INTRODUCTION/QUICK START

7

Introduction / Quick start

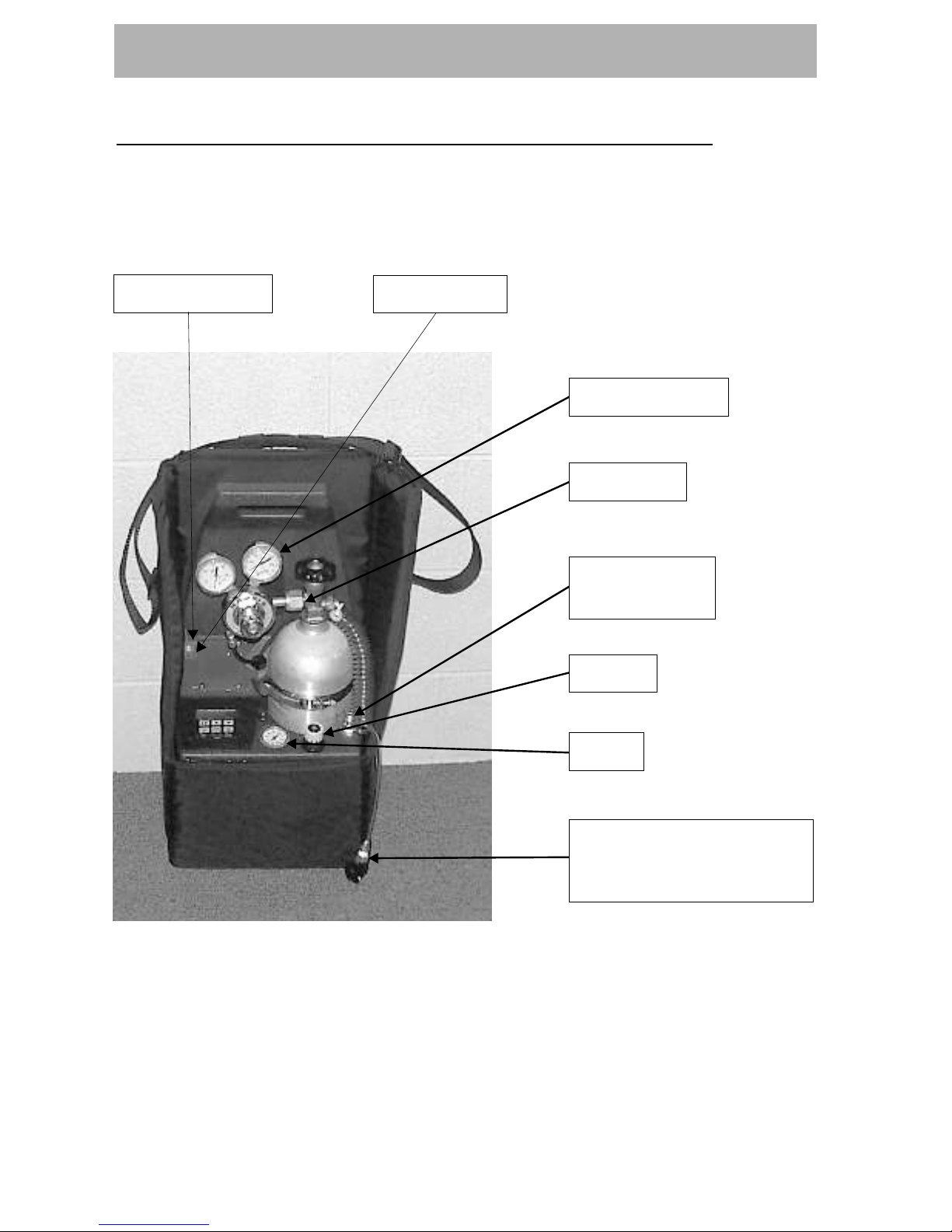

Introduction: The MP15 Micro Purge Basics Controller is used to

operate QED Well Wizard bladder sampling pumps to purge and sample

ground water. The MP15, with its self-contained CO2 cylinder (or

another compressed gas source connected to the bypass supply fitting)

is taken portably from well to well. The MP15 has specific design fea-

TM

tures to make MicroPurge sampling easier. These features include:

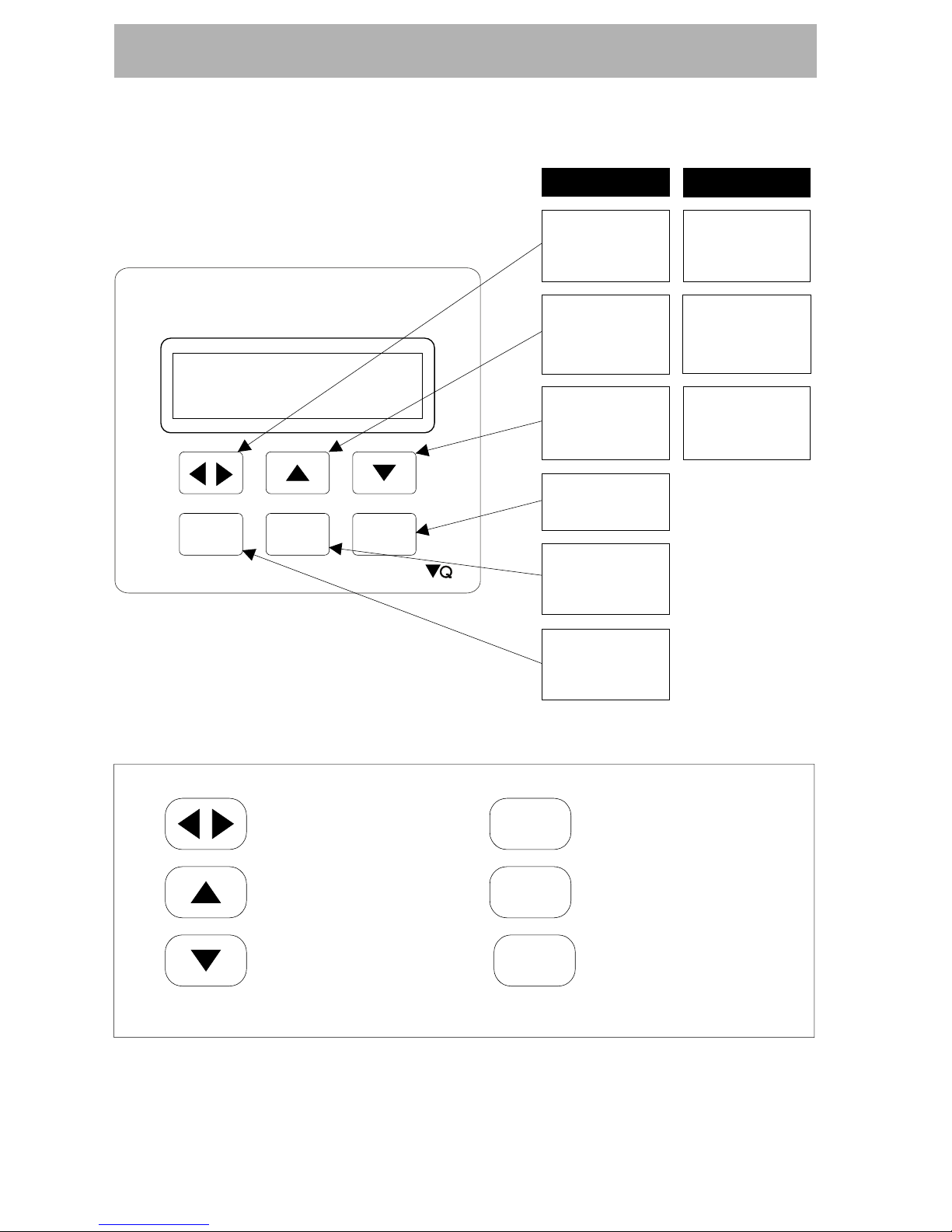

MicroPurge Mode Operation Simple Increase / Decrease keys

allow you to easily set the flow rate you need for each well.

ID Time Set Mode Operation Quickly recalls pre-determined set-

tings for each well by specifying a 3-digit ID.

Level Delay Interface The controller plugs into the optional MP30

MicroPurge Drawdown / Water Level Meter to provide direct feed-

back of well drawdown and to pause pump operation until the level

recovers.

The optional MP30 MicroPurge Drawdown / Water Level Meter plugs

into the MP15 to provide water level feedback. The MP30 uses a stan-

dard conductivity probe to detect the ground water surface and a marked

tape allowing the user to measure the depth. When the meter is set in

MicroPurge mode, the probe is lowered a specific distance below the

static water level and fixed in this position. During well sampling if the

water level drops below the user-set probe position, the MP15 is paused

which prevents further drawdown by the pump. Once the level recovers

the MP15 begins pump operation again, starting in the pump refill cycle.

Use of the MP15 with the MP30 is detailed later in this manual.

Insert Batteries: Remove the battery cover on the top of the MP15.

Insert 3, AA alkaline batteries into the battery holder and carefully rep-

lace the holder in the carrier. Replace the battery cover and tighten the

4 screws. Batteries should last for about 6-8 weeks of typical full-time

field use. If the MP15 will be stored longer than 3 months, the alkaline

batteries should be removed to prevent leakage.