Black 0002

Black0002

CONTENTS

INSTALLATION TOOLS REQUIRED

INSTALLATION PREPARATION

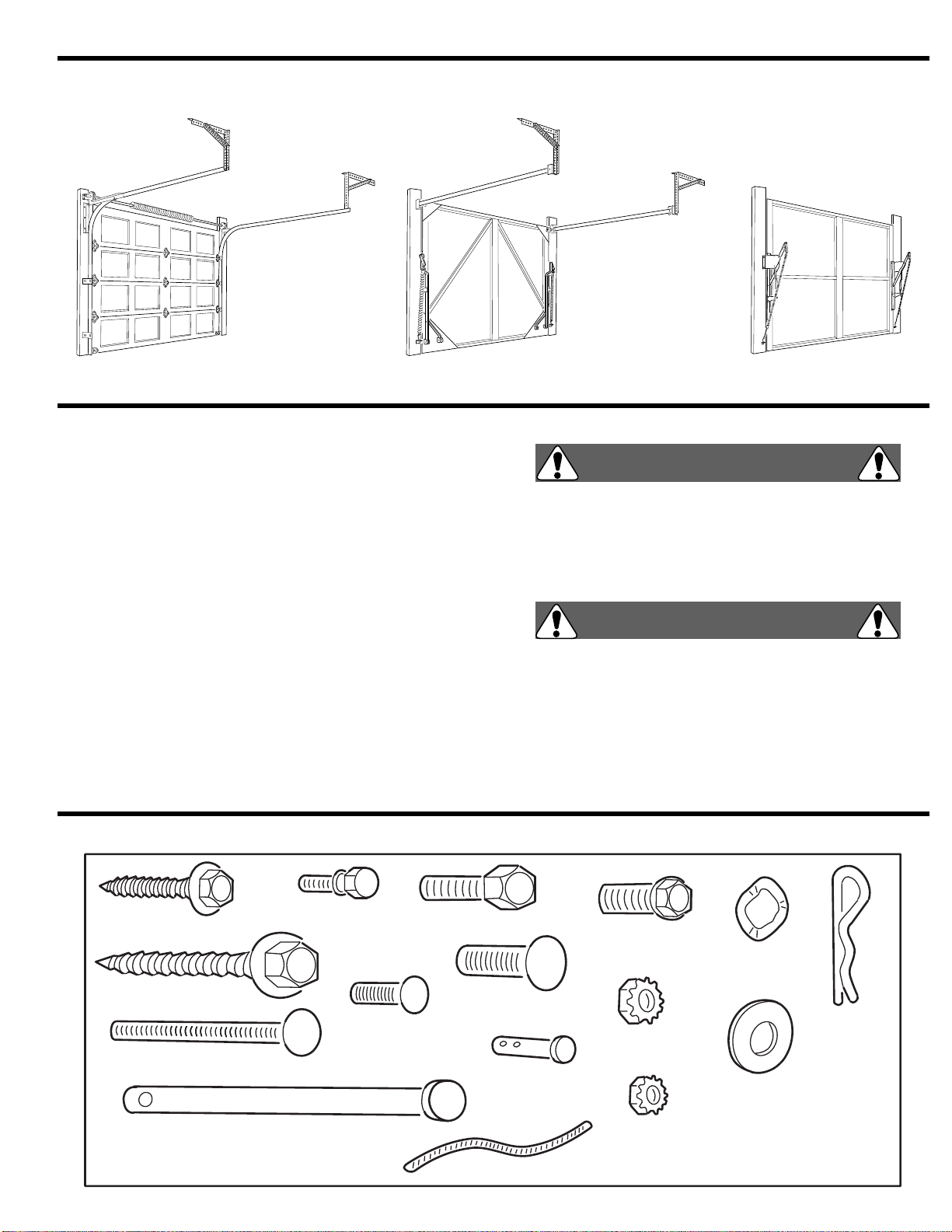

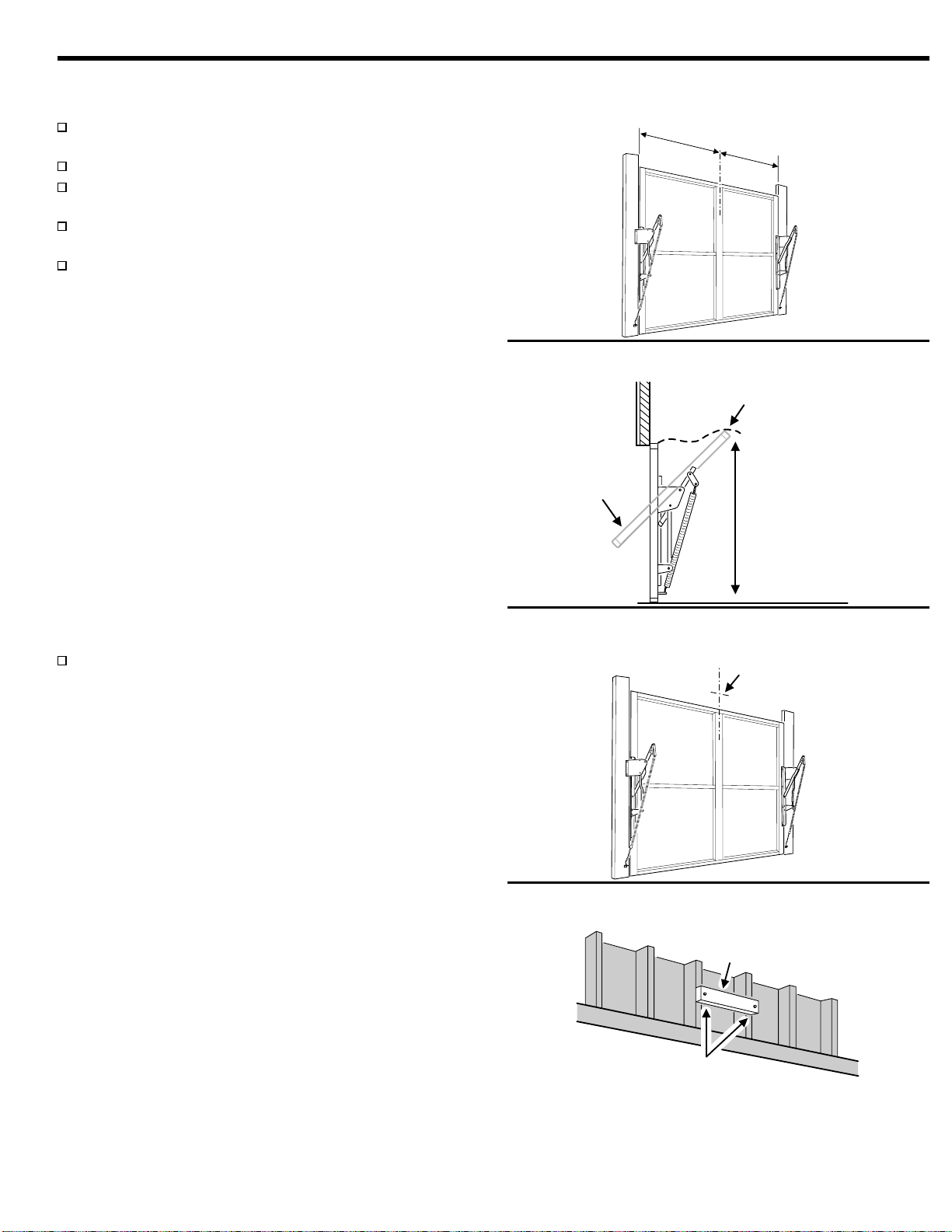

GARAGE DOOR TYPES

. . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHECK DOOR BALANCE

. . . . . . . . . . . . . . . . . . . . . . . . . 1

HARDWARE IDENTIFICATION

. . . . . . . . . . . . . . . . . . . . . 1

OPERATOR PARTS IDENTIFICATION

. . . . . . . . . . . . . . . 2

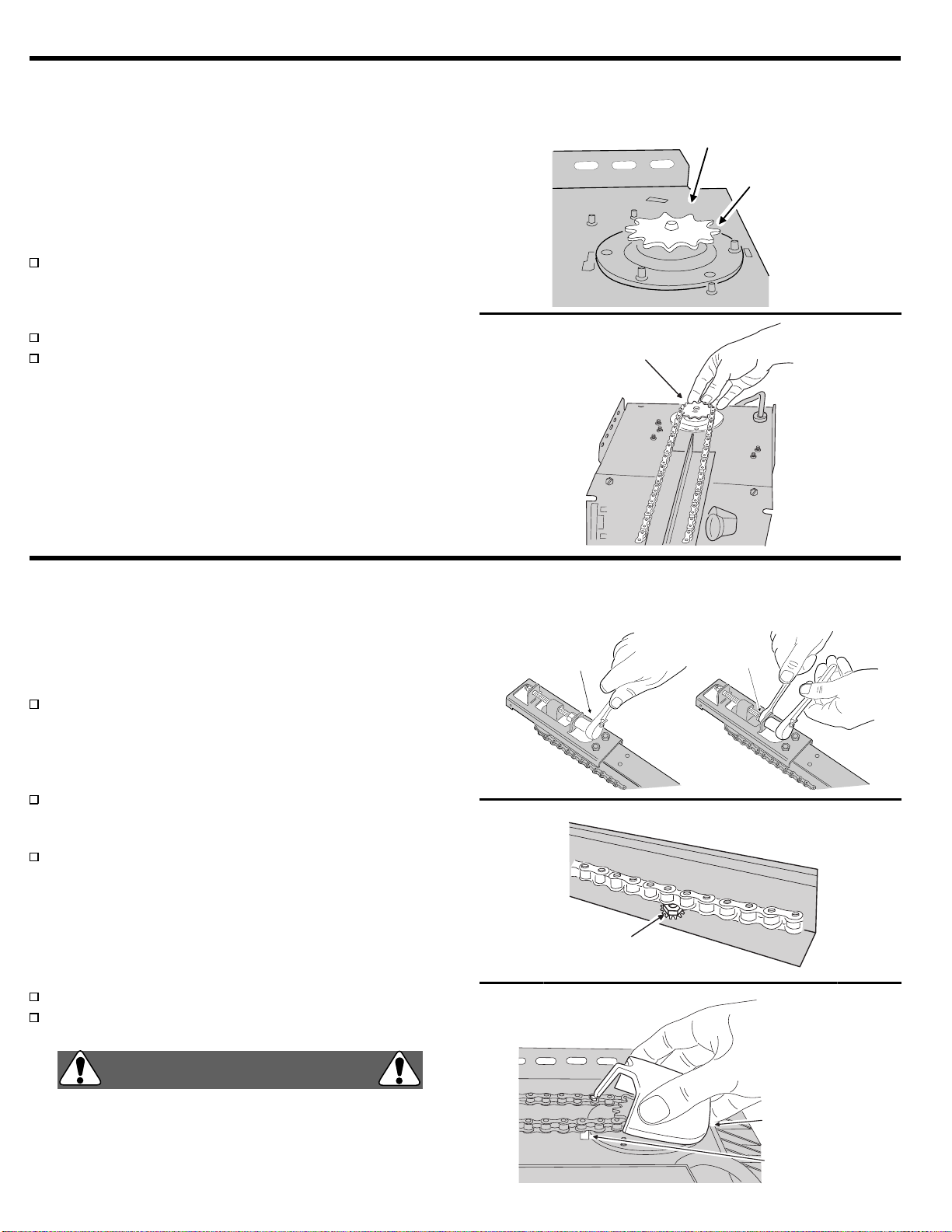

OPERATOR PRE-ASSEMBLY

ASSEMBLY STEP 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Attaching Rail to Operator . . . . . . . . . . . . . . . . . . . . . . . 3

ASSEMBLY STEP 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Attaching Chain to Sprocket. . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY STEP 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adjusting Chain and Installing Sprocket Cover . . . . . . . 4

OPERATOR INSTALLATION

INSTALLATION STEP 1A

. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sectional Door and One-piece Track Door Header

Bracket Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION STEP 1B

. . . . . . . . . . . . . . . . . . . . . . . . . . 7

One-piece Door without Track Header

Bracket Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION STEP 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Header Bracket . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION STEP 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting Rail to the Header Bracket . . . . . . . . . . . . . 9

INSTALLATION STEP 4

. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Positioning the Operator. . . . . . . . . . . . . . . . . . . . . . . . 10

INSTALLATION STEP 5

. . . . . . . . . . . . . . . . . . . . . . . . . 11

Hanging the Operator . . . . . . . . . . . . . . . . . . . . . . . . . 11

INSTALLATION STEP 6

. . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Pushbutton. . . . . . . . . . . . . . . . . . . . . . . 12

INSTALLATION STEP 7

. . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Lens Cover and Light Bulb. . . . . . . . . . . 13

INSTALLATION STEP 8

. . . . . . . . . . . . . . . . . . . . . . . . . 13

Attaching the Trolley Release Handle. . . . . . . . . . . . . 13

INSTALLATION STEP 9

. . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing the DoorSentry Infrared Safety Beam . . . . . 14

INSTALLATION STEP 10

. . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring the DoorSentry Infrared Safety Beam . . . . . . . 15

INSTALLATION STEP 11A

. . . . . . . . . . . . . . . . . . . . . . . 16

Sectional Door, Door Bracket and Door Arm

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

INSTALLATION STEP 11B

. . . . . . . . . . . . . . . . . . . . . . . 17

One-piece Doors (With and Without Track), Door

Bracket and Door Arm Installation. . . . . . . . . . . . . . . . 17

INSTALLATION STEP 12

. . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting Operator to Power Source . . . . . . . . . . . . 18

OPERATOR ADJUSTMENTS

ADJUSTMENT STEP 1

. . . . . . . . . . . . . . . . . . . . . . . . . . 19

Aligning the DoorSentry Infrared Safety Beam. . . . . . 19

ADJUSTMENT STEP 2

. . . . . . . . . . . . . . . . . . . . . . . . . . 20

Testing the Radio Remote Control . . . . . . . . . . . . . . . 20

Programming the receiver. . . . . . . . . . . . . . . . . . . . . . 20

ADJUSTMENT STEP 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the Up and Down Limits. . . . . . . . . . . . . . . . . . 21

ADJUSTMENT STEP 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adjusting the Door Force . . . . . . . . . . . . . . . . . . . . . . . 22

USER INFORMATION

USER INSTRUCTIONS 1

. . . . . . . . . . . . . . . . . . . . . . . . . 23

Using the Garage Door Operator. . . . . . . . . . . . . . . . . 23

USER INSTRUCTIONS 2

. . . . . . . . . . . . . . . . . . . . . . . . . 24

Care for the Garage Door Operator. . . . . . . . . . . . . . . 24

OPERATOR ACCESSORIES

. . . . . . . . . . . . . . . . . . . . . . 25

SERVICE INFORMATION

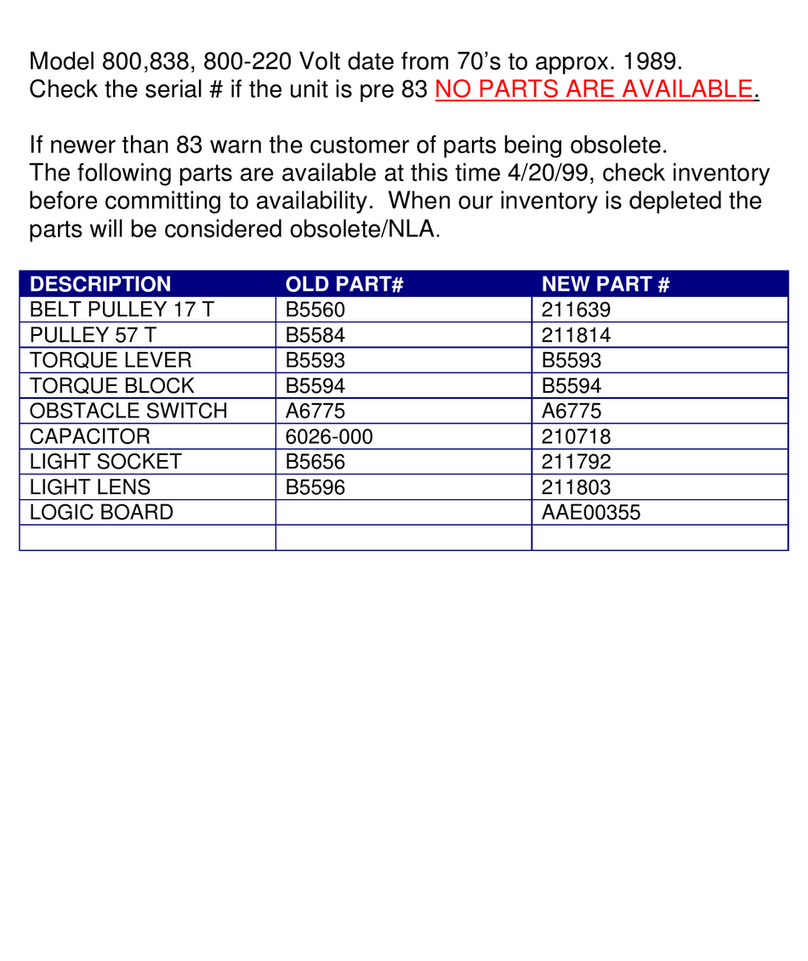

REPLACEMENT PARTS LIST

. . . . . . . . . . . . . . . . . . . . . 26

T-Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

REPLACEMENT PARTS LIST

. . . . . . . . . . . . . . . . . . . . . 27

Operator Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

INDEX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

TROUBLE SHOOTING TABLE

. . . . . . . . . . . . . . . . . . . . 29

LIMITED WARRANTY

. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

IMPORTANT SAFETY NOTES

Please read the instructions carefully! This garage door

operator is designed to provide safe and reliable service if

installed and tested as described in this manual. A garage door

is the largest mechanical appliance in a residence. Care must

be taken to prevent injury or death during installation and

operation of the garage door and garage door operator.

The following formats are used for safety notes in this manual:

WARNING

This type of warning note is used to

indicatepossiblemechanicalhazardsthat

may cause serious injuries or death.

WARNING

This type of warning note is used to

indicatepossibleelectricalshockhazards

that may cause serious injuries or death.

CAUTION

This type of warning note is used to

indicate the possibility of damage to the

garage door or garage door operator.

Hammer

Pliers

Wire Cutter

7/16", 1/2" and 9/16" Sockets

and Wrench

Phillips Head

Screwdriver Flat Head Screwdriver

Drill

3/16" and 1/4" Bits

Tape Measure

Step Ladder 1/2", 7/16" and 9/16"

Open End Wrenches

Short

Socket Extension