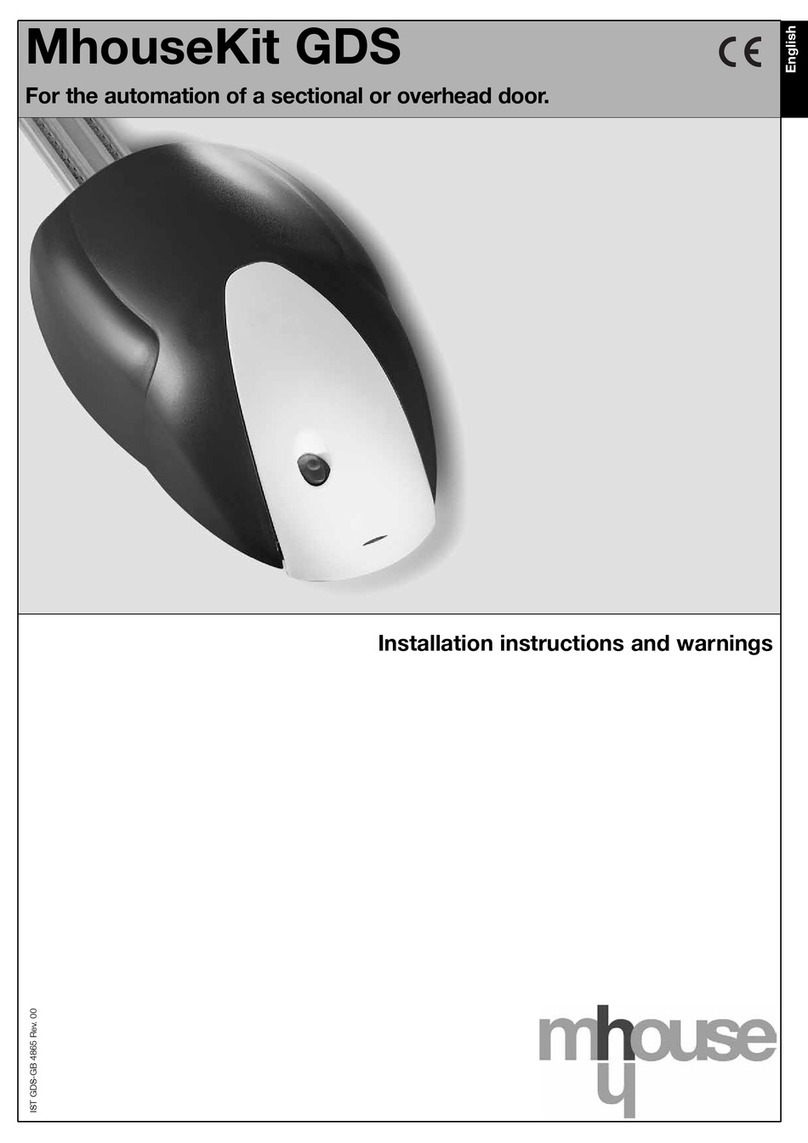

Instructions GD1-GD10 3

1 Warnings

Important installer and user safety instructions.

• If this is the first time that you install a GD sectional or up-and-over door

automation system we recommend that you dedicate some of your time

to reading this manual. You should read it before you start installing the

system, so you don't have to rush to finish the work.

Keep all the components of the GD system handy so that you can read,

check and verify all the information contained in this manual. However,

do not carry out the adjustment and memorization stages otherwise,

during the actual installation of the products, you will have to deal with

settings that differ from the original factory ones.

• When reading this manual, pay special attention to the sections marked

by the following symbol:

these sections are particularly important for safety.

• Store this manual safely for future use.

• This manual, as well as the design and manufacture of the devices that

make up GD, comply fully with the standards and regulations in force.

• Considering the hazards that may exist during the installation and oper-

ation of GD, it is necessary that also the installation be carried out in strict

compliance with current legislation, standards and regulations, particu-

larly:

• This manual contains important information regarding personal

safety; before you start installing the components, it is important

that you read and understand all the information contained here-

in. Do not proceed with the installation if you have doubts of any

sort; if necessary, refer to the MHOUSE customer service depart-

ment for clarifications.

• Follow all installation instructions.

• Before you start with the installation, make sure that each sin-

gle GD device is suitable for the intended automation purposes;

pay special attention to the data provided in chapter 6 “Technical

Characteristics”. If even a single device is not suitable for the

intended application, do not proceed with the installation.

• Before you start with the installation, check whether additional

devices or materials are needed to complete the automation with

GD based on the specific application requirements.

• The GD0 automation system must not be installed outdoors.

• The GD automation system must not be used until the automa-

tion has been commissioned as described in paragraph 3.7.2

“Commissioning”.

• The GD automation system cannot be considered as a suitable

intrusion protection system. If you require efficient protection you

need to integrate GD with other devices.

• The packing materials for GD must be disposed of in compli-

ance with local regulations.

• Do not make modifications to any components unless provided

for in this manual. This type of operations will only cause mal-

functions. MHOUSE disclaims any liability for damage resulting

from modified products.

• Components must never be immersed in water or other liquids.

Also during installation, do not allow liquids to enter the gearmo-

tor or other open devices.

• In the event that liquid substances have penetrated inside the

automation devices, immediately disconnect the power supply

and contact the MHOUSE customer service department. The use

of GD in these conditions can be dangerous.

• Keep all components of GD away from heat sources and open

flames; these could damage the components and cause malfunc-

tions, fire or dangerous situations.

• Connect the gearmotor only to a power supply line equipped

with safety grounding system.

• All operations requiring the opening of the protection shell of

GD device must be performed with the gearmotor disconnected

from the power supply; if the disconnection device is not identifi-

able, post the following sign on it: “WARNING: MAINTENANCE

WORK IN PROGRESS”.

• In the event that any automatic switches or fuses are tripped,

you must identify the failure and eliminate it before you reset

them.

• If a failure occurs that cannot be solved using the information

provided in this manual, refer to the MHOUSE customer service

department.

Particular warnings concerning the suitable use of this product in relation

to the 98/37CE “Machine Directive” (ex 89/392/EEC):

• This product comes onto the market as a “machine component” and

is therefore manufactured to be integrated to a machine or assembled

with other machines in order to create “a machine”, under the directive

98/37/EC, only in combination with other components and in the man-

ner described in the present instructions manual. As specified in the

directive 98/37/CE the use of this product is not admitted until the man-

ufacturer of the machine on which this product is mounted has identified

and declared it as conforming to the directive 98/37/CE.

Particular warnings concerning the suitable use of this product in relation

to the 73/23/EEC “Low Voltage” Directive and subsequent modification

93/68/EEC:

• This product responds to the provisions foreseen by the “Low Voltage”

Directive if used in the configurations foreseen in this instructions manu-

al and in combination with the articles present in the Mhouse S.r.l. prod-

uct catalogue. If the product is not used in configurations or is used with

other products that have not been foreseen, the requirements may not

be guaranteed; the use of the product is prohibited in these situations

until the correspondence to the requirements foreseen by the directive

have been verified by those performing the installation.

Particular warnings concerning the suitable use of this product in relation

to the 89/336/EEC “Electromagnetic Compatibility” Directive and subse-

quent modifications 92/31/EEC and 93/68/EEC:

• This product has been subjected to tests regarding the electromag-

netic compatibility in the most critical of use conditions, in the configura-

tions foreseen in this instructions manual and in combination with articles

present in the Mhouse S.r.l. product catalogue. The electromagnetic

compatibility may not be guaranteed if used in configurations or with oth-

er products that have not been foreseen; the use of the product is pro-

hibited in these situations until the correspondence to the requirements

foreseen by the directive have been verified by those performing the

installation.