Micom Autodoor EDM NII Series User manual

EDM NII Series

Control Manual

MICOM AUTODOOR

Automatic Sliding Door Operator

Model: EDM NII Series

(Effective from Lot No. 1206)

Original Instructions

OPERATION MANUAL

(Date: June 2012)

OSAKA –JAPAN

www.micomautodoor.com

EDM NII Series

Control Manual

IMPORTANT NOTICE

Please read these instructions carefully before installing the door operator. We are not

responsible for any loss or damage if these precautions are not followed. The device must be

installed correctly according to the installation and wiring instructions.

During maintenance and installation, the power should be turned OFF.

Please use the correct power supply. Control box accepts 100VAC only.

(Do not connect 220-240VAC directly)

Make sure that the operator is grounded or connected to earth! The coating of the operator is

made of an electrically conductive metallic material, which will easily induce electrical conduction!

Make sure the ground or earth wire is connected!

The operator housing is not completely sealed, therefore it should be noted that excessive

moisture or a corrosive atmosphere could destroy the electronic components contained within.

Do not attempt to modify, repair, or alter any parts within the control box. Do not remove screws

and bolts from the internal structure of the Control Unit. The failure to comply will result in loss of

warranty.

Installation and maintenance of this product can be performed by MICOM authorized technician or

personnel only.

Before switching ON the power supply, make sure that no objects obstruct the travel of the

automatic doors.

Ensure door travel area is clear before switching power switch ON. Failure to comply may cause

incorrect operation.

Do not switch off power supply whilst door(s) is in motion. Failure to comply could result in death

or serious injury.

Take special care of finger entrapment when used as manual slide door with mains power off.

Failure to comply may cause a finger trap hazard.

Operation speeds should comply to relevant standards

Do not obstruct door movement. This could result in stalling the door operation, due to our

overload protection feature. To re-start, power Off / On is necessary.

Follow all indicated instructions, as improper installation could cause severe damage.

Please keep these instructions.

EDM NII Series

Control Manual

W

a

r

n

i

n

g

C

a

u

t

i

o

n

IMPORTANT SAFETY NOTICE!!!

When the door starts for the first time, it will automatically perform a series of opening and

closing cycles (normally between 3 to 5 times) –Known as ‘teaching’or ‘self-learning’mode.

Please note these learning cycles are performed at LOW speed.

Keep clear of the entrance and doors. Ensure that no pedestrians pass through the doors

during initial learning, installation or maintenance. Keep clear of doors when opening or

closing during learning. It is advisable to identify and restrict the area with warning signs.

EDM NII Series

Control Manual

Contents

No.

Section

Page

1

Identifying Control Box Features and Modes

5

1.1

Main Control Box NII Series

5

1.2

Switching: Operation mode and Initialization

6

2

Requirements

7

3

Executing Self learning cycle (TEACHING)

7

4

Control Box settings 1 (Hardware settings by switches)

8

4,1

Setting for open direction

8

5

Control Box settings 2 (Software settings for internal parameters)

9

5.1

Basic Settings

9

5.1.1

Hold Open time

9

5.1.2

Opening/Closing Speed

9

5.1.3

Opening/Closing Cushion (Low) Speed

9

5.1.4

Opening/Closing Break Force

9

5.1.5

Opening/Closing Force (Torque)

9

5.1.6

Pressing Force

9

5.1.7

Partial Open (Half Open)

10

5.1.8

Teaching Stroke

10

5.1.9

Other Function Use

10

5.2

Applied Settings

11

5.3

LED display –How to operate, read and change settings

12

5.4

Parameter List

14

5.4.1

Basic settings Code table

14

5.4.2

Application Code setting group 1 (d codes) table

15

5.4.3

Application code setting group 2 (P codes) table

17

5.4.4

Error code (E codes)

19

6

Extended functions

20

6.1

Description of signal of OUT board

20

6.2

Description of signals of I/O board

21

6.3

Signal layout on the extension boards

22

6.4

Corresponding table between Board address and DIP switch

22

7

Adjustment of sensor

22

8

Checking Operation

23

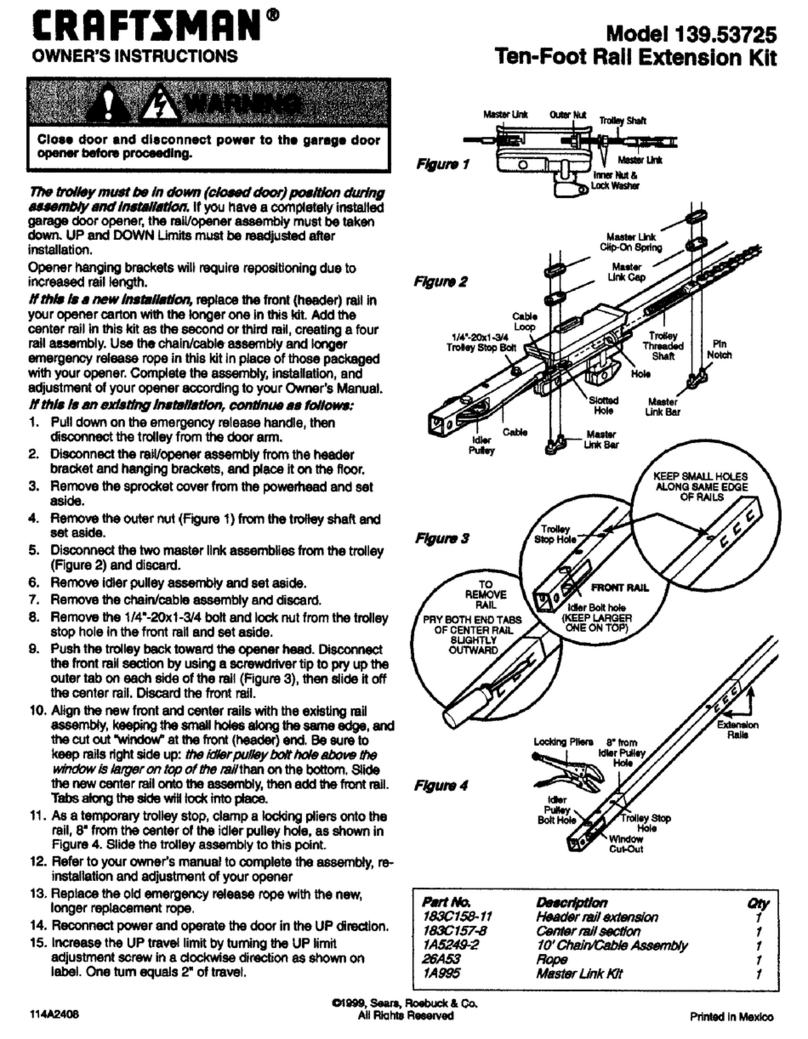

1. Identifying Control Box Features and Modes.

1-1 Main Control Box NII Series

1

Green LED (Light Emitted Diode)

1. Power indicator

2. When in ‘program mode’ – Green LED flashes

6

LED Indicator of Extension Board (If included)

Green: Input-Output board / Red: Output board

2

Red LED (Light Emitted Diode)

1. Sensor indicator / activation

2. Program setting. Application ON/OFF indicator

7

Run / Program Switch

Change into Program mode from Run Mode.

*Additional operation required

3

2P connector - Factory test use only.

8

Test Button / Pass Button - When switched to:

Rum mode: Activation Signal for Test open cycle

Program mode: Changes current setting code or value

4

LED DISPLAY (LED 1 & 2) –When switched to:

Run mode: Displays Cycle Counter (Stepped in 10,000 Cycles)

Program mode: Displays Setting code and Value

* During start up: Displays optional extension board number, if included

* In case of Error: Displays Error code

9

SET button –When switched to:

Program mode: Change or accept setting value

Run mode: Press and hold for 5 sec. Full Cycle counter will

appear

5

Buzzer

If Buzzer setting is ON will beep to indicate: Error, Emergency open or close

mode, Battery operation mode. (ref. d0 setting code)

10

DIP switch

Switch1: Setting for open direction (Do not adjust Switch 2 & 3)

Switch2&3: Must be in OFF position (Factory test use only)

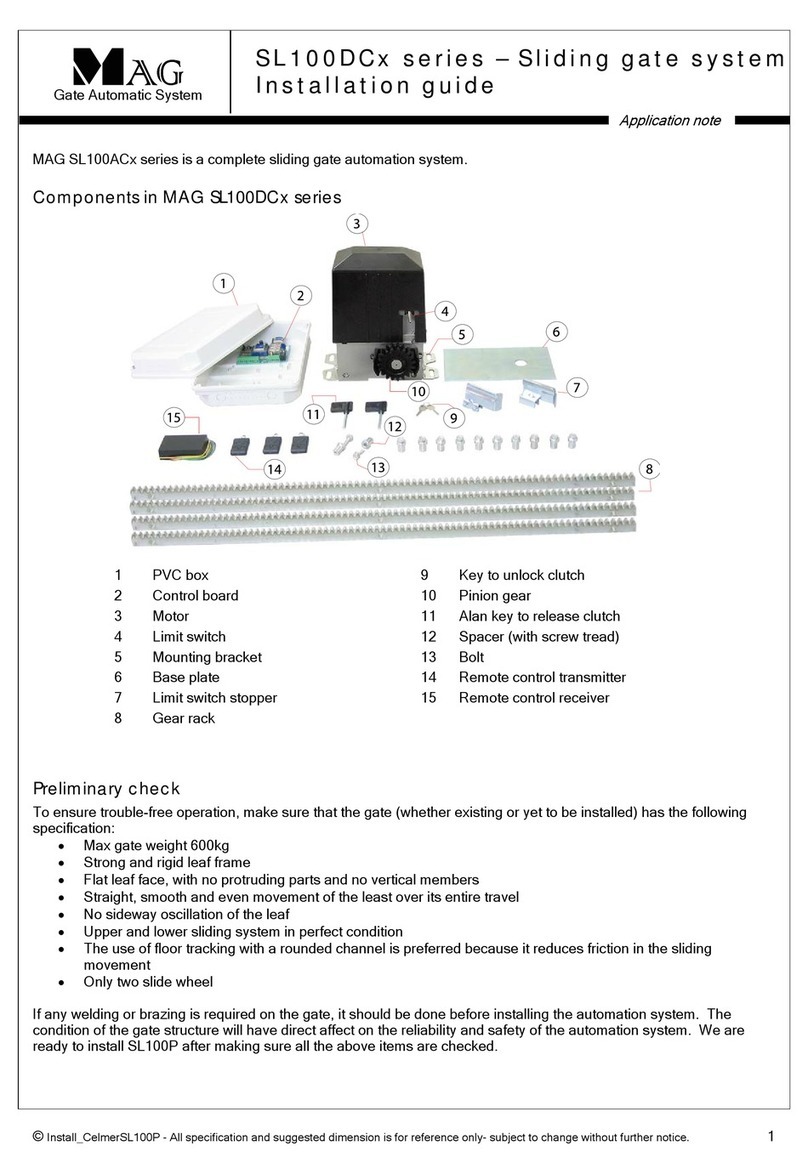

PROGRAM MODE

CHECK MODE

RUN MODE

Push and hold the SET button.

Change the slide switch to PROGRAM.

Change the slide switch to PROGARM

Change the slide switch to RUN

RUN

PROGRAM

RUN

PROGRAM

SET

PASS

PUSH & HOLD

RUN

PROGRAM

1-2 Switching: Operation mode and Initialization.

Run mode

In this mode the door moves normally.

Check mode

In this mode you can confirm the current settings of parameter. However you cannot change

settings.

Program mode

In this mode you can confirm and change current settings and values. Reset to factory default

settings is also available.

Reset Operation (Factory Default Reset)

If you change some settings by mistake and the door does not move correctly, it is easy to recover

to factory default settings by reset operation.

If you execute reset operation, default factory settings will be reloaded, except for special setting

code “C”, which is included within the basic code group.

At the same time, door stroke data (teaching) is cleared from the memory. Therefore it will be

necessary for the control to relearn the door stroke. A self learning (teaching) operation will

automatically commence after the run mode is selected again. Re-adjustment of settings may be

necessary after reset operation.

If the door weight or door stroke are changed, reset is also required.

How to execute Reset Operation (Factory Default Reset).

Holding both PASS and SET buttons while in Program mode. A beep sound will indicate reset is

successful. (Hold for approx 5 seconds)

2. Installation Requirements –ENSURE:

All components have been installed correctly in accordance with the installation manual and all

wiring has been connected referring to EDM NII Series wiring drawings. (except main cover and

activator on the main cover)

The door should be easily moved open and closed by hand without abnormal sounds.

Confirm that wires and cables do not touch moving components such as belt or hanger roller

assembly.

Run / Program mode selecting switch should be set in ‘Run’ position to execute the teaching

operation.

3. Executing Self learning cycle (TEACHING)

Self learning cycle is executed after installation by turning the mains power switch ON for the first

time. The door will close (*1) to the full closed position, then open automatically (*2) at slow speed.

When the door has reached to the full open position, the first stage of the teaching cycle is complete

and the door will start to close at normal speed.

Activate the sensor and check the door will open smoothly. Here, the breaking position is located at

the center of doorway is automatically calculated. After a few cycles, the operator will optimize the

braking point taking into consideration operating speed, breaking force and door weight.

Teaching data such as the door stroke and braking position will be stored within the control unit,

even if the mains power is OFF.

Once the mains power is turned ON, the stored data will be reloaded when the door reaches the

fully closed or open end position.

Motor torque value during teaching mode will be the same as factory default values. Or if

re-teaching, will be the same as basic setting code values held within the memory. For max torque

when teaching switch application code ‘dL’ OFF.

(*1) If the door does not close, check Red LED (sensor indicator) is ON. If Red LED is ON, this means

there is an activation signal being received. Once reaching the full open position, after the sensor

signal is off and the hold open time is complete, the door will close and return to full closed position.

(*2) If teaching stroke setting (Basic Setting Code ‘b’) is changed from factory default setting. The

teaching function will not be automatic. It is required to be activated by a sensor or test button, after

door has reached full closed position. The door will open at programmed teaching speed. On

Activation of sensor before fully closed, the door will re-open at slow speed.

4. Control Box settings 1 (Hardware settings by switches)

4-1 Setting for open direction

Door open direction is set by a DIP Switch on the Control Box (CB).

DIP Switch 1 is for determination of open direction. As shown.

DIP Switch 2 and 3 shall be in OFF position.

SW

1

2

3

ON(Up)

LEFT

OFF(Down)

RIGHT

DOUBLE

Shall be in off position

*To confirm change of opening direction –Mains Power OFF / ON is necessary.

5. Control Box settings 2 (Software settings for internal parameters)

For standard doors it is possible to operate with default settings. A standard door is a single leaf door

that weights approx 45kg to 90kg. However attention must be paid to the DIP Switch setting for open

direction.

Heavier door(s) that exceed standard doorlimits in weight and size will require adjustment of parameters

in order to optimize door operation.

5-1 Basic Settings

According to door operation requirements, door parameters can be changed as follows:

5-1-1 Hold Open time Basic setting code (LED1) ‘0’

Hold open time is adjusted in 16 steps from ‘0 to F’, by basic setting code ‘0’.

Value

0

1

2

3

4

5

6

7

8

9

A

b

C

d

E

F

time(sec)

0

1

2

3

4

5

6

7

8

9

10

20

30

40

50

60

5-1-2 Opening/Closing Speed Basic setting code (LED1) ‘1&5’

Opening speed is adjusted in 16 steps from ‘0 to F’ by basic setting code ‘1’.

Closing speed is adjusted in 16 steps from ‘0 to F’ by basic setting code ‘5’.

5-1-3 Opening/Closing Cushion (Low) Speed Basic setting code (LED1) ‘2&6’

Opening cushion (low) speed is adjusted in 16 steps from ‘0 to F’ by basic setting code ‘2’.

Closing cushion (low) speed is adjusted in 16 steps from ‘0 to F’ by basic setting code ‘6’.

5-1-4 Opening/Closing Break Force Basic setting code (LED1) ‘3&7’

Opening break force is adjusted in 10 steps from ‘0 to 9’ by basic setting code ‘3’.

Closing break force is adjusted in 10 steps from ‘0 to 9’ by basic setting code ‘7’.

*As default break force is set for light weight doors and/or single leaf door, check and confirmthat the

break force is correct for your door(s).

5-1-5 Opening/Closing Force (Torque) Basic setting code (LED1) ‘4&8’

Opening force is adjusted in 10 steps from ‘0 to 9’ by basic setting code ‘4’.

Closing force is adjusted in 10 steps from ‘0 to 9’ by basic setting code ‘8’.

*If using narrow and/or light weight door(s). To prevent jumping when the doors start to move, set

Open/Close Force (torque) value lower. Normal doors require setting minimum ‘3’ and above.

5-1-6 Pressing Force Basic setting code (LED1) ‘9’

Pressing force is adjusted in 5 steps from ‘0 to 4’ by basic setting code ‘9’.

If you select 0, pressing function is disabled. (No pressing force)

5-1-7 Partial Open (Half Open) Basic setting code (LED1) ‘A’

Partial open is defined by a percentage of the full open width as shown in the chart below.

Partial open operation is related to setting ‘d/7’ of the applied setting group 1(d codes).

Value

0

1

2

3

4

5

6

7

8

9

Width

(%)

12.5

25

37.5

50

62.5

75

87.5

93

95

98

Fix mode only

If you set ‘d/7’ OFF (AUTO) (Default Setting), upon the door being held open by heavy traffic, the partial

open position will change to full open position automatically.

If you set ‘d/7’ ON (FIX), the partial open setting will not to change to full open.

If you select partial open width to setting 7, 8 or 9, automatic full open function is disabled, to prevent a

finger trap hazard.

5-1-8 Teaching Stroke Basic setting code (LED1) ‘b’

Changing Teaching Stroke from default setting: Please note there is no need to change from the

default factory setting.

It is possible to set the teaching length value from 1 to 9. This corresponds to the length of travel, which

will be at full speed.

If you set at ‘1’ or higher, the door will open at normal speed, performing the teaching stroke. Note that

the teaching stroke MUST not exceed more than 70% of total door stroke.

If you set at ‘0’ (default), the door will move a low speed until the teaching stroke is complete.

(Generally the teaching stoke is only required once during set up or after adjustment).

Value

0

1

2

3

4

5

6

7

8

9

Teaching

Stroke(cm)

0

ALL

SLOW

30

60

90

120

150

180

210

300

400

5-1-9 Special Function Use Basic setting code (LED1) ‘C’

C-0 = ES - Emergency Stop (Factory Default).

In case an emergency signal is received, the control will immediately stop the door in any position. This

can also be used and applied to breakout mechanisms. Upon turning off ES signal, the door will return

to closed position.

C-1 = H1 - Heavy Door / Resistance.

H1 setting allows the user to utilize EDM NII for cold room applications and/or heavy doors. This is

particularly useful in case of cold room doors. H1 will delay registering an E1/E2 Error for 2.5sec after

activation. This gives time to for the movement of heavy doors to begin. Unlike lighter doors whereby

E1/E2 will be registered if there is no movement 0.5sec from activation.

C-3 = EMS - Battery Back Up.

EMS Battery back-up allows normal operation (open/close) for as long as the battery has charge. Open

and close speed are steady, however speed may be affected.

C-7 = PS - Panic Signal.

Panic Signal once activated, overrides any another signal and will reverse the door to full open from

any position. Panic Signal is commonly used in case of Fire Alarm input or together with our battery

system.

C-8 = RS - Ratchet Function.

Ratchet Function (Flip-Flop) allows the user to operate the door by pressing an activation button once

to open the door. The door will not close and remain in the hold open positions for an infinite amount of

time. The user can close the door by pressing the activation button again, and then the door will return

to the closed position.

C-9 = AS - Side Screen Safety Function.

Side Screen safety input allows the use of additional sensors to protect the area in front of the door/s

leading edge when opening. For example, following activation of the main sensor (SS), the door will

begin to open. Upon a pedestrian standing in front of the leading edge, a sensor mounted above this

area, called side screen safety (AS) will be activated. SS and AS signals are now both ON, the door will

creep at low speed until the AS input goes OFF. Once AS is OFF, the door will resume normal opening

speed.

C-A = HS –Half Open Function.

HS is a special half open function used as a standalone half open signal, for use in factory locations for

example. HS is used when you need to combine Full Open and Half Open functions. In case a large

cargo is to pass through a large entrance, the doors are operated by SS signal. This gives full open.

Incase pedestrian are to pass through the same entrance, use of a push button connected to HS can

be used and the door will open partially, in order to allow pedestrians through without opening fully.

Standard Half open HO signal is independent of HS signal.

5-2 Applied Settings

Changing applied setting might be helpful for some special operation applications

To use applied settings, NII-G (I/O Board –Input/ Output) or NII-R (Output Board) type control box may

be required in some cases. Please enquiry for more details.

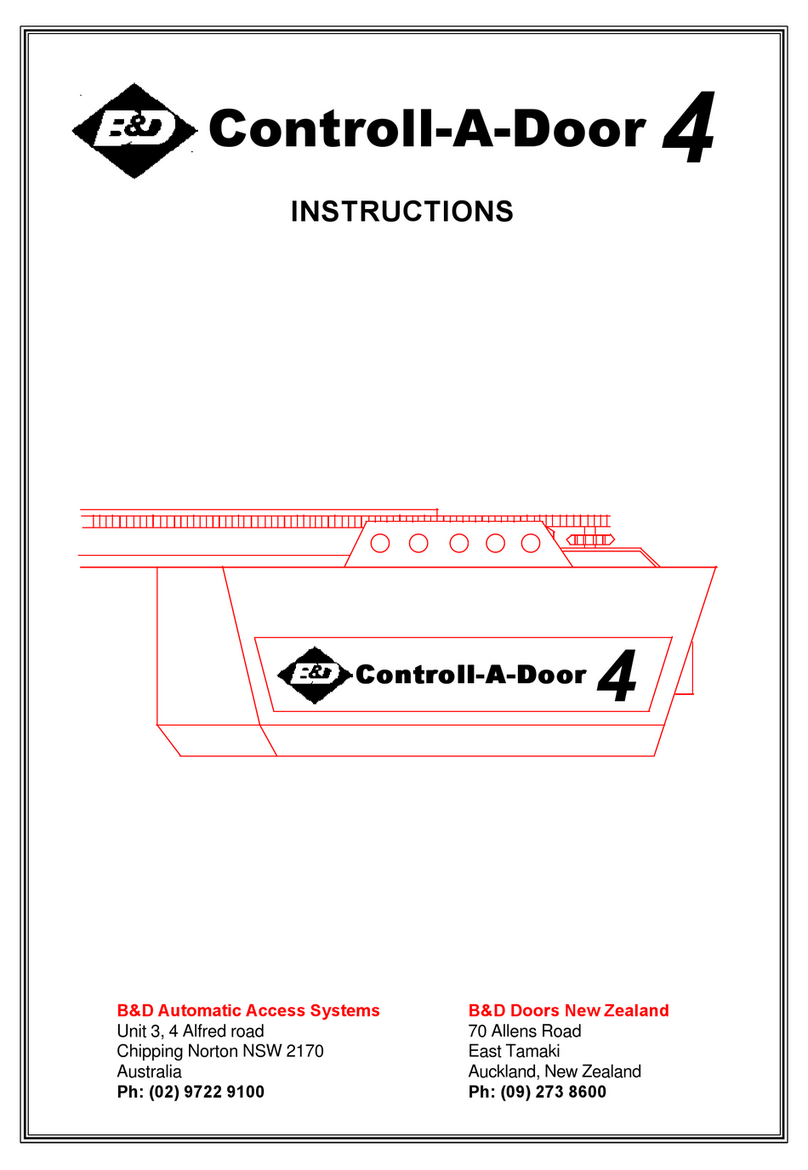

blink

PASS

PASS

Pass

Pass

Open Time

Open High

Speed

Red LED

(Value)

Each function

will be active

when LED is ON.

Red LED

Pass

Buzzer

Pass

Red

LED

Red

LED

Teaching

Error

Indicator shows how many

times errors have

occurred (error counter)

after Error code.

Above example shows E0

(teaching) Error has

occurred 19 times.

Normal operation Error (Indicates Error which has just happened)

1. The LED indicator shows number of open

cycles (door open counter) from 10

thousand to 990 thousand, except when

the door is at full opened position.

2. This example indicates the door has

opened more than 230 times.

3. A decimal point appears continuously

when the door counter exceeds one

million.

Error Counter Indicator

1. Indicator shows the error code and

it's counter.

2. The value of each error is from

0000 to 9999.

(Maximum value is 9999)

This above example shows when E0 error

is happening and total counter of this

E0 error is 132 times.

Electro

Special

Setting

Setting Code

(0~C) Value

Setting

Code

Value

Indication order

Error counter

(Upper 2 digit)

Error code

Error counter

(Lower 2 digit)

Pass

Internal

Reset

Error history (counter)

d0-dL

OFF&ON

Basic setting group Applied setting group1

(on/off setting)

Open Counter

1

0

C

d0

d3

E0

E9

Error Indication

Return to basic

settings

same as

above

SET

SET

SET

SET

SET

SET

SensitivityP1

Application Code group 2

(Japanese Only - Except PE)

PASS

Red LED will glow

if changed from

default setting

This above example shows open counter

value at 1,234,567 cycles

Depress and holding

the SET button.

*Red LED is same as

Sensor Indicator

Setting

Code

Value

same as

above

same as

above

SET

Note: Only during program mode,

set button is active.

Error

Code

Error Counter

4. The LED Display will turn OFF 2

minutes after the door is closed.

5. The total number of door cycles can be

read by depressing SET button and

holding. LED display will indicate "oP"

followed by number of open cycles.

Decimal point.

RUN Mode Check mode, Program mode

5-3 LED display –How to operate, read and change settings

Thousand times.

IMPORTANT NOTES –MOTOR PROTECTION: NII Control Box will now find the error and stop the motor by

itself to prevent overheating of the motor by overload.

Previous to this NII Control Box version, if Error E1 (Opening Safety) or E2 (Closing Safety) happened

continuously, the control box would register an E0 Error. Should E1 or E2 Error continue to happen and not

be resolved, an E0 Error would register 5 times in a row, at which point the Control Box would stop the motor.

An E0 Error would be shown on the LED display and the door would be in a failsafe stopped position.

With this New Control Box version, it will now stop the motor when an E1 or E2 Error happens 5 times in a

row. This is for added protect of the motor. Please note an E0 Error will no longer be applicable to this type of

overload situation.

IMPORTANT - To return back to normal operation:

1. To recycle the doors and reset Error protection (failsafe mode) switch mains power Off/On.

2. Please look to solve the cause of error. E1 and E2 Errors are mainly resolved by reducing the physical

resistance on the door. Note the door must run freely and easily.

Doors should be easy to push open by hand. Travel must be smooth and without noise.

Previous to this NII Control Box version, incase teaching distance is less than 150mm, an E0 Error would be

registered automatically, this would be added to other continuous E0 Errors and the motor would continue to

operate.

With this New Control Box version at the first E0 error, the door would assume in a failsafe stopped position.

Just in case rollers are not sitting on the rail correctly.

This motor protection features is always activated.

When the motor stops, green and red LED blinks at the same time

Buzzer for error notice can be used when switching Application Code setting ‘d0’ on.

5-4 Parameter List

5-4-1 Basic settings Code table

Code

Parameter names

LED Indicator

Setting Range

LED1

Code

LED2

Value

Min

max

0

Hold Open Time

0

1

0

F*

1

Open High Speed

1

9

0

F*

2

Open Low Speed

2

5

0

F*

3

Open Break Force

3

4

0

9

4

Open Force

4

4

0

9

5

Close High Speed

5

5

0

F*

6

Close Low Speed

6

4

0

F*

7

Close Break Force

7

4

0

9

8

Close Force

8

4

0

9

9

Pressing Force

9

1

0

4

A

Partial open width

A

3

0

9

B

Teaching stroke

b

0

0

9

C

Special settings

C

0

0: ES Standard

1: H1 (Cold Room)

3: EMS

7: PS

8: RS

9: AS

A: HS

Select only to the number

shown for input function.

Default

Setting

*Note; The value follow in sequence from 0 to F. ( 0,1,2,3,4,5,6,7,8,9,A,B,C,D,E,F)

5-4-2 Application Code setting group 1 (d codes) table

This group contains setting parameters, which are either ON or OFF.

NEW –Function Added

Memorizing Application Code Settings –Application Code Setting can be retained after any control box reset.

(Previously, application code settings were also returned to default settings after a control box reset.)

See Application Code ‘dP’ to retain Applications Code Settings.

CODE

INDICATION

Parameter name

DESCRIPTION

LED 4 (RED)

LED 1

LED 2

ON

OFF*

d

0

BUZZER

Set ON when you need buzzer sound, in case of error,

battery operation or PS operation.

ON

OFF

d

1

CLOSE BRAKING

POSITION

Set ON (150mm) if you need a wider cushion / low

speed travel range before fully closed.

150mm

70mm

d

2*

18 / 30 MODE

(AUTO)

Setting Automatically when the motor for EDM30NII is

connected.

30

18

d

3

ELECTROMAGNETIC

LOCK

Setting ON Automatically if an Electromagnetic Lock is

detected. Set to OFF when the Electromagnetic Lock is

NOT connected.

YES

NO

d

4

BATTERY SYSTEM

(Emergency system)

Set on with Battery Close system (BC) or

Set on when you need to CLOSE by Panic Signal (PS).

BC

BO

d

5

OPEN PRESSING

Set ON if you do not need pressing force at full open.

NO

YES

d

6*

CLOSE PRESSING

(Vibration detected)

Set ON if the motor generates vibration at closed

position.

Closing press will be cut off only when vibration

detected.

Set OFF. Always closing press at full close.

YES &

NO

YES

d

7

HALF OPEN mode

(Partial open)

Set ON if you do NOT wish partial open to go to full

open automatically.

FIX

AUTO

d

8

RS –Hold Open

Ratchet Switch

New Function - If SB is ON during closing, the door will

re-open and remain open in Ratchet (RS). To close,

switch (RS) must be activated again. Set ON to Hold

Open after SB.

ON

OFF

d

9

SB FUNCTION ON

CLOSE END

Set on if you need to open by SB signal when the door

fully closed.

YES

NO

d

A

SELF CLOSING

DEVICE

(Mechanical open

device)

Set ON if mechanical self closing device is fitted (Japan

Only)

YES

NO

d

B

SAFETY FUNCTION

(When obstruction)

Set OFF in case of an obstacle during the closing travel,

the door stops and RETURNS to full open.

Set ON if you do not want the door to RETURN. Just

STOP

STOP

RETUR

N

d

C

RS FUNCTION

DURING OPENING

(Special Ratchet

Function)

Set ON for RS signal to release door at hold open. RS is

not accepted during the open travel for safety reason.

Set OFF (yes) if you allow RS signal during opening

travel.

YES

NO

d

D

INTER-LOCK

Dual door connection and control (Japan Only)

YES

NO

d

E

Hold Open

(Push Button)

Activation by Push Button only. If SB is ON during

closing, the door will re-open. The door will hold open

and only close with a Push Button (SS & G) activation.

(Door will not close after set open time).

YES

NO

d

F

AS FUNCTION

(Side Screen Safety)

DOOR: AS signal only accepted during opening cycle

On AS activation, door moves slowly.

FIX: AS signal only accepted in Door Closed or Full

open position. Door will not move. While door is moving

AS signal ignored

For AS signal –Setting C-9 must be selected.

DOOR

FIX

d

H

DOOR PRESS

WHEN ES

Set OFF in case breakout / panic door is in use with ES

signal. (Stop after break out)

Set ON if door press function is required with ES signal.

(continue to full open after break out)

ON

OFF

d

J

LOW SPEED WHEN

POWER ON

Set ON if the speed during the teaching cycle is too fast.

PROGR

AMED

MAX

d

L

TORQUE WHEN

POWER ON

Increase the programmed torque power or Set ON if the

door force during the teaching cycle is not strong

enough.

PROGR

AMED

MAX

d

P

Retain Application

Code Settings after

Reset to Default Values

Set ON to retain Application Code settings after manual

reset to default values. Note: d3 is reset to ‘NO’.

ON

OFF

Warning: Adjustment of parameter should only be carried out an authorized representative. Parameters

should not be changed unless the person performing the change understands the operation of the product.

Otherwise the door may not operate correctly after adjustment.

All parameter are OFF (factory default settings). Only dL is now ON from Lot 1206.

5-4-3 Application code setting group 2 (P codes) table

Note: Setting P1 to Pd & PF are for Japanese domestic use and not required to be employed out side

of Japan. The full range of P codes are available, however only PE code is only NECESSARY to be

utilized when required.

We recommend NOT changing these parameters unless advised to do so. They are for special use,

except in the case of PE code, which changes Normal Open Contacts to Normal Close Contacts.

CODE INDICATION

Description

CODE

SETTING

P1

00~60

Error detection threshold during high speed opening cycle

P2

00~60

Error detection threshold during low speed opening cycle

P3

00~50

Low speed travel range during opening cycle.

P4

0.3~2.5

Start opening error detection time

P5

00~50

Error detection threshold during high speed closing cycle

P6

00~10

Error detection threshold during low speed closing cycle

P7

00~50

Low speed travel range during closing cycle.

P8

0.3~2.5

Start closing error detection time

Pb

0.0~1.0

Door opening delay time

PC

02~30

Activation signal delay time

Pd

00~50

Error detection threshold by obstacle size during closing cycle

PE

00~0F

NO, NC SELECTION (SEE CHART BELOW)

PF

00~09

Before closing warning signal time

PH

00-05

Breaking & Stop Movement –Time before Low Speed after breaking

PJ

02-04

Interval of Door Speed Checking (02=0.2sec / 04=0.4sec)

Setting PH-00 & PJ-02 –Door movement from breaking to low speed is very

smooth

Setting PH-05 & PJ-04 - Door movement from breaking to low speed is very

sudden. (Door Stop –Low Speed)

PL

00--02

Open Pressing Power

If you change from default setting the parameter of P code, the RED LED is turned to ON.

PE Code: NO or NC SELECTION CHART (Blank columns - NO contact)

CODE

SETTING

AS

SB

PS

ES

CODE

SETTING

AS

SB

PS

ES

PE

00

PE

08

NC

PE

01

NC

PE

09

NC

NC

PE

02

NC

PE

0A

NC

NC

PE

03

NC

NC

PE

0b

NC

NC

NC

PE

04

NC

PE

0C

NC

NC

PE

05

NC

NC

PE

0D

NC

NC

NC

PE

06

NC

NC

PE

0E

NC

NC

NC

PE

07

NC

NC

NC

PE

0F

NC

NC

NC

NC

5-4-4 Error code (E codes)

Code

indication

Error Name

(Buzzer sound pattern )

Troubleshoot

(Possible Causes, Description, Remedy)

E0

Failed teaching

(─ ─ ─ long sound only and

no short sound)

Door travel distance during teaching cycle is too short.

(less than 150mm)

Door speed and/or braking force do not match the door

weight (Increase breaking force or reduce operating speed)

Obstructed during teaching cycle.

Teaching stroke setting (Basic code setting “b”) is wrong.

Wire connection problem or hardware problem.

(Change the controller and/or motor)

Note: Operational stop after x1 times E0 error occurs.

During operational stop, both GREEN & RED LED flash.

(With Buzzer sound –if switched ON). To recover, confirm

the door is not locked. Switch mains power OFF and ON.

Re-teach will be performed.

E1

Open error

(・─・─・─ 1 short sound between

long sounds)

Obstruction during the opening cycle.

Door is physically locked.

E2

Close error

(・・─・・─・・ 2 short sound between

long sounds)

Obstruction during the closing cycle.

E3

INTER-LOCK

(・・・─・・・─ 3)

Inter Lock system failure

E4

LOOSE BELT

(・・・・─・・・・ 4)

Obstruction during teaching cycle just after Power on.

Door is physically locked.

Loose belt.

E5

BROKEN BELT

(・・・・・─ 5)

Broken belt

E6

Electro Magnetic Lock

(・・・・・・─ 6)

Wrong setting on control box –Check: Lock or no Lock

Lock pin dose not move properly

Check wiring of lock cables

E7

No. of Times Battery and emergency

operation

(・・・・・・・─ 7)

Not error - Battery operation or PS signal is activated.

E8

Times of power on

Not error - Number of power on

E9

Internal reset times

Not error - Number of internal software reset (Usually

almost equal to values in E8)

EA

Internal interference

Error from inside the control box such as interference from

heavy noise.

Code

indication

Error Name

(Buzzer sound pattern )

Troubleshoot

(Possible Causes, Description, Remedy)

Eb

Wrong setting of DIP switch

DIP switch 3 is in wrong position. (No counter of error

history)

EC

Over load

Door resistance is increased from initial installation. -

Confirm and clear / reduce the door resistance. (should be

easy to push by hand)

In case this error occurs, the hold open timer changes

internally to 30 seconds.

Display will only show this error only when the EC error is

currently occurring.

(No counter of Error history)

Error counter will appear after error codes displayed. See section 5-3.

6. Extended functions

Optional functions are available with NII-R type controller which includes an extension board named

OUT board, or with NII-G type controller which includes another extension board named I/O board.

Each board has a unique board address setting (by DIP switch), which means you can select each

signal function.

6-1 Description of signal of OUT board

Board

address

Signal name

symbol

(Common side)

Description

0

Default

Opening

OPN (CO)

Output during opening motion

Closing

CLS (CC)

Output during closing motion

Stop

STP (CS)

Output if door stopped (excluding full open/closing)

Half-OPening

HOP (CH)

Output during half-opening motion

1

WArning

WA (CW)

Output before starting to close

ERRor

ERR (CER)

Output when an error occurs (until restored)

Open End

OE (COE)

Output at a fully open condition

(same as OA on the I/O board)

Close End

CE (CCE)

Output at a fully closed condition

(same as CA on the I/O board)

2

Safty Beam

SBO (CSB)

Output while photocell is being detected

UnLock

UL (CUL)

Output showing that an electric lock is unlocked

Table of contents

Other Micom Autodoor Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

TRADEDOR

TRADEDOR TD55DM installation guide

Automatic Technology Australia

Automatic Technology Australia EasyRoller GDO-4 Installation instructions and owner's manual

Chamberlain

Chamberlain MotorLift500 instructions

Anaheim Automation

Anaheim Automation Security+ 3850AD owner's manual

Genie

Genie IntelliG 1200 Product guide

BFT

BFT deimos ultra bt a 400 Installation and user manual