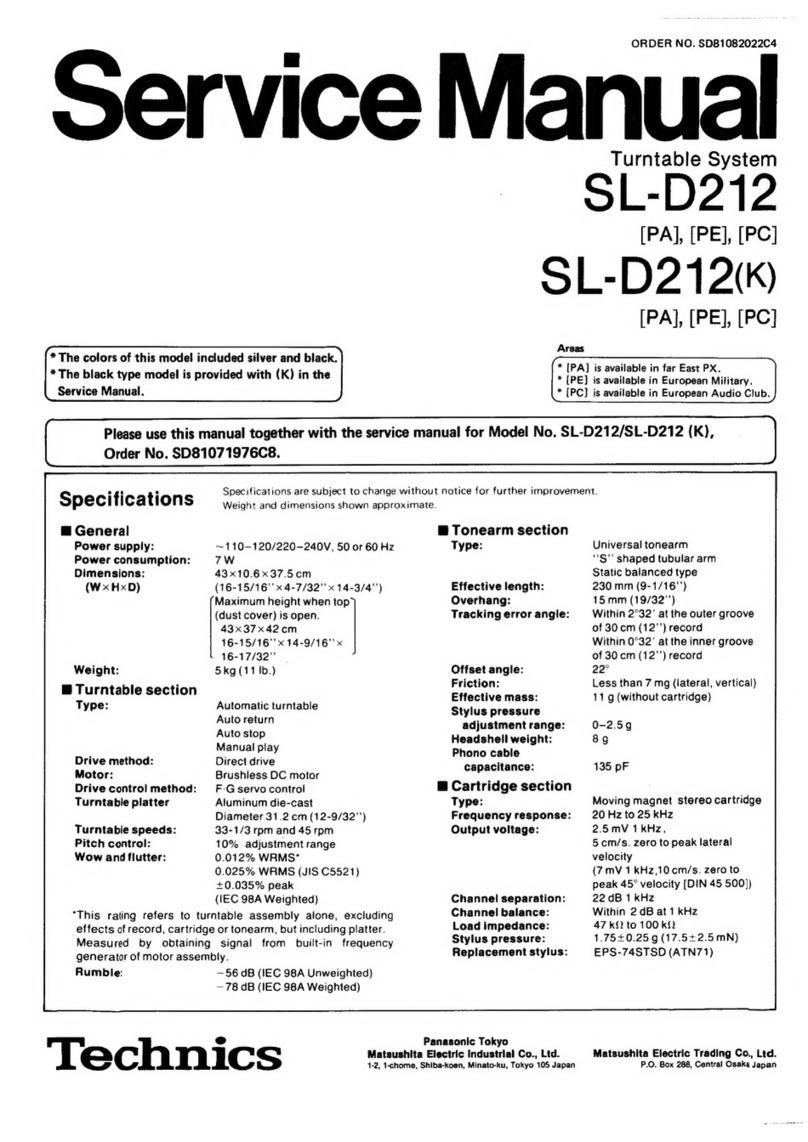

m

MESSUNGEN

UND

JUSTIERUNGEN

sees

Deutsch

see

e

Zu

verwendende

Instrumente

1.

Elektronisches

Gleichstrom-Voltmeter

2.

Oszilloskop

oder

Frequenzzahler

Schritt

Gegenstand

Justiermethode

Auto-Start-Position

1

Uberpriifen,

da&

der

Tonarm

in

der

Startposition

(auf

der

Tonarmablage)

ist.

2

Durch

Drehen

der

Auto-Start-Positions-

Justierschraube

justieren.

Bei

Absenken

des

Tonarms

zu

weit

innen:

Die

Justierschraube

im

Uhrzeigersinn

drehen.

Bei

Absenken

des

Tonarms

zu

weit

auBen:

Die

Justierschraube

entgegen

dem

Uhrzeigersinn

drehen.

(Gerdterickseite)=——>

_

*Fir

die

Justierung

mu

unbedingt

eine

30

cm-

Platte

verwendet

werden.

Justierschraube

=

Tonarm-lifthdéhe

1

Das

Gerat

so

einstellen,

wie

in

Abb.

1

gezeigt.

2

Den

Netzschalter

auf

ON

stellen

und

die

Starttaste

driicken,

um

den

Tonarm

nach

innen

zu

bewegen.

3

Die

Lifttaste

driicken,

so

da&

der

Abstand

zwischen

der

Tonabnehmer-Nadelspitze

und

der

Fiihrungsschiene

27.7

mm

betragt.

Um

den

Abstand

zu

vergroBern....

die

Justierschraube

entgegen

dem

Uhrzeigersinn

drehen.

Um

den

Abstand

zu

verkleinern....

die

Justierschraube

im

Uhrzeigersinn

drehen.

Tonabnehmer

Justierschraube

Tonarm-Reibungs-

winkel

Das

Gerat

so

einstellen,

wie

in

Abb.

1

gezeigt.

Den

Netzschalter

auf

ON

stellen

und

die

Starttaste

driicken,

um

den

Tonarm

nach

innen

zu

bewegen.

Die

Reibungswinkel-Justierschraube

drehen,

bis

die

Armmitte

mit

der

Justierschraube

V-Kerbe

am

Liftbalken

itbereinstimmt.

Gegenstand

Justiermethode

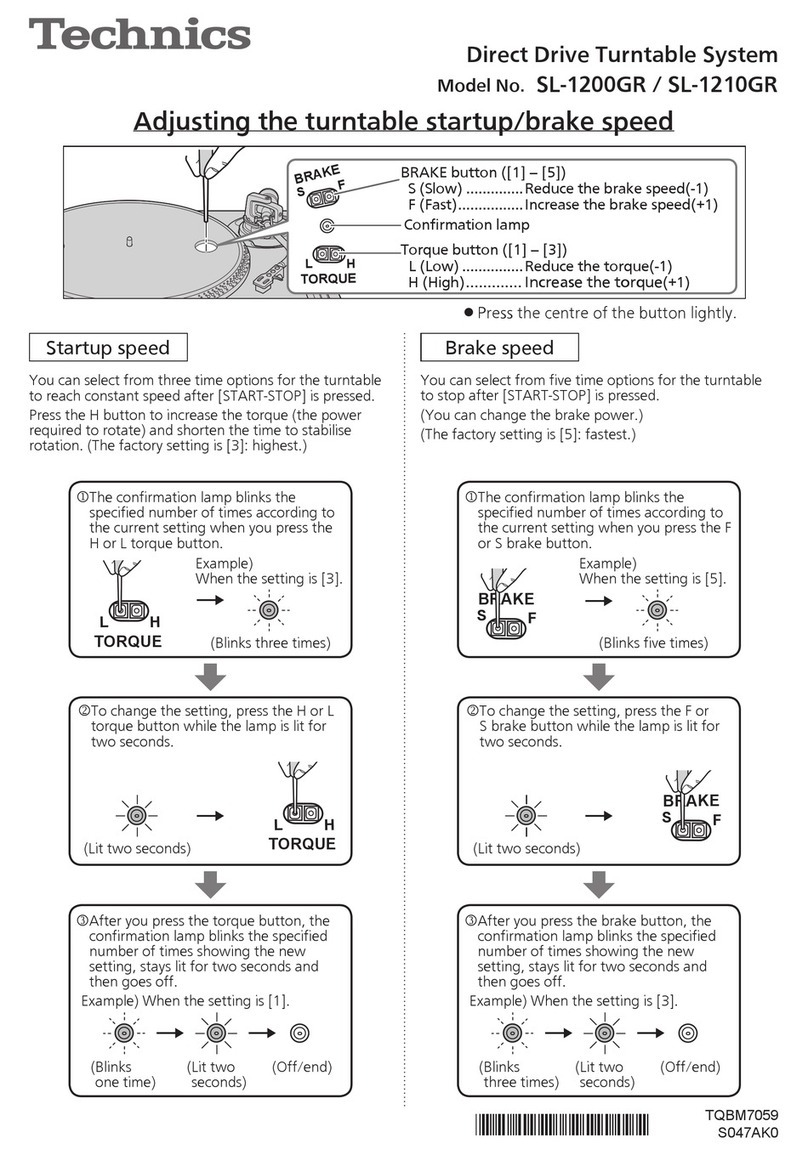

Servo-Verstarkungs-

und

Kompensations-

Spannung

Das

Gerat

so

einstellen,

wie

in

Abb.

1

gezeigt.

Das

elektronische

Gleichstrom-Voltmeter

an

TP315

(Q306)

Basis

oder

Anschlu8

CN301

Stift

2

und

TP3

(Masse).

Den

Netzschalter

auf

ON

stellen

und

die

Starttaste

driicken,

um

den

Tonarm

nach

innen

zu

bewegen.

Den

Tonarm

ganz

nach

rechts

stellen.

VR501

dann

so

einstellen,

da&

die

Spannung

3.6V

betragt.

(Servo-Verstarkungs-Justierung)

Den

Tonarm

in

die

Mitte

stellen

und

iiberpriifen,

da&

die

Ausgangsspannung

1.8V

betragt.

Falls

die

Spannung

nicht

1.8V

betragt,

die

Platinen-Befestigungsschraube

Idsen

und

die

Platine

mit

einem

Schraubenzieher-

nach

links

oder

rechts

bewegen,

bis

die

Ausgangsspannung

1.8V

betragt.

Nach

der

Justierung,

die

Platinen-Befestigungs-

schraube

wieder

festdrehen.

Mitte

(Kompensationsspannungs-Justierung)

(1.8V)

(~~)

Uhrzeigersinn

Platinen-Befestigungsschraube

(3.6V)

>

Schraubenzieher

——,

Entfernen

sie

die

Etikette

DB

[VR501

Zeitgeberfrequenz

Drehzahl

Das

Gerat

so

einstellen,

wie

in

Abb.

1

gezeigt.

Das

Klebband

vom

Gehdauseschalter

entfernen.

Mit

einem

Klemmenkabel

0.4.

TP7

(Q3

Emitter)

mit

TP326

(1C301

Stift

14)

verbinden.

Das

Oszilloskop

oder

den

Frequenzzahler

an

TP316

(1C301

Stift

4)

anschlieBen.

Den

Netzschalter

auf

ON

stellen.

VR301

so

justieren,

da&

der

Ausgangswellenform-

Zyklus

40us

+

2us

betragt.

Ebenfalls

VR301

so

justieren,

da&

die

Ausgangsfrequenz

25

kHz

+

1.25

kHz

betragt.

40us

*

2us

Frequenz:

25

kHz

+

1.25

kHz:

Das

Gerat

so

einstellen,

wie

in

Abb.

1

gezeigt.

VR202

Eine

17

cm-Platte

abspielen.

gee

VR202

drehen,

um

die

Drehzahl

auf

die

Nenndrehzah!

Schneli©

Langsa

zu

justieren

(45

U/min).

Eine

30

cm-Platte

abspielen.

VR201

drehen,

um

die

Drehzahl

auf

die

Nenndrehzahl

zu

justieren

(33-1/3

U/min).

Anmerkung:

Unbedingt

zuerst

45

U/min

justieren.