drive unit must be sheltered against falling objects.

If the drive unit has been detached, e.g. for maintenance, it

must be mounted again using instrucons given above. The

drive unit must be detached, together with its motor. In

cases where more demanding repairs are required, always

deliver the door operator to the manufacturer for mainte‐

nance. An exploded view of the drive unit and the part num‐

bers can be found later in this manual.

Type of motor

Mounng flange of the motor

Slipping clutch on the input sha

Disengagement clutch

Limit switches

Hollow sha worm gear

Only properly authorised and

trained personnel may dismantle or

repair the door operator.

Door operator TVR(FC) 5 / Rev 1.41 ‐ 5

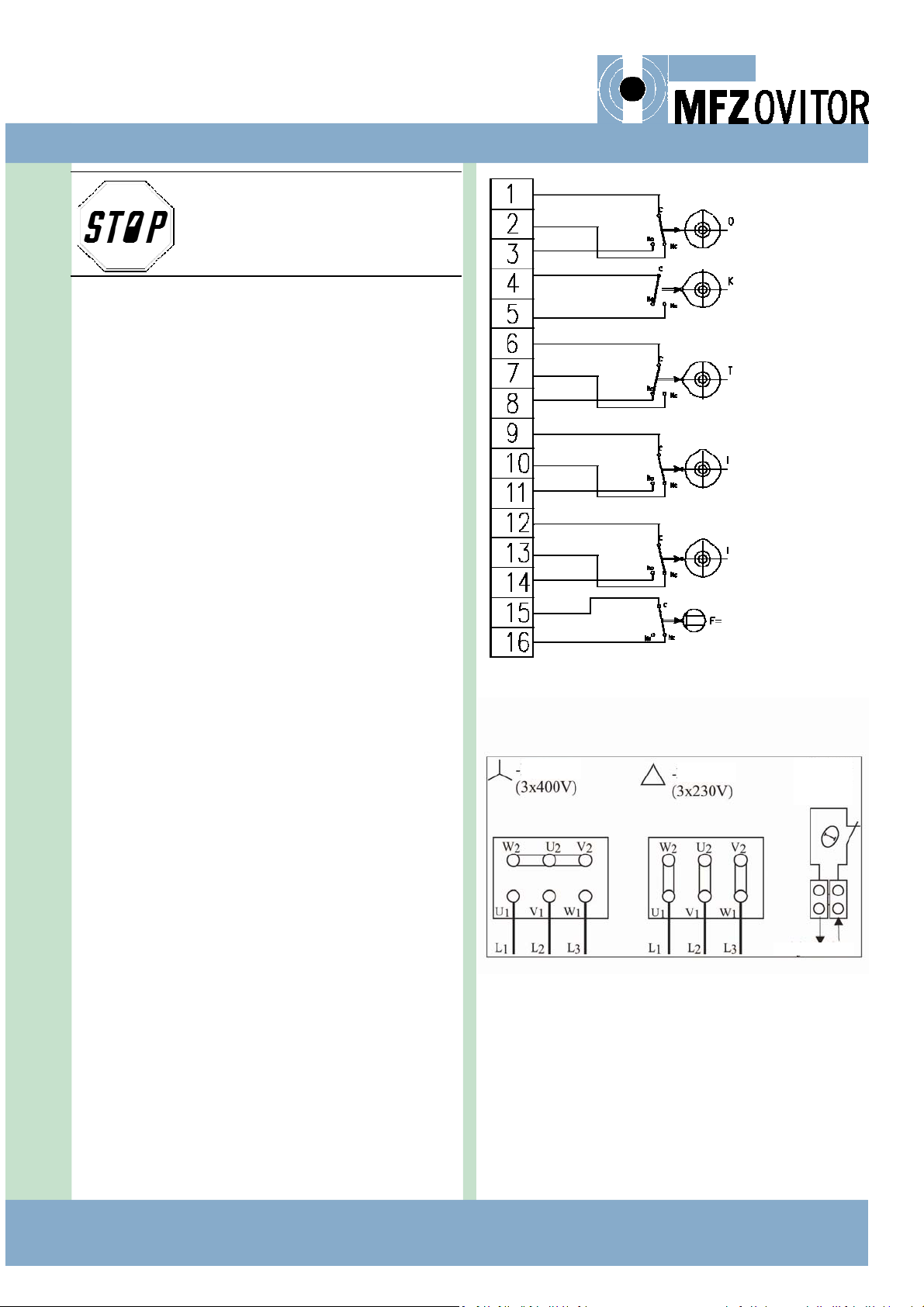

6. ELECTRICAL INSTALLATION

Perform the installaon and make the connecons accord‐

ing to the wiring and circuit diagrams provided specifically

for this case by control system supplier.

The temperature detectors of the gear unit, the possible

micro switch of the disengagement clutch and the micro

switches of the limits are already connected to the connect‐

ors in the limit switch box according to the fig. 3. Do not

modify these connecons without first consulng the manu‐

facturer.

Open and close the cover of the limit switch box carefully so

that its enclosure class will not decrease in installaon. First

loosen the fixing bolt of the cable gland lead‐through (part

number 569) on the side of the limit switch box. Then loos‐

en all fixing bolts of the cover (1/2 turn) crosswise. Aer

that loosen the bolts completely and take off the cover. In‐

stall the limit cable in the cable gland and ghten it. Check

the cable’s sealing. Make the necessary connecons.

Aer checking the adjustment and operaon of the limit

switches, install the cover of the limit switch box in its place.

Check that the sealing on the gear unit’s side has not

suffered damage during the installaon. Check that no dirt

remains between the cover and the gear unit. If there is a

disengagement mechanism (F) in the gear unit, check that

the slot in the end of the disengagement sha is in the cor‐

rect posion with respect to the shoulder inside the disen‐

gagement lever. If the parts do not match, the cover cannot

be posioned correctly and could be damaged when the

fixing bolts are ghtened. When the cover is correctly in

place, ghten the fixing bolts evenly. Also ghten the fixing

bolt in the cable gland lead‐through. Aer ghtening the

bolts, check that the lever of the disengagement clutch

funcons properly. The lever must turn 90 degrees.

Fig. 4.

Only properly authorised and

trained personnel is allowed to car‐

ry out electrical installaon.

connecon connecon Terminal for

thermal trip

in motor

winding

Control current

Fig. 3. Connecon example OKTIIF

(GREEN)

(WHITE)

(YELLOW)

(RED)

(RED)

DISENGAGEMENT

6 ‐Door operator TVR(FC) 5 / Rev 1.41

7. SET UP

7.1 ADJUSTMENT OF THE SLIPPING CLUTCH

The torque transmied by the drive unit must always be

adjusted in due consideraon of the safety requirements of

the door operaon. The limitaon of the torque is done by

adjusng the slipping clutch situated between the electric

motor and the gear box. When delivered from the factory

the slipping clutch is le loose so that no torque can be

transmied from the electric motor.

Adjustment:

1. Loosen the M8 lock nut at the end of the worm sha.

2. Hold the worm sha with a spanner.

3. Start turning the adjustment screw inwards (= clockwise)

unl the required torque has been obtained.

The torque should be adjusted so that it is just high enough

to move the door over its complete travel and low enough

to permit the clutch to slip as soon as the door is obstructed

in its movement. A direct safety risk is produced if the

torque is set to a considerably higher level than required for

the door operaon.

7.2 ADJUSTMENT OF THE LIMIT SWITCHES

To ensure correct adjustment, familiarise yourself with the

funconing of the limits in the control system. For further

informaon of the limit switches, check the documentaon

of the control system.

Limit switches are adjusted as shown in fig. 6.

1. The limit switches are adjusted with the locking screw

(N) and fine adjustment screw (M) (Allen key size:2.5

mm).

2. First turn the cam wheel near to the right posion and

ghten the locking screw (N).

3. Fine adjustment can be done by screwing the adjustment

screw (M).

Adjustment of the doors limit posions.

1. Move the door manually to the posion that corre‐

sponds the acvaon posion of the limit switch.

2. Adjust the cam wheel to its correct posion (micro

switch is near to acvaon). Note the rotaon direcon

of the limit sha!

3. It is recommended to perform the final fine adjustment

by operang the door with the drive unit.

4. Check the proper operaon of all protecve and external

devices.

Fig. 6. Adjustment of the limit switches

Fig. 5. Slipping clutch

Safety regulaons state that the door

movement must not produce a pressing

force exceeding 800 N. If the door can‐

not be moved by hand, due to a fault in

the counterbalancing or for some other

reason, it is not permied to adjust the

slipping clutch to a higher torque. The

reason for the incorrect operaon must

be removed or corrected.

Before starng to adjust the slipping

clutch, check and make sure that the

door can easily be moved manually in

every part of its travel.

Slipping

clutch lining

Worm sha

Lock nut (M8)

Adjustment screw for

torque of slipping clutch

Door operator TVR(FC) 5 / Rev 1.41 ‐ 7

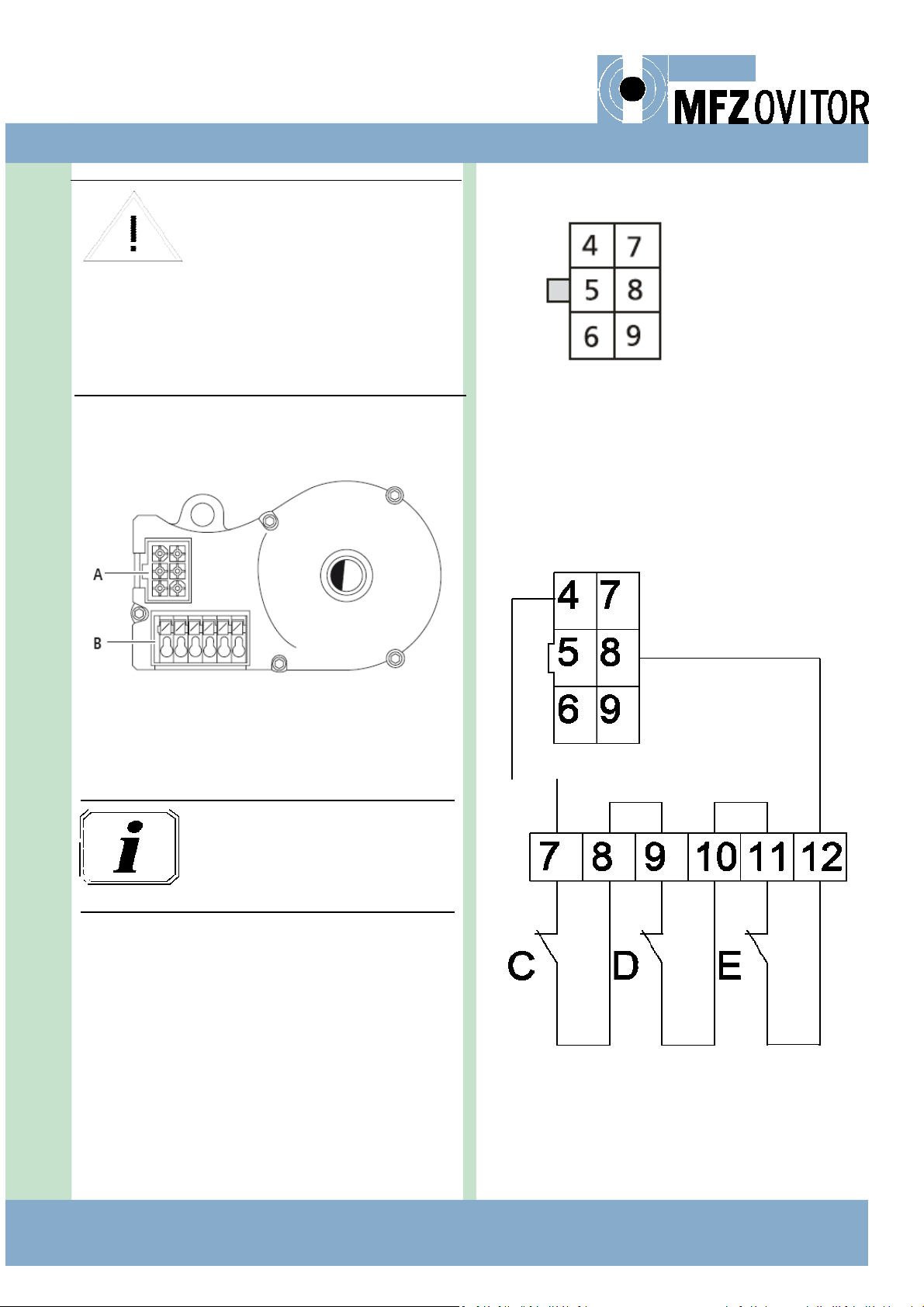

7.3. DIGITAL SETTINGS ‐LIMIT SWITCH AND SAFE‐

TY CIRCUIT FOR DRIVE

Informaon!

Please refer to the control unit’s oper‐

ang manual for instrucons on seng

the end posions.

Wiring allocaon

The numbers on the plug are also the wire numbers:

4: Safety circuit input

5: RS485B

6: GND

7: RS485A

8: Safety circuit output

9: 7...18 VDC

AVE (absolute value encoder) plug terminal (7‐12)

C. Thermal element in the drive

D. Manual emergency control (crank or chain)

E. Disengagement

Electric interface

A: AVE plug (absolute value encoder plug)

B: AVE plug terminal (absolute value encoder plug

terminal)

At the inial installaon phase, the rota‐

on direcon of the electric motor can

be wrong.

Be prepared to stop the movement to

wrong direcon immediately by using

the STOP buon.

Interchange two phase conductors to

change the rotaon direcon. It is rec‐

ommended to make the change in the

control unit.

8 ‐Door operator TVR(FC) 5 / Rev 1.41

8. OPERATION

Conduct weekly inspecons to determine changes in the

sounds of the gear unit or oil leaks from the gear unit. If you

note oil leaks or unusual sounds during drive unit operaon,

stop the drive immediately and make sure that it cannot be

used. If you cannot determine the cause of the problem,

deliver the drive unit to the manufacturer for repair.

Note that dust may accumulate on the drive unit during its

operaon. If necessary, clean the drive unit regularly. The

dust layer must not be thicker than 5 mm. Do not use high‐

pressure cleaning machines to clean the drive unit.

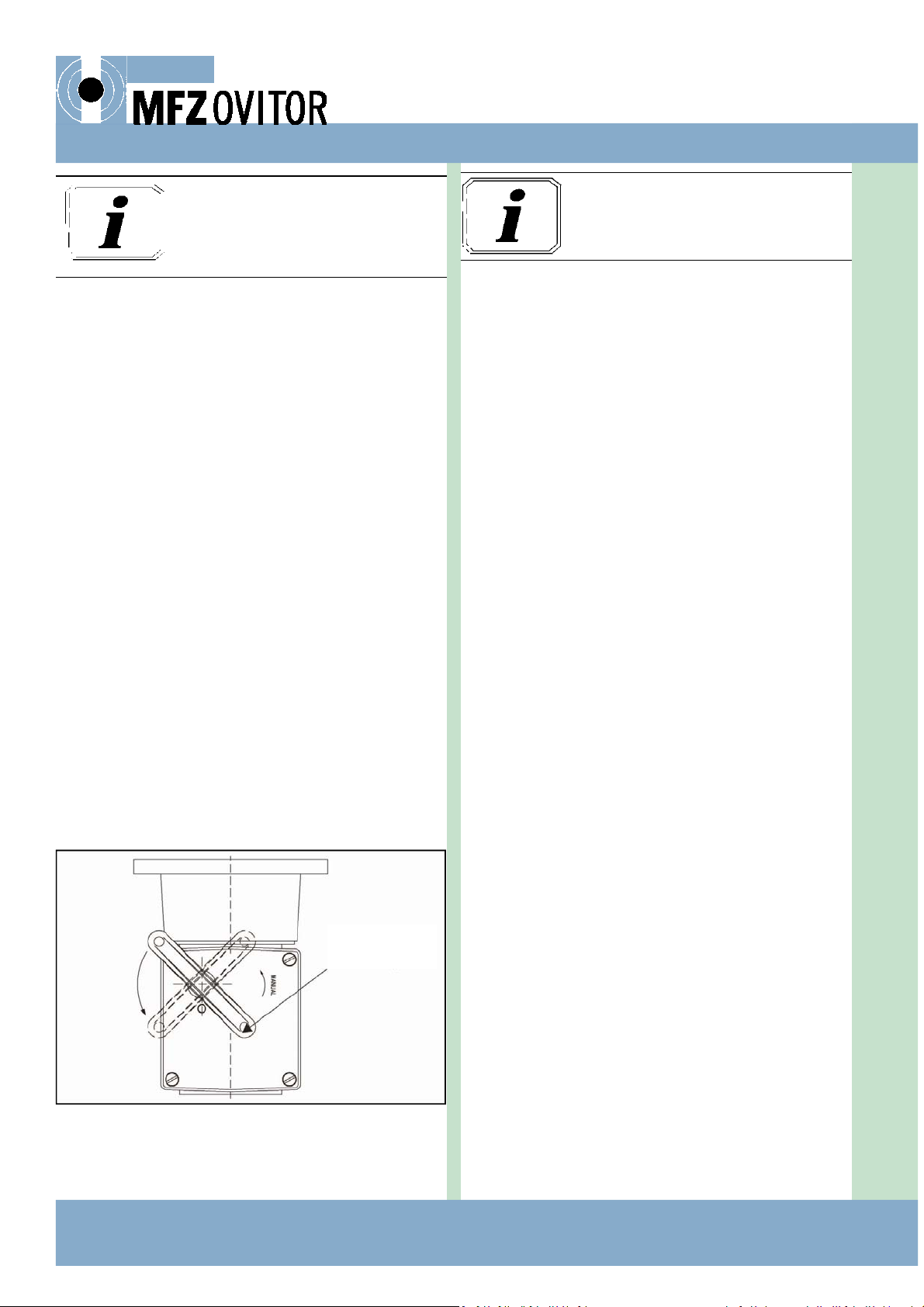

8.1 DISENGAGEMENT CLUTCH (NOT TVR TYPE)

Disconnecon of the drive unit is done by turning the disen‐

gagement lever. This enables the manual operaon of the

door. To disengage, turn the lever of the clutch 90 degrees,

as shown in fig. 7. For operaon of the lever from floor level,

aach ropes to the holes at the ends of the lever.

The movement of the lever affects a micro switch. While

affected, the micro switch disconnects the control current.

For normal electric operaon, move the lever back to its

original posion.

Note! Switching back to electric operaon is allowed only by

turning the disengagement lever to its posion for electric

operaon and by moving the door manually unl the clutch

dogs are engaged perfectly (→click).

Fig. 7. Disengagement clutch

9. SERVICE AND MAINTENANCE

All service and maintenance work must be carried out care‐

fully and only by thoroughly trained personnel. Perform

maintenance of the door and the door operator only when

the door is not moving. To prevent unintenonal staring of

the door operator, lock the main switch of the control sys‐

tem in the 0 posion.

Semi‐annual service and maintenance:

Check the condion and adjustment of the slipping

clutch

Check the ghtness of all fixing bolts in the gear unit and

the electric motor.

If a chain is used in power transmission, check the align‐

ment of the sprockets.

Check the condion of the chain and the sprockets.

Examine the condion of the gear unit visually.

Check the sounds of the gear unit.

Check the ghtness of the gear unit.

Remove the dust that has accumulated on the gear unit

and the motor.

In addion to this, check the condion of the enre gear

every three years.

Correct lubricaon is of primary importance for the func‐

oning of a worm gear. The oil grade for the inial filling is

shown on the rang plate. In the specified operang condi‐

ons, oil changes are not necessary. The oil quanty should,

however, be checked at the me of installaon and at least

once a year during normal maintenance of the door.

The inial filling oil used is suitable for an environment with

temperature variaons from –20 oC to +40 oC. For drive

units that are run with an especially high operang frequen‐

cy such that the surface temperature of the unit is constant‐

ly above +40oC, oil changes are recommended. In such oper‐

ang condions, the first oil change should occur aer ap‐

prox. six months of operaon and subsequently at three

year intervals.

When changing the oil, always use the same type of oil used

previously. It is not allowed to mix oils of different types or

from different manufacturers. Mixing oil types may damage

the rotary sha seals and cause oil leaks

When changing the oil, please note that hot oil may cause

burns. Always use protecve gloves and remove leaking oil

immediately with an oil‐absorbing substance.

Observe the regulaons and instruc‐

ons given in this manual when oper‐

ang the door.

Disengagement

lever

Please note the instrucons in the

”Operaon” secon for observing gear

unit condion.

Door operator TVR(FC) 5 / Rev 1.41 ‐ 9

Fig. 8. Gear side of the clutch and the fricon lining

9.1 CHANGING THE FRICTION LINING OF THE

SLIPPING CLUTCH

Changing the fricon lining of the slipping clutch is the only

special service operaon required. The operaon is done as

follows:

1. Check the thickness of the fricon lining of the slipping

clutch through inspecon hole in the side of the

mounng flange between the gear box and the electric

motor. The inspecon hole is covered with a detachable

plasc plug. If the fricon lining is worn out, carry out

points 2‐6.

2. Unscrew the adjustment screw fully (fig. 5)

3. Detach the motor from the gear

4. The gear side of the clutch has a guide for the correct

alignment of the fricon lining. Make sure the new fric‐

on lining is aligned correctly.

5. Aach the motor with the gear

6. Adjust the slipping clutch according to chapter 7.1

4

9.2 PERMITTED LOAD

The door operator’s maximum permied torque has been

informed in the rang plate. It is not allowed to connect the

door operator to drive a mechanism, the operaon of which

would, e.g. through ineral forces, exert on the output sha

of the gear a torque exceeding the permied maximum

torque.

The permied service life of the door operator is 12 000

operang hours with the maximum permied nominal out‐

put of the electric motor.

9.3 SPARE PARTS

Every separate component manufactured by Ovitor Oy has a

part number composed of three or dour digits. When order‐

ing spare parts, always menon the serial number of the

drive unit (on the gear unit rang plate) and the part num‐

ber shown in the drawing. With the help of the serial num‐

ber, it is possible to determine the correct part from the

producon informaon of the gear unit.

9.4 FAULT TRACING

Very oen, faults in electric door operaon originate from

devices connected to the control system (e.g. from align‐

ment of photo cells). First find out whether the fault is in

the door’s construcon, in the control systems or in the

drive unit.

Turn the disengagement lever of the gear unit to manual po‐

sion and check that the door can be easily moved manually

in both direcons over the complete travel of the door. If

the door cannot be moved at all, the fault may be in the dis‐

engagement mechanism. If the door moves only heavily, the

fault is in the door’s construcon or in its balancing arrange‐

ments. In this case, the door itself must be repaired

If the door can be moved manually, move it to half‐open po‐

sion and turn the lever of the disengagement mechanism

to its electric operaon posion. Move the door manually so

that the clutch dogs are perfectly engaged. Drive the door in

the opening and closing direcons. If the door does not

move in one or both direcons, the fault is probably in the

control system. However, if the electric motor is running but

the output sha of the gear unit is not rotang, the fault is

in the disengagement mechanism of the gear unit.

If the drive unit is not equipped with a disengagement

clutch (type TVR), the door must be released for manual op‐

eraon by some other means so that the movement of the

door can be checked.

If the fault is in the control system, please refer to the con‐

trol system documentaon.

If the fault is in the drive unit, please refer to the following

table.

9. SERVICE AND MAINTENANCE

10 ‐Door operator TVR(FC) 5 / Rev 1.41

9. SERVICE AND MAINTENANCE

Manifestaon Fault Acon

Loud sounds from the fixing point of the

gear unit

Fixing of the gear unit is loose Tighten the fixing bolts; if they are damaged, replace

Unusual sounds from the gear unit Damage to the worm sha or wheel Contact the manufacturer

Unusual sounds from the gear unit Damage to the bearings Contact the manufacturer or replace the bearing

Unusual sounds from the gear unit Not enough oil Check the oil quanty, add more if necessary; find out the

reason for diminished oil quanty, check for possible oil leaks

Vibraon of input sha at the bearing point Damage to the bearing Contact the manufacturer or replace the bearing

Unusual sounds from the drive motor Refer to the documentaon provided by the drive motor

supplier

Thermal protecon of the gear unit stops

the drive unit

Door’s resistance to moon has increased Check the condion of the door and its fixings

Thermal protecon of the gear unit stops

the drive unit

Not enough oil Check the oil quanty, add more if necessary; find out the

reason for diminished oil quanty, check for possible oil leaks

Thermal protecon of the gear unit stops

the drive unit

Damage to the worm sha or wheel Contact the manufacturer

Oil leak from the gear unit frame Mechanical damage in the gear housing Contact the manufacturer

Oil leak from the gear unit frame Fixing bolts of the gear unit halves are loose Check and ghten the fixing bolts

Oil leak from the rotary sha seal Seal has worn out or there is dirt between the

seal and the sha

Contact the manufacturer or check the rotary sha seal and

replace it if necessary

Disengagement mechanism doesn’t work Gear locked when the door was driven with

force against an inelasc obstacle

Rotate the input sha of the gear unit e.g. from the side of

the electric motor

Disengagement mechanism doesn’t work Disengagement mechanism has been damaged Contact the manufacturer

Place where door travel stops has changed Adjustment of the limit switches has changed Check that the adjustment ghtness of the limit cams has not

decreased. Tighten and adjust the limits again.

Limit switches do not stop the door Limit sha is damaged or does not rotate Contact the manufacturer

Limit switches do not stop the door Micro switch for the limit does not funcon Replace the limit switch

Clack between the gear and motor Flexible clutch worn out Replace the clutch

The motor runs, but gear sha is not turn‐

ing

Slipping clutch is slipping Adjust or replace the slipping clutch

Door operator TVR(FC) 5 / Rev 1.41 ‐ 11

12 ‐Door operator TVR(FC) 5 / Rev 1.41

10. DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

Ovitor Oy

Sienie 24

00760 Helsinki

Finland

Descripon and idenficaon of the partly completed machinery:

Door operator TVR(FC) 5 with various limit and gear transmissions

The essenal requirements of EC Machinery Direcve 2006/42/EC have been applied and fulfilled for the above menoned

machinery to be used with industrial doors, gates and barriers. The relevant technical documentaon has been compiled in

accordance with Annex VII, Part B of EC Machinery Direcve 2006/42/EC.

In addion the partly completed machinery is in conformity with the EC 2006/95/EC Low Voltage Direcve LVD, 2004/108/

EC Electromagnec Compability EMC and 2002/95/EC the Restricon of the use of certain Hazardous Substances in Electri‐

cal and Electronic Equipment RoHS.

The above listed products are delivered according to the following standards to the extent to which they may be applicable:

EN ISO 12100:2010, EN 60204‐1+A1+AC, EN 60335‐1+A11+AC, EN‐55014‐1+A1, EN 61000‐3‐

2+A1+A2, EN 61000‐3‐3, EN 61000‐6‐2, EN61000‐6‐3+A1, EN 61439‐1, EN 61439‐3, EN 60529+A1,

EN 13241‐1+A1, EN 60335‐2‐103, EN 13241+A1, EN 12453, EN 12445, EN 12604, EN 12605, EN

12978+A1

SFS‐Inspecta Serfioin OY has issued a cerficate ascertaining that the manufacturer's quality system meets the require‐

ments of standard SFS‐EN ISO 9001:2008 and the general guidelines ABC 200, cerficate 1229‐06.

We undertake, in response to a reasoned request, to supply it in electronic form to the market surveillance authories with‐

in a reasonable period.

The party authorized to compile the technical documentaon is:

Ovitor Oy / Engineering Manager

Sienie 24

00760 Helsinki

Finland

The devices are not intended to funcon independently but as a part of an electrically operated machine. In the design, con‐

strucon and servicing of the machinery, it must be ensured that the loads to which the door mechanism is subjected do not

exceed the values given in the instrucon manual of the mechanism, and that the permied service life of a door mecha‐

nism is no more than 12 000 operang hours. As regards the installaon, sengs and servicing of the machinery, the in‐

strucons issued by us for the type of installaon in queson must be observed.

The partly completed machinery must not be put into service unl the final machinery into which it is to be incorporated has

been declared in conformity with the provisions of the Machinery Direcve.

Helsinki, 14th of September 2016

_______________

Juha‐Ma Lyhykäinen

Producon Manager

Ovitor Oy

Table of contents

Other MFZ Ovitor Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Henderson

Henderson Magic 600 operating manual

Novoferm

Novoferm Novomatic 403 Installation, operating and maintenance instructions

Raynor

Raynor Commander II Safety Signal 3240RGD owner's manual

Casanoov

Casanoov BUNKER B500 manual

ABON

ABON Ultra S Installation and operating instructions

moore o matic

moore o matic XX325 Assembly and installation instructions

Chamberlain

Chamberlain LiftMaster MJ5011U installation manual

Chamberlain

Chamberlain Series 1000E owner's manual

Chamberlain

Chamberlain Power Drive 3132E owner's manual

Nice

Nice AVIO500 Instructions and warnings for installation and use

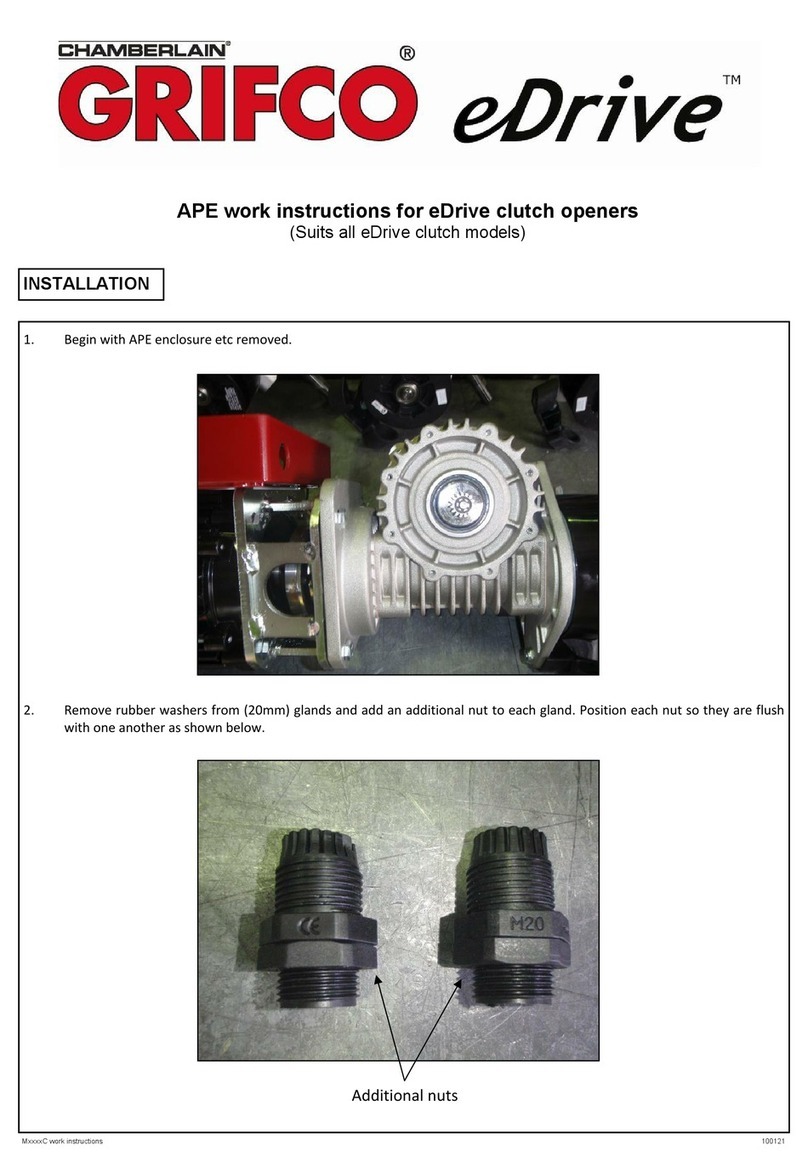

Chamberlain

Chamberlain Grifco eDrive instructions

Chamberlain

Chamberlain T installation manual