MICRO-AIR Twister RP1 User manual

TWISTER

Micro Air®Installation and Operation Manual

IMPORTANT:

This manual contains speci!c cautionary statements relative to worker safety. Read this manual thoroughly and

follow as directed. It is impossible to list all the hazards of dust control equipment. All persons involved with the

equipment or systems should be instructed how to operate in a safe manner.

RP1

CAUTIONS:

Avoid mixing combustible materials, such as buf•ng

lint, paper, and wood with dust generated from

grinding ferrous metals due to the potential •re hazard

caused by sparks in the unit.

Under no conditions should cigarettes or any other

burning object be put into the unit.

All users of MicroAir dust collection equipment

should comply with all National and Local Fire Codes

and/or other appropriate codes when determining the

location and operation of dust control equipment.

This unit is not suited for applications where explosion

potential is present. Consult the Factory to determine

if there is a risk.

SPECIFICATIONS:

INPUT VOLTAGE:

120V 60Hz 1 Phase

MOTOR/CURRENT:

1.5HP 1PHASE 3450RPM TEFC 120V: 18Amps

OVERALL DIMENSIONS:

Base Unit: 76” H x 25” W x 20” D

FILTER AREA:

80/20 Media: 174 Sq. Feet

Poly Media: 150 Sq. Feet

AIR REQUIREMENTS:

• Minimum air line is 3/4”

• Air Pressure regulated 80 – 90 psi.

• Clean, dry, compressed air at the correct pressure

is required for the cleaning system to operate

correctly. It is recommended that a pressure

regulator and coalescing •lter be installed

between the compressed air source and the inlet

to the table.

INSTALLATION:

INSPECTION:

The MicroAir Twister (RP1) is shipped on one skid.

This skid should be inspected for any visible damage

that may have occurred during shipment. Note any

damage on the packing slip.

EQUIPMENT/TOOLS REQUIRED:

• Standard wrenches.

• Screwdriver

• Forklift

• Pipe Wrench

ASSEMBLY OF UNIT:

Determine the location where the unit is to be

installed. Be sure to allow suf•cient room around the

unit to service the •lters, and allow for exhaust air.

1. Uncrate the unit. Use caution not to damage the

paint while dismantling the crate.

2. Remove any options ordered from the skid.

3. Assemble the optional wall bracket onto the

unit.

4. Carefully mount the unit into its location.

COMPRESSED AIR INSTALLATION

The compressed air inlet for the Roto-Pulse cleaning

system is on the side of the unit. A 3/4” air line is

required (at a minimum) with 80 – 90 psi clean dry

air, for proper operation of the Roto-Pulse®System.

1. Locate the compressed air connection.

2. Connect your standard air •tting to the provided

3/4” NPT thread.

3. Connect your air line to the •tting.

1

ELECTRICAL INSTALLATION:

ALL ELECTRICAL WORK MUST BE DONE BY

A QUALIFIED ELECTRICIAN ACCORDING

TO LOCAL CODES

INSTALLATION CAN CAUSE EXPOSURE TO

LIVE COMPONENTS. DISCONNECT ELEC-

TRICAL POWER BEFORE PROCEEDING

WITH INSTALLAITON. PROPER LOCK OUT/

TAG OUT PROCEDURES SHOULD BE USED.

If the unit is ordered with 120V electrical wiring there

is no additional wiring required. Simply plug the unit

into any 110/120V electrical plug rated for 15A.

UNIT OPERATION:

1. To start the unit, turn the switch located on the

front of the unit to the on position. To stop the

unit, turn the switch to the off position.

CARTRIDGE CLEANING OPERATION:

The Micro-Air®Twister is designed with the Roto-

Pulse® Cleaning System to clean the cartridge !lters.

This system provides superior cleaning performance

using a rotating tube with pre-drilled holes. As the

diaphragm valve opens, the Roto-Pulse®tube rotates

while air exits the holes, thus providing the cleaning of

the cartridge.

• For proper cleaning, the compressed air pressure

should be regulated at 80 - 90 psi maximum.

• During normal operation the Roto-Pulse®

cleaning system is activated by depressing the

pulse button located on the electrical box.

• The Roto-Pulse®cleaning operation dislodges

particles from the cartridges. Particles then fall

down into the collector.

NOTE: When servicing the collection system, be sure

to turn the unit off.

PULSE TIMING:

The Twister is provided with a manual pulse option

as the standard for all units. The !lters can be pulse

cleaned by depressing the pulse button (located on

the front of the electrical box) and holding it down

for approximately 2 seconds. Since the unit does not

have “Auto-Pulse” the !lters should be pulse cleaned

regularly throughout the day. In addition they should

be pulsed several times after the blower has been shut

off.

NOTE: Cleaning of the filters too often will decrease

your level of performance. A certain level of dust

cake on the filters will improve the efficiency of the

filter cartridges. You should try to maintain a mini-

mum of 1 in w.c. of pressure differential across the

filters. If you can not maintain this minimum level

of differential across the filters the time between

cleaning pulses should be increased until this can be

achieved.

MAGNAHELIC INSTALLATION:

1. Turn off dust collector and disconnect power to

the unit.

2. Mount the Magnehelic Gauge into the

Magnehelic Mounting Bracket and place the (2)

male barb !ttings in the pressure ports locatedon

the side of the Magnehelic Gauge.

3. Also use the two pressure port plugs supplied

with the Magnehelic Gauge on the two ports

located on the backside of the gauge.

4. Mount the bracket. Do not mount the bracket on

the unit. Mounting screws may damage internal

components.

5. Using 1/4” clear tubing (Additional length can be

purchased) connect the “LOW” pressure port on

the gauge to the clean air plenum and “HIGH”

pressure port to the dirty air plenum.

6. Reconnect the power to the unit and start the dust

collector.

2

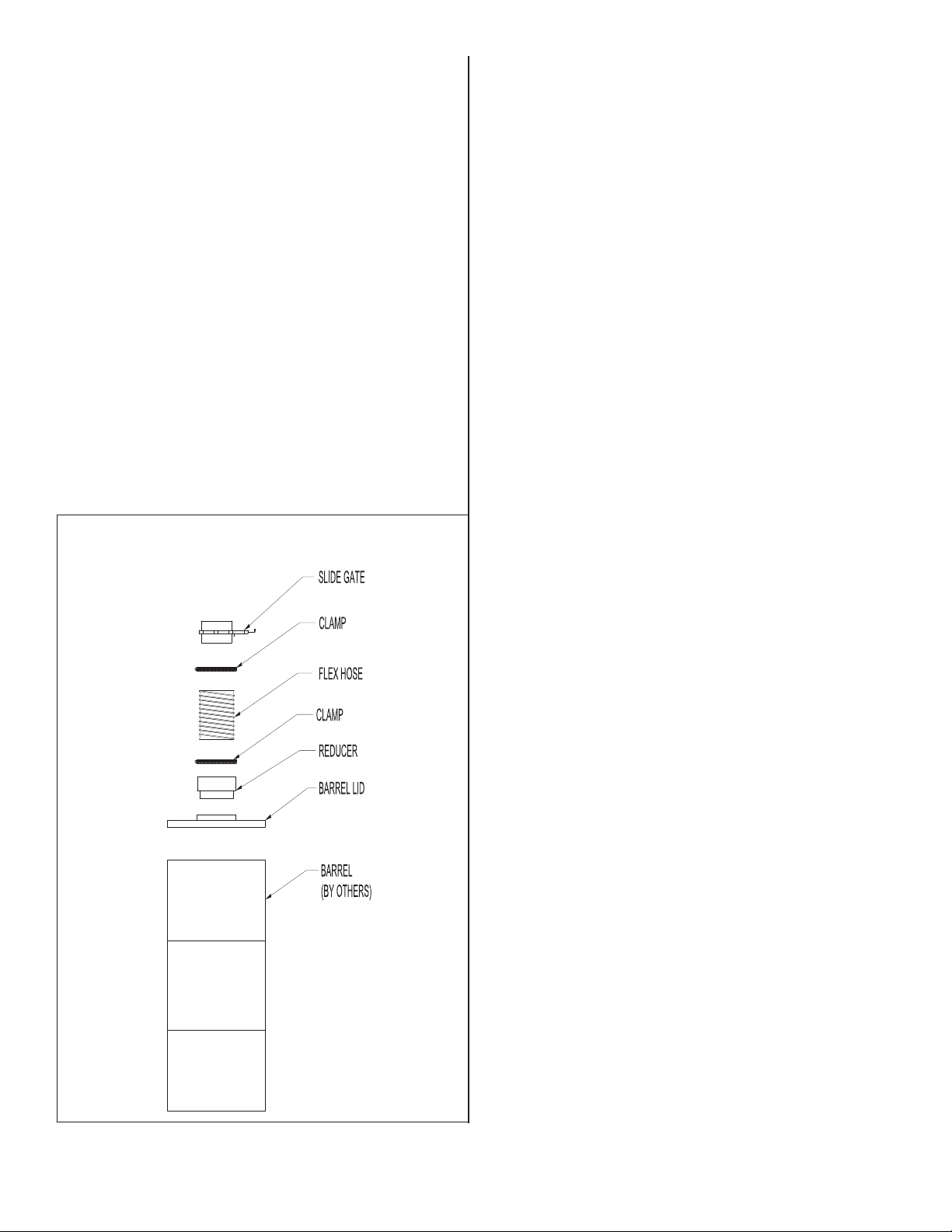

BARREL LID INSTALLATION:

1. Remove parts from box and inspect for any

possible damage incurred during shipping.

2. Using the 10” hose clamp attach the 8” flex hose

to the collar on the slide gate.

3. With the remaining 10” hose clamp attach the

barrel lid flex hose to the collar on the top of the

8” to 10” reducer.

4. Attach the 10” side of the reducer to the barrel

lid.

5. With barrel lid installed a 55 gallon barrel (not

provided) can be placed under the barrel lid for

material collection.

FILTER CHANGE:

1. Turn unit off. Manually pulse the unit several

times to remove excess material from the filter.

2. Disconnect power to the unit.

3. Open the slide gate to empty any remaining

material from the hopper.

4. Remove the barrel, barrel lid kit, and hopper by

loosening the lowest joint band. The drop out

plate will come off with the hopper.

5. Remove the 4-Prong knob and seal washer from

below the filter. Save the knob.

6. Slide the filter down out of the unit.

7. Reverse steps 4-6 to install new filter.

See Parts List Diagram for additional assistance.

3

Parts List Diagram

Item # Part # Description Item # Part # Description Item # Part # Description

1 36720-10 Roto-Pulse Assembly 20 P1050 Edge Protector 35 P2704 3/8” Washer

2 38151-01 Body Weldment 21 P119 5/16-20 Bolt 36 P2766 Pulse Push Button

3 38154-01 Clean Air Plenum 22 P124 3/8 - 16 Bolt 37 P3403 5/8” ID Hose

4 38155-01 Roto-Pulse Seal Plate 23 P1363 Cord w/Plug 38 P3411 1” Hose Clamp

5 38155-02 Blower Seal Plate 24 P141 3/8” Nut 39 P3158 8” Slide Gate

6 38155-03 Motor/Fan Plate 25 P142 3/8” Lock Washer 40 P345 14 Ga Cord

7 38155-04 Drop-Out Plate 26 P164 1/4-20 Bolt 41 P3508 5/16” Rivnut

8 38155-05 Exhaust Grill 27 P1954 Cord Strain Relief 42 P3559 Rubber Washer

9 38158-01 Hopper 28 P2059 #8 Screw 43 P3585 Hose Barb

10 38160-01 Silencer Assembly 29 P2075 Diaphram Valve 44 P3649 Knob

11 38162-01 Joint Band 30 P2301 1 1/2HP Motor 45 P3734 1/4” OD Air Hose

12 38165-01 Electrical Box Weldment 31 P2302 Blower Assembly 46 P3735 90° Presto Lock

13 38168-01 Electrical Box Cover 32 P233 5/16” Washer 47 P3924 Straight Presto Lock

33 P242 1/4” Lock Washer 48 P7401RM 80/20 Cartridge Filter

34 P249 5/16” Lock Washer 48 P7410RM Poly Cartridge Filter

4

Notes:

Installation Date: Location:

Machine Number: Installer:

Air Pressure: Air Line Size:

FilterType: 80/20 Cellulose Media (Red) OR Polyester Media (White)

Distributor Company: Contact Name:

Phone Number: ( ) -

Other Notes:

Micro Air Inc Form. No. L2466 09/18

5

Table of contents

Other MICRO-AIR Dust Collector manuals

Popular Dust Collector manuals by other brands

ROMANOFF

ROMANOFF 1000 CFM product manual

Oneida Air Systems

Oneida Air Systems XXVM001500 owner's manual

ILMEG

ILMEG X-150 Installation and operating instructions

Enke

Enke I.VAC User and maintenance handbook

ISTblast

ISTblast DCM-100 instruction manual

Oneida Air Systems

Oneida Air Systems XXK050100 owner's manual

Donaldson Torit

Donaldson Torit TBV-2 Installation and operation manual

Woodtec

Woodtec XW117 instruction manual

Bucktool

Bucktool DC30A instruction manual

Jet

Jet DC-1200-M operating instructions

Donaldson Torit

Donaldson Torit Unimaster UMA 40 Installation and operation manual

Texas Equipment

Texas Equipment COLLECTOR BOX Assembly instruction