boreCONTROL

Contents

1. Safety .......................................................................................................................................... 5

1.1 Symbols Used .................................................................................................................................. 5

1.2 Warnings........................................................................................................................................... 5

1.3 Notes on CE Identification................................................................................................................ 5

1.4 Proper Use........................................................................................................................................ 6

1.5 Proper Environment ......................................................................................................................... 6

2. Functional Principle, Technical Data ......................................................................................... 6

2.1 Short Description.............................................................................................................................. 6

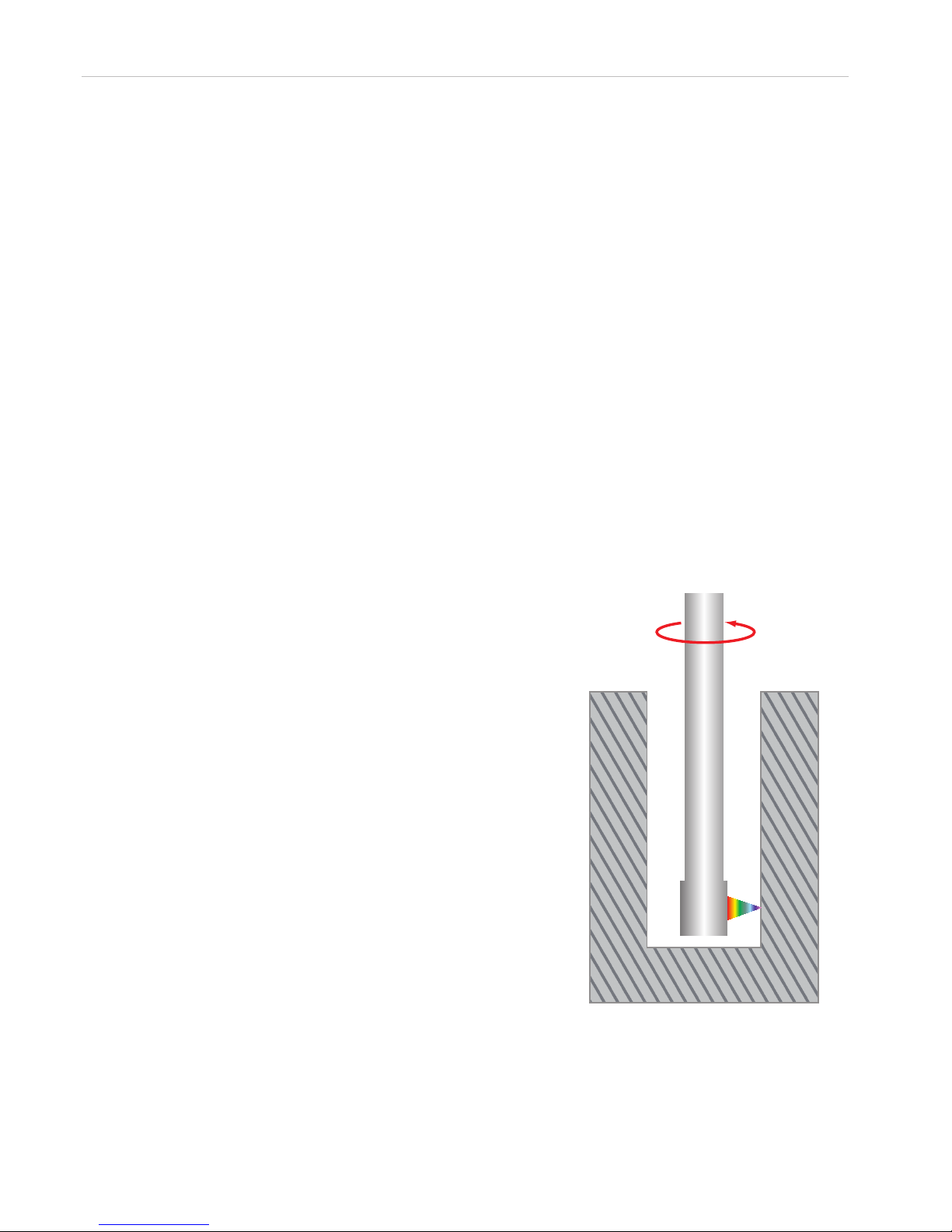

2.2 Measuring Setup .............................................................................................................................. 7

3. Delivery ....................................................................................................................................... 8

3.1 Supplied Items.................................................................................................................................. 8

3.2 Storage ............................................................................................................................................. 8

4. Mounting..................................................................................................................................... 8

4.1 Rotation Unit BCM2410.................................................................................................................... 8

4.2 Controller BCC2410 ......................................................................................................................... 9

4.3 IFC24x1........................................................................................................................................... 10

4.4 Electrical Connections BCC2410................................................................................................... 10

4.4.1 Power Supply ................................................................................................................................. 10

4.4.2 Rotation Unit BCM2410.................................................................................................................. 11

4.4.3 IFC 24x1.......................................................................................................................................... 11

4.4.4 RS232 ............................................................................................................................................. 11

4.5 Electrical Connections IFC24x1 ..................................................................................................... 12

4.5.1 Power Supply ................................................................................................................................. 12

4.5.2 Ethernet .......................................................................................................................................... 12

4.5.3 Rotation Unit ................................................................................................................................... 13

4.6 Mounting the Sensor Lance BCS241x-x ........................................................................................ 14

4.7 Dismounting the Sensor Lance BCS241x-x................................................................................... 15

5. Acquiring the Dark Signal........................................................................................................ 16

6. Warranty.................................................................................................................................... 17

7. Service, Repair ........................................................................................................................ 17

8. Decommissioning, Disposal ................................................................................................... 17

9. Declaration of Incorporation.................................................................................................... 18