Micro-Aide VDL S7?300 User manual

EVENT RECORDERS ALARM REPORTERS DATA LOGGERS

CLOCK SYNCHRONIZERS CURRENT SENSORS VOLTAGE MONITORS

BATTERY MONITORS LIGHT OUT DETECTORS CUSTOM ENGINEERING

Rail Signal Products

MICRO-AIDE

USER M ANUAL

VDL

SIEMENS S7-300

DATA LOGGER

CD inside contains

the latest User Manuals

and firmware

VDL S7‑300

Data Logger

USer ManUaL

Rail Signal PRoductS

Micro‑Aide

www.micro‑aide.com

Micro‑Aide corporAtion Tel: 626‑915‑5502 Fax: 626‑331‑9484 E‑mail: support@micro‑aide.com

685 Arrow Grand Circle Covina, CA 91722

Revised: July 29, 2014

Copyright©2008 by MICRO‑AIDE Corporation

All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means without the

written permission of MICRO‑AIDE Corporation.

The information in this document is subject to change without notice. MICRO‑AIDE believes the information contained in

this document to be accurate. However, MICRO‑AIDE assumes no responsibility for any errors or omissions.

Windows, Windows XP, Windows 7, Excel, Access, Notepad and Word are registered trademarks of Microsoft Corporation.

HyperTerminal is a registered trademark of Hilgraeve Inc.

Ethernet is a registered trademark of Xerox Corporation.

iiiMicro‑Aid e

TC

tabLe of ContentS

Chapter 1 – generaL DeSCription

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Key Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Comparing the VDL S7‑300 and CWR‑24E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Firmware Modification History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup Database Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

About this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 – inStaLLation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Initial Check‑Out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Peripheral Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

USB Device Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terminal Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Vital‑Processor Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ethernet Port (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Internal Modem (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

GPS Receiver (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Alarm Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Input Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting to the Siemens S7‑300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3 – SetUp

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Logging On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

User Interface Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fields and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Working with Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Completing Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Data Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

VDL S7‑300 USer ManUaL

iv Micro‑Aid e

TC

Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setup (S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Time / Date (T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reset System (R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

System Parameters (S). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Analog Configuration (A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Timer Inputs (W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Event Names (E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Input Names / Identifiers (I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Virtual Inputs (V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Network (N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Print Setup Data (P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transfer Files (T). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Download Setup Data (D) ‑ Saving the Database . . . . . . . . . . . . . . . . . . . . . . 34

Upload Setup Data (U) ‑ Restoring the Database . . . . . . . . . . . . . . . . . . . . . . .35

Log Off (X) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 4 – operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Multi‑User Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Establishing an Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Establishing a Modem Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Logging On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

How to Operate the VDL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Query Events (Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Selecting a Single Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Selecting a Range of Dates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Query Report Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

View Events (V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Include Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Live Status (L). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Event Record Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

No Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Include Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Symbol Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

CSV Report Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

CSV Sample Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

CSV Input Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Capturing Event Records to a PC File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 5 – front paneL operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

USB Host Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Liquid Crystal Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

tabLe of ContentS

vMicro‑Aid e

TC

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

How to Use the USB Host Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Saving Records to a Flash Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Saving Event Records from a Complete Day . . . . . . . . . . . . . . . . . . . . . . . . .50

Saving Event Records from a Range of Times and Dates. . . . . . . . . . . . . . . . . . .51

Files Written to the Flash Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Events Text File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Events Binary File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Setup Database Binary File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

How to Use the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Event Record Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Browse Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Event Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Input Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Alphanumeric Editing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

TimZone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

CSMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

UName. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

ENames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

INames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Analog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Virtual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

TLimits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PCode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Baud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Diag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

RESET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Chapter 6 – MaintenanCe

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Adjusting the LCD Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Working Inside the Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Replacing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Installing the Optional GPS Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Installing the Optional Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Installing the Optional Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Reconnecting the Internal Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Diagnostic Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Checksum Test Program Memory (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Flash Memory Test (F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

GPS Receiver Test (G) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

VDL S7‑300 USer ManUaL

vi Micro‑Aid e

TC

Ethernet Test (E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Modem Test (M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Keypad Test (K). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Relay Test (R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Temperature (T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

System Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Updating the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Trouble‑Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

appenDix a – teChniCaL Data

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Transfer Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Terminal Port Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

appenDix b – optionS anD aCCeSSorieS

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

appenDix C – USb DeViCe DriVerS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Installing the Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Windows XP Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Windows 7 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Making a USB Device Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

1Micro‑Aid e

1

Chapter 1 – generaL DeSCription

introDUCtion

Since 1988 MICRO‑AIDE has provided the rail signal industry with a broad range of event recording

devices and systems that vary in capacity, size and features. Our considerable expertise in this eld has

also been used to create a highly innovative product referred to as a Vital‑Processor Data Logger (i.e.,

VDL). The VDL is unique in its ability to gather and report event data by communicating directly with a

Programmable Logic Controller (PLC). The VDL does not require wired attachments to spare vital and/

or non‑vital relay points in order to report Digital Input events. Considerable material and labor‑related

expense can be avoided by using the VDL in place of a standalone Event Recorder. Additionally, a user

interested in gathering incident or maintenance data will no longer need to log onto the PLC. Instead,

critical data can be acquired by accessing the VDL which operates strictly as a passive, non‑vital moni‑

toring device.

The VDL can be used with an Ansaldo Microlok II and Siemens S7‑300 controller. The installed rmware

determines which PLC will be monitored. The hardware used by both versions is identical.

This User Manual describes the Siemens S7‑300 version of the VDL. The current version of the Microlok II

and S7‑300 rmware are available for free downloading from the following web page:

www.micro‑aide.com/support/downloads.htm. To be used with a VDL, the Siemens S7‑300 must be

equipped with the CP 340 Communications Processor option.

Like many devices, the VDL utilizes an internal real‑time clock for date and time stamping events.

Historically, these real‑time clocks have been susceptible to drift. Over the course of several months the

accumulated drift can exceed several minutes. This factor can greatly complicate incident investigation

and reporting. However, the VDL eliminates the problems introduced by clock inaccuracy once and for

all. The GPS Receiver option utilizes GPS technology to set the time and date. Alternatively, the Ethernet®

Port option allows the Data Logger to communicate with a LAN‑based time server. Time servers broad‑

cast time and date information using the SNTP protocol. The VDL is designed to support Unicast and

Multicast SNTP messaging. Any of these three methods provide for time stamping that is 100% accurate

and drift‑free without the need for any user intervention.

As a convenience to its user, the VDL can copy Event Records directly to a FAT‑32 formatted ash drive.

The USB Host Port is a standard feature of the Data Logger. Install a ash drive into the unit’s front panel

socket, press a few keypad buttons and in seconds Event Records from any time span are written as a

.txt le. The .txt le can then be read, e‑mailed or printed as required.

Every VDL comes equipped with a built‑in keypad and display screen located on the front panel. This

allows the user to effectively operate the Data Logger without additional peripheral devices. However,

each logger will support applications that require PC‑based storage of Event Records. The logger is

equipped with USB and serial Terminal Ports. It can also be equipped with an optional Ethernet Port.

Collectively they provide for increased exibility when interfacing with the logger. The USB Device and

Ethernet Ports provide high speed data transfer rates of 960 Kbps and 850 Kbps, respectively. A PC is then

used to retrieve, store and review Event Record data of interest to the user.

An optional 33,600 Baud internal modem can also be installed. It too allows the user to remotely access

and operate the Data Logger. A standard phone line connection allows the user to gather critical Event

VDL S7‑300 USer ManUaL

2Micro‑Aid e

1

Records from any location, however distant. The modem can also be used to provide dial‑out alarm

reporting to a maintenance facility.

The VDL is also equipped with four general purpose Analog Inputs. The Analog Inputs can be used to

monitor both DC and AC voltages such as battery levels and commercial power voltages.

Eight Virtual Inputs allow the user to create Event Records based upon a specic logical association of

several Digital, Analog, Timer and other Virtual Inputs. The Virtual Input feature can be very useful in ana‑

lyzing failure conditions or in creating alarm indications. Tedious and confusing site‑specic proles are

not required when using the Virtual Input feature.

Sixteen Timer Inputs can be used to measure and report the elapsed time between any two events. As

an example, the duration of a bit transition, the time between two separate bit events or the occurrence

of an Analog Input event and a bit event can be reported. Additionally, separate High and Low Limit

Values can be assigned for each timer. An event occurrence that is too fast or slow when compared to

the Limit Values is identied in a Timer Input Event Record.

All MICRO‑AIDE rail signal products, including the VDL S7‑300, are designed to be easy to use and main‑

tain. Each design is based upon the premise that value and reliability start with attention to detail and a

concern for usability rather than needless complexity. Our goal in creating the VDL was to provide the

rail signal industry with an instrument maintainers and signal technicians will nd easy to operate long

after the Data Logger has been installed and set up.

Key featUreS

Listed in the following are some of the features included with every VDL S7‑300.

• A serial comm connection to the S7‑300 is used to report events from 999 Digital Inputs.

• No external wiring of Digital Inputs is required.

• Security is improved, as event data is available directly from the VDL without having to log onto the

PLC.

• The USB Host Port allows copying of Event Records to a FAT‑32 formatted ash drive.

• The 960 Kbps USB Device Port can be used in lieu of the serial Terminal Port.

• The optional GPS Receiver allows the logger’s real‑time clock to operate 100% accurately without

any user intervention.

• The optional internal Ethernet Port allows for remote LAN‑based access via a Telnet connection.

• If the LAN includes a time server, the optional Ethernet Port also allows the logger’s real‑time clock to

be precisely controlled using SNTP. Unicast and Multicast protocols are supported.

• Automatic adjustment for Daylight Saving Time (DST) can be enabled or disabled. The DST feature is

in full compliance with the Energy Policy Act of 2005 which took effect in 2007.

• The time zone setting of the logger can be assigned to any of seven zones used in North America.

• The storage capacity is 284,785 Event Records (expandable to 1,182,769).

• Event Records can be logged for 128 distinct days.

• Event Records are stored in ash memory devices that do not require a battery power source.

Records are retained even if power is removed.

• Setup data and Event Record data can be easily and quickly transferred to a PC le.

• Every Event Record includes a measurement for each of four Analog Inputs.

• Analog Inputs can range from 51.1 V (.1 V scale) to 255 V (1 V scale), DC or AC.

Chapter 1 – generaL DeSCription CoMparing the VDL S7‑300 anD CWr‑24e

3Micro‑Aid e

1

• Analog Inputs are tested against separate High and Low Limit Values that are assigned by the user.

Crossing either Limit Value will create an Event Record.

• Events are date and time stamped to the nearest tenth of a second.

• Eight Virtual Inputs can be programmed to create Event Records that identify alarm or fault condi‑

tions of special interest to the user.

• Sixteen Timer Inputs can be used to measure and report intervals between any pair of events.

• Limit Values can be assigned to establish a range of acceptable and unacceptable timed intervals.

• Timer Inputs create Event Records that list the timed interval and its relationship to the programmed

Limit Values.

• Installation is quite simple. Input wires are terminated in detachable, tension clamp terminals. Wire

sizes as large as 12 AWG can be used.

• Maximum power consumption is less than 4 W. A 9 to 36 Vdc power source can be used to power the

logger.

• The internal temperature of the logger is measured and reported.

• The user interface provides full cursor control when using a PC.

• Three distinct levels of password security provide protection against unauthorized access.

• Several diagnostic commands can be executed to verify important system operations.

• Firmware updates can be uploaded to the logger via any port (i.e., Terminal, modem, USB Device or

Ethernet). Additionally, new rmware can be uploaded directly via a USB ash drive.

• MICRO‑AIDE’s GEA (Graphical Event Analyzer) software is fully compatible with the VDL S7‑300. GEA

can be used to poll, save, review, plot and analyze Event Record data.

CoMparing the VDL S7‑300 anD CWr‑24e

Most of the recording features of the CWR‑24E Event Recorder have been included as capabilities of

the VDL S7‑300. The hardware design of the VDL is a specic conguration of the CWR‑24E. Nevertheless,

there are several important distinctions. They have been highlighted in Table 1 on page 3.

Feature VDLS7‑300 CWR‑24E

Digital Inputs 999, via PLC 20, hard wired

RS‑232 Ports Terminal and PLC Serial Port Terminal Port only

Event Record time stamps .1 sec. .001 sec.

Flashing Events not available available

Flash Rate Reporting not available available

Train Speed Monitors not available 4 available

Std. Event Record capacity 284,785 307,123

Table 1: VDL S7‑300 and CWR‑24E Differences

firMWare MoDifiCation hiStory

Features have either been introduced or modied as the result of the following rmware modications.

V1.00 Initial release.

V1.01 A phone line disconnect is performed automatically if the Data Logger does not transmit any data for

ve minutes.

V1.02 Corrected time information associated with Event Records written to USB Host port.

VDL S7‑300 USer ManUaL

4Micro‑Aid e

1

V1.03 A potential issue involving the Query feature and evaluation of Virtual Inputs occurring at very high rates

was resolved.

V1.04 Corrected LCD message displayed prior to initialization.

V1.05 The Administrative Password and Passcode are no longer listed in the Print Setup Data command during

a Restricted Access session.

V1.06 The behavior of the Ethernet Port empty condition was modied.

V1.07 Corrected writing of Date and Image Records at the start of a new ash memory block.

V1.08 Added one wait state to all SRAM accesses. Must be used with boot loader version 1.01.

V1.09 Any time and date interval can now be selected when saving Event Records to a USB ash drive. The USB

Host Port can now be used to upload new rmware directly from a ash drive.

V1.10 The Digital Input capacity was expanded from 256 to 999.

V1.10 retains compatibility with 256 input installations, however VDLs being updated from V1.0x to V1.10

and later must also have their Setup Databases updated. Failure to do so may result in erroneous Event

Record data.

V1.11 Added support for SNTP‑Unicast. Unicast message is sent at the completion of the initialization period and

hourly thereafter.

V1.12 Query feature now works with non‑contiguous dates in the date table. This x also applies to GEA Query.

Corrected problem with the Live Status of Virtual Inputs V5‑8. Corrected Event Record problem with

Analog Inputs A2‑4.

SetUp DatabaSe CoMpatibiLity

Occasionally, modications to the rmware of the logger will result in a new memory map of the Setup

Database. When this occurs the previously created Setup Database will be incompatible with the new

rmware. Table 2 on page 4 details the compatibility status of each rmware version. A green check

mark ()in any given row indicates compatibility with the previous Setup Database. A red X ()indi‑

cates that a new Setup Database will have to be created for the rmware version listed.

FirmwareVersion Compatibility

V1.00

V1.01

V1.02

V1.03

V1.04

V1.05

V1.06

V1.07

V1.08

V1.09

V1.10

V1.11

V1.12

Table 2: Setup Database Compatibility

Chapter 1 – generaL DeSCription aboUt thiS ManUaL

5Micro‑Aid e

1

When an incompatibility occurs, contact MICRO‑AIDE before preparing a new Setup Database. E‑mail

a copy of the existing Setup Database along with the applicable rmware revision number. MICRO‑AIDE

will convert the database and return a le that is fully compatible with the new rmware version.

Never attempt to use an incompatible Setup Database. The operation of the logger can be severely

impacted.

aboUt thiS ManUaL

This document is intended to provide the user with comprehensive, easy‑to‑read instructions on how

to install, set up, operate and maintain the MICRO‑AIDE VDL S7‑300. This document refers to Version

1.13 of the VDL S7‑300 rmware. Specically, the sample data and command details depicted were

prepared using a Version 1.13 logger. Wherever possible, step‑by‑step instructions have been included.

In the event the user has questions about any of the described procedures the user should contact

MICRO‑AIDE for assistance. Additional copies of this manual are available upon request.

Micro‑Aid e corporAtion

685 Arrow Grand Circle

Covina, CA 91722

Tel: 626‑915‑5502 Fax: 626‑331‑9484

E‑mail: support@micro‑aide.com

The MICRO‑AIDE “Material Return” and “Limited Warranty” policies can be found on the inside back

cover of this manual.

The next chapter describes how to install the VDL.

VDL S7‑300 USer ManUaL

6Micro‑Aid e

1

USer noteS

7Micro‑Aid e

2

Chapter 2 – inStaLLation

introDUCtion

This chapter describes how to properly unpack and install the VDL S7‑300 prior to operation. It is advis‑

able to perform the Initial Check‑Out Procedure before attempting to set up the Data Logger.

UnpaCKing

Each VDL is packed in a shipping carton that is properly sized for the device. Abundant packing materi‑

als are provided to minimize mechanical shock to the contents. Before opening the carton inspect it for

damage. Damage to the carton should be noted. Carefully remove the logger. It is advisable to save all

packing materials in the event the unit ever needs to be returned to MICRO‑AIDE.

Inspect the unit for visual damage. It should not be scratched, dented or deformed in any way. If it

appears the logger was damaged in shipment the responsible carrier should be notied immediately.

MICRO‑AIDE will assist the user in ling a claim in the event damage was sustained during shipment.

initiaL CheCK‑oUt proCeDUre

Before the VDL is installed at a signal facility it is recommended that an operational check of the logger

be performed. The following materials are required as a part of this procedure.

• 12 Vdc power source.

• Common hook‑up wire for power and testing inputs (12 to 22 AWG).

• Wire strippers and small, at‑head screwdriver.

• PC equipped with a communications program (e.g., HyperTerminal®) and either a USB port or serial

comm port set to operate at 38,400 Baud.

• Digital Voltmeter (DVM).

Perform each step in the sequence listed in the following. If a problem arises, refer to the sections entitled

“Diagnostic Testing” on page 76 and “Trouble‑Shooting Guide” on page 82. Elements common to

most installations are illustrated in Figure 1 on page 8 and Figure 2 on page 9.

1. With the power off, connect the power source positive and negative conductors to either pair of ter‑

minals labeled “B” and “N”, respectively. They are located at the right end of the logger’s top panel.

2. Connect the PC’s serial comm port to the DE‑9 male connector labeled “Terminal”. Use the cable

provided by MICRO‑AIDE or a DE‑9 to DE‑9 straight‑through cable. Figure 6 on page 87 illustrates

the proper wiring of the cable. Alternatively, connect a USB A‑B cable between the logger’s port

labeled “USB Device to PC” and any USB port available on the PC.

VDL S7‑300 USer ManUaL

8Micro‑Aid e

2

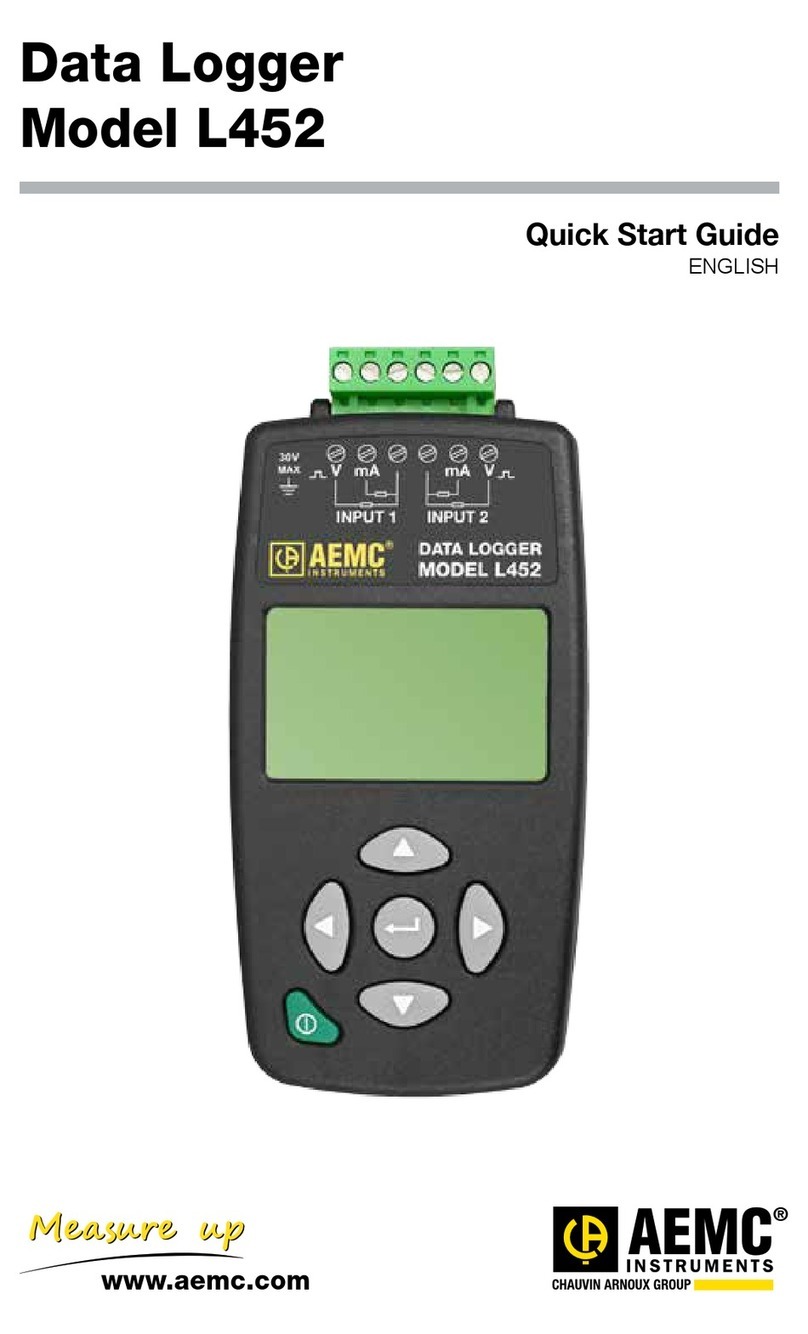

Figure 1: Typical Installation ‑ Front Panel View

TIME DATE

16:20:59 02-20-14

S7-300 Data Logge r

COVINA_ARROWGRAND9.7

Modem

Terminal

Power

Adj.

Save

USB

Flash Drive

1 2 3 Browse

4 5 6 Alpha

7 8 9 Setup

0Esc

Enter

Save

MICRO-AIDE

20-positon keypad

F

LED indicators (3)

E

LCD contrast adjustment

D

USB Host Port

C

80-character LCD

B

Detachable tension clamp connectors (3)

A

F

E

D

C

B

A

To use the logger’s USB Device Port the proper drivers must be installed in the PC. Appendix C de‑

scribes how to locate and install the correct drivers.

The factory default setting for the Terminal Port is 38,400 Baud. Refer to the procedure entitled “Terminal

Port Baud Rate” on page 21 for details on changing the Baud rate. The VDL requires 8 data bits, no

parity and 1 stop bit (i.e., 8‑N‑1).

3. Set the PC to emulate an ANSI terminal. In the case of HyperTerminal, click on the File, Properties

command. Select the Settings tab. Enable Terminal keys. Select ANSI from the Emulation drop‑down

list box.

4. Apply power to the PC. Ensure that the communications program is set for a direct connection to the

appropriate communications port.

5. Apply power to the VDL. The Liquid Crystal Display (LCD) panel should illuminate. The PC will display

the following message (Terminal Port).

Micro-Aide CWR-24E Flash Boot Loader 1.01

Press ESC for boot loader

Chapter 2 – inStaLLation initiaL CheCK‑oUt proCeDUre

9Micro‑Aid e

2

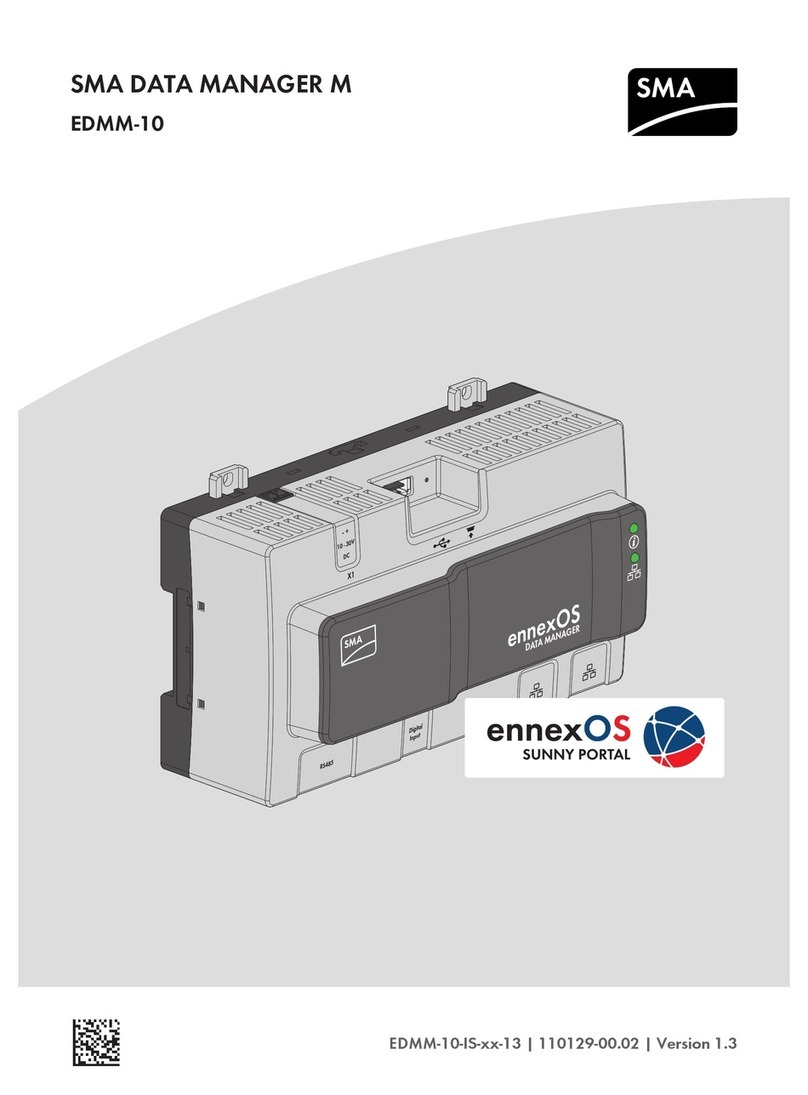

Figure 2: Typical Installation ‑ Top Panel View

Terminal To

Vital-Processor

GPS

Antenna

Ethernet

Phone

Line

A1 A2 A3 A4

Analog

B B N NRly

USB

Device

To PC

Processor Port

M

Optional GPS Receiver

L

Output relay

K

Optional 33.6K Baud modem

J

USB Device Port

I

Optional Ethernet Port (Telnet, SNTP-Multicast & -Unicast)

H

Terminal Port

G

PC

ACCESS METHODS

RJ-11

USB

Type A-B

CAT-5

RS-232 DE-9

Female - Female

M

L

KJIH

G

RS-232 DE-9

Female - Female

Orient

skyward

VDL S7‑300 USer ManUaL

10 Micro‑Aid e

2

The preceding message should be ignored. Do not press the Esc key. The user must wait several seconds

for the VDL to complete its initialization process.

6. After the logger completes its initialization the date and time should appear on the LCD. The date

and time may need to be changed. The procedure for changing the date and time is described in

the section entitled “Time / Date (T)” on page 17. The following password challenge will be dis‑

played.

Siemens S7-300 Data Logger. Ver 1.13 (C) 2011 MICRO-AIDE INC.

***** NOT SET *****

Event storage capacity: 284785

Enter password:

Password Request

7. If the logger fails to display the password request, check the power and peripheral connections

and Baud rate and communications settings. If the problem can be isolated to the VDL contact

MICRO‑AIDE customer service for instructions on how to proceed.

Repair and return policies are described on the inside back cover of this manual.

8. The remainder of the Initial Check‑Out Procedure presumes the logger is congured to operate with

the factory default settings and Event Records have not been logged into memory. If this is not the

case the user may wish to reset the unit. Refer to the section entitled “Reset System (R)” on page 18

for details.

9. From the PC’s keyboard type PASSWORD in upper‑case letters. This is the default password.

Complete the entry by pressing the Enter key. The Main Menu, shown in the following, will be dis‑

played.

MICRO-AIDE Vital-Processor Data Logger

S Setup

L Live Status

Q Query Events

V View Events

T Transfer Files

D Diagnostics

X Log Off

Main Menu

10. Press the Lkey. The VDL will now display the real‑time status of Digital and Analog Inputs.

11. Connect the 12 Vdc positive and negative test leads to the two inputs of Analog Input A1.

12. Verify the Analog Input reading for A1 is within .15 Vdc of the correct reading. The correct polarity of

the applied voltage should also be indicated.

13. Repeat the previous two steps for the remaining three Analog Inputs.

14. Press the Esc key once to return to the Main Menu. Perform a Query of the Event Records by pressing

Q at the PC keyboard. Select today’s date and then press Enter. Finally, press the F1 function key.

Refer to the section entitled “Query Events (Q)” on page 38 for additional details.

15. Verify that a Power On Event Record is reported listing today’s date.

16. Before completing the Initial Check‑Out Procedure verify the LCD is providing acceptable contrast.

If it needs to be improved adjust the potentiometer located at the logger’s front panel. Refer to the

section entitled “Adjusting the LCD Contrast” on page 73.

Chapter 2 – inStaLLation inStaLLation proCeDUre

11Micro‑Aid e

2

This concludes the Initial Check‑Out Procedure. This procedure may be used at any time to verify that

the VDL is operating properly. Power can now be removed from the logger. Connections to the PC

should also be removed.

In the event that a failure occurs during any part of this procedure a series of diagnostic tests should

be performed. Refer to the sections entitled “Diagnostic Testing” on page 76 and “Trouble‑Shooting

Guide” on page 82. Alternatively, the user may wish to contact MICRO‑AIDE customer service.

Instructions on how to proceed will be offered. “Material Return” and “Limited Warranty” policies are

described on the inside back cover of this manual.

inStaLLation proCeDUre

The following sections describe the recommended Installation Procedure. Figure 1 on page 8 and

Figure 2 on page 9 illustrate elements that are common to most installations. The illustrations also de‑

pict the location of each connector used in the installation.

LoCation

The location where the VDL is to be installed should comply with a few simple requirements. The ambient

temperature near the logger should be in the range from ‑40 ºC to 72 ºC.

MoUnting

The VDL can be mounted on top of a suitable shelf or secured to a back board. Each logger is equipped

with non‑slip, rubber feet. Precautions should, however, be taken to prevent the unit from dropping off

the edge of the shelf or desktop. The shelf mounting brackets provided with the unit can be used for this

purpose. To attach the shelf mounting brackets remove the four rubber feet. The provided screws and

threaded holes vacated by the rubber feet are used to install the brackets. If a PC is to be used it must

be properly secured.

Contact MICRO‑AIDE in the event 19″ rack mounting brackets are required. Refer to the section entitled

“Accessories” on page 89 for ordering details.

Site preparation

The equipment location must have access to a stable 9 to 36 Vdc power source. A pair of wires must be

run from the power source to the location where the logger will be mounted. The VDL wire ends must be

stripped approximately 1/4″. The stripped ends will be secured by tension clamp terminals located along

the top panel of the unit. One wire must be connected to the positive voltage of the power source

and the other wire must be attached to the return of the power source. The tension clamp terminals will

accept wire sizes as large as 12 AWG. The two wires must be properly secured to prevent damage. It is

preferable not to run the wires adjacent to electrical equipment such as motors that may generate large

electrical disturbances.

The serial comm port labeled “To Vital‑Processor” must be connected to the CP 340 Communication Port

of the Siemens S7‑300. Use the cable provided by MICRO‑AIDE or a DE‑9 to DE‑9 straight‑through cable.

Figure 6 on page 87 illustrates the proper wiring of the cable. The VDL must be mounted within six

cable feet of the vital‑processor.

The Analog Inputs also use a tension clamp style of detachable connector. Each wire should be tagged

with its circuit identity. Each input cable or wire bundle should be secured to prevent damage to the

connections at either end.

The VDL can be programmed to issue an alarm indication signal. A form C relay with normally closed

and normally open contacts is available at the connector alongside where power is attached to the

logger. The contacts are rated for 2 Adc at 24 Vdc and 1 Aac at 125 Vac. The relay can be used to con‑

trol an external light or warning device.

VDL S7‑300 USer ManUaL

12 Micro‑Aid e

2

The GPS Receiver option utilizes an external antenna. The bulkhead‑style antenna is designed to be

mounted outdoors on any surface less than 3/8″ in thickness. It requires a 1/2″ diameter hole to be drilled

through the mounting surface. The hole should be properly sealed. The antenna assembly also includes a

washer, nut and 16' cable.

peripheraL eqUipMent

If a PC is to be co‑located with the VDL an appropriate AC power source must be available. Additional

connections can be made as described in the following sections.

USb DeViCe port

If an on‑site PC is to be used MICRO‑AIDE recommends that the USB Device Port be connected to a USB

port of the PC. The USB Device Port will support data transfer rates of 960 Kbps. A standard USB Type A‑B

cable is used for this purpose. Table 14 on page 87 lists the bit transfer rates of each user‑accessible

port.

To use the logger’s USB Device Port the proper drivers must be installed in the PC. Appendix C de‑

scribes how to locate and install the correct drivers.

terMinaL port

As an alternative, the PC can be connected to the Terminal Port. The Terminal Port cable should be kept

to a minimum distance, preferably less than 20'. MICRO‑AIDE provides, as a standard feature, an RS‑232

DE‑9 to DE‑9 cable. The cable is suitable for use with any PC comm port or USB‑to‑serial adapter cable.

Each logger is shipped with a pair of MICRO‑AIDE manufactured RS‑232 cables. Both cables are wired

identically and can be used interchangeably with the Terminal and Vital‑Processor Ports. The shield wire

in each cable is not attached. Consequently, the logger chassis and peripheral device are electrically

isolated. This further improves the isolation properties of the system.

VitaL‑proCeSSor port

The VDL logs Event Records for Digital Inputs by establishing a communications connection with the

Siemens S7‑300. Accordingly, the VDL port labeled “To Vital‑Processor” must be connected to the CP 340

Communications Port.

ethernet port (optionaL)

The optional Ethernet Port may be used to connect the VDL to a LAN or PC. A standard CAT‑5 Ethernet

cable is used to connect to the LAN via a hub or switch. The length of either cable must be limited to 50'.

Table 14 on page 87 lists the bit transfer rates of each user‑accessible port.

internaL MoDeM (optionaL)

If the VDL is equipped with the optional internal modem, a standard telephone line can be attached to

the logger. The telephone line must be terminated with an RJ‑11 connector like those commonly used in

residential telephone service. Test the telephone line rst to ensure that a dial tone is available.

gpS reCeiVer (optionaL)

The GPS Receiver option is the preferred means of precisely controlling the logger’s real‑time clock. The

optional feature includes a bulkhead‑mount antenna designed specically for use with the receiver

module. For improved reception the antenna should be mounted outside of the equipment house or

cabinet, as it requires unobstructed skyward access. The antenna is designed to be moisture proof and is

rated to operate over a broad temperature range.

The antenna is equipped with a 16' coaxial cable. The antenna end of the cable is non‑detachable. The

other end of the cable terminates in an MCX‑male connector. The MCX connector must be secured to

the logger’s connector labeled “GPS Antenna” located along the top panel.

This manual suits for next models

1

Table of contents