MGF BLITZ User manual

This manual has been written, where possible, in compliance with Regulations 98/37/CE "Machines Regulation",

2006/42/CE " ew Machines Regulation" and with U I/ISO 10893 "Instructions manuals: writing and

contents rules”

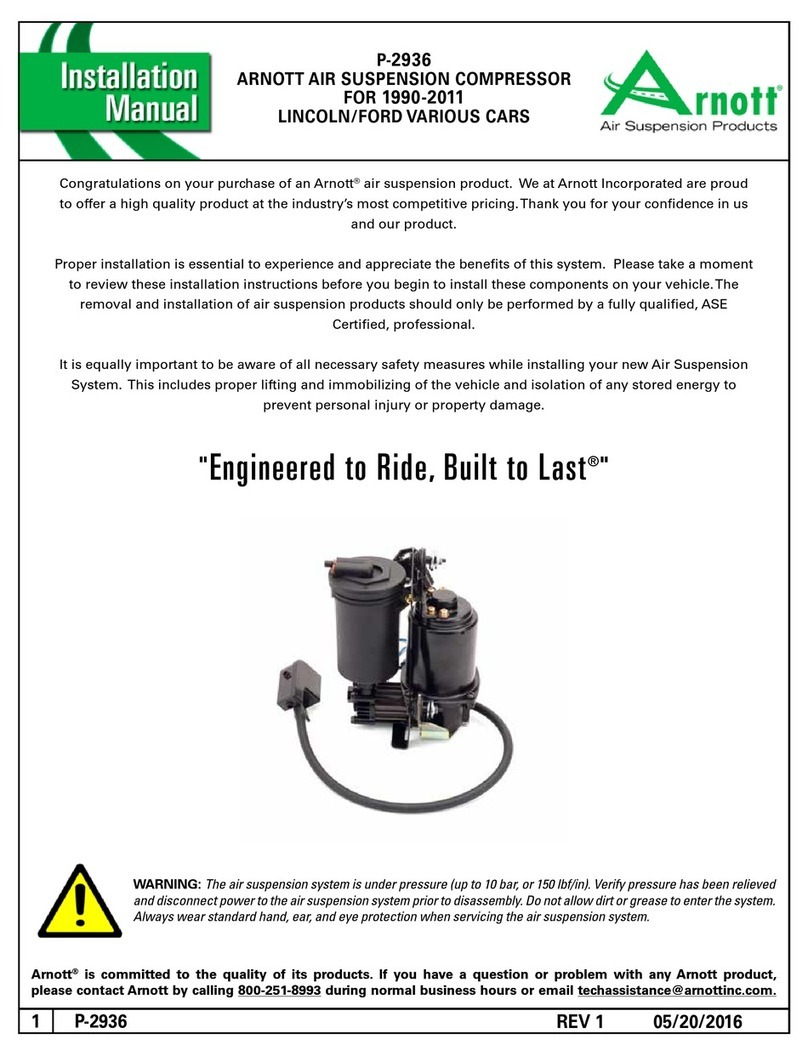

Art. 904500

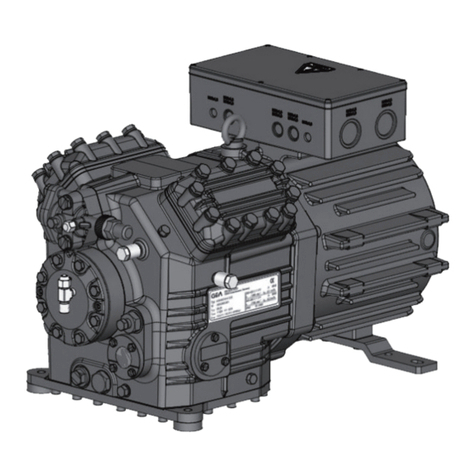

BLITZ

Electrocompressor

User manual

rev. 2.1 dated 27/0 /2012

Introduction

Introduction

This manual is an integrating part of the machine and gives you important instructions on installations, correct use,

maintenance and waste disposal of this machine.

Reading this manual and accomplying carefully its instructions is an important conditions for warranty and

for a safe use of this system.

Unclogging electrocompressor BLITZ art. 904500 is used for: unclogging pipes in general, testing of small gas

systems, water, air, for loading of expansion vessels and boilers for all actions in which compressed air is

required.

The end user must also give right use instructions to other users may be in touch with this machine.

The manufacturer declines every responsibility for damages caused by misuse or bad appliance of rules

indicated in this manual.

General informations

General informations

Art. Model

904500 BLITZ Unclogging electrocompressor

914500 Compressed air attachement kit

904540 Gun Kit + Quick connection pipe

System Description

System Description

OPERATION PRINCIPLE

BLITZ unclogging electrocompressor is a machine able to unclogg

pipes clogged with a powerful high pressure jet of compressed

air.

ENVIRONMENTAL CONDITIONS

Temperature: from 0 to 50°C

Humidity: from 10% to 90% U.R. Non- condensing

LIGHT

Make sure there is adequate lighting conditions of the work area to perform work on any part of the system in safe

conditions.

VENTILATION

It is necessary to ensure a good ventilation to the pump, or an air flow from the fan motor to the pump head.

VIBRATIONS AND SOUNDS

The pump is equipped with anti-vibration rubber mounts to minimize vibration transmitted to the supporting surface and to

reduce the generated noise.

In case of installation of the bracket, provide the use of anti-vibration mounts to prevent the occurrence of unwanted

vibrations.

Provide connection through joints or flexible tubing to the pump to prevent the transmission of vibration from the pump.

TECHNICAL FEATURES

Weight: 15 Kg

Dimensions: 1 5 x 420 x 4 0 mm

Tank capacity: 4,2 L

Max Pressure: bar

Air connection: 1/4”

Suction: 2,5 L/min

Supply: 230 V ~ 50Hz

Power: 1100W

Protection: IP23

The pump is equipped with anti-vibration rubber mounts to minimize vibration transmitted to the supporting surface.

The maximum sound level in terms of installation is indicated by : 95 dbA @ 1m

User instructions

User instructions

PREPARATION

Before start working , check that the packaging is intact and inside there are all the required accessories. Make sure that the

machine is equipped with a label with the technical specifications. Keep the packing materials for shipping, do not disperse in

the environment, however, keep them away from children. Make sure that the environmental conditions

(temperature,humidity,wind,brightness...) of the working allow to operate in absolute safety.

Before you tie to the grid, check that the information on the nameplate and in this booklet correspond to the characteristics

of the network itself . The installation must comply with local regulations, provided with earth connection and a breaker. The

use of extension cords must include the appropriate wire gauge and waterproof connections .The extensions blinds must be

fully carried out , in order to reduce the risk of overheating . The contact with water should be avoided in every way.

MGF disclaims any liability for damage to persons or property caused by a bad connection or by an inadequate

network.

Performance...

TO UNCLOGG A DRAIN

1.

Close the quick tap ( 114 ) and tighten the screw without using pliers or other tools

. Close also the slide tap (211151).

2. Bring the pump to the desired pressure by adjusting the knob (410040). The clockwise rotation increases the pressure.

The compressor is equipped with a check valve: to lower the pressure in the tank, open the valve slide and rotate the

knob counterclockwise. We suggest to try with a pressure not too high (~ 3 atm.) And to increase later in case the pipe

does not uclogg.

3. Fill with water to unclog the pipe, insert the tapered buffer (251 136), possibly using swabs with a larger diameter

(251134-251135) provided for larger discharges.

4. After making sure that the discharges adjacent to the one to unclog are closed by something so that water does not leak

in piping (eg a wet rag), open the faucet quickly by holding the swab into the drain.

TO TEST SYSTEMS

1. Connect the pump to be tested using the hose supplied. Make sure the lock nut of the hose to the tap (251151) is tight.

2. Close the quick tap and tight the screw with the same precautions as above; slide open the tap and set the pump to the

desired pressure.

3. For the period of time for the test to be carried out, remember to turn off the caliper tap. To keep the system under

pressure without leaving the compressor connected, MGF recommends to use HELP (Art. 904400). The instrument is not

provided.

TO UPLOAD EXPANSION VESSELS OF BOILERS

Connect the pump to expansion vessel to load and run operations 1. and 2. of the previous paragraph.

Security

Security

GENERAL SECURITY INSTRUCTIONS

Use the machine only for the purpose for which it is intended and in full compliance with the general safety regulations:

•

The machine and its accessories have to be keept far from children.

•

Keep clean and well lit working area

•

Place the machine in a way that the loading operation can take place in complete safety

•

Do not use pipes or electrical cable to move the car. Use the handle for transport. Do not move the compressor with the

tank under pressure.

The compressor has to work on a secure, horizontal and dry plane. Do not direct water jets and / or flammable liquids on the

compressor, or use them for cleaning. Do not place flammable objects close to the compressor.

The machine has been designed to work with compressed air. And it is forbidden to use the machine to compress other types

of fluid. The use of the compressor with tools that are not standard requires compliance with specific rules and a minimum

distance of 3 m between the work area and the compressor.

It 's normal that the compressor will heat up slightly. Avoid touching the metal parts, in particular the pressure regulator.

Wait at least 10 seconds before restarting the machine after the stop. Always ensure good ventilation to the engine, leaving

open the air vents.

Remember that opening the drain valve you will generate a rapid reaction (recoil) on the pipe ( 10005). The intensity of this

reaction depends on the pressure at which the pump is loaded, but is in any case less than 20 N (~ 2 kg).

Firmly grasp the

pipes before opening the taps. Keep away strangers and especially children. Never direct the hoses at people, animals or

things.

When the machine works it makes a sound pressure of less than 3dB. The opening of the quick tap can exert acoustic

pressures of up to 113dB (in the case where the pipe is not inserted into the drain to uncklog).

Insert the hose into the drain

before opening the tap quickly. Wear hearing protection devices.

Attention! The warranty that covers the machine and all its accessories declines in the case of failure to

observe the instructions given in this booklet.

DANGEROUS AREAS

The machine presents no danger zones if all the protections are not removed or if they are not damaged.

Check periodically the efficiency, in order to ensure mechanical protection of the organs in movement and insulation of

electricalparts.

Avoid working on the nozzles under pressure: risk of thrown objects at high speed and micro abrasions and cuts to the skin

in the case of sudden jets from the nozzle itself.

SAFETY DEVICES

The machine does not of itself require special safety devices. The emergency stop is not expected because there would be

improvements in terms of safety compared to a normal stop.

In the case of the specific risks of plant would require precautions for safety, it is good to have foreseen them during the

preparation. Please contact our helpline for advice and special designs.

SEGNALS

RESIDUAL RISKS

During the installation carefully evaluate residual risks related to the job you are performing: environmental conditions,

lighting, maintenance condition of your tools.

DPI generic such as gloves and safety shoes are highly recommended to reduce the risk of injury related to the work of

installation rather than the system itself.

Maintenance

Maintenance

ORDINARY MAINTENANCE

Every 50 hours you should remove the suction filter and clean the filter element with compressed air.

Download periodically condensate from the tank: unplug the appliance from the mains, open the tap and turn the pump

tilting slide properly until the complete emptying of the tank.

DIAGNOSTICS AND TROUBLESHOOTING

Suggestion:

The research of problem analysis should be made from upstream to downstream (supply -> pump -> Online -> nozzles),

isolating the various parts and searching for any abnormalities.

THE ENGINE DOES NOT START: Make sure the cable is not damaged and, in the second analysis, the plug is inserted into a

suitable electrical network.

THE ENGINE SUDDENLY STOPS: Possible intervention of the thermal protector. Wait a few minutes and restart. If the

problem persists, contact your assistance representative.

THE ENGINE IS VERY HOT : Ensure good ventilation to the engine. If the problem persists, contact your assistance

representative.

THE COMPRESSOR DOES NOT REACH THE DESIRED PRESSURE: Check that all valves are closed and the valve is sufficiently

narrow. In the second analysis, check the tightness of the taps, in particular the state of the seal of the quick tap. If you

need to replace it use only original MGF spare parts.

COMPRESSOR LOADS SLOWLY: Check the cleanliness of the air intake filter. If the problem persists, call the assistance.

TECHNICAL ASSISTANCE AND REPAIR

Do not improvise repairers.

Do not modify the equipment, this could cause an unsafe operation.

For technical assistance, please contact us in one of the following ways:

telephone: 0521/ 1 301 (4 lines r.a.)

fax: 0521/ 1 202

email: [email protected]om

We will help you in the shortest possible time.

It is possible to use a service assistance on site, free of charge for warranty or previously agreed operations. If this is not

possible the operation will be charged in accordance with the currente rate.

Material being shipped for repair must be authorized by the RMA (binding condition for the withdrawal of any goods for

repair).

Additional informations

Additional informations

WASTE DISPOSAL

Waste and installation work should be collected in homogeneous categories and disposed of in accordance with local

regulations.

The machine must be disposed as special electric waste, through the transfer at a recycling depot. The waste disposal levy

has already been paid when required.

SHUTTI G DOW A D ELIMI ATIO

Before putting pemanently out of service the system, empty the oil pump exhausted and provide to transfer it to a disposal

facility, authorized to collect free of charge.

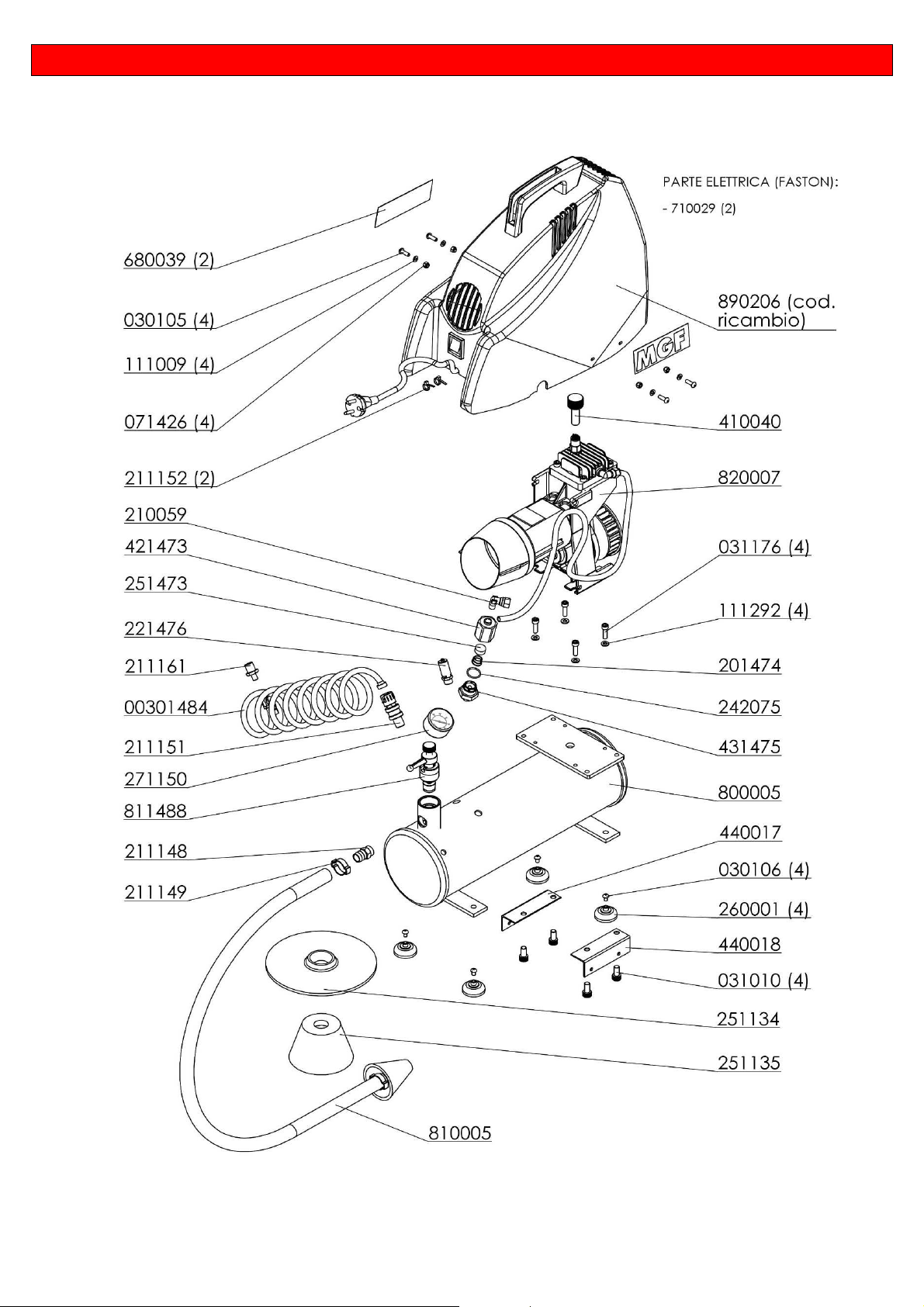

Spare parts

Spare parts

Conformity declaration

Conformity declaration

MGF srl - Via Mendes, - 43055 Mezzani (PR) - Italia declares under its responsability that Electrocompressor BLITZ cod. 904500 is in

conformity with 2006/42/CEE; For electromagnetic compatibility, to 9/336 CEE directive, to EN55014, to EN 60555/2 and EN 60555/3;

with reference to the safety of electrical equipment to directive 2006/95/CEE and to harmonized legislation CENELEC HD 400.1.2.3

MGF

MGF srl –– Via Mendes, – 43055 Mezzani PR – tel. 0521- 1 301 www.mgftools.com

This manual suits for next models

1

Table of contents

Other MGF Air Compressor manuals