Michaelo Espresso Cafina c60 User manual

This copyright protected manual is

intended exclusively for

use with machines supplied by

Michaelo Espresso

Reproduction of any part of this

manual is strictly prohibited

Cafina Technical

Service Manual

Installation Setup

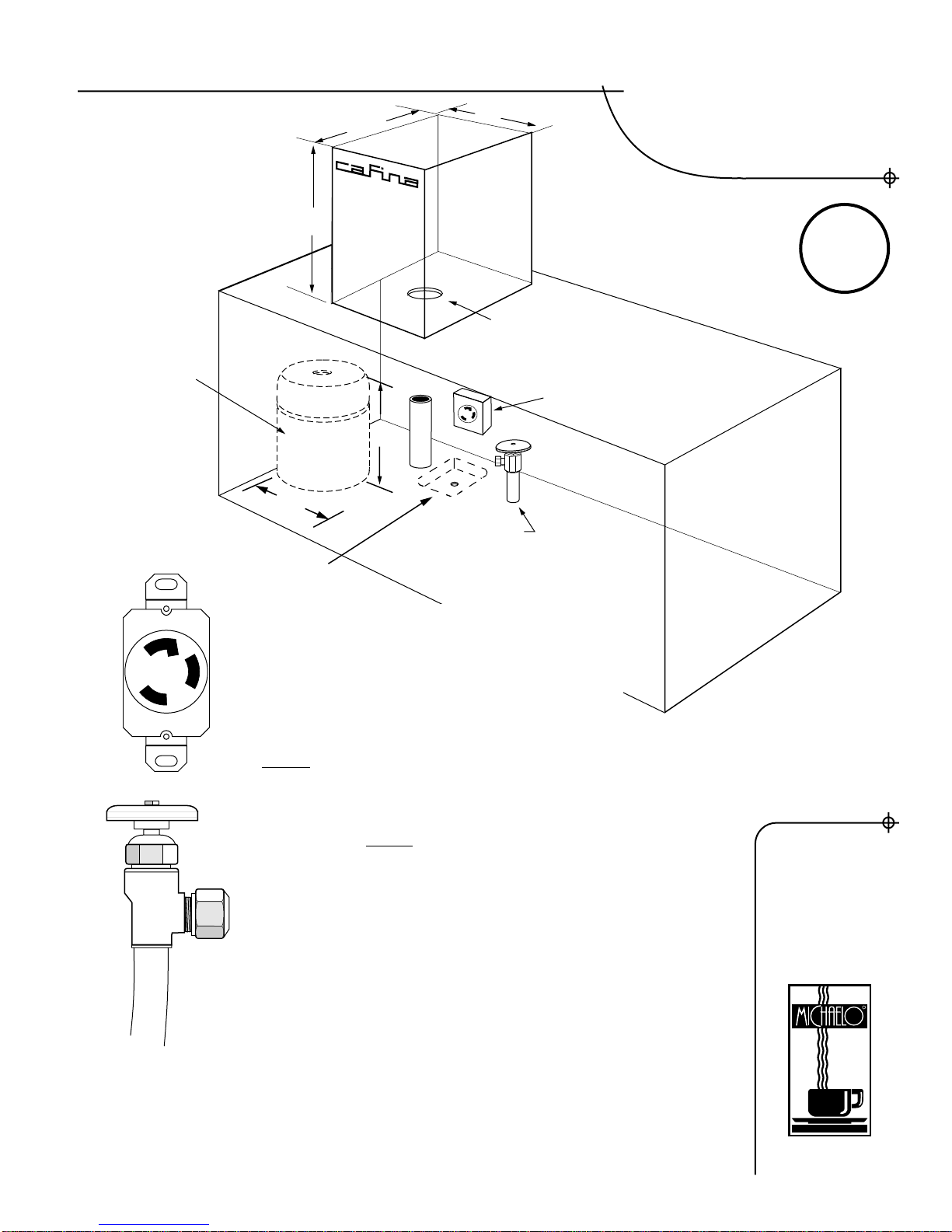

Installation Setup / Checklist Page 1 of 2

Cold water feed line:

3/8” Compression Fitting with Shut Off Valve

Located within 6-10 feet of Cafina

Water line must be flushed thoroughly

Filtration:

Water line MUST have a coarse particulate

filter

A fine carbon filter is strongly advised

Hardness Should be below 7 GPG

(A water softener may also be needed)

Drain:

Floor Sink or drain should be within 6 feet

Path for drain hose must not have Horizontal runs

Drain Hose must have a 2” air gap at floor

18”

23”

36”

11”

16”

Drain

Accumulator Tank

(optional item - May

be provided with the

machine)

2-3/8” hole for lines

NEMA L630R

Water

3/8” compression with

shut off

Optional

Floor Sink

30 Amp, 220 Volt outlet:

NEMA L6-30-R

Outlet within 6 feet of Cafina

208 Volts minimum at outlet

(A booster may need to be installed)

2

3

Section 2: Installation/Tools

Cafina c60 Service Manual

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Installation Check list

Page 2 of 2

Set Cafina Pump Pressure to 8 bars. Go to the service position,

select handling, and switch the pump on. Check pressure on gauge.

Turn off pump and release pressure by running the bypass valve,

adjust pump as needed and check again.

Run the Reference. If beans are available at the time of installation,

follow the Run Reference instructions in the service manual.

Run Each Drink. Test each drink button at least once.

Test Steam and Water buttons.

Run A Cleaning Cycle.

Check over equipment for shipping damage. Report any damage found to Michaelo:

800-545-2883.

Check Incoming Water Pressure. It should be between 45 PSI and 90 PSI, if the

incoming pressure is greater than 90 PSI there MUST be a pressure reducer placed in

the line. Preferably before the filtration system.

Flush Incoming Water Line. Run several gallons of water through the lines at full force

before connecting to the machine. This is extremely important; there are several very

small ports that will become clogged if this procedure is not followed.

Install long legs.

Hook up Water Line. Use white Teflon washers as needed.

Install Drain Hose with clamp provided and ensure that it runs continuously downward.

The end of the hose should have an air gap at the floor drain.

Purge Brew Boiler. Unscrew the top of the Hex shaped Safety valve above the brew

boiler until water flows out into the drip tray. Re-tighten valve.

Check White Coffee Chute. Should be snug against grinders, tighten screw.

Check Piston Assembly Mounting Screws. Screws can work loose in shipping.

Check Incoming Voltage and Amperage. The Cafina requires 208v MINIMUM, and

ideally 220v. The unit is 5400W and MUST have a 30-amp breaker.

Do Not plug Cafina in until Water is hooked up.

Section 2 : Installation/Tools

Cafina c60 Service Manual

4

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Recommended tools

Recommended Tools Page 1 of 1

Michaelo recommends

Wiha Brand System 6 with

284 series long blades

Wihatools.com

Open end wrenches

22mm

20mm

14mm

12mm

7mm

Set of Metric

Allen Wrenches

Small Phillips for ICU board

adjustments

8mm Socket for

Grinder Burr Change

Standard and Phillips

Screwdrivers

Wire Brush and Dental Pick

Allen Wrenches with long

handles 2.5mm, 3mm, 4mm

2

5

Section 2: Installation/Tools

Cafina c60 Service Manual

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Section 2 : Installation/Tools

Cafina c60 Service Manual

6

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Service Call Worksheet

1. Check condition of Filters:

Incoming Pressure Output Pressure

2. Number of shots on hit counter

3. Run Protocol in Service Mode

(delete when finished)

4. Check Water flow and Flowmeter under “System” in Manager mode.

Actual flow time:

4-6 Seconds is normal for 65ml

5. Grind Times:

From reference or run shot then look at Manager mode page 3

Consider changing burrs if over 2.5 sec

6. Check for coffee grounds in Slider area under Piston.

Vacuum if needed

7. Run Reference if needed

Double shots should average 14 seconds

8. Run hot water until Boiler Autofills

Wait 30 seconds then test Steam Output

9. Check that drain line is running smoothly

10. Delete Filter counter

Upon completion of call, fax this sheet

back to Michaelo (206) 695-4951

Technician: ________________________

Service Company: ____________________

PO #:_____________________

Date: ____________________

Customer: Machine Serial #:

PSI PSI

Record DP Codes Here:

Number of DP 30 Codes / Cleanings:

Sec

Double*

Double**

Sec

Sec

OK, no leaks

OK, no leaks

Cafina Service Worksheet

3

Section 3: Service Call Instructions

Cafina c60 Service Manual

7

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

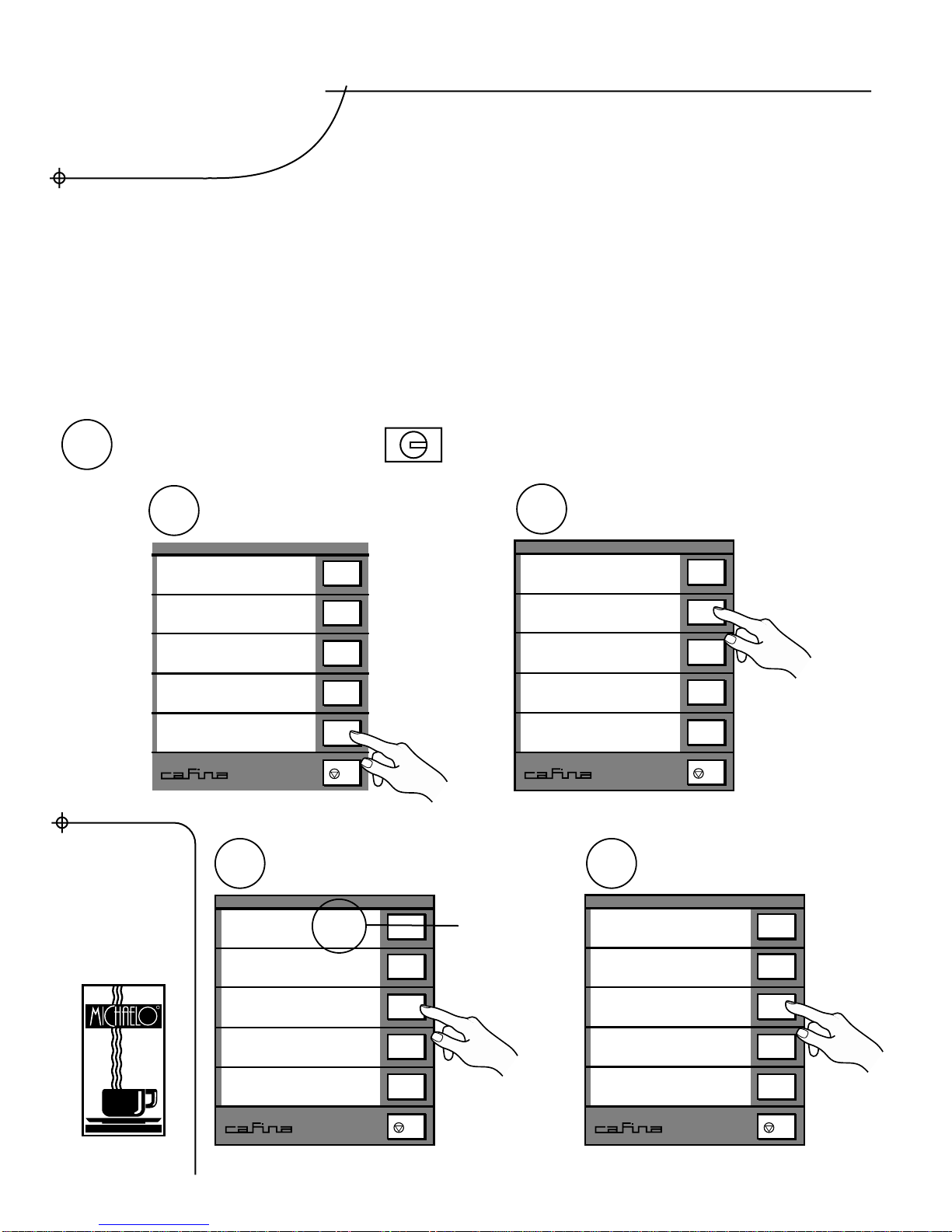

Filter Reminder Reset

Page 1 of 1

Since the reminder needs to be reset with a service key,

we recommend resetting the count at every service call

and monitoring the filters independently.

Key to Service Position

Select Next Select filter

Press delete to reset the

counter to the pre-set value Select YES to confirm

c60 s

set cleaning

filter

product names

run reference

next >>

c60 s

product data

protocol

handling

temperature

next >>

c60 s

filter 47204

filter pre-set 6000

delete >>

filter +5000

filter -5000

c60 s

**filter**

delete?

YES >>

NO >>

1

5

2 3

4

This counter

counts down

from the pre-set

value

MANAGER

OFF

ON (Service)

The Cafina filter reminder displays a

flashing “filter” message over the drink

menu after a preset number of drinks

have been run ( 60,000 is the default).

Section 3: Service Call Instructions

Cafina c60 Service Manual

8

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

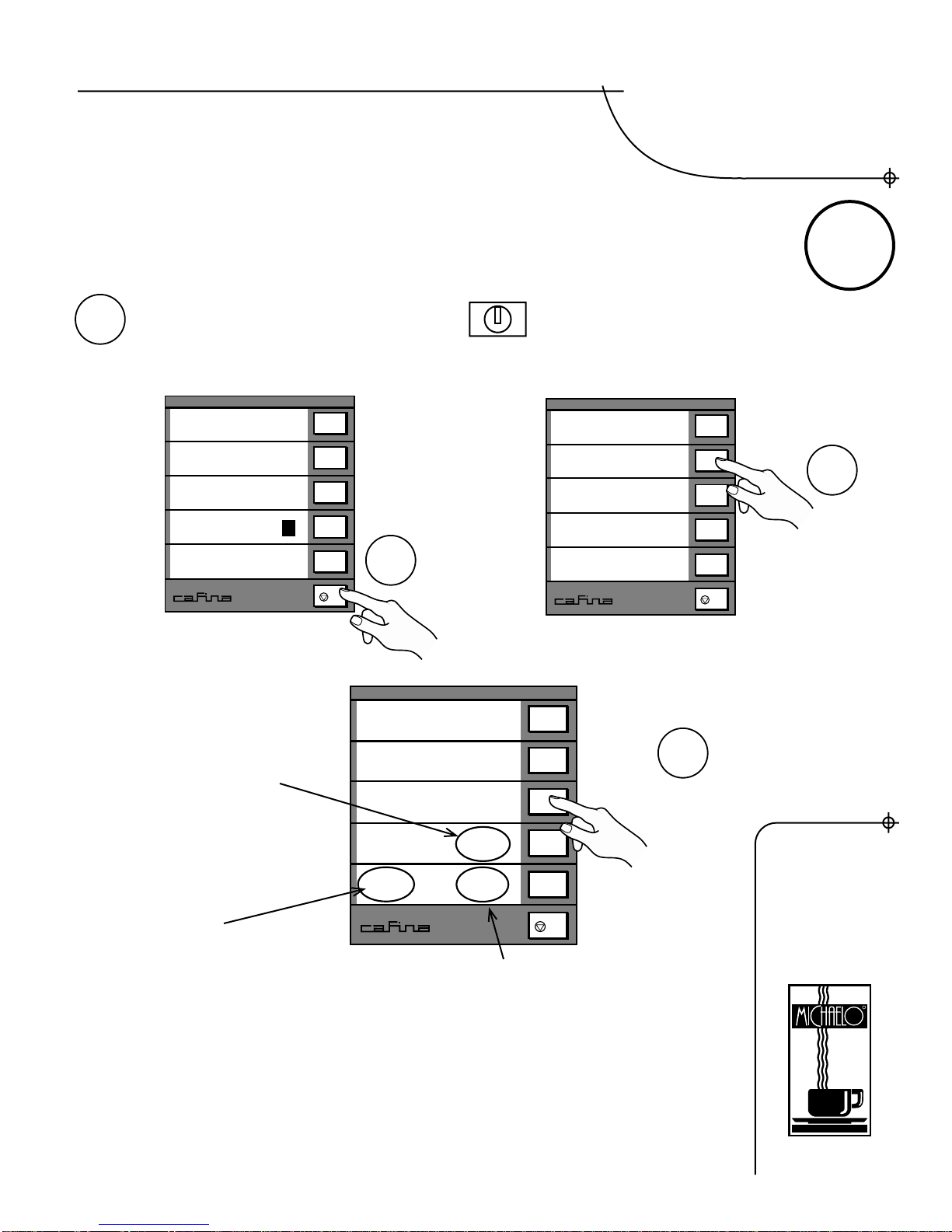

Grind Time Check

Grind Time Check Page 1 of 1

The time displayed will always be the time of the last drink made.

V3.51 Software automatically displays the grind time of the last drink made on

page 3 in Manager mode (If Grind time doesn’t display in Manager, go to main

Reference page in service to see time.)

Select the Reference Drink you wish to check

and allow the machine to brew it. Reminder: The

Reference Drink name is followed by an asterisk.

Turn key to Manager position

Press Shift twice to view 3rd Screen of Manager

Mode and note the time recorded next to

Grinding.

1

3

MANAGER

OFF

ON

Default 1st page of drink menu

when machine is on

c60 s

Single

Double*

Triple

Americano 12

Americano 16

2

c60 s

protocol

System

Grinding 1.78

Manager Screen 3

Grinding

time for

last drink

brewed

Evaluating Grinder Burr Condition from the Grind Time Reading

Evaluating Grinder Burr Condition from the Grind Time Reading

New Burrs = less than 1.7

Normal Burrs = 1.2 - 2.25**

*If Double Shot is not 14 Grams, call Michaelo for grind time range

**If time = greater than 2.25 - Call Michaelo for advice

FOR 14 GRAM DOUBLE SHOT*

FOR 14 GRAM DOUBLE SHOT*

The condition of the grinder burrs is

monitored by watching the change in grinding time

for the reference drinks. The grind time increases as the

grinder burrs wear out. Worn burrs take longer to grind

the same amount of coffee.

Check each Grinder Separately

3

Section 3: Service Call Instructions

Cafina c60 Service Manual

9

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Clogged Filters may cause:

“no water” reading

DP 31 (Boiler slow to fill)

DP 11 & 13 (poor flow through coffee)

Bypass Valve

Should be Closed all the time

Flushing Valve

Incoming

Water Pressure

Water Pressure

to Cafina

The water pressure to the Cafina will slowly decrease over

time as the filters become clogged.

Test the flow through the filters by opening the Flushing valve.

The outgoing gauge may still read high with clogged filters if

no water is being used, but will drop as soon as the flushing valve

is opened.

The Coarse Filter should be changed when it turns brown.

When the filters clog up it shows that they’re working. They are

stopping the coarse and fine sediment from harming the machine

and changing the taste of the coffee.

Checking Filters, Typical Set-up

Page 1 of 1

Section 3: Service Call Instructions

Cafina c60 Service Manual

10

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

System test

System Test

No Coffee water flow test

The System Test is used to make sure the water is

flowing freely through the machine before running ref-

erence or troubleshooting shot time problems

c60 s

Double*

start >>

actual time 4.5s

136 65ml

Press Shift twice

c60 s

protocol

System

Grinding 1.78

Key to Manager Position

1MANAGER

OFF

ON

c60 s

daily counter

water quantity

coffee quantity

lock buttons

0

4

3

2Select System

Press Start

Water flow Time

4-6 seconds Normal flow time for 65ml of water

6-8 seconds Run several cleaning cycles and try again

8+ seconds Check water flow from Brew Valve

See next page

Flowmeter Pulse

Count Pre-set amount of water

3

Section 3: Service Call Instructions

Cafina c60 Service Manual

11

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

c60 s

Double*

start >>

actual time 4.5s

136 65ml

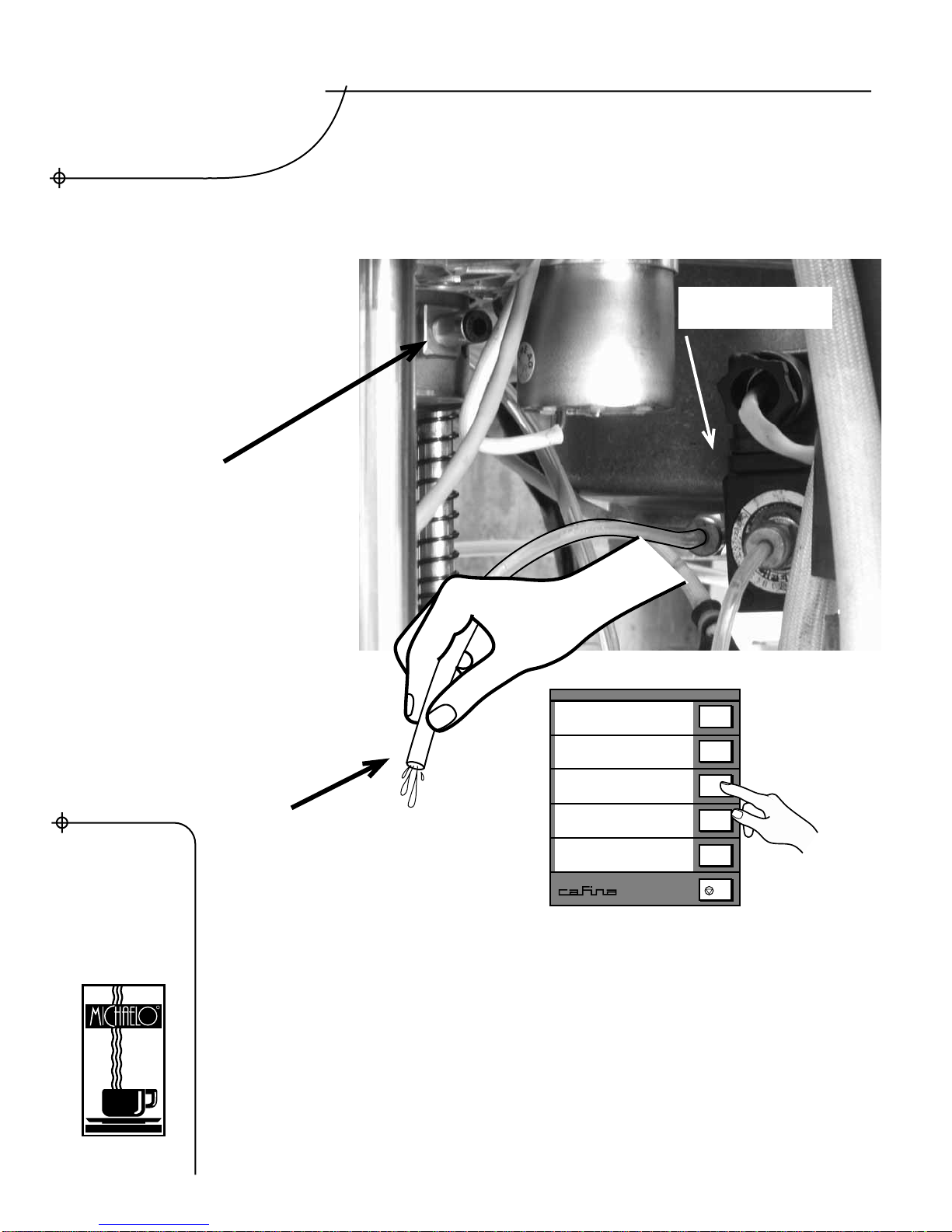

Disconnect the line to the

bottom of the brew chamber

If actual time returns to normal the problem is a clog in

the Brew Chamber, Tamp or Spout

If actual time is still over 8 seconds then look for a clog

in the:

Flowmeter, Brew Valve, or Brew Boiler

Remove the Spout Panel

Replace the Grounds

Drawer

Run System test

while holding the line

pointed into the drip-tray

Turn Key to Manager

Press shift twice

to display System Test

Times the water flow from the Brew Valve

before it goes to the Piston

Use if the System test is over 8 seconds to

isolate the location of the clog

Brew Valve

Check Water Flow from Brew Valve

Page 1 of 1Page 1 of 1

Section 3: Service Call Instructions

Cafina c60 Service Manual

12

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

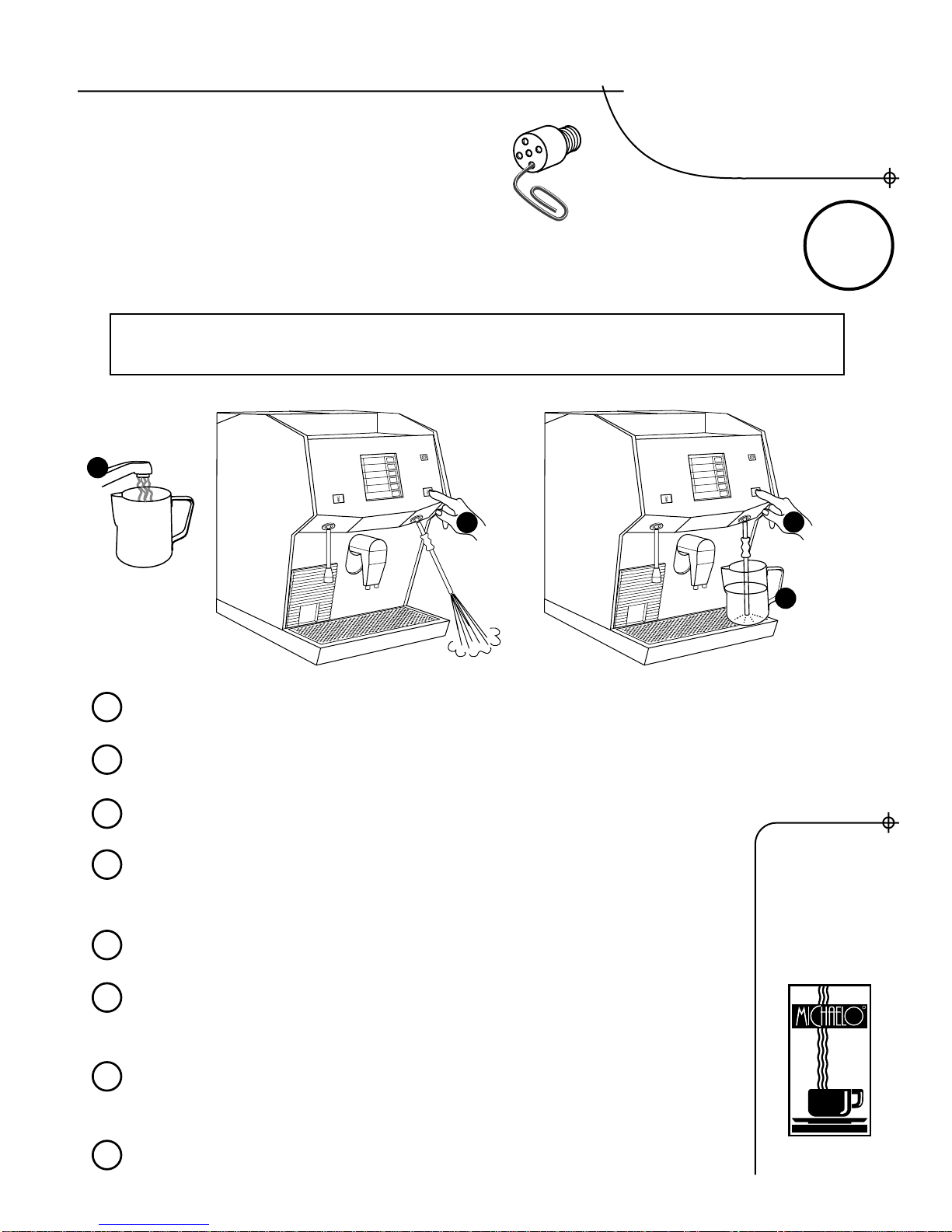

Remove the Steam Tip

Fill a Milk Pitcher with cold water (Never use any cleaner!)

Heat the Steam Wand by running it for 10 seconds

Turn the Steam off and immediately insert the Wand into the

cold water

Run Steam again for 2 seconds then turn off

Wait 10 seconds for the water to be sucked up into the wand/

valve

Repeat steps 5 and 6 four to five times to soften and flush out

the clog

Refill the pitcher with fresh cold water and repeat if needed

Steam Wand Backflush

Steam Wand Backflush Page 1 of 1

A clogged Steam Tip is the most

likely cause of weak steam flow.

Remove the Steam Tip by unscrewing it

from the wand and clean out the holes.

If cleaning the tip doesn’t restore good flow

try this cold water backflushing procedure:

NEVER leave the steam wand in the milk pitcher.

The milk will be sucked up into the wand and may contaminate the boiler.

1

2

3

4

5

6

7

8

2 Seconds On

10 Second Pause

Repeat 5 times

10 Second

pre-heat

2

35

4

3

Section 3: Service Call Instructions

Cafina c60 Service Manual

13

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Section 3: Service Call Instructions

Cafina c60 Service Manual

14

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Page 1 of 8

Check DP codes in Protocol

Record codes then Delete when prompted

Check grind time for each grinder

Run Cleaning Cycle or System Test to empty coffee chamber

Run bypass valve in handling to check for clog

Remove and clean Bypass Elbow if needed

Remove Piston, set aside

Move Grinder collars by hand to check for free play

Remove Collar and clean threads if hard to turn

Clean inside of machine

Clean Dispensing spout, Bean hopper, and all panels

Install new Piston

Plug machine in with key in the ON position

O-data should count automatically (pulses at top of travel)

if not clear o-data in service mode and turn OFF/ON

Check that pump is set to 8 bars

Run Reference for both Grinders

Check Steam Wand for leaks

Delete Filter counter

Run hot water, check that boiler autofills

Check each drink button

Check filters and drain line

General Service Checklist

General Service Checklist

4

Section 4: General Service

Cafina c60 Service Manual

15

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Top Cover

• Remove the two 2.5mm Allen screws on either side of the cover.

• Lift cover and disconnect grounding wire.

Sides

• Remove Top Cover

• Grasp side panel at front edge, top and middle with fingertips.

• Pull sharply out.

* To replace: insert rear of side panel into back panel. Snap the front edge

into place with the heel of your hand.

Grab Side panel

with fingertips and

pull sharply to

open.

2.5mm Allen screws

#2303083

Page 2 of 8

Remove Panels

Back Panel (Usually can stay on for Piston change)

• Remove Top Cover and Sides

• Loosen the 10mm nuts on the bottom tabs first,

then the 4mm Allen screws on the top tabs.

• Swing panel out from the bottom.

Section 4: General Service

Cafina c60 Service Manual

16

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

4

1. Remove Grounds Drawer

2. Remove the 2.5mm Allen screw in the upper left corner

3. Remove Drip Tray Grating

4. Loosen the two 7mm nuts on the underside bottom edge of the panel

5. Push Spout to lowest position

6. Swing bottom of panel out of the front of the Drip Tray

7. Disconnect brew lines by reaching behind panel and pulling the clear

lines off of the short silicon connector tube

Always reconnect

the Brew Line to the

Right Hand side!

Line from Bypass Valve

Swing bottom of

panel out to front

of Drip Tray

Loosen 7mm nuts

2.5mm Screw

2301041

Push

Spout

Down

Page 3 of 8

Remove Dispensing Spout Panel

Remove Dispensing Spout Panel

Silicone Connector Tubes

Stay on Spout

Tubes #2701015

Complete

Spout

2601003

Section 4: General Service

Cafina c60 Service Manual

17

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Page 4 of 8 Replace the Step Motor Cable even if

it looks OK. The stress from thousands

of cycles can damage the wires even if

the outer insulation looks fine.

1Unplug connector and disconnect cable clamps from Step Motor control Board

2Plug the cable end without jumper wires into the circuit board

3Secure the cable clamp

4Set the Step Motor Board aside until you have reinstalled the piston

5Cable MUST be threaded through guides on step motor frame!

NOTE:

Inspect the new cable. Notice that, although the connectors at each end of the

cable are identical, one end has two black jumper wires attached. This end of

the cable must be connected to the Step Motor.

Step Motor Cable (2703048)

Plug end with black

jumpers goes to step

motor

Cable MUST be threaded

through guides when

reinstalling

Step Motor

STEP MOTOR

BOARD 2703027

Replace Step Motor Cable -

see next page

Make sure to re-install

the Cable Clip

Section 4: General Service

Cafina c60 Service Manual

18

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

4

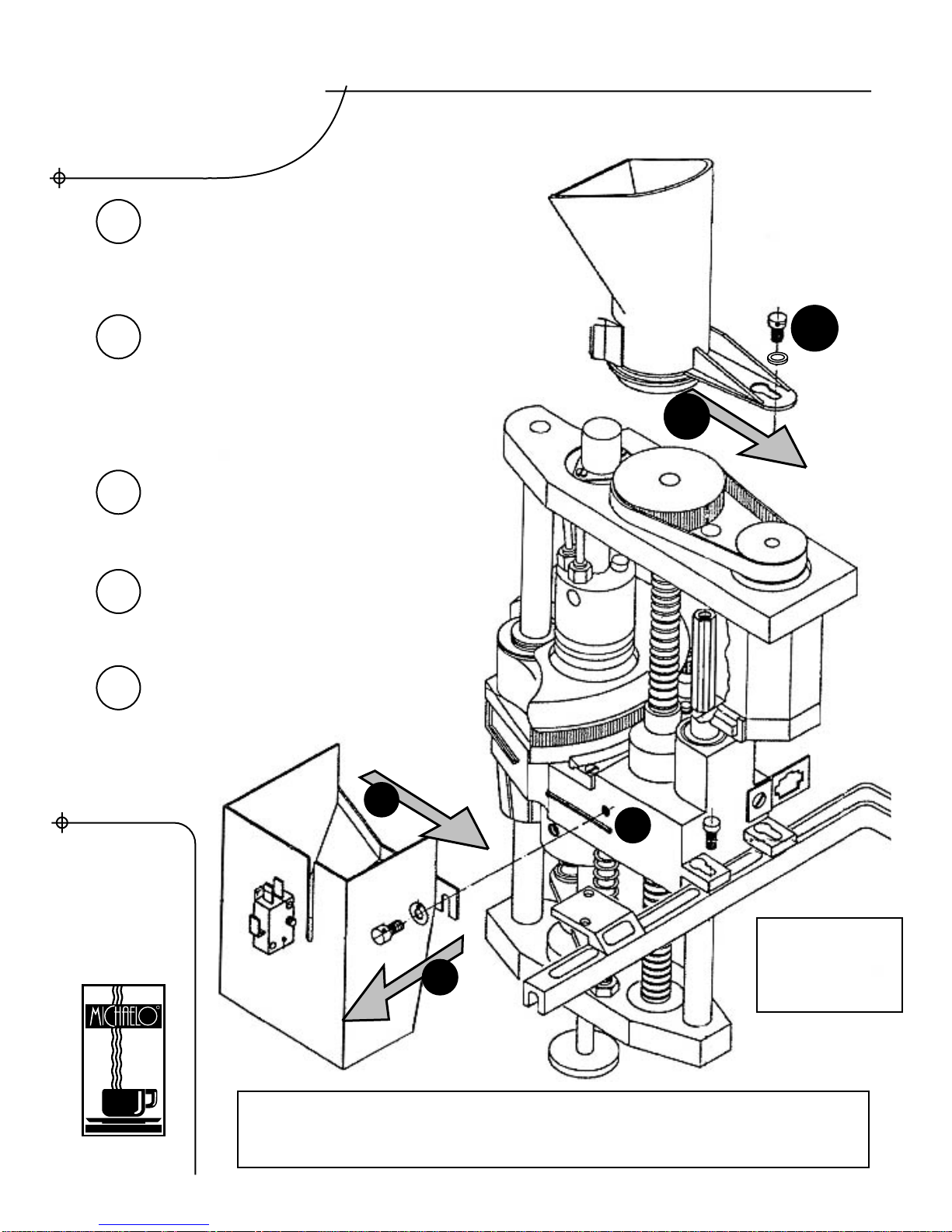

Replace Piston

Replace Piston Page 5 of 8

Before replacing piston:

• Unplug Machine

• Remove Top Cover

• Remove Dispensing Spout Panel

Disconnect ribbon cable from top

of Step Motor Board

Slide Step Motor Board up and out

of guides

Unplug power lead from bottom of

Step Motor Board

Disconnect cable from Step Motor:

• Pry gently with screwdriver

• Plug pulls directly to the left

• Be careful not to bend pins

• Plug end with black jumpers

goes to step motor

• Refer to page previous for detailed

instructions

Unhook cable from guides on Step

Motor frame

It may be easier to screw the piston

down by hand and unhook the

cable from the front

Cable MUST be threaded through

guides when reinstalling

Set Board and attached cable aside

Raise Piston by turning

sprocket counter clockwise

1

2

3

4

5

6

7

PISTONASSEMBLY

STEP MOTOR

BOARD

PISTONASSEMBLY Line Pot Cable

2703036

2

STEP MOTOR

4

5

6

Step Motor Board

2703027

Section 4: General Service

Cafina c60 Service Manual

19

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Replace Piston

Page 6 of 8

Remove 3mm Hex Screw and Lock

washer - Use one drop of Locktite when

replacing

Slide Grounds Chute forward

Remove Chute and set aside

When replacing, be sure that grinder

tunnels are fully inserted into Chute

Remove 3mm Hex Screw

and Washer

Slide Puck Chute forward to

release from notch on Piston

Pull Puck Chute away from Piston

Leave chute sitting loosely in

place

When replacing the Puck Chute, be sure it is fully seated in the notch or

water will leak during cleaning cycle

8

9

10

11

12

8

9

10

10

11

11

12

12

Grounds

Chute

2253089

Puck chute &

Switch

2253087

2703391

Section 4: General Service

Cafina c60 Service Manual

20

© 2003 Michaelo Espresso,

Inc. All rights reserved.

Michaelo Espresso

3801 Stone Way N.

Seattle, WA 98103

(800) 545-2883

(206) 695-4950

Fax (206) 695-4951

Table of contents

Popular Coffee Maker manuals by other brands

Oster

Oster BVSTDC3401013 instruction manual

Rheavendors Group

Rheavendors Group Variflex user manual

Rocket

Rocket R NINE ONE user manual

Philips

Philips SENSEO HD7854 user manual

Astoria

Astoria LOFT HOML Use and maintenance manual, Instructions for the user

VKI Technologies

VKI Technologies 2001 Operation and service manual