MICRO-AIR FRP User manual

Installation and Operation Manual

This manual contains specific cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all the hazards of dust control equipment. All persons involved with the equipment or

systems should be instructed how to operate in a safe manner.

MODEL FRP

DUST

COLLECTOR

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

!

MICRO AIR®FRP

CLEAN AIR SYSTEMS

2

TABLE OF CONTENTS

CAUTIONS 3

SPECIFICATIONS 4

INSTALLATION

INSPECTION 5

CODES 5

SET-UP 5-6

ACCESSORY INSTALLATION

DUST COLLECTION HOPPER 7

DUST COLLECTION TRAY 7

BARREL LID 7

TOP MOUNTED BLOWER 8

REAR MOUNTED BLOWER SHROUD 8

REAR MOUNTED SILENCER OR HEPA 8-9

MAGNEHELIC GAUGE 9

PHOTOHELIC GAUGE 9

COMPRESSED AIR INSTALLATION 10

ELECTRICAL INSTALLATION 10-11

UNIT OPERATION 11

CARTRIDGE CLEANING OPERATION 11

ROTO-PULSE CLEANING TIMER ADJUSTMENTS 11-12

AFTER-PULSE CLEANING TIMER ADJUSTMENTS 12

PULSE CONTROL ONLY WIRING SCHEMATICS 13-20

FULL CONTROL WIRING SCHEMATICS 21-28

CABINET PARTS LIST 29

ELECTRICAL PARTS LIST 30

ROTO PARTS LIST 31

DOOR PARTS LIST 31

WARNING

Process owners/operators have important responsibilities

relating to combustible hazards. Process owners/operators

must determine whether their process creates combustible

dust, fume, or mist. If combustible dust, fumes, or mist is

generated, process owners/operators should at a minimum:

• Comply with all applicable codes and standards.

Among other considerations, current NFPA standards

require owners/operators whose processes involve

potentially combustible materials to have a current

hazard analysis, which can serve as the foundation for

their process hazard mitigation strategies.

• Prevent all ignition sources from entering any dust

collection equipment.

• Design, select, and implement fire and explosion

mitigation, suppression, and isolation strategies that

are appropriate for the risks associated with their

application.

• Develop and implement maintenance work practices to

maintain a safe operating environment, ensuring that

combustible dust, fumes, or mist does no accumulate

within the plant.

Micro Air recommends process owners/operators consult

with experts to ensure all of these responsibilities are met.

As a manufacturer and supplier of Industrial Filtration

Products, Micro Air can assist process owners/operators in

the selection of filtration technologies. However, process

owners/operators retain all responsibility for the suitability

of fire and explosion hazard mitigation, suppression, and

isolation strategies. Micro Air assumes no responsibility

or liabitlity for the suitability of any fire and/or explosion

mitigation strategy, or any items incorporated into a

collector as part of an owner/operator hazard mitigation

strategy.

Improper operation of a dust control system may contribute

to conditions in the work area or facility that could result

in severe personal injury and product or property damage.

Check that all collection equipment is properly selected and

sized for the inteded use.

Always follow the requirements of all authorities having

jurisdiciton (National and Local) in the application,

installation, orperation and servicing of the dust collector.

Many of the processes outlined in this manual will expose

the installer to circuits powered by high voltage. This

installation is recommended for professional electricians or

Micro Air trained factory service personnel. Lock out/ Tag

out procedures are required.

The installation/operation manual must be read and

followed in its entirety.

FRP MICRO AIR®

CLEAN AIR SYSTEMS

3

!

4

MICRO AIR®FRP

CLEAN AIR SYSTEMS

MODEL FRP SPECIFICATIONS

CABINET DIMENSIONS:

FRP4 72” H x 53” W x 48” D

FRP6 92” H x 53” W x 48” D

FRP6-2 94” H x 95” W x 48” D

FRP6-3 94” H x 136” W x 48” D

FRP8 112” H x 53” W x 48” D

FRP8-2 114” H x 95” W x 48” D

FRP8-3 114” H x 136” W x 48” D

FRP8-4 114” H x 179” W x 48” D

Add 64” to height for long legs and 16” for short legs.

FILTER AREA:

FRP4 600-1000 square feet

FRP6 900-1500 square feet

FRP6-2 1800-3000 square feet

FRP6-3 2700-4500 square feet

FRP8 1200-2000 square feet

FRP8-2 2400-4000 square feet

FRP8-3 3600-6000 square feet

FRP8-4 4800-8000 square feet

Lower number is for PTFE and Spunbond filters, higher

number is for all other media types.

INPUT VOLTAGE:

120V 60Hz 1 phase

208-230V / 460V 60Hz 3 Phase

MAXIMUM CURRENT:

Pulse Only 1 Amp

5HP 208V: 13.6 Amps

230V: 11.8 Amps

460V: 5.9 Amps

7.5HP 208V: 19.4 Amps

230V: 18.0 Amps

460V: 9.0 Amps

10HP 208V: 24.9 Amps

230V: 23.6 Amps

460V: 11.8 Amps

15HP 208V: 36.8 Amps

230V: 34.0 Amps

460V: 17.0 Amps

20HP 230V: 46.0Amps

460V: 23.0 Amps

30HP 230V: 68.0 Amps

460V: 34.0 Amps

COMPRESSED AIR:

Minimum air line of 3/4 inch at 80 psi minimum and 90

psi maximum. Oil and moisture free compressed air is

required for proper operation.

5

FRP MICRO AIR®

CLEAN AIR SYSTEMS

INSTALLATION:

INSPECTION:

The Micro Air dust collector is shipped on one or more

skids. All skids should be inspected for any visible damage

that may have occurred during shipment.

Report any damage to the delivery carrier.

CODES:

Codes may regulate recirculating filtered air in your facility.

Consult with the appropriate authorities having jurisdiction

to ensure compliance with all national and local codes

regarding recirculating of filtered air.

Codes may regulate acceptable locations for installing dust

collectors. Consult with the appropriate authorities having

jurisdiction to ensure compliance with all national and local

codes regarding dust collector installation.

Collectors must be anchored in a manner consistent with

local code requirements. Anchors must be sufficient to

support dead, live, seismic, and other anticipated loads.

SUGGESTED EQUIPMENT & TOOLS:

Crane or Lift truck Clevis Pins and Clamps

Lifting Straps or Chain Drift Pins

Spreader Bars Pipe Sealant

Socket Wrenches Screwdrivers

Pipe Wrenches Drill and Drill Bits

1/2” diameter anchor bolts End Wrenches

Adjustable Wrench Level

SET-UP

1. Determine the location where the unit is to be installed.

Be sure to allow sufficient room to access the unit for

servicing and maintenance on all sides.

2. Lift the unit with a lift truck or overhead crane rated to

support the dust collectors weight. Use all the lifting

lugs provided and lift in a method described in Figure

1, 2 or 3.

3. Bolt on each of the legs with the hardware provided

(Figure 4).

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

MICRO AIR®FRP

CLEAN AIR SYSTEMS

4. When supplied, bolt on angle braces with provided

hardware (Figure 5). Ensure each leg is plumb before

tightening the bolts.

5. When the legs and angle braces have been completely

installed each leg should be anchored to the ground

using all the provided holes in the base plates (1/2” dia.

anchors are recommended).

6. Install provided hole plugs into unused bolt holes in

legs

Caution: The unit is not designed to

be operated while hanging from lifting

brackets. Unit must be mounted on legs

and cross bracing installed when supplied.

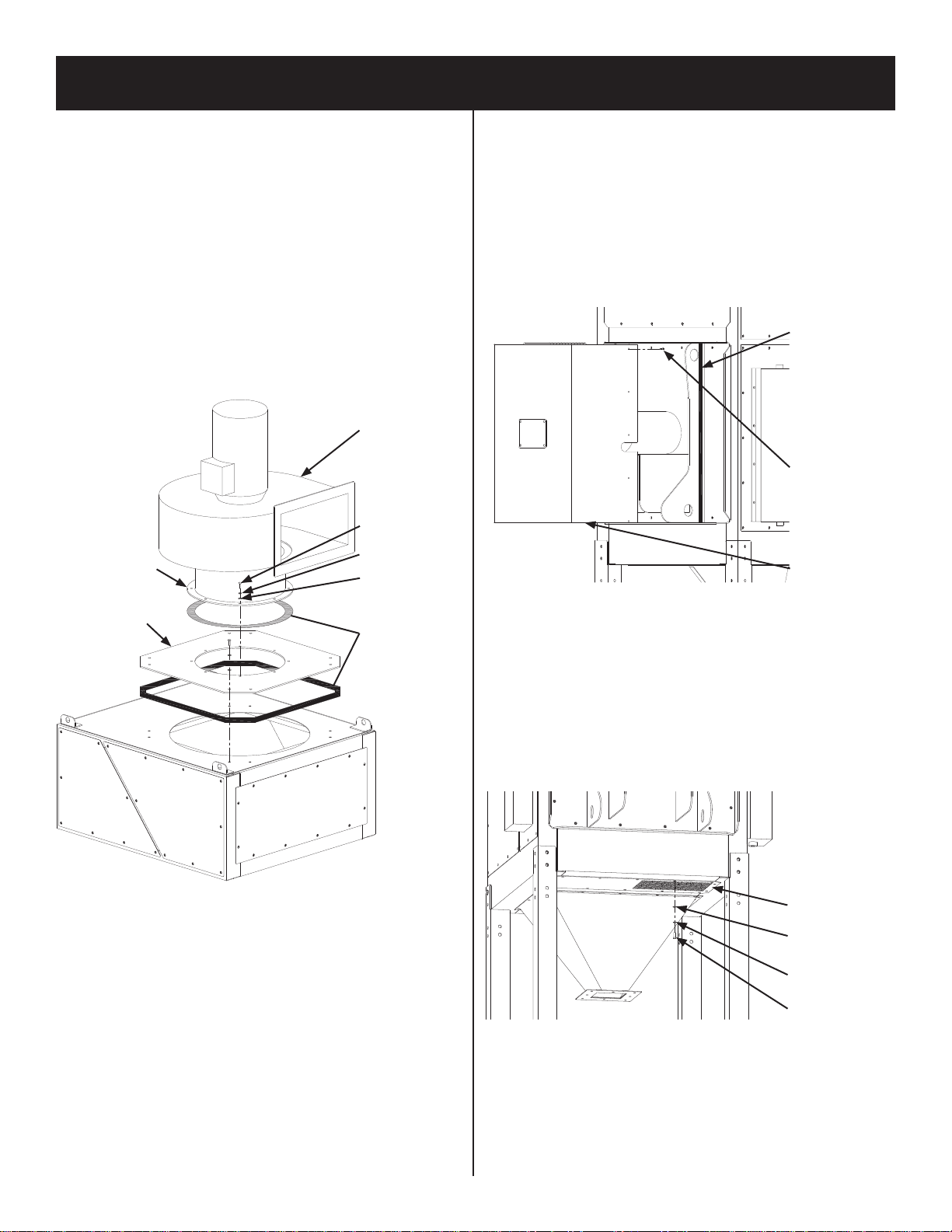

7. FRP4, FRP6 and FRP8 require installation of the top

inlet plenum as shown in FIG. 6.

a. Apply self-adheasive foam on the bolt hole flange

of the inlet plenum.

b. Place inlet plenum on top of dust collector and

align the bolt holes.

c. Attach the inlet plenum using 14 ea. 5/16” bolts,

washers and lock washers.

d. Three cap plates can be removed and reinstalled to

allow you to use the opening best suited for your

installation.

6

FIGURE 5

!

FIGURE 6 Self-Adheasive

Foam

Lock Washer

Flat Washer

Hex Bolt

Top Inlet Plenum

ANCHOR DETAIL

Anchor should project

a minimum of 1 3/4-in

and account for nut,

washer, base plate and

shims.

Embedment depth,

6” minimum.

FRP MICRO AIR®

CLEAN AIR SYSTEMS

ACCESSORY INSTALLATION:

DUST COLLECTION HOPPER

1. Apply self-adheasive foam to the bolt hole flange on

the hopper (Figure 7).

2. Align the hole pattern on the hopper flanges with the

hole pattern on the underside of the unit.

3. Attach the hopper using 16 ea. 5/16” bolts, washers and

lock washers.

DUST COLLECTION TRAY

1. Apply self-adheasive foam to the bolt hole flange on

the tray (Figure 8).

2. Align the hole pattern on the tray flanges with the hole

pattern on the underside of the unit.

3. Attach the tray using 16 ea. 5/16” bolts, washers and

lock washers.

BARREL LID

1. Bolt adapter plate and hopper adapter to the hopper

using the four sets of 3/8” hardware (Figure 9).

2. Clamp the pipe section to the barrel lid

3. Slide the pipe section over the hopper adapter and

adjust so that the barrel lid is resting on the barrel.

4. Roll the gasket down until it is resting on the flange of

the pipe section.

5. Clamp the pipe section and gasket together.

7

FIGURE 7

Lock Washer

Flat Washer

Hex Bolt

Self-Adheasive

Foam

Hopper

FIGURE 8

Lock Washer

Flat Washer

Hex Bolt

Self-Adheasive

Foam

Hopper

FIGURE 9

Dust Collection

Hopper

Clamp

Gasket

Hopper Adapter

Adapter Plate

Barrel (By

Others)

Barrel Lid

Clamp

Pipe Section

MICRO AIR®FRP

CLEAN AIR SYSTEMS

TOP MOUNTED BLOWER

1. Apply self-adheasive foam to the bottom side of the

blower flange (Figure 10).

2. Carefully lift the blower and position over the adapter

plate using a lift truck or crane.

3. Align and lower the blower to the top of the adapter

plate, ensuring the blower outlet is in the correct

discharge orientation for your installation.

4. Install all bolts through the blower flange into the

adapter plate and tighten until secured.

Note: In most installations the adapter plate will arrive

installed on the unit. In the event it needs relocated to

another module see figure 10.

REAR MOUNTED BLOWER MOTOR SHROUD

Note: Do not install motor shroud before completing the

electrical connection to the motor.

1. Place the motor shroud, as shown in Figure 11 over

the motor having located the slotted hole of the motor

shroud on the right hand side. This will allow the

wiring conduit to clear the motor shroud.

2. With the shroud in place mark the centers of the six (6)

holes in each vertical brace.

3. With the holes having been marked remove the motor

shroud and use a 7/32” diameter drill bit to drill

through the braces.

4. Apply the self-adheasive foam to the vertical braces as

shown in Figure 11.

5. Re-install the motor shroud around the motor and

attach using the twelve (12) self-tapping screws

provided.

6. The four bolts and small cover on the back of the motor

shroud may be removed to allow for the checking of

proper motor rotation.

REAR MOUNTED BLOWER SILENCER & REAR

MOUNTED HEPAAFTER FILTER

1. Remove the bolts from the exhaust grille (Figure 12A).

2. Align holes from the silencer flange with holes located

on the exhaust grille.

3. Attach the silencer with the hardware removed in step

one (Figure 12B)

8

FIGURE 10

Lock Washer

Flat Washer

Hex Bolt

Self-Adheasive

Foam

Self-tapping

Screw

Adapter Plate

Blower Flange

FIGURE 11

Self-Adheasive

Foam

Motor Shroud

FIGURE 12A

Exhaust Grille

Lock Washer

Flat Washer

Hex Bolt

Blower

FRP MICRO AIR®

CLEAN AIR SYSTEMS

MAGNEHELIC GAUGE

1. Mount the magnehelic gauge into the magnehelic

mounting bracket following the mounting instructions

contained in the magnehelic packaging.

2. Mount the two male barb fittings in the pressure ports

located on the side of the magnehelic gauge.

3. Mount the two pressure port plugs in the pressure ports

located on the back of the magnehelic gauge.

4. Mount the bracket using the four (4) self-taping screws

provided.

5. Using the 1/4” diameter clear tubing connect the

“LOW” or “-” pressure port on the gauge to the clean

air plenum and the “HIGH” or “+” pressure port to the

dirty air plenum (Figure 13).

PHOTOHELIC GAUGE

1. Mount the photohelic gauge into the photohelic

mounting bracket following the mounting instructions

contained in the photohelic packaging.

2. Mount the two male barb fittings in the pressure ports

located on the side of the photohelic gauge.

3. Remove cover from electrical box so that wiring

diagram on back of cover can be used.

4. Remove the two red wires that are connected to the

timer board pressure switch input (HI & COM) and

relay CR1, or the two red wires that are connected to

the timer board pressure switch input (HI & COM)

and the differential pressure switch (HI & LOW). See

specific unit wiring schematic for further clarification.

5. Wire the photohelic gauge as the electrical diagram

shows. Use the 3/4” conduit opening on the

photohelic, connecting to the pulse control electrical

box.

6. Replace the cover back onto the photohelic gauge and

mount the bracket using the four (4) self-taping screws

provided.

7. Using the 1/4” diameter clear tubing connect the

“LOW” or “-” pressure port on the gauge to the clean

air plenum and the “HIGH” or “+” pressure port to the

dirty air plenum (Figure 14).

8. The right set point dial of the gauge should be

positioned at the filter differential set point you want

the Roto-pulse system to be enabled. The left should

be positioned at the filter differential set point you wnat

the Roto-pulse sytem disabled.

9

FIGURE 12B

Exhaust Grille

Lock Washer

Flat Washer

Hex Bolt

Silencer

FIGURE 13

Clean Air

Plenum

Dirty Air

Plenum

FIGURE 14

Dirty Air

Plenum

Conduit to Pulse

Control Box

Clean Air

Plenum

MICRO AIR®FRP

CLEAN AIR SYSTEMS

COMPRESSED AIR INSTALLATION:

The compressed air inlet for the Roto-Pulse cleaning

system is at the top of the surge tank located on the side of

the unit (Figure 15). A minimum of a 3/4 inch diameter

line and clean, dry compressed air at a pressure of 80 psi

to 90 psi is required for proper operation of the Roto-pulse

cleaning system. For models FRP8-3 and FRP8-4 two 3/4

inch diameter lines from a minimum 1 inch diameter header

line are required. A unit specific combination regulator/

filter dryer is highly recommended for proper operation.

ELECTRICAL INSTALATION:

Caution: Installation can cause

exposure to live components. Disconnect

electrical power before proceeding with

installation. Proper lock out/tag out

procedures should be used.

PULSE CONTROLS ONLY ELECTRICAL BOX

1. Open the electrical box cover located on the side of the

unit. Make connections from your 120V supply power

to terminal L, N and G (Figure 16).

2. When supply power has been terminated, reconnect

the power. Momentarily turn the motor blower on and

adjust pressure switch via set screw until contact is

made. Use an ohm meter to measure continuity across

the pressure switch.

FULL CONTROL ELECTRICAL BOX

1. Determine the location for mounting the electrical box

(on the unit or remotely). If mounting is on the unit

mount near the pulse jumper box in order to minimize

electrical runs if feasible.

2. Mount the electrical box.

3. Open the electrical box cover located on the side of

the unit. Make connections from your 208V, 230V, or

460V supply power to power distribution terminal L1,

L2, and L3 (Figure 17). Wire size should be rated for

FLA of your application.

10

FIGURE 15

Compressed Air Inlet

3/4” Female NPT

!

Set Screw Power Connection

Pressure Switch

Timer Board

FIGURE 16

FIGURE 17

Timer Board

Overload Power Distribution

Terminal

Contactor

FRP MICRO AIR®

CLEAN AIR SYSTEMS

4. Wire from the Overload T1, T2, and T3 to the motor

electrical housing. Wire size should be the same as

step 3.

5. Wire from the timer board in the full control electrical

box and the pulse jumper box on the side of the unit.

Wire size is 14AWG minimum.

6. Reconnect the power. Momentarily turn the unit

on and off with the start/stop switches. Confirm

the rotation of the motor is in the proper direction.

Rotation can be viewed at the open end of the blower

motor.

7. If motor rotation is in the proper direction then AMP

draw information is located on the inside of the Full

Electrical Control Box cover. If motor current is higher

than rated for the motor supplied, do not continue

operation. Re-check your wiring and if problems

continue contact your Micro Air representative for

instructions.

UNIT OPERATION:

1. Turn the blower on. This action will cause the filter

unit to activate and start cleaning filters.

2. Once the unit is running, the Roto-Pulse cleaning

system will be operational. Operation is detected by

hearing a 0.07 second air pulse approximately every 5

seconds. If adjustment to timing of pulses is desired

refer to the section “Roto-Pulse Cleaning Timer

Adjustments”.

3. Check the After-Pulse cleaning cycle by turning off

the blower. The unit should continue to pulse every 5

seconds for a period of approximately 17 minutes. If

adjustment to the after-pulse time is desired refer to the

section “After-Pulse Cleaning Timer Adjustments”.

CARTRIDGE CLEANING OPERATION:

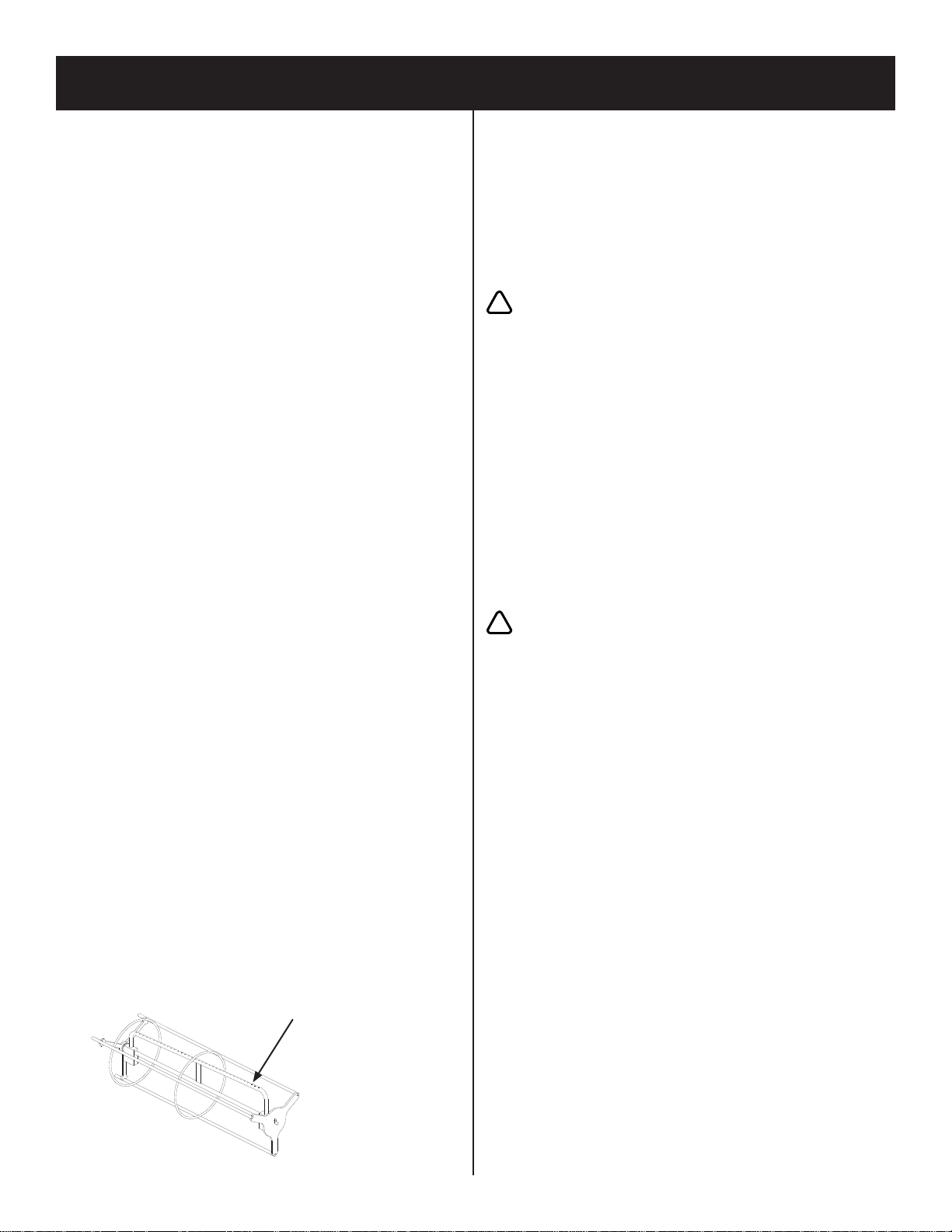

The Micro Air Dust Collector is designed with the

Roto-Pulse Cleaning System to clean the cartridge filters.

This system provides superior cleaning performance using

a rotating tube with pre-drilled holes. As the pulse valve

opens, the Roto-Pulse tube rotates while air exits the holes,

thus providing the cleaning of the cartridge (Figure 18).

1. For proper cleaning, the compressed air pressure should

be regulated at 80 psi to 90 psi.

2. During normal operation the Roto-Pulse cleaning

system is factory set to clean two (2) cartridge filters

for a period of 0.07 seconds every 5 seconds.

3. Once the unit is turned off the cleaning cycle will

continue for a period of 17 minutes. Do not service the

filters until cleaning is completed.

Caution: Allow 20 minutes of downtime

before opening filter access doors.

After-Pulse system is operational after unit

is turned off.

4. The Roto-Pulse cleaning operation dislodges particles

from the cartridges. Particles then fall down into the

dust tray or collection hopper.

5. After continued use of the unit, the dust collection

barrel or dust tray will need to be emptied. The

frequency of servicing will vary depending on the type

and quantitity of dust that is collected.

ROTO-PULSE CLEANING TIMER

ADJUSTMENTS:

Caution: Adjustment can cause

exposure to live components.

1. Turn the blower off.

2. Open the electrical box cover.

3. The timer control board is preset at the factory to clean

two (2) cartridge filters every 5 seconds. This time can

be adjusted from 1 second to 999 seconds. To adjust

this time press the select button on the timer board until

the “off time” LED is lit. Press the up/down buttons

until the desired value is displayed. Press select to set

the new value.

Note: Cleaning of the filters too often will decrease your

level of performance. A certain level of dust cake on

the filters will improve the capture efficiency of the

filters. You should try to maintain a mimimum of 1 in.

w.c. of pressure differential across the filters. If you

can not maintain this minimum level of differential

pressure across the filters the time between cleaning

pulses should be increased until this can be achieved.

4. The timer control board is preset at the factory to have

a cleaning pulse duration of 0.07 seconds. This can be

adjusted from 0.05 seconds to 600 seconds. To adjust

this time press the select button on the timer board until

the “on time” LED is lit. Press the up/down buttons

until the desired value is displayed. Press select to set

the new value.

11

FIGURE 18

Roto-Pulse Tube

!

!

MICRO AIR®FRP

CLEAN AIR SYSTEMS

Note: While this time can be adjusted it is recommended

that you leave the “ON TIME” at the factory setting.

If less cleaning is needed you should increase the time

between pulses as a means of reducing the amount

of cleaning. If more cleaning is needed you should

decrease the amount of time between pulses. Beware,

as the time between pulses is decreased for additional

cleaning, this will increase your compressed air

consumption and create an additional load on your

compressed air system.

5. Once adjustments have been made close the electrical

box cover.

6. Start the unit and observe the new pulse settings and

determine if additional adjustments are necessary. If

more adjusting is needed, repeat the previous steps.

AFTER-PULSE CLEANING TIMER

ADJUSTMENTS:

Caution: Adjustment can cause

exposure to live components.

1. Turn the blower off.

2. Open the electrical box cover.

3. The timer control board is preset at the factory to have

an After-Pulse cleaning duration of 999 seconds (17

minutes). This can be adjusted from 0 seconds to 999

seconds. To adjust this time press the select button on

the timer board until the “off time” LED is lit. Press

and hold the select button for 3 seconds. Press the up/

down buttons until the desired value is displayed. Press

select to set the new value. The after-pulse operation

can be disabled by setting the time value to zero (0)

seconds.

12

!

FRP MICRO AIR®

CLEAN AIR SYSTEMS

13

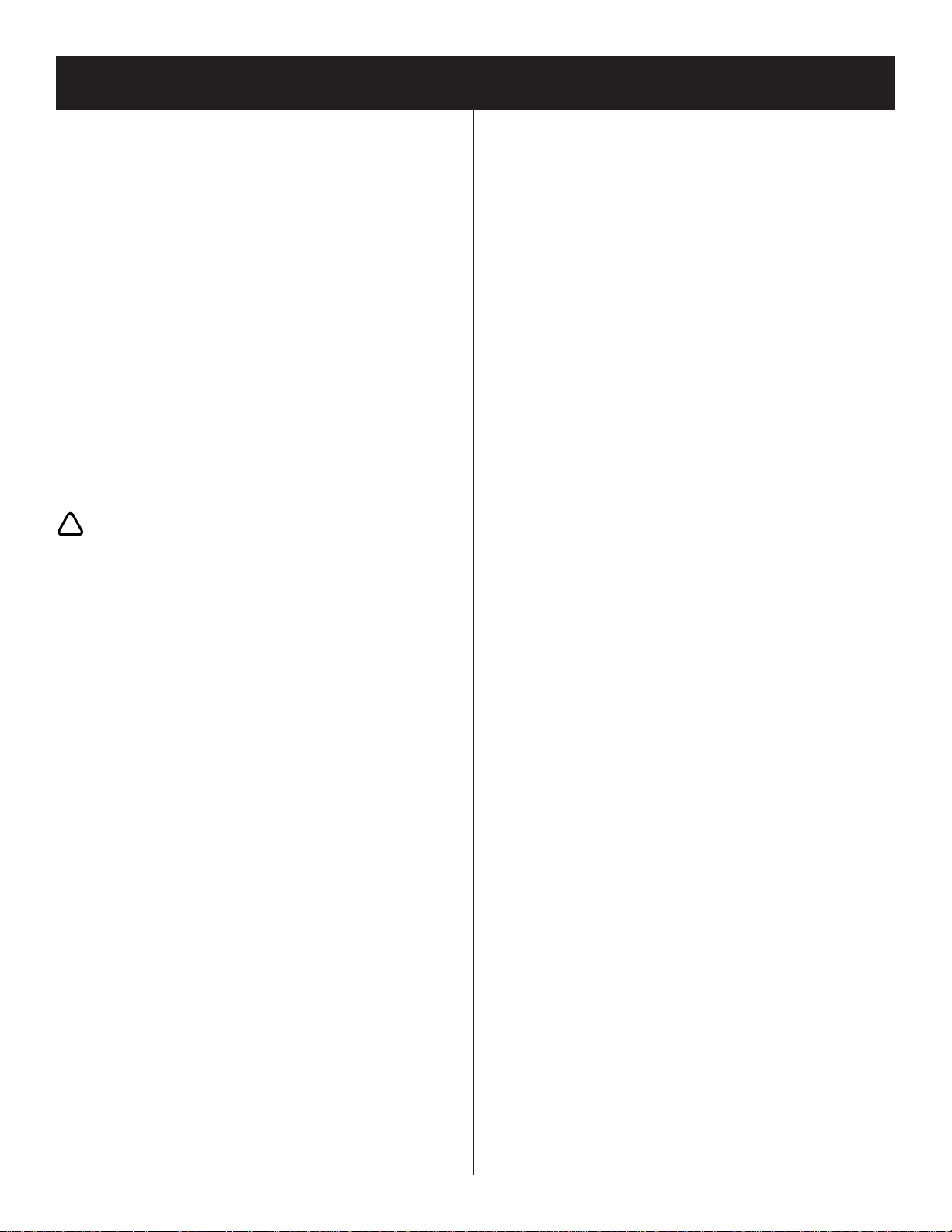

FRP4 PULSE CONTROL ONLY WIRING DIAGRAM

14

MICRO AIR®FRP

CLEAN AIR SYSTEMS

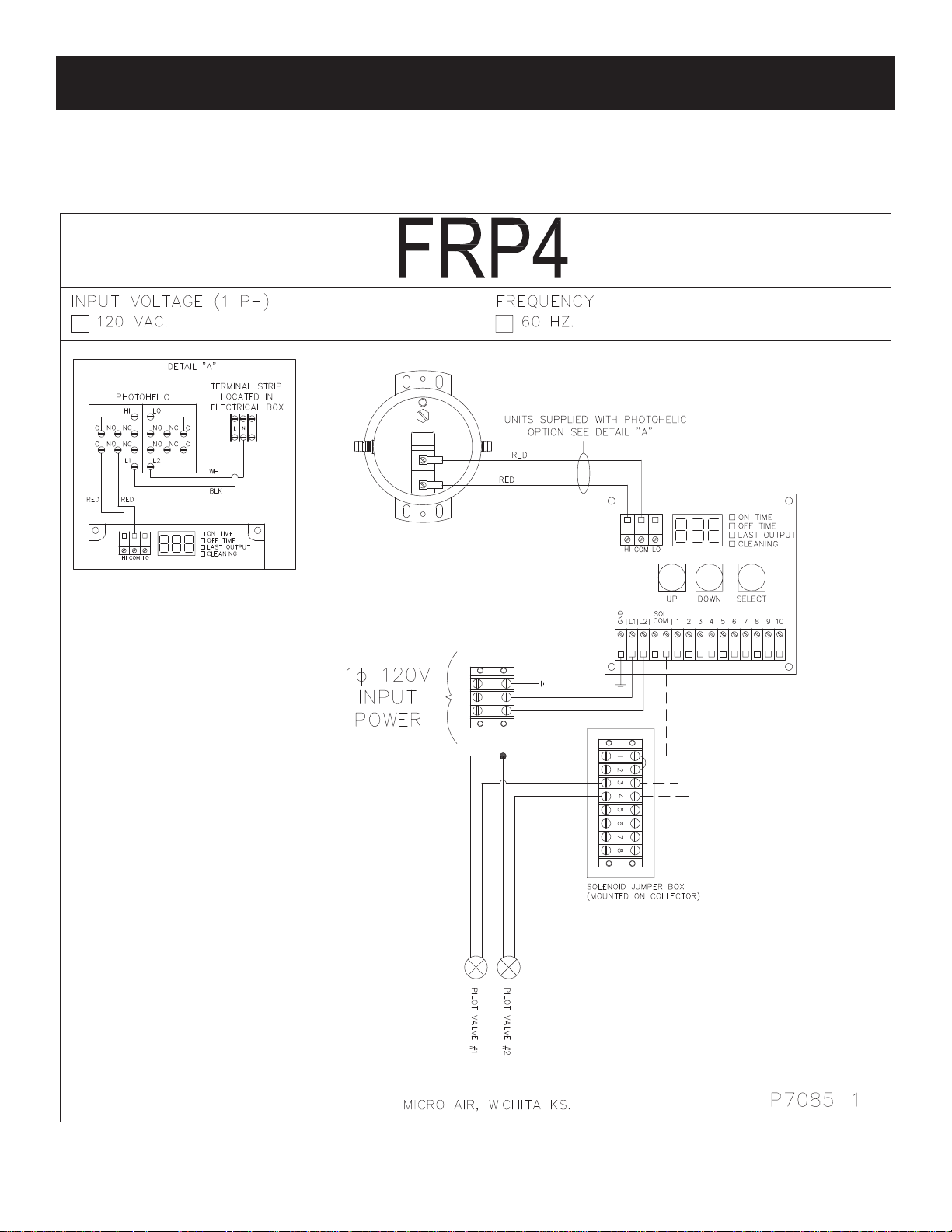

FRP6 PULSE CONTROL ONLY WIRING DIAGRAM

15

FRP MICRO AIR®

CLEAN AIR SYSTEMS

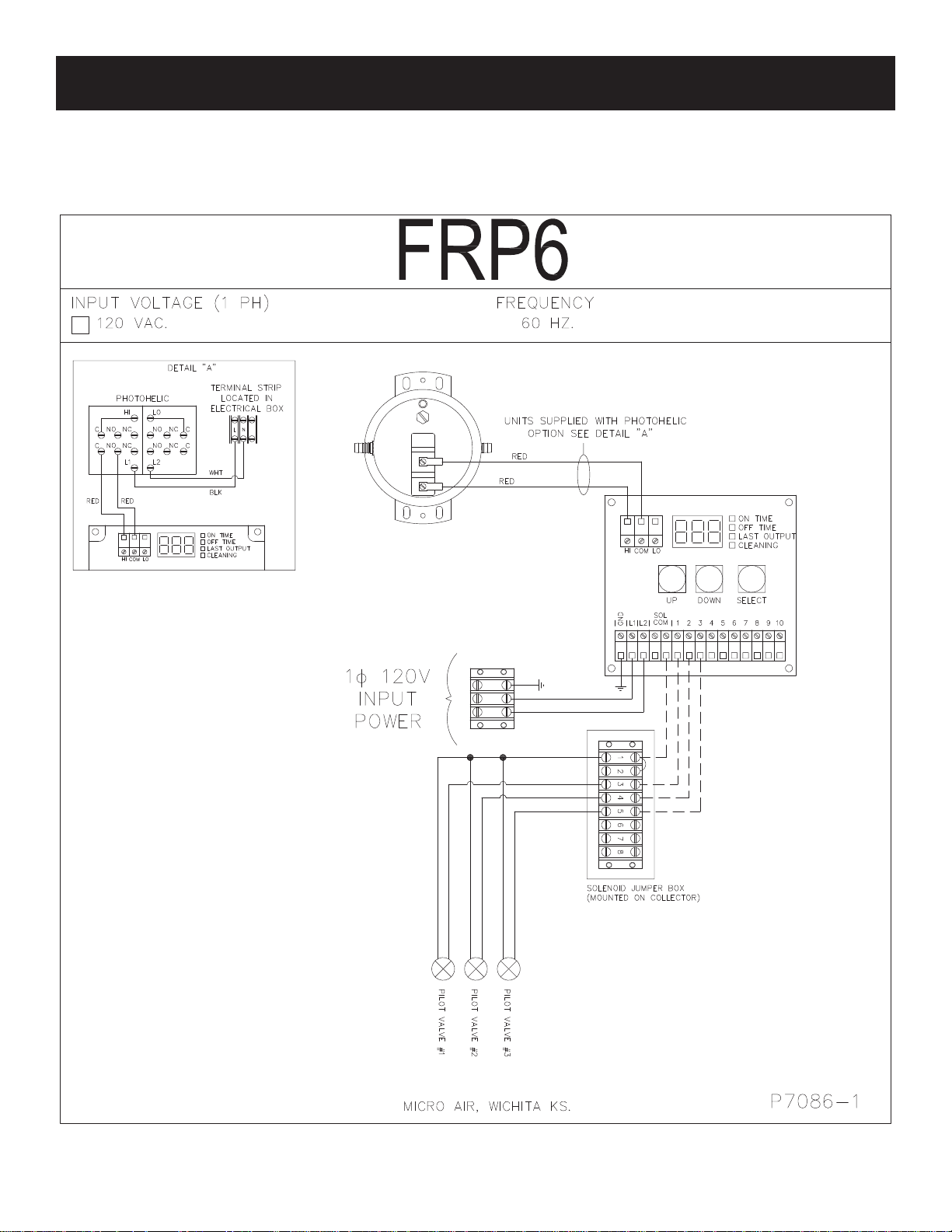

FRP8 PULSE CONTROL ONLY WIRING DIAGRAM

16

MICRO AIR®FRP

CLEAN AIR SYSTEMS

FRP6-2 PULSE CONTROL ONLY WIRING DIAGRAM

17

FRP MICRO AIR®

CLEAN AIR SYSTEMS

FRP6-3 PULSE CONTROL ONLY WIRING DIAGRAM

18

MICRO AIR®FRP

CLEAN AIR SYSTEMS

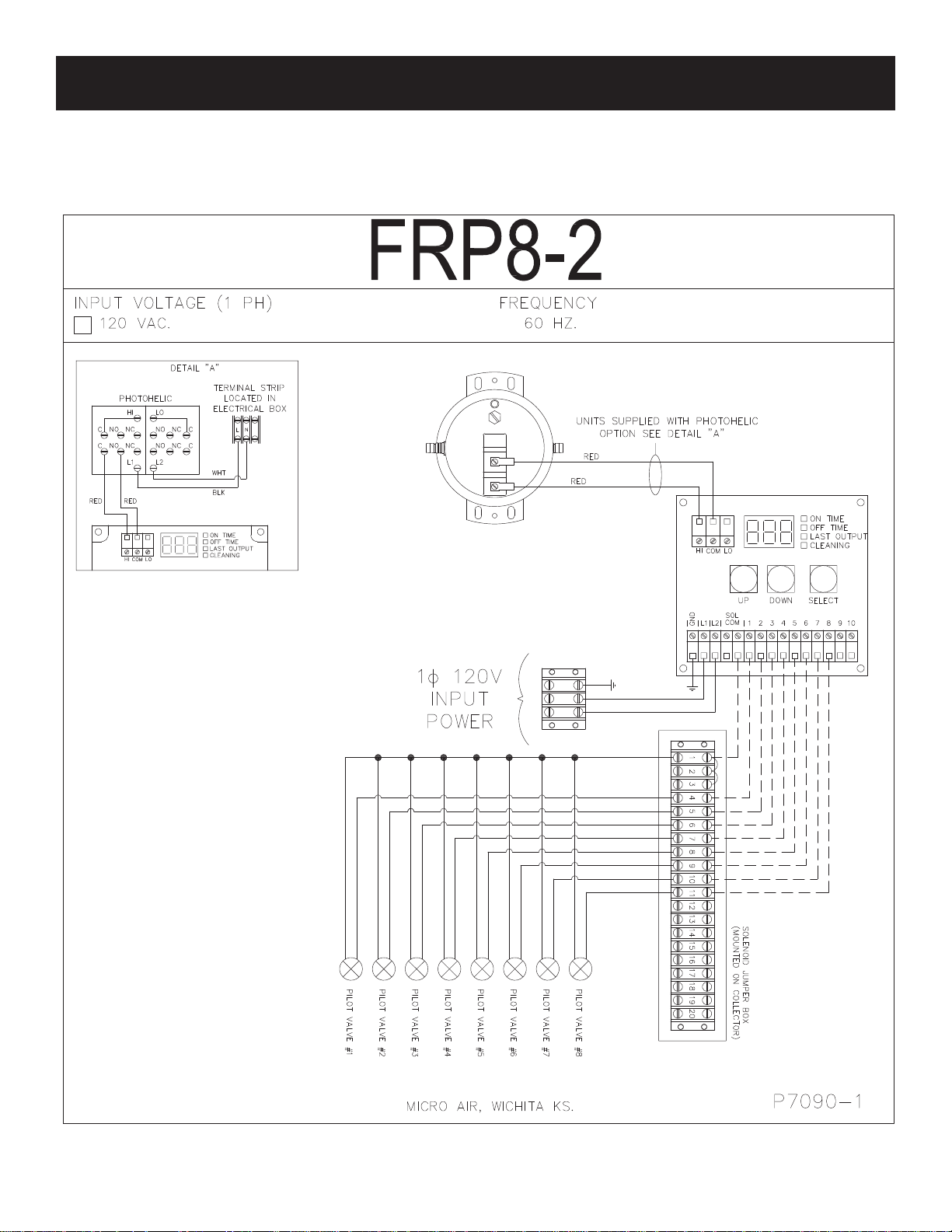

FRP8-2 PULSE CONTROL ONLY WIRING DIAGRAM

19

FRP MICRO AIR®

CLEAN AIR SYSTEMS

FRP8-3 PULSE CONTROL ONLY WIRING DIAGRAM

20

MICRO AIR®FRP

CLEAN AIR SYSTEMS

FRP8-4 PULSE CONTROL ONLY WIRING DIAGRAM

This manual suits for next models

8

Table of contents

Other MICRO-AIR Dust Collector manuals

Popular Dust Collector manuals by other brands

Chiko

Chiko CBA-500AT3-HI instruction manual

King Industrial

King Industrial KC-4043KWRC Service manual

Jet

Jet IAFS-1700 Operating instructions and parts manual

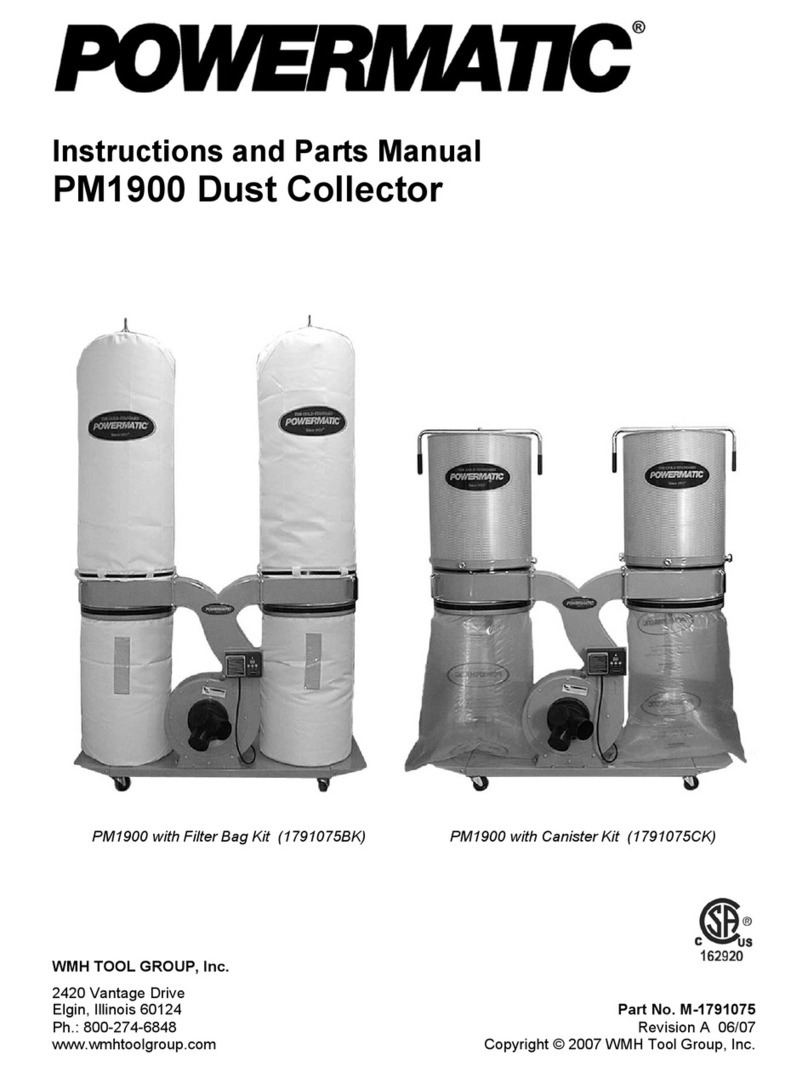

Powermatic

Powermatic PM1900 Instructions and parts manual

Blastrac

Blastrac 655DC operating instructions

Elektra Beckum

Elektra Beckum SPA 2000 Betriebsanleitung