Michell Engineering Gyro SE MK II Manual

Gyro SE MK II Pictorial Setup Instructions

Open the carton and remove the top polystyrene sheet. Carefully lift out platter, motor housing, power supply, armboard etc.

Remove the large polystyrene block to enable removal of the metal chassis from the bottom of the carton. Remove the spider

from the underside of the polystyrene block.

Check the contents of the package:

•one acrylic spider with cable fixing pad installed

•three conical feet

•three threaded spring tower sleeves with internal thrust balls

•three spring assemblies with white Teflon washers

•three aluminum spring covers

•one cast aluminum chassis

•one inverted main bearing assembly

•one platter nut

•one partially filled vial of synthetic bearing oil

•one platter

•one motor assembly

•one drive belt

•one power supply

•one arm adaptor plate (armboard)

•three black Delrin armboard de-coupling spacers, three Allen head socket screws

•one Allen key

•one record clamp

•one nylon cable tie

A Note about the inverted main bearing

Michell’s unique inverted bearing pumps oil from the well at the base of the bearing shaft and floods the thrust ball at the top

of the shaft. The oil then returns to the well via a relief hole drilled down the shaft to re-circulate once again. The oil well at

the base of the shaft must be filled sufficiently to allow the bearing to pick up the oil. Too little oil and no circulation will occur.

Too much and the oil will overflow when the bronze housing is dropped onto the inverted shaft. Use a tissue if this occurs.

Assembling the turntable

1. Screw the three conical feet fully onto the threaded studs on the underside of the acrylic spider but do not tighten. The feet

will be used for leveling the deck later.

2. Put the three felt rings over the spring support spindles. These rings serve to protect the acrylic base each time the clamp

is used.

3. Screw the spring assemblies onto the threaded spring support sleeves until all the threads are fully showing above the

black Delrin bushing. Then locate the three hollow spring support towers onto the three support spindles on top of the acrylic

spider. Drop the white Teflon rings on top of each spring base. NOTE: When handling the support towers, make sure not

to lose the thrust ball that sits inside the sleeve of each tower.

4. Position the motor to the top left of the spider as shown below. The cable fixing pad attached to the underside of one of the

spider legs should face rearward. Using a precision bubble level placed on top of the spider in its center, adjust the conical

turntable feet beginning with the corner that is lowest until the spider is level.

5. Mount your tonearm to the armboard making sure the word FRONT on the underside is facing towards the front of the arm.

If your armboard already has a grounding strap pre-installed go to step 6. If not, locate the grounding strap and install to the

left-rear (when viewed from above) arm mounting screw using the nut and washer supplied in the kit as shown below. The

smaller ring terminal should be used. If the existing left-rear arm mounting bolt is too short, replace it with the longer one

which is included with the turntable or armboard.

6. Install the three Delrin armboard spacers snugly into the turntable chassis. DO NOT OVERTIGHTEN OR YOU WILL

SNAP OFF THE THREADED STUDS. Breakage is not under warranty.

NOTE: The turntable is supplied with 12mm long de-coupling spacers and the correct length socket head Allen

screws for the armboard that is supplied with the deck. If changing armboards or tonearm configuration, you may

have to obtain shorter (10mm) spacers and/or different length socket head screws. If your deck was supplied with a

Rega armboard and you are mounting a Tecnoarm or Rega-based arm with a Michell VTA adjuster, you will need to

obtain the shorter 10mm spacers. This is necessary to reduce the extra height introduced by the VTA adjuster in

order to have sufficient VTA adjustment range.

7. Fit the armboard / tonearm to the chassis using the socket head screws and Allen Key. The screws should be just snug.

Important note: Do not over-tighten or you will over-compress the embedded O-rings, defeating the de-coupling

effect. Further tightening will then shear the Delrin studs off the bottom of the spacers. If you find that the top

screws bottom out in the spacers before securing the armboard, then they are too long and MUST be changed for

shorter ones or you will shear off the Delrin studs below the spacers. Contact your dealer or distributor.

.

8. Install the other end of the grounding strap to one of the protruding Delrin studs as shown in the photo below using the

knurled finger nut. Note: On a black painted chassis insure that the grounding strap ring terminal is attached to the

area where paint has been removed to expose bare aluminium. This promotes a solid electrical grounding contact. It

is imperative that the grounding strap is fitted and has continuity between the armboard and the chassis or hum and

static problems may occur.

9. While holding the main bearing assembly upside down, carefully withdraw the slotted aluminum base/shaft from the bronze

housing taking great care not to lose the thrust ball that resides inside. Put the bronze housing aside, again being careful not

to let the thrust ball roll out.

10. From underneath the metal chassis, insert the spindle into the threaded center hole of the metal chassis and screw the

slotted base fully home. Using a large coin inserted into the slot underneath, tighten the bearing base as tight as you can to

insure that it does not loosen over time as the platter rotates against it.

11. Fill the fluid well at the base of the shaft with oil to a depth of about 3-4 mm. Put one drop of oil onto the top of the bearing

shaft and another drop or two down the sides of the shaft to pre-lubricate it. Carefully replace the bronze bearing housing

onto the spindle shaft, making sure not to lose the thrust ball. Spin the record spindle clockwise to distribute oil to the top of

the shaft. Remove the bronze housing momentarily to see if the bottom was immersed in oil. If not, add more oil and repeat.

12. Lower the assembled chassis over the motor housing and the three spring towers, ensuring the three spring bases and

white Teflon washers are seated correctly into the counter-bored holes on the underside of the chassis. You can use your

fingers to feel that the spring bases do not protrude below the underside of the metal chassis. This indicates the Teflon

washers and spring bases are correctly seated. Slide the turntable into its final position making sure that the motor is

centered within the chassis ring that surrounds it.

13. Dress the tonearm cable by inserting the supplied cable tie into the slots of the cable fixing pad on the underside of the

rear spider leg and securing it loosely around the arm cable. The cable should form a loose arc from the underside of the

tonearm to the rear foot and should not contact the surface on which the deck is sitting.

14. Now carefully lower the platter over the threaded record spindle and secure it in place with the knurled platter nut,

insuring that the nut's recessed side is facing downward. Connect the power supply lead to the motor lead.

15. Fit the drive belt around the smaller 33 RPM groove in the motor pulley and in the lowest groove in the platter. (The lower

pulley groove is for 45 RPM). Note: A 78 RPM-only pulley is available for listening to 78 RPM LP’s.

16. Using a precision miniature bubble level on top of the armboard or platter, adjust the knurled suspension towers for

perfect level, making sure the chassis is freely suspended with approximately 3 mm (1/8”) clearance between the underside

of the metal chassis and the tops of each of the felt buffer pads on the spider.

17. Although not absolutely necessary, you may wish to fine tune the suspension for perfect piston-like bounce. Since each

spring is slightly eccentric, rotating one or more will affect the bounce. Only rotate springs anti-clockwise while holding the

metal knurled tops to prevent dislodging the spring’s base or making a level change. Due to manufacturing tolerances,

springs do not have identical properties so swapping location of the springs may also improve the bounce. Perfect setup has

been achieved when a light push on the turntable's spindle results in a free and even vertical bounce for a number of cycles.

Adjusting tension on the tonearm cable will also affect the bounce.

18. Install the three spring covers making sure they seat fully on the chassis.

19. Make final adjustments to the arm and cartridge as per the manufacturer’s instructions. Plug the power supply into the

AC mains and enjoy!

© Copyright 2009 Artech Electronics Ltd. 1-800-631-6448

Table of contents

Popular Turntable manuals by other brands

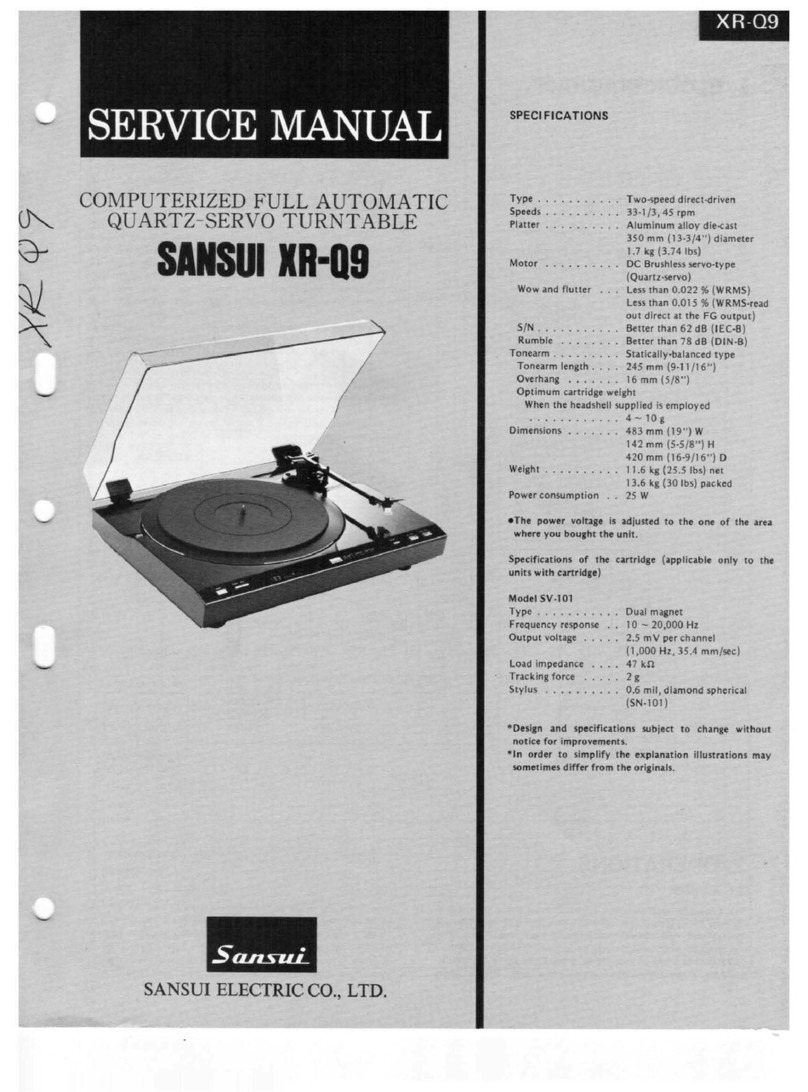

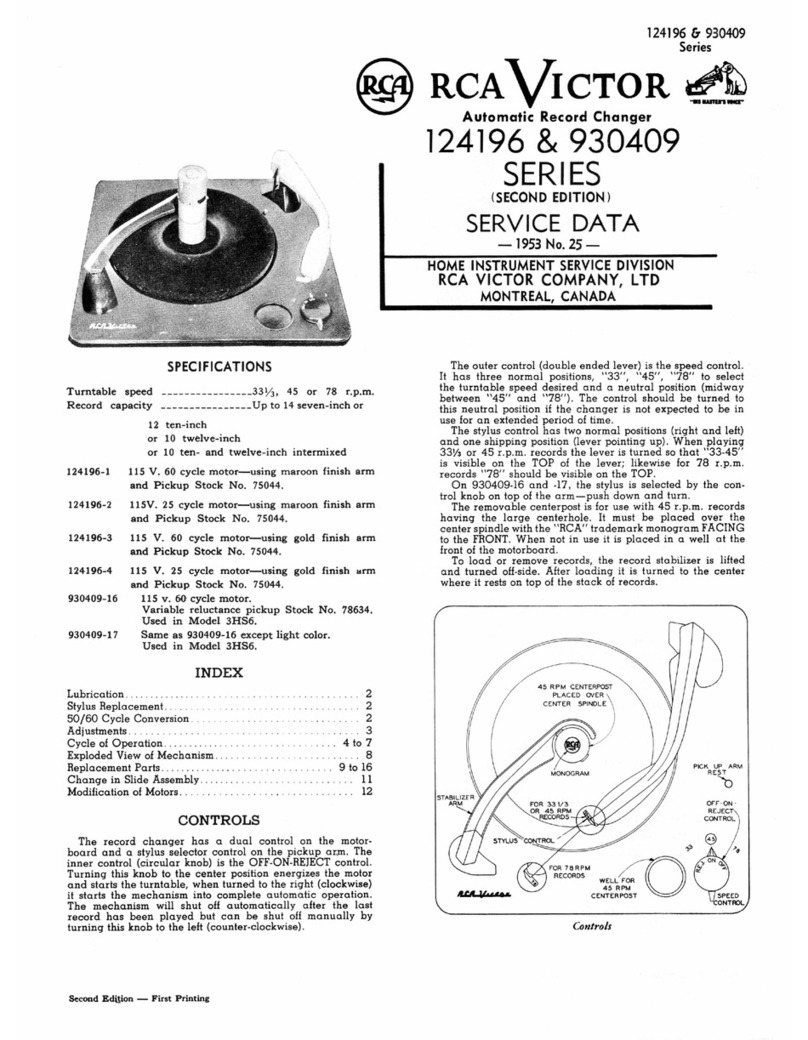

RCAVICTOR

RCAVICTOR 124196 series Service data

AVID HIFI

AVID HIFI Ingenium P&P user manual

808audio

808audio TT100 quick start guide

IMG STAGE LINE

IMG STAGE LINE DJP-104P instruction manual

Bigben

Bigben TD113 instruction manual

Premier Technology

Premier Technology HRL7500 Installation and operating instructions