Installation-Operation-Maintenance

GZ 2 - GZ 4 / 100 - 1450 kW

4

Norms and regulations

The following standards and regulations are to be observed

during installation and operation of the burner.

HeizAnlV

Heating system ordinance

FeuVo

Firing ordinance of the German federal states

1. BImSchV

First ordinance for implementation of the German Emission Pro-

tection Law

VDI 2035

Guidelines for preventing damage from corrosion and scale

formation in hot water heating installations

VDE

Regulations and special requirements issued by the energy util-

ity companies

EN 303, part 1 and part 2

Heating boilers with forced draft burners

EN 60335, part 1

Safety of household and similar electrical appliances

DIN 4705

Calculating the dimensions of chimneys

DIN 4751

Hot water heating installations – safety requirements

DIN 4755

Oil firing installations – construction, execution, safety require-

ments

DIN EN 267

Automatic forced draught burners for liquid fuels – definitions,

requirements, construction and testing

DIN 51603, part 1

Fuel oils extra light

DIN 57116

Electrical equipment of firing installations

Please comply with the valid regional building code.

Exhaust system and effective heat demand

Boiler, burner and exhaust system (chimney) constitute an oper-

ating unit; account must be taken of low exhaust temperatures

when reducing the output

For exhaust temperatures below 160°C, the system must be de-

signed so as to avoid damage from condensation.

The uncondensed (humid) flue gas volume is an important indi-

cation of the size of the flue gas installations an chimneys re-

quired.

It is advisable to install draft limiters (supplementary air sys-

tems) to achieve stable combustion values under varying condi-

tions and to reduce possible humidity in the chimney. These

should be installed in the chimney where possible, to avoid pos-

sible noises in the flue pipe.

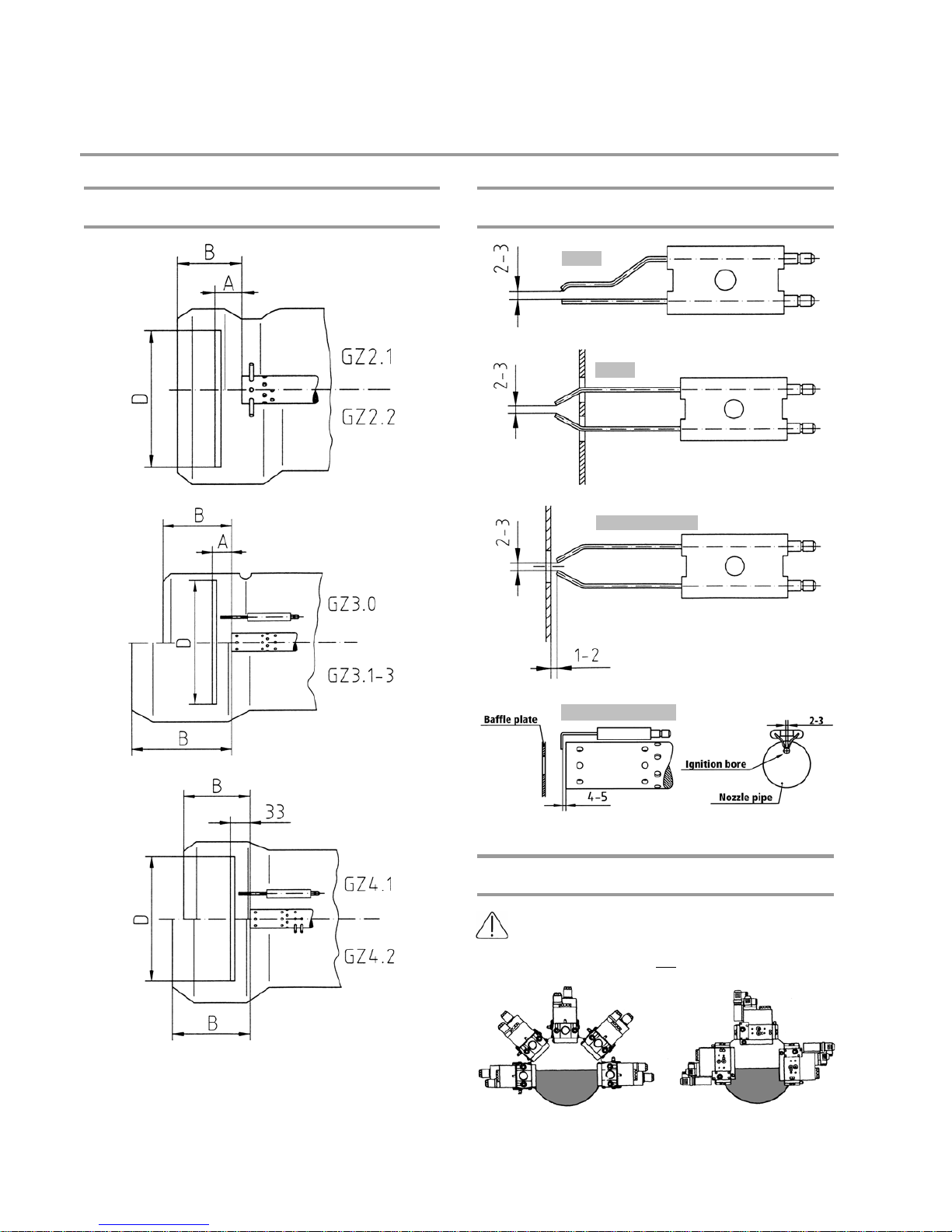

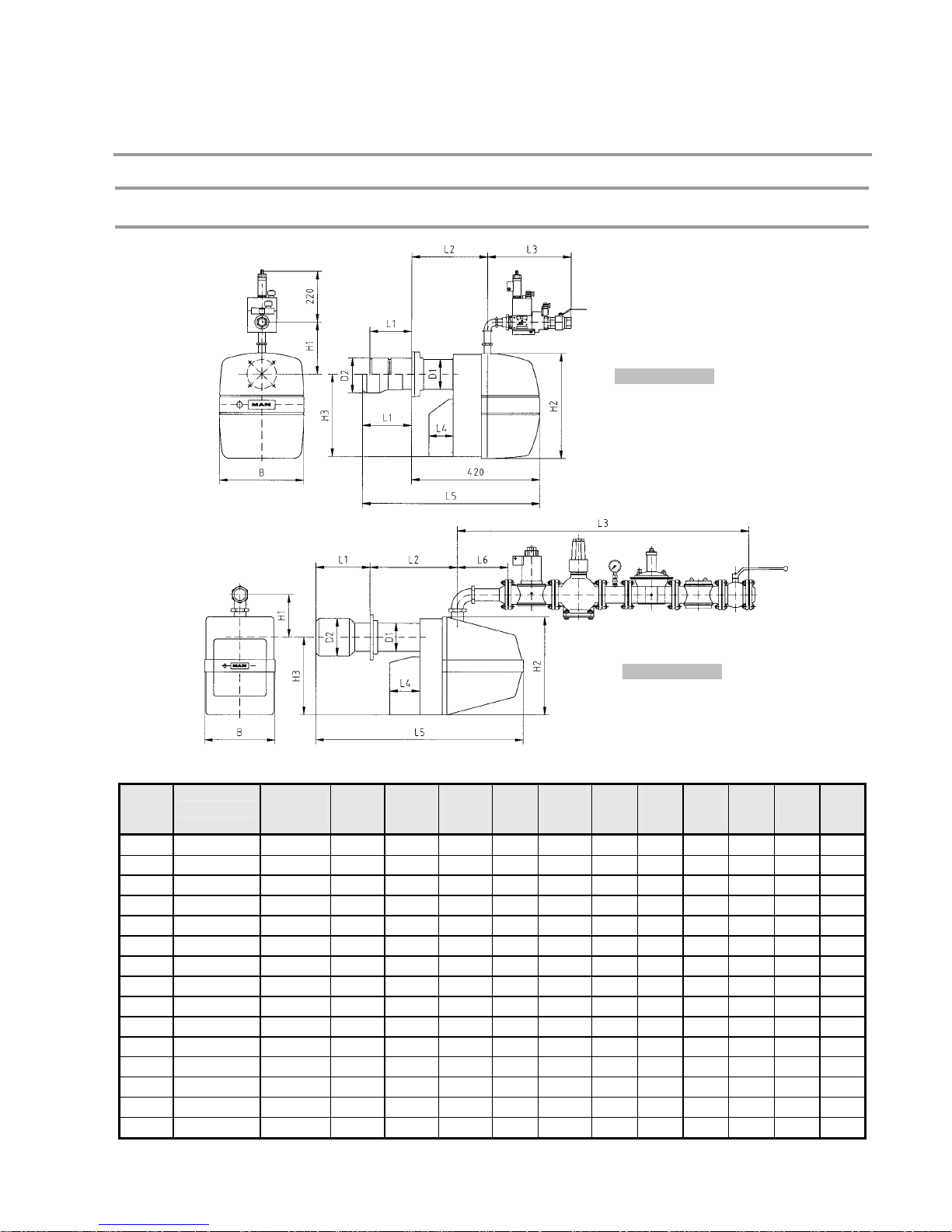

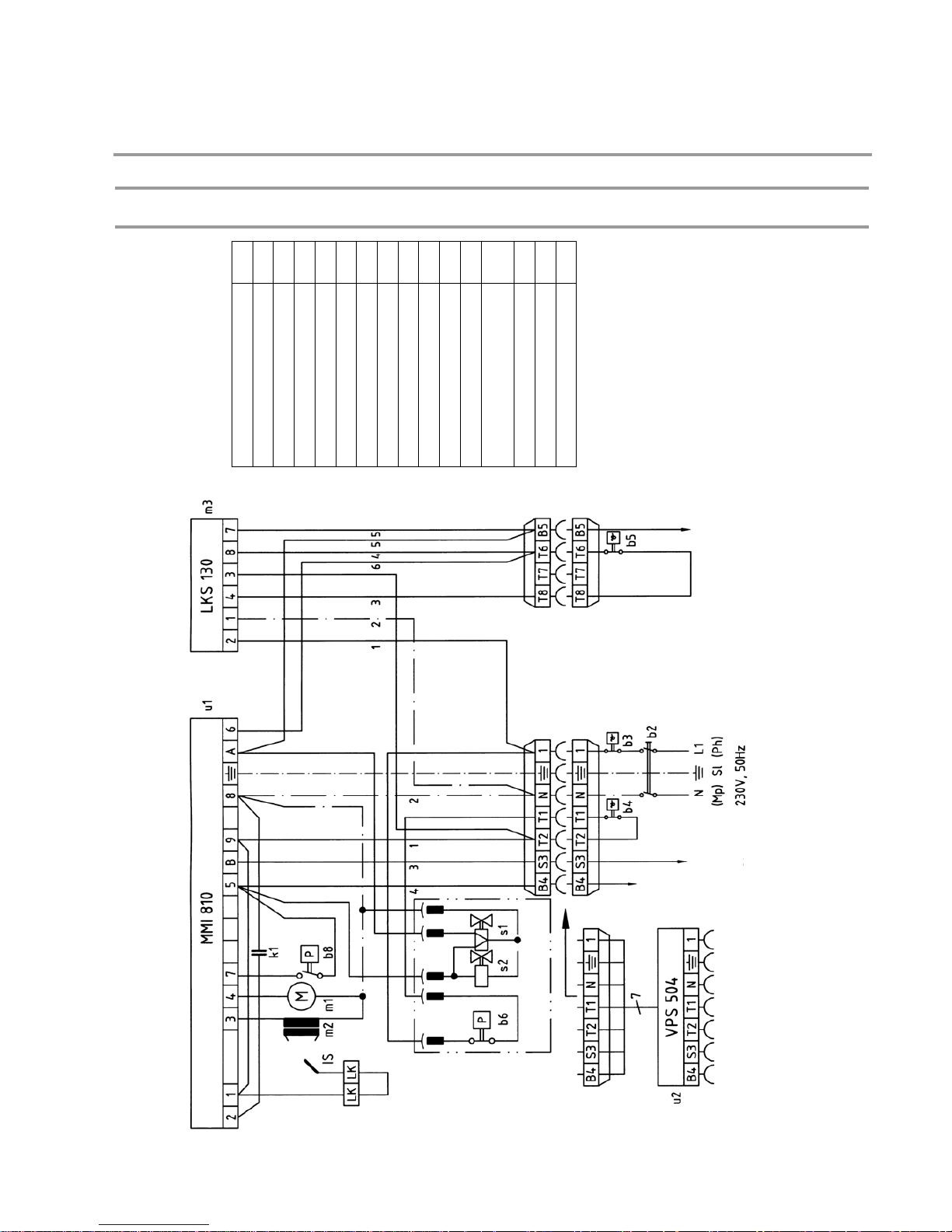

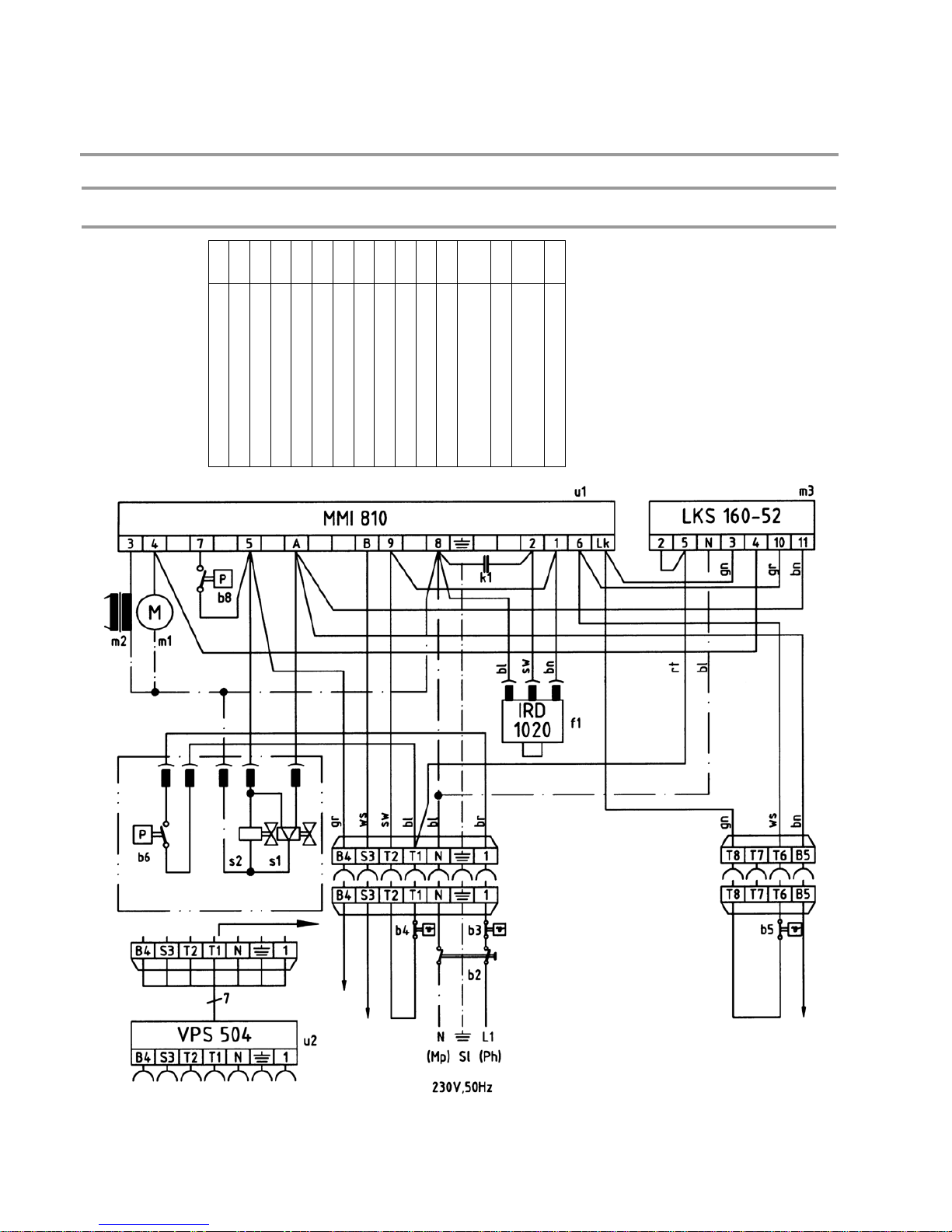

Modern conception

The gas burners in the GZ 2 - GZ 4 series are fully automatic

two-stage burners in monobloc design. They are suitable for

natural gas and liquefied gas according to DVGW paper G 260,

designed according to DIN 4788, and tested according to

DVGW and CE.

The burners are equipped with automatic gas firing units for in-

termittent operation as per DIN EN 298 or DIN 4788; automatic

gas firing units for continuous operation on request.

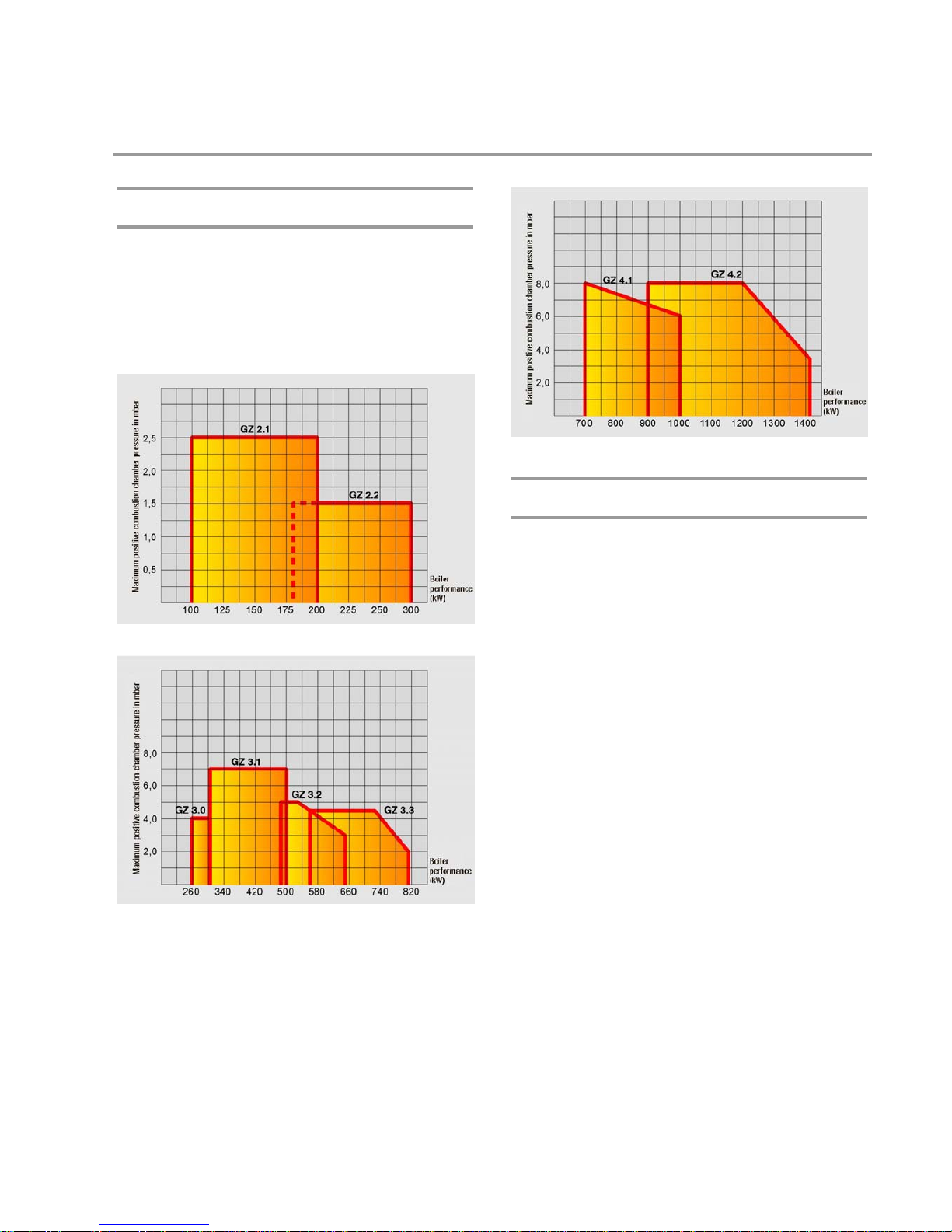

The GZ 2 - GZ 4 gas burners are pressurised burners with very

high impeller pressing and a steep impeller characteristic line.

Because of these features and the variable adjustment of the air

admission nozzle, these burners are appropriate for modern

high-performance boilers with reversible flames as well as for

older natural draught boilers. The modern conception of the

two-stage GZ 2 - GZ 4 burners with a maximum output range

of 50:100% (GZ 2 - GZ 3) or 60:100% (GZ 4) guarantees ideal

graduation of the two load-stages depending on operating

conditions.

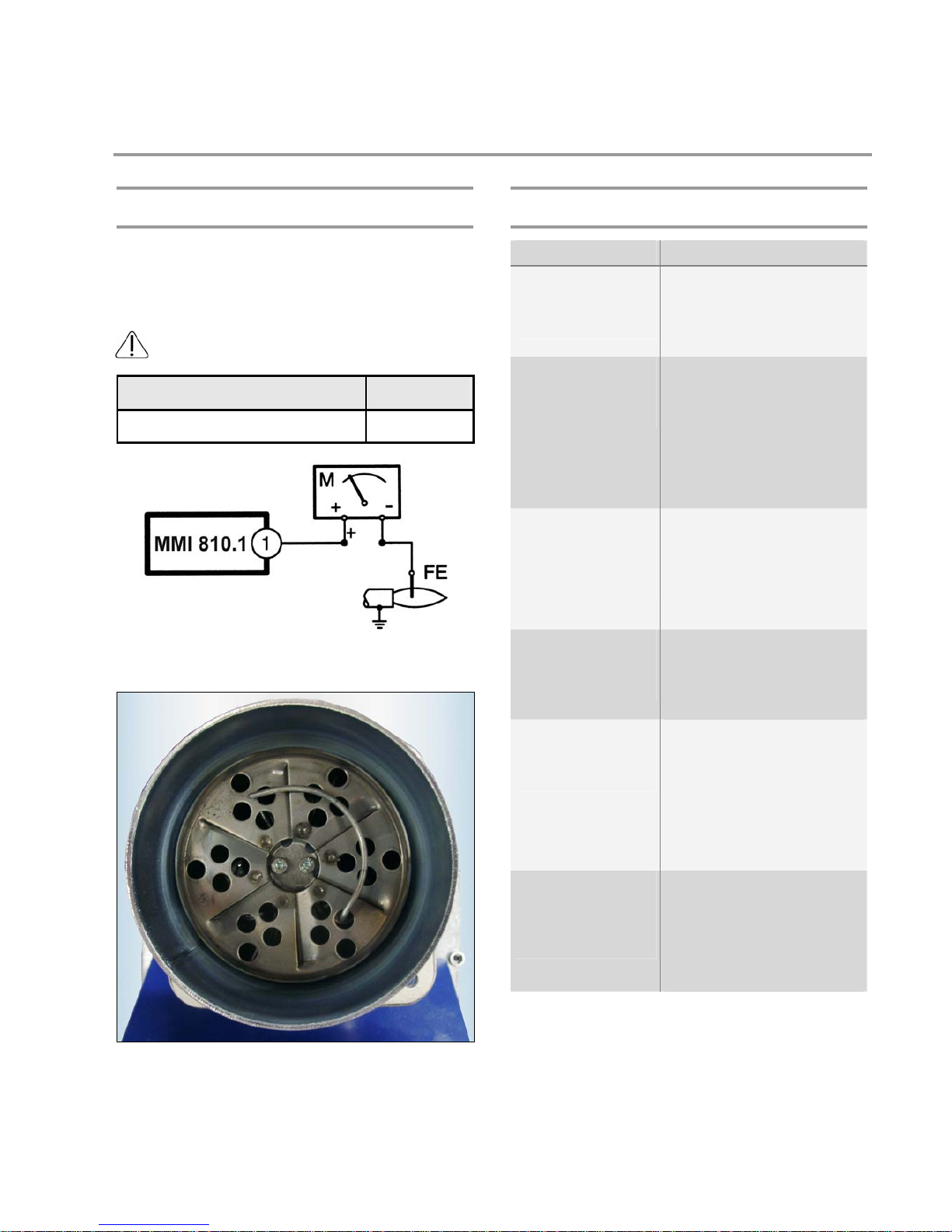

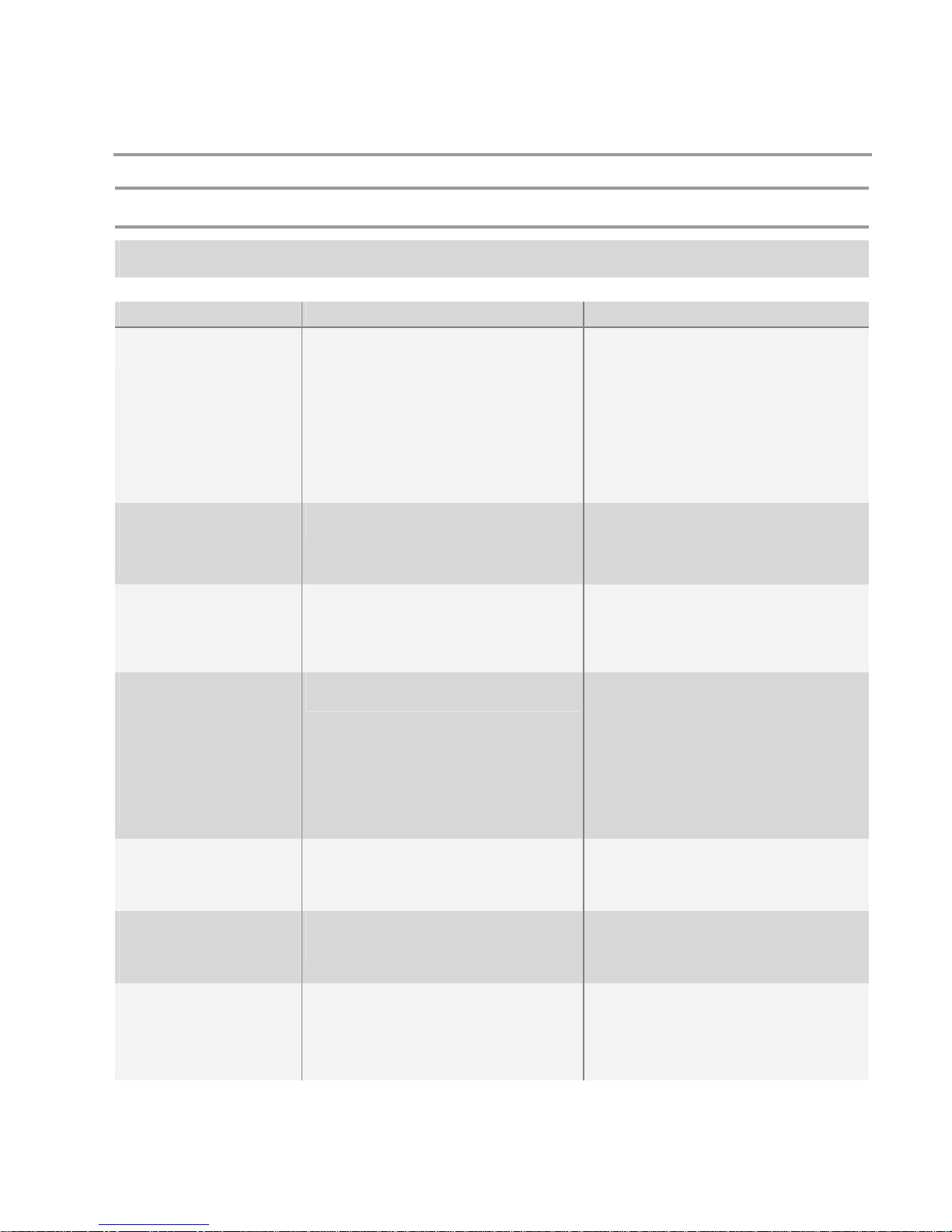

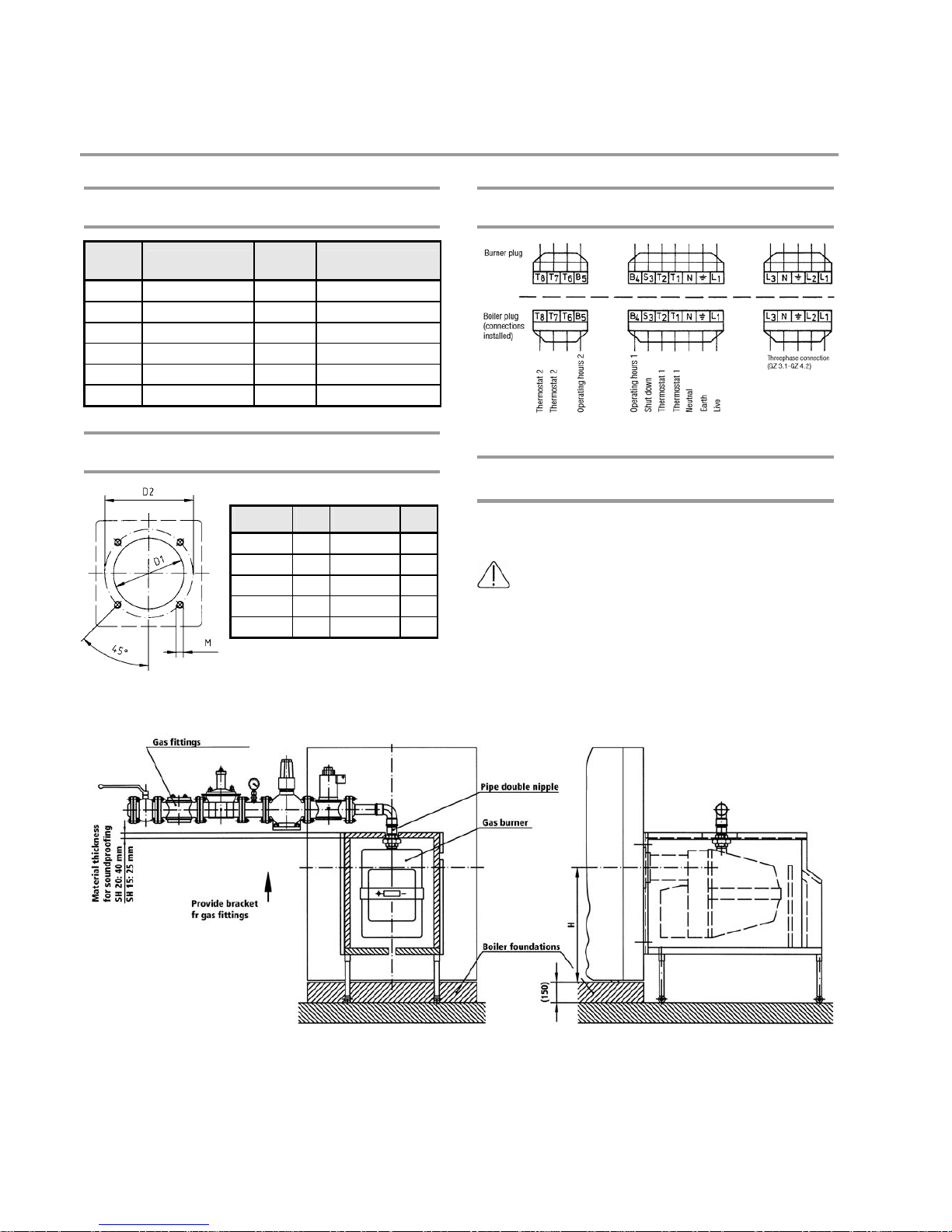

Useful design

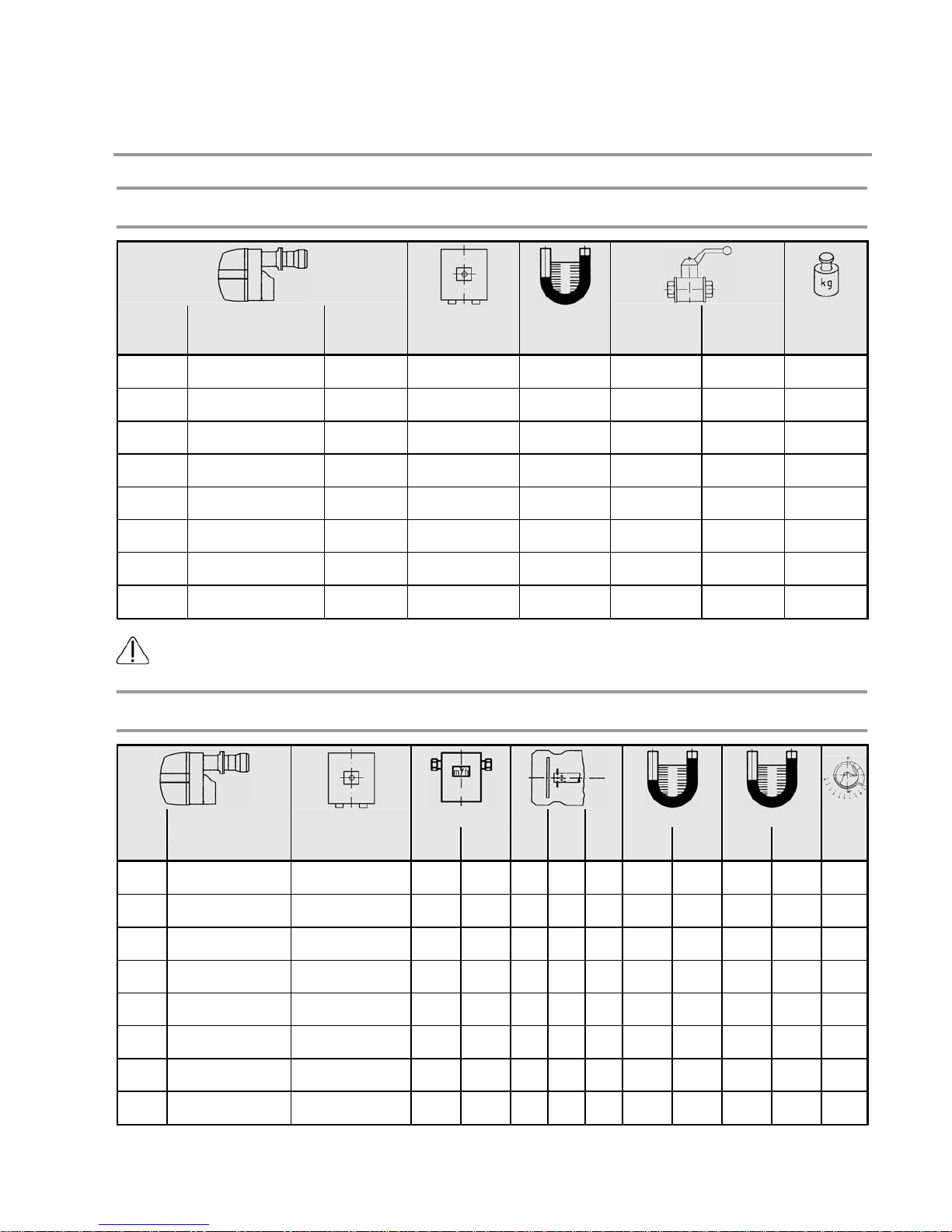

Diecasting light metal case, power-dependent burner pipe and

high-performance mixing system, adjustable air admission noz-

zle and air damper servomotor for two-stage operation, A.C.

motor (GZ 2 - GZ 3.0) or threephase motor (GZ 3.1 - GZ 4), ig-

nition transformer, fan impeller, gas compact ramp (GZ 2 - GZ

3.0) or gas ramps assembly (GZ 3.1 - GZ 4), air pressure switch,

automatic firing sequence control with infrared flame detector

(GZ 2 - GZ 3) or ionisation flame control (GZ 4), internal plug

connections and plugs according to DIN 4791, mounting flange

with gasket and fastening screws.

Every burner is pre-tested.