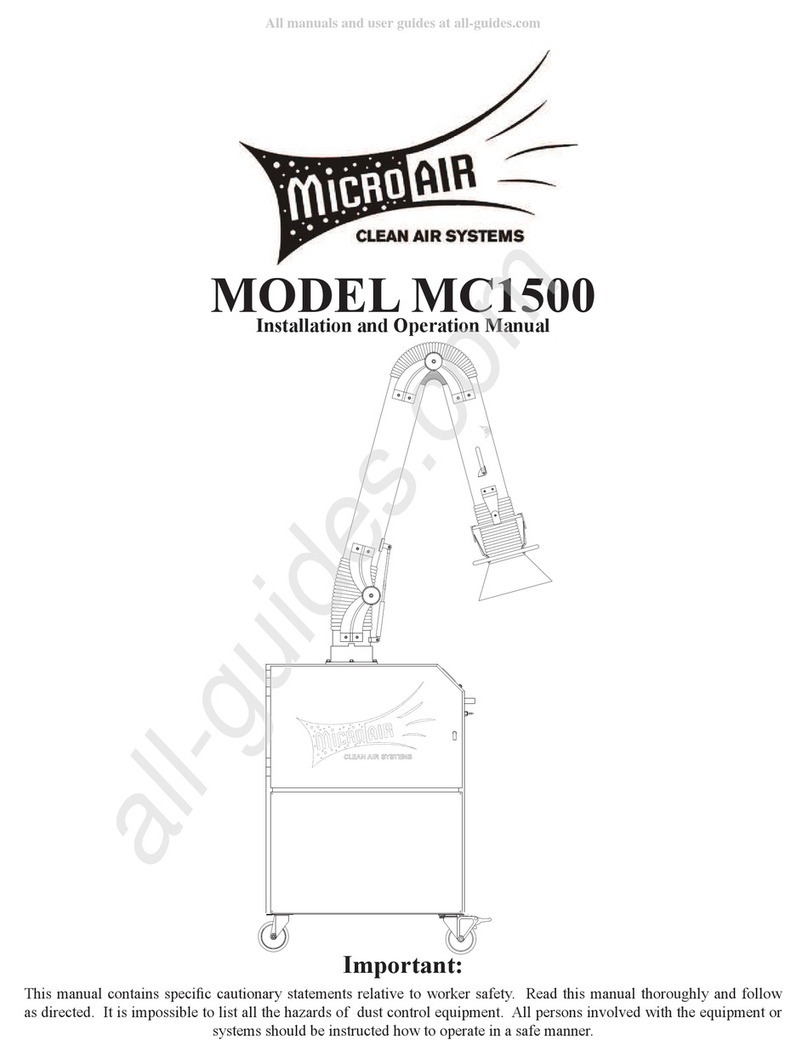

MICRO-AIR MC1500 User manual

Installation and Operation Manual

Important:

This manual contains speci•c cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all the hazards of dust control equipment. All persons involved with the equipment or

systems should be instructed how to operate in a safe manner.

MODEL MC1500

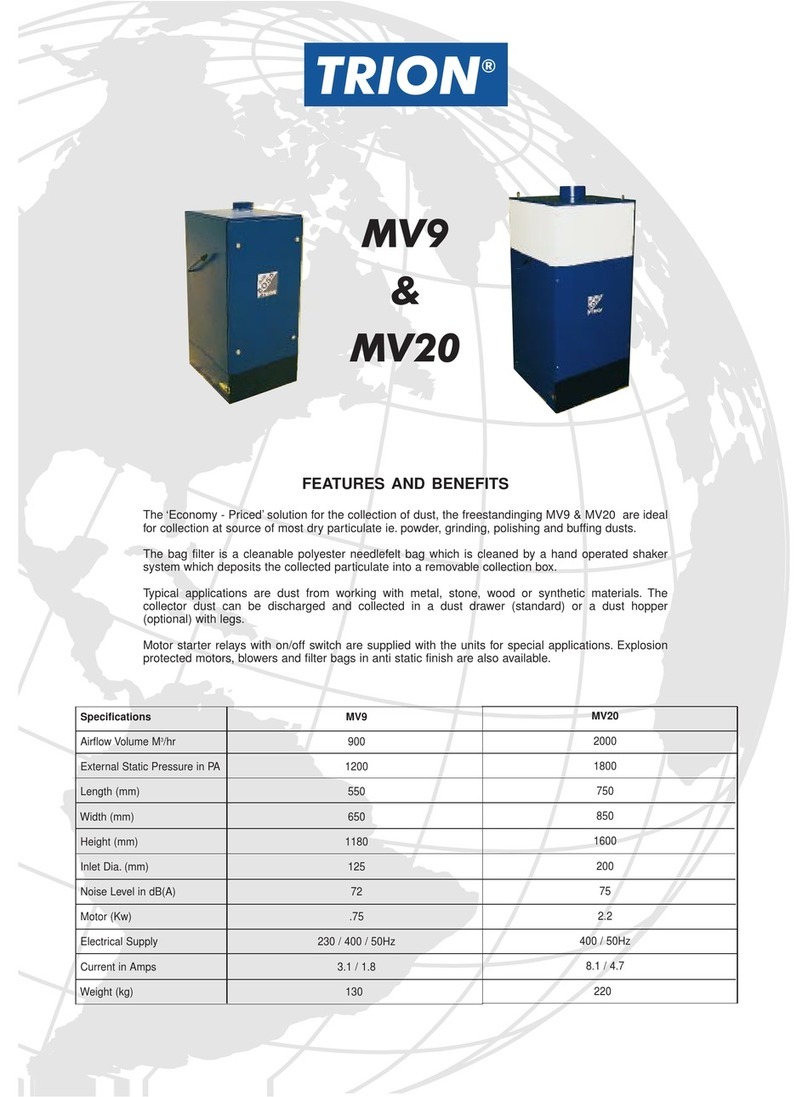

MODEL MC1500 SPECIFICATIONS

INPUT VOLTAGE:

208-230V / 460V 60Hz 3 Phase

MAX. CURRENT:

12.0 Amps at 208-230V

6.0 Amps at 460V

MOTOR:

TEFC 5HP, 3 Phase

COMPRESSED AIR:

80 psi. minumum, 90 psi. maximum. 1/4” NPT male

nipple connection. Clean, dry air requried.

FILTER AREA:

174 sq. ft. per cartridge •lter (348 sq. ft. total)

DIMENSIONS: 48” h. X 25-1/2” w. X 32-1/2” l.

SHIPPING WEIGHT: 525 lbs.

ACTUAL WEIGHT: 475 lbs.

PACKAGE CONTENTS:

1 Ea. MC1500

OPTIONS (These items are separately packed):

1 ea. 8” dia., 7’ Arm Assembly

1 ea. 8” dia., 9’ Arm Assembly

2 ea. 6” dia., 7’ Arm Assembly

2 ea. 6” dia., 9’ Arm Assembly

Caution:

All electrical work must be done by a

qualified electrician according to local, state

and national codes.

PRE-OPERATING INSTRUCTIONS:

NOTE: The following instructions will vary depending on

options received.

1. Remove the shipping crate, shipping straps and plastic

wrapping from the unit.

2. Remove the MC1500 from the shipping skid and set on

a level surface.

3. Remove the attachment option from the shipping

carton.

4. Install the arm assembly onto the base unit (Fig. 1A).

5. Insert the lamp plug on the arm into the receptacle

located directly behind the base of the arm on the

MC1500. Secure the arm cable in clamp provided on

mounting plate (Fig. 1B).

OPERATING INSTRUCTIONS:

1. Choose a suitable, level place near the workstation and

position the unit so that the hose/arm assembly will be

placed near the source of pollution being generated.

The MC1500 has locking wheels at the front handle

end. The wheels are locked by stepping down on the

!at plate on the wheels.

2. Grasp the hood by the handle ring and position within

18” of the source of pollution.

3. Plug the power cord into a outlet of the appropriate

voltage and phase.

MICRO AIR®MC1500

CLEAN AIR SYSTEMS

!

2

Fig. 1A

Fig. 1B

Bolt

Connect hose to unit

using hose clamp.

Flat Washer

Lock Washer

4. Turn the power switch on (located near the Mini-Helic

gauge).

5. The light control switch (optional) is mounted on the

hood. Turn the light on as needed.

6. Adjust the hood to capture the maximum amount of

contaminants. Periodically adjust the position of the

hood to keep it in maximum capture range.

7. If the unit fan is rotating incorrectly, switch L1 and L2

connections to reverse the rotation direction.

MINI-HELIC GAUGE OPERATION:

1. As the cartridge filters collect airborne pollutants

they will eventually begin to become loaded with

particulate. The filter loading will cause an increase in

static pressure and a decrease in air flow.

2. The Mini-Helic gauge on the control panel indicates

static pressure. Note the reading at the initial start-up.

As the unit is operated the static pressure will gradually

increase as the filters become loaded. This will indicate

the need to back flush the system.

CARTRIDGE CLEANING:

NOTE: Pulse clean cartridge filters frequently for proper

operations. Failure to do so will decrease performance and

lead to pre-mature filter failure.

1. The MC1500 is designed with a Roto-Pulse system to

clean the cartridge filters.

2. Attach a shop air hose to the inlet located on the front

of the MC1500. It is recommended that a pressure

regulator and water trap be installed between the shop

air and the MC1500,

NOTE: Do not exceed 90 psi of shop air. Exceeding 90psi

will result in filter damage.

3. Shut off the MC1500 blower.

4. Push the cartridge back-flush control button (mounted

on the control panel) three or more times. This

operation initiates the Roto-Pulse system which spins

the tube inside the cartridge filter. As the tube spins, air

dislodges the dirty particles from the cartridge filters.

Theses particles then settle into the two removable dust

trays.

5. After several cleaning cycles, the dust particles that

have been collected by the MC1500 will need to be

emptied from the dust trays. The frequency of dust

removal depends on the type and quantity of pollutant

that is collected. The dust trays should be emptied

before the particles have accumulated to a depth of 1/2

inch.

6. To remove the dust trays from the MC1500, turn the

unit off. Open the cartridge access door and slide out

the dust trays.

7. Dump the dust out of the trays.

8. Slide dust trays back into the MC1500. Close and latch

the filter access door.

CHANGING FILTERS:

Caution:

Always make sure that the unit is turned

off before changing filters or servicing the

unit.

1. Turn the MC1500 off and open the filter access door.

2. Remove the cartridge filters retained by wing nuts.

3. Slide new cartridge filters into the cabinet and retain

with wing nuts.

4. Close the filter access door.

GENERAL MAINTENANCE:

1. Check the wiring for loose connections for cracked

insulation.

4. No lubrication is required for the motor because it is a

permanent pre-lube design.

5. Once per month grease the suction arm base assembly

with a bearing grease listed to not react with aluminum.

MC1500 MICRO AIR®

CLEAN AIR SYSTEMS

3

!

4

Fig. 2

OPTIONAL HEPA / CHARCOAL FILTER INSTALLATION:

KIT CONTENTS:

1. 1 Ea. Filter Track

2. 2 Ea. Stretch Cord

3. 6 Ea. #8 x 1/2” SMS

4. 1 Ea. HEPA Filter or RCM Module

INSTALLATION:

1. Remove the four (4) screws used to attach the lower panel and remove lower panel from the MC1500.

2. Locate filter tracks shown in Fig. 2. Filter track is to be located flush to front edge of cabinet bottom and centered

above the exhaust opening.

4. Secure filter track to the MC1500 using six (6) each #8 x 1/2” sheet metal screws provided.

5. To install filter, slide the filter in between tracks so that the airflow arrow points downward.

6. Retain the filter with stretch cords provided.

7. Replace the lower panel.

MICRO AIR®MC1500

CLEAN AIR SYSTEMS

Locate Filter Enclosure Flush

With Edge Of Cabinet Bottom

Lower Panel

RCM or HEPA

#8 x 32 SMS

Filter Track

Stretch Cord

5

Fig. 3

OPTIONAL SILENCER INSTALLATION:

KIT CONTENTS:

1 Ea. Silencer Box Assembly

6 Ea. #8 x 1/2” SMS

INSTALLATION:

1. Remove the four (4) screws used to attach the lower panel and remove the lower panel from the MC1500 unit.

2. Locate the silencer box assembly (Fig. 3). Silencer assembly is to be located !ush to front edge of cabinet bottom and

centered above the exhaust opening.

3. Attach the silencer box assembly using the six (6) sheet metal screws provided.

4. Replace the lower panel.

MC1500 MICRO AIR®

CLEAN AIR SYSTEMS

Lower Panel

#8 x 32 SMS

Silencer Box Assembly

6

MICRO AIR®MC1500

CLEAN AIR SYSTEMS

PAGE LEFT INTENTIONALY BLANK

7

MC1500 MICRO AIR®

CLEAN AIR SYSTEMS

OPTIONAL BIG WHEEL INSTALLATION:

KIT CONTENTS:

1 Ea. Big Wheel Assembly

8 Ea. 5/16-18 x 1” Hex Bolt

INSTALLATION:

1. Position the unit on its’ side with the bottom exposed.

2. Remove the four (4) bolts, !at washers and lock washers retaining each "xed wheel. Retain the hardware for use in

step four.

3. Place the Big Wheel Assembly onto the unit. Align the eight slotted holes over the holes in the unit, making sure that

the Big Wheel Assembly presses against the back wall of the unit.

4. Install the lock washer, !at washer and the 1” long hex bolts supplied with the kit. Secure the Big Wheel assembly to

the unit with the eight (8) 1” long hex bolts. Make sure the bolts are tight.

5. Position the unit onto the wheels and reattach any attachments removed for installation.

Caution:

Source capture arms or other attachments must no be attached during kit installation.

!

Fig. 5A

Fig. 5B

Lock Washer

Flat Wahser

5/16-18 x 1” Hex Bolt

8

MC1500 WIRING DIAGRAMS

Fig. 6

MICRO AIR®MC1500

CLEAN AIR SYSTEMS

9

Fig. 7

MC1500 MICRO AIR®

CLEAN AIR SYSTEMS

MC1500 WIRING DIAGRAMS

10

MICRO AIR®MC1500

CLEAN AIR SYSTEMS

ITEM PART NO. DESCRIPTION

1. 37107-01 Lamp Plate

2. P2170 Lamp

3. P2168 Lamp Socket

4. P2466 6” Hood Assembly

P2469 8” Hood Assembly

5. 37106-01 Switch Box

6. P2219 Rocker Switch

7. P164 1/4-20 x 3/4” Hex Head Bolt

8. P246 1/4 Flat Washer

9. P2482 Hood Disc Pad

10. P2485 1/4-20 Nylock Hex Nut

11. 37104-01 Damper Handle Stop Plate

12. P2206 5/16” Flat Washer

13. P2484 5/16” Nylock Hex Nut

14. 37103-01 Damper Handle

15. P2478 1/2-13 x 2.25” Hex Head Bolt

ITEM PART NO. DESCRIPTION

16. P2468 Cup Washer

17. P2467 Friction Pad

18. P2479 1/2-13 Nylock Hex Nut

19. P141 3/8-16 Hex Nut

20. P142 3/8” Lock Washer

21. P2206 Flat Washer

22. P2481 3/8-16 x 1.25” Carriage Bolt

23. P2461 6” Gas Shock

P2462 8” Gas Shock

24. P2483 1/4-20 x 1” Hex Head Bolt

25. P2312 Micro Air Decal

26. P2232 Hose Clamp

27. P2616 6” Dia. Flex Hose

P2617 8” Dia. Flex Hose

N/S P2471 4 Conductor Cable - 9’ long

N/S P2472 4 Conductor Cable - 15’ long

6” & 8” DIAMETER ARM ASSEMBLY PARTS LIST

Fig. 9

11

MC1500 PARTS LIST

ITEM PART NO. DESCRIPTION

1. 36876-01 Cabinet

2. 36885-01 Back Panel

3. 34294-02 Filter Door

4. P3280 Impeller

5. P2320 Motor (208/230-460V, 3-Phase)

6. 36923-01 Motor Mount

8. 36561-01 Dust Tray

9. 36882-01 Lower Panel

10. 36720-14 Roto Assembly

11. P2534 Transformer

12. P3911 Relay

P3916 Overload Protector (208-230V)

P3915 Overload Protector (460V)

13. P3283 Swivel Caster

14. P3284 Fixed Caster

15. P7401RM 80/20 Cartridge Filter

16. P3392 Push Button Air Valve

17. P2215 Handle

* Specify Length Required

ITEM PART NO. DESCRIPTION

18. P1372 Latch

19. P2221 Mini-Helic Gauge

*20. P1367 3/4” x 1” Foam Gasket

P3743 3/4” x 1-1/4” Foam

21. 36712-01 Accumulator Tank

22. P3281 1” Diaphragm Valve

23. P3278 Receptical

*24. P1818 Power Cord

25. P2735 230V Plug

P2736 460V Plug

26. P2222 1/4” Barb x 1/8” NPT

27. P2210 1/8” Male x 1/4” Male Hex Nipple

28. P3649 Filter Knob

29. 36933-01 Adapter Plate (Dual Inlet)

36932-01 Adapter Plate (Single Inlet)

33. P2835 Hinge

Fig. 10

MC1500 MICRO AIR®

CLEAN AIR SYSTEMS

CAUTION: BEFORE DISASSEMBLING THE UNIT OR DOING ANY INSPECTING OF THE PARTS, MAKE

CERTAIN THAT THE POWER HAS BEEN CUT OFF AND THE BLOWER HAS COME TO A COMPLETE STOP.

NEVER RUN THE UNIT WITH THE ACCESS DOOR OPEN OR REMOVED.

PROBLEM POSSIBLE CAUSE REMEDY

Unit fails to start No incoming power

Blown breaker or fuse

Primary voltage to motor contactor is below 10%

tolerance

Burned out motor

Tripped overload (3 Phase)

Check line voltage

Replace fuse or throw breaker

Take steps to increase voltage to primary

Replace motor

Reset overload protector

Unit runs slowly or

inadequate capture

velocity

Wired for wrong voltage or improper rotation

Dirty filters

Internal obstruction

Check input voltage

Check wiring diagram

Switch L1 & L2 (3-phase only)

Service / Replace filters

Check if damper is open

Check inlet for blockage

Check hoses for proper connection

Check hoses for holes

Vibration Loose mounting bolts

Foreign objects in blower

Dirty disposable filters

Tighten bolts

Remove debris from blower

Service or replace filters

Unit runs for a

short period of

time and stops

Exhaust restrictor plate removed

Incorrect extension cord size (120V)

Re-install Restrictor plate

Plug directly into outlet

Use a cord rated to 20 Amps

Stronger resistance

during rotation of

the arm

Lack of grease in the rotating socket Grease the rotating socket

Arm will not stay

where it is placed

The joints are loose Tighten the joints

TROUBLE SHOOTING CHART

12

MICRO AIR®MC1500

CLEAN AIR SYSTEMS

13

MC1500 MICRO AIR®

CLEAN AIR SYSTEMS

Serial Number:

Supply Voltage:

Date Installed:

Installed By:

Notes:

L1346

09/18

Other manuals for MC1500

1

Table of contents

Other MICRO-AIR Dust Collector manuals

Popular Dust Collector manuals by other brands

RoboVent

RoboVent VentBoss 300 Series owner's manual

Oneida Air Systems

Oneida Air Systems Dust Deputy AXD002030 owner's manual

Chiko

Chiko CCB-080AT-08-HC-V1 instruction manual

Trelawny

Trelawny A45 Operation and maintenance manual

DeWalt

DeWalt DWE575DC quick start guide

Hafco Woodmaster

Hafco Woodmaster DC-90 instruction manual

Makita

Makita DX06 instruction manual

Donaldson

Donaldson DLM V Series Installation, operation and maintenance manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operating and parts manual

Grizzly

Grizzly G0548ZP owner's manual

Woodstock

Woodstock W1666 instruction manual

Dust Right

Dust Right 650 CFM instruction manual