01 general information

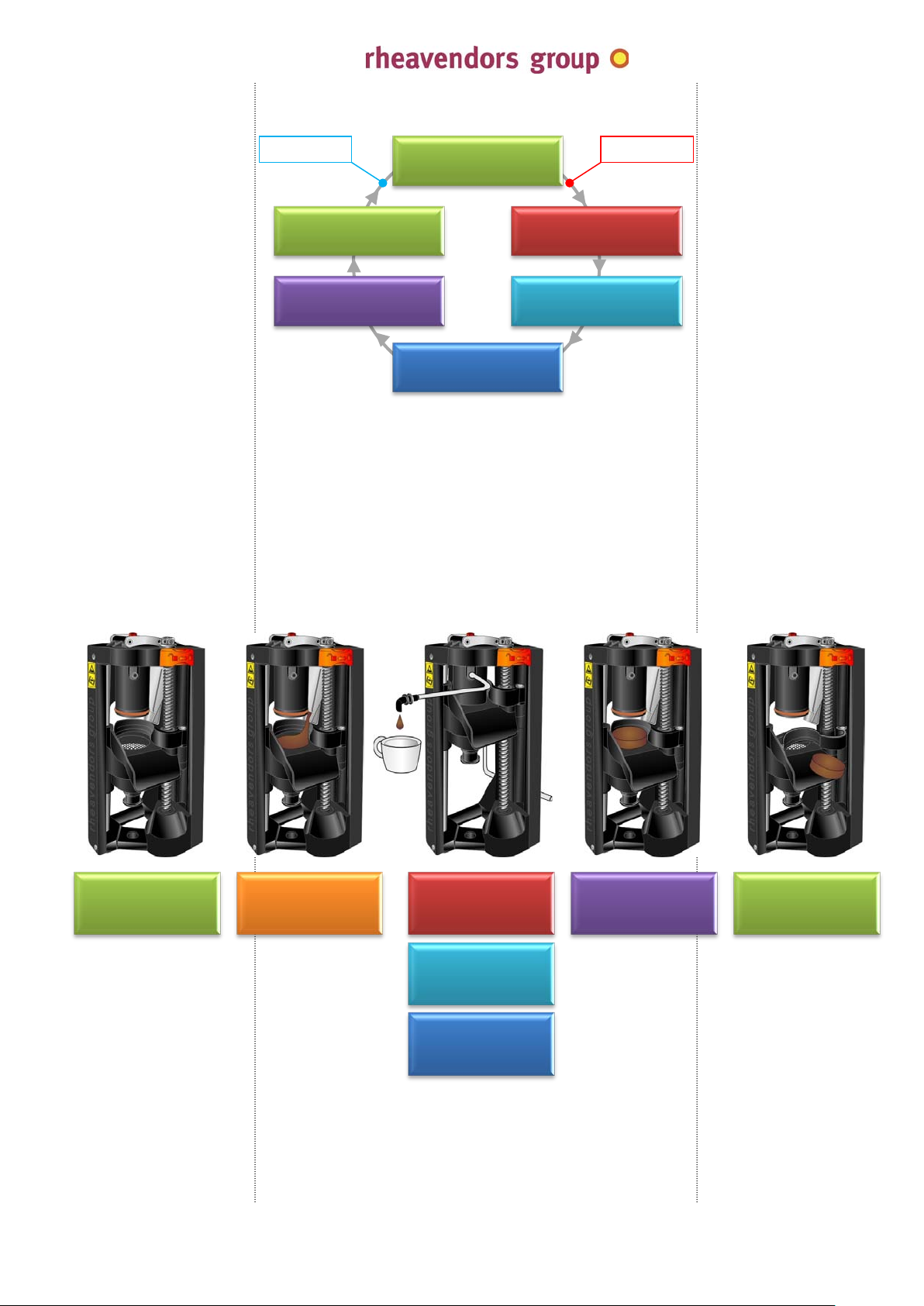

presentation:

description:

brewing chamber:

features:

maintenance:

the manufacture of the Variflex®coffee brewer has originated from

the experiences directly acquired by the users of our machines, as

a development of classic coffee brewers; the cup drink quality is

the fundamental parameter that has guided the design of this

coffee brewer, characterised by:

•constant quality dispensing cycle;

•compact and solid structure;

•easy and simple maintenance;

the peculiarity of the Variflex®coffee brewer is represented by the

fact that the brewing chamber volume is automatically adjusted to

the ground coffee quantity to make the best use of the dose; the

interaction between mechanics and software is such that every

single work phase can be actively controlled, which can ensure an

espresso, the top quality of which is constant all over the time,

whereas the doses ejected at the end of the dispensing cycle are

compact, perfectly dry and fully used up; the springs that are

responsible for instability and variability between one cycle and the

other one have been removed from the brewer and all phases have

been conceived to make the best and most homogeneous use of

the dose; ground products are guided as far as the middle of the

brewing chamber in such a way that the dose is compact and

homogeneous during the compressing and brewing cycle;

the Variflex®coffee brewer has been originally designed with a

brewing chamber, the diameter of which is 45 mm; any future

development will provide for chambers having a different diameter,

which means further flexibility in performance;

the reliability of the coffee brewer is obtained by using materials

selected for their specific features: two different steels and an

aluminium alloy represent the metal part of the coffee brewer

whereas the "plastic" part is made of materials widely tested in the

world of vending machines and of innovative materials, such as

PPA, a thermoplastic material that can support high mechanical and

thermal stresses; all components have been designed to ensure full

reliability during work phases;

the coffee brewer mounted on the machine is hit by a heated air

flow that can keep the coffee brewer at such a temperature that no

heat is taken away from the coffee water, without ageing the

components of the coffee brewer too early;

no tool is required to install and uninstall the machine; just click on

a release key to disengage the coffee brewer from its work seat

whereas the assembly, guided by two pins, is ensured by the

simple movement of your hand downwards until you hear a

fastening "click"; no electric part remains on the Variflex®coffee

brewer; no operation is required for the water supply ensured by a

quick coupling that occurs by making the same movement intended

to position the assembly in its work seat;

if removed from the vending machine, the coffee brewer can be

completely dipped in washing tanks; the upper and lower pistons

can be removed with no tools for an easy, rapid and simple

inspection;

no lubrication is required by the Variflex® coffee brewer;

the software conceived at the same time as the Variflex® coffee

brewer enables the operator to program the coffee dose ground

traditionally (time required to activate the grinder), but - as an

alternative - to determine its weight (see 06.);

MAN0000014 rel. 00 dated 03.02.2014 page n° 3 of n° 18 pages

www.rheavendors.com tel: 0039 02 966 551 fax: 0039 02 96 55 086 e mail: rheavendors@rheavendors.com

rheavendors group's sole property

Variflex®coffee brewer by