MICROELETTRICA MC30-BC User manual

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

1

of

37

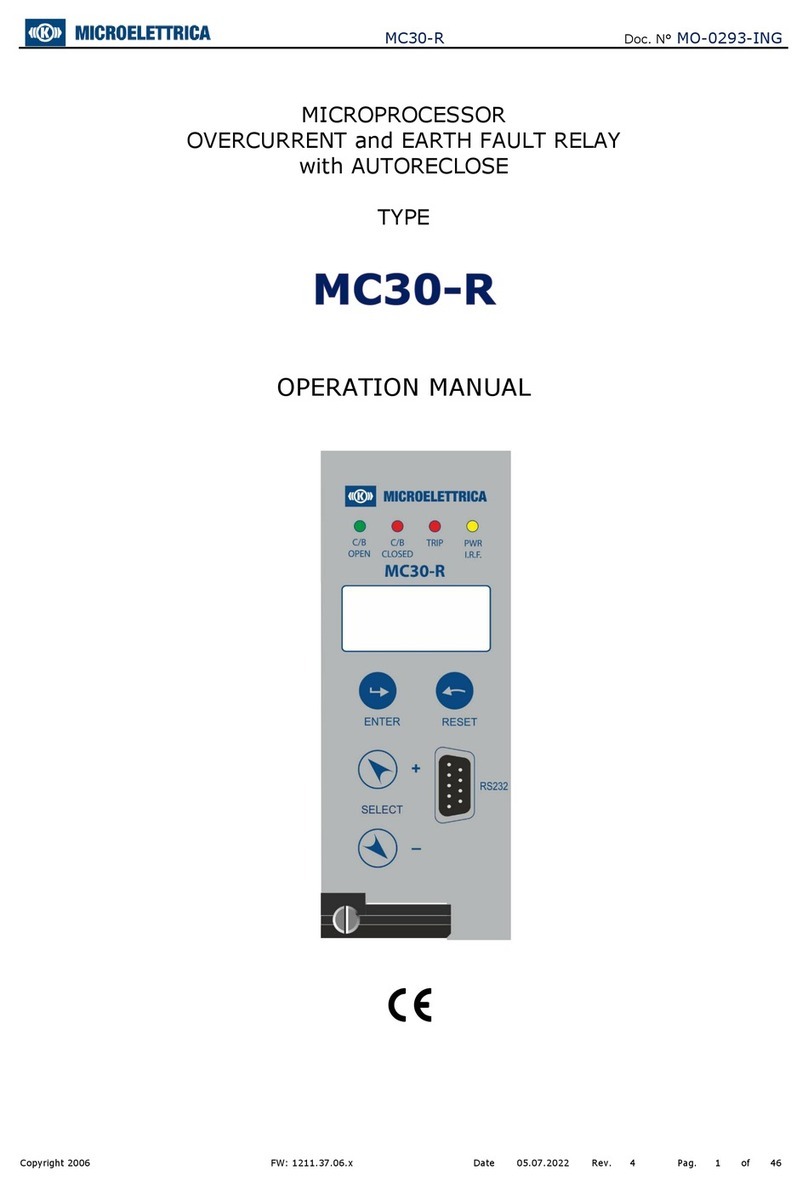

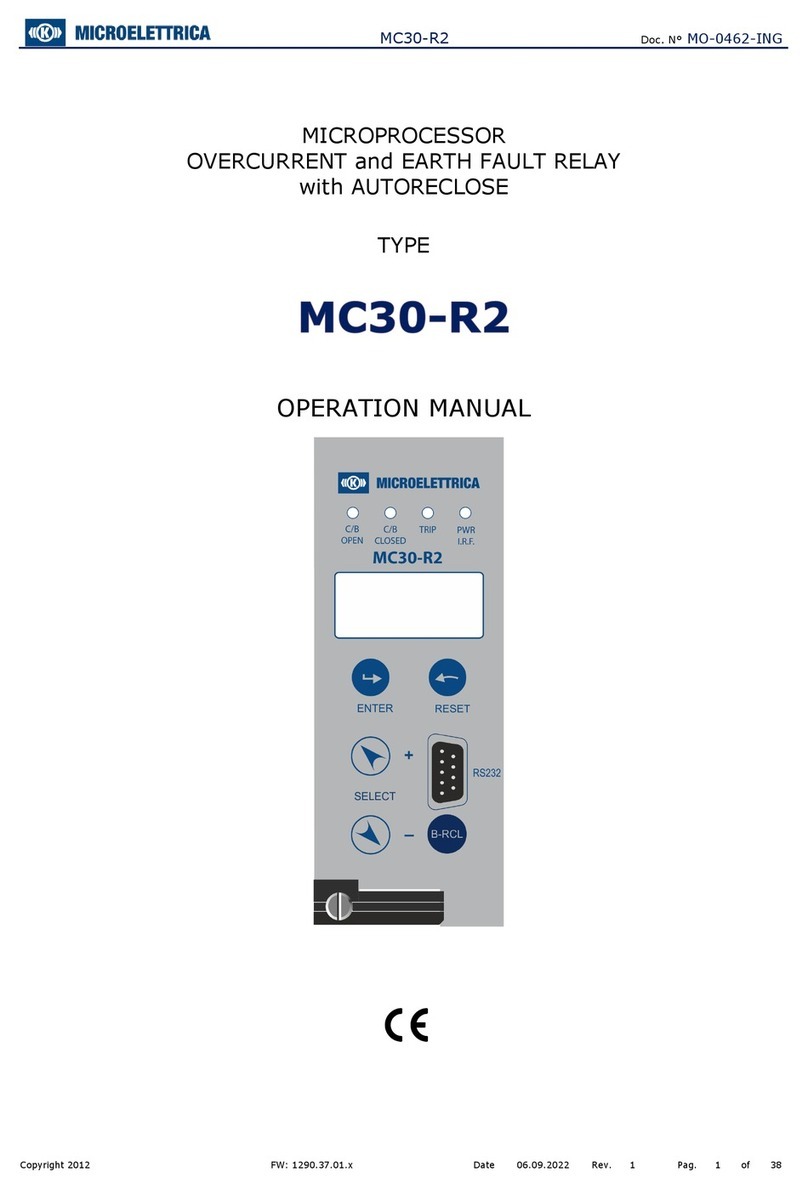

MICROPROCESSOR

OVERCURRENT & EARTH FAULT+

BROKEN CONDUCTOR

RELAY

TYPE

OPERATION MANUAL

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

2

of

37

1. General Utilization and Commissioning Directions ________________________________________________________3

1.1 - Storage and Transportation______________________________________________________________________3

1.2 - Installation __________________________________________________________________________________3

1.3 - Electrical Connection ___________________________________________________________________________3

1.4 - Measuring Inputs and Power Supply _______________________________________________________________3

1.5 - Outputs Loading ______________________________________________________________________________3

1.6 - Protection Earthing ____________________________________________________________________________3

1.7 - Setting and Calibration _________________________________________________________________________3

1.8 - Safety Protection______________________________________________________________________________3

1.9 - Handling ____________________________________________________________________________________3

1.10 - Maintenance ________________________________________________________________________________4

1.11 - Waste Disposal of Electrical & Electronic Equipment __________________________________________________4

1.12 - Fault detection and repair ______________________________________________________________________4

2. General Characteristics _____________________________________________________________________________5

2.1 - Power Supply ________________________________________________________________________________5

2.2 - Operation and Algorithms _______________________________________________________________________6

2.2.1 - Reference Input Values _____________________________________________________________________6

2.2.2 - Input quantities ___________________________________________________________________________6

2.2.3 - Time Current Curves IEC (TU1029 Rev.0) _______________________________________________________8

2.2.4 - Time Current Curves IEEE (TU1028 Rev.0) ______________________________________________________9

3. Functions and Settings (Function) ____________________________________________________________________10

3.1 - T> (F49) - Thermal Image protection level_________________________________________________________10

3.1.2 - Thermal Image Curves (TU0445 Rev.0)________________________________________________________11

3.2. - I> (1F51) - First overcurrent protection level ______________________________________________________12

3.3 - I>> (2F51) - Second overcurrent protection level ___________________________________________________13

3.4 - IH (3F51) - Third overcurrent protection level ______________________________________________________14

3.4.2 –Automatic doubling of Overcurrent thresholds on current inrush_____________________________________14

3.5 - Io> (1F51N) - First Earth Fault protection level _____________________________________________________15

3.6 - Io>> (2F51N) - Second Earth Fault protection level __________________________________________________15

3.7 - IoH (3F51N) - Third Earth Fault protection level _____________________________________________________16

3.8 - BF (F51BF) - Breaker Failure____________________________________________________________________16

3.9 - BC (I2/I1) –Broken Conductor __________________________________________________________________17

3.10 –F86 –Lock-out relay_________________________________________________________________________17

3.11 –S Sel –Setting Selection _____________________________________________________________________18

3.12 - I.R.F. - Internal Relay Failure __________________________________________________________________18

3.13 - Osc - Oscillographic Recording _________________________________________________________________19

3.14 - CBMng –Close Breaker Manage ________________________________________________________________19

3.15 - Comm –Communication Parameters ____________________________________________________________20

3.16 - LCD –Display and Buzzer operation _____________________________________________________________20

4. Logic Blocking of Functions _________________________________________________________________________21

4.1 - Blocking outputs _____________________________________________________________________________21

4.2 –Blocking Inputs______________________________________________________________________________21

5. Output Relays ___________________________________________________________________________________21

6. Digital Inputs____________________________________________________________________________________22

7. Self-diagnostic___________________________________________________________________________________22

8. Relay Management _______________________________________________________________________________23

9. Signalizations ___________________________________________________________________________________24

10. Keyboard Buttons _______________________________________________________________________________24

11. Serial Communication Port ________________________________________________________________________25

11.1 - Main RS485 Serial Communication Port __________________________________________________________25

11.2 - Communication Port on Front Face Panel _________________________________________________________26

12. Menu and Variables ______________________________________________________________________________27

12.1 - Real Time Measurements _____________________________________________________________________27

12.2 - Meas (Instantaneous Measurements) ____________________________________________________________27

12.3 - Counter (Operation Counters) __________________________________________________________________28

12.4 - LastTrip (Event Recording) ____________________________________________________________________28

12.5 - R/W Set (Programming / Reading the Relay Settings) _______________________________________________29

12.5.1 - CommAdd (Communication Address)_________________________________________________________29

12.5.2 - Time/Date (Time/Date) ___________________________________________________________________29

12.5.3 - RatedVal (Rated Input Values) ______________________________________________________________29

12.5.4 - Function (Functions)______________________________________________________________________30

12.6 - RelayCfg (Relay Configuration) _________________________________________________________________32

12.7 - Commands ________________________________________________________________________________32

12.8 - Info&Ver (Firmware - Info&Version) _____________________________________________________________32

13. Keyboard Operational Diagram _____________________________________________________________________33

14. Password ______________________________________________________________________________________34

14.1 - MS-Com Password___________________________________________________________________________34

15. Maintenance ___________________________________________________________________________________34

16. Power Frequency Insulation Test ____________________________________________________________________34

17. Connection Diagram _____________________________________________________________________________35

18. Overall Dimensions ______________________________________________________________________________35

19. Direction For Pcb's Draw-Out And Plug-In _____________________________________________________________36

19.1 - Draw-Out _________________________________________________________________________________36

19.2 - Plug-In ___________________________________________________________________________________36

20. Electrical Characteristics __________________________________________________________________________37

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

3

of

37

1. General Utilization and Commissioning Directions

Always make reference to the specific description of the product and to the Manufacturer's instruction.

Carefully observe the following warnings.

1.1 - Storage and Transportation

must comply with the environmental conditions stated on the product's instruction or by the applicable IEC

standards.

1.2 - Installation

must be properly made and in compliance with the operational ambient conditions stated by the Manufacturer.

1.3 - Electrical Connection

must be made strictly according to the wiring diagram supplied with the Product, to its electrical

characteristics and in compliance with the applicable standards particularly with reference to human safety.

1.4 - Measuring Inputs and Power Supply

carefully check that the value of input quantities and power supply voltage are proper and within the permissible

variation limits.

1.5 - Outputs Loading

must be compatible with their declared performance.

1.6 - Protection Earthing

When earthing is required, carefully check its effectiveness.

1.7 - Setting and Calibration

Carefully check the proper setting of the different functions according to the configuration of the protected

system, the safety regulations and the co-ordination with other equipment.

1.8 - Safety Protection

Carefully check that all safety means are correctly mounted, apply proper seals where required and periodically

check their integrity.

1.9 - Handling

Notwithstanding the highest practicable protection means used in designing M.S. electronic circuits, the

electronic components and semiconductor devices mounted on the modules can be seriously damaged by

electrostatic voltage discharge which can be experienced when handling the modules.

The damage caused by electrostatic discharge may not be immediately apparent, but the design reliability and

the long life of the product will have been reduced. The electronic circuits reduced by M.S. are completely safe

from electrostatic discharge (8 KV IEC 255.22.2) when housed in their case; withdrawing the modules without

proper cautions expose them to the risk of damage.

a.

Before removing a module, ensure that you are at the same electrostatic potential as the equipment by

touching the case.

b.

Handle the module by its front-plate, frame, or edges of the printed circuit board. Avoid touching the

electronic components, printed circuit tracks or connectors.

c.

Do not pass the module to any person without first ensuring that you are both at the same electrostatic

potential. Shaking hands achieves equipotential.

d.

Place the module on an antistatic surface, or on a conducting surface which is at the same potential as

yourself.

e.

Store or transport the module in a conductive bag.

More information on safe working procedures for all electronic equipment can be found in BS5783

and IEC 147-OF.

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

4

of

37

1.10 - Maintenance

Make reference to the instruction manual of the Manufacturer; maintenance must be carried-out by specially

trained people and in strict conformity with the safety regulations.

1.11 - Waste Disposal of Electrical & Electronic Equipment

(Applicable throughout the European Union and other European countries with separate collection program).

This product should not be treated as household waste when you wish dispose of it. Instead, it should be handed

over to an applicable collection point for the recycling of electrical and electronic equipment.

By ensuring this product is disposed of correctly, you will help prevent potential negative consequence to the

environment and human health, which could otherwise be caused by inappropriate disposal of this product. The

recycling of materials will help to conserve natural resource.

1.12 - Fault detection and repair

Internal calibrations and components should not be altered or replaced.

For repair, please ask the Manufacturer or its authorised Dealers.

Misapplication of the above warnings and instruction relieves the Manufacturer of any liability.

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

5

of

37

2. General Characteristics

The MC is a very innovative and versatile line of Protective Relays which takes advantage of the long and

successful experience coming from the M-Line.

The main features of the MC-Line relays are:

Compact draw-out execution for Flush Mounting or for assembly in 19” 3U chassis for 19” Rack systems.

User friendly front face with 2x8 characters LCD Display, four signal Leds, four keys for complete local

management and 9-pin socket for local RS232 serial communication.

Four user programmable Output Relays. On request one of the Output Relays can be replaced by a Can Bus

port for control of additional I/O modules.

Three optoisolated self-powered Digital Inputs.

RS485 communication port (independent from the RS232 port on front panel)

Totally draw-out execution with automatic C.T. shorting device.

Input currents are supplied to 3 current transformers: measuring phase currents.

An additional internal CT directly measures the residual (Zero Sequence) current of the three inputs.

Current inputs can be 1 or 5A: selection between 1A or 5A is made by movable jumpers provided on the Relay

card. (See Fig 1)

The Measuring Ranges of the different inputs

respectively are:

Phase Currents

:

(0.1-40) In

Residual Current

:

(0.01-10) In

Make electric connection in conformity with the

diagram reported on relay's enclosure.

Check that input currents are same as reported on

the diagram and on the test certificate.

2.1 - Power Supply

The auxiliary power is supplied by a built-in module fully isolated a self-protected.

The relay can be fitted with two different types of power supply:

Type 1

24V(-20%) / 110V(+15%) a.c.

24V(-20%) / 125V(+20%) d.c.

Type 2

80V(-20%) / 220V(+15%) a.c.

90V(-20%) / 250V(+20%) d.c.

Before energizing the unit check that supply voltage is within the allowed limits.

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

6

of

37

2.2 - Operation and Algorithms

2.2.1 - Reference Input Values

Display

Description

Setting Range

Step

Unit

I1

100

A

Rated Primary current of phase C.T.

1

-

9999

1

A

I2

5

A

Rated Secondary current of phase C.T.

1

-

5

1/5

A

In

100

A

Reference main primary current of the relay

1

-

9999

1

A

StIn

0

H

Start time “In” for main current

0

-

23

1

H

InL

1

A

Relay second primary current low

1

-

9999

1

A

StInLH

0

H

Start time for InL second current

0

-

23

1

H

Freq

50

Hz

System rated frequency

50

-

60

10

Hz

TW

60

sec

Warming-up time constant for Thermal Image

60

-

3600

1

sec

Ib

105

%In

Maximum admissible continuous overload for Thermal Image

50

-

130

0.1

%In

2.2.2 - Input quantities

2.2.2.1 - Mains Frequency (Freq)

The relay can operate either in 50Hz or 60Hz systems.

The rated Mains Frequency “Freq” must be set accordingly.

2.2.2.2 - Phase Current inputs (I1)

The relay directly displays the r.m.s. value of the Phase Currents “IA”, “IB”, “IC” flowing in the Primary of

the input Current Transformers and refers all its measurements to that value.

To make the relay properly working with any C.T., when programming the relay settings, input the value

“I1” of the primary current of the phase C.Ts

The measure is not displayed below

:

< 5% In

2.2.2.3 –Reference Primary Current

To have a better accuracy [In] case of use of CT with bigger ratio, a further setting is foreseen.

This setting better define the rated current of the feeder regardless of the CT ratio.

To get a double setting range, two values of reference primary current are foreseen:

- MAIN

- SECOND

It is possible to switch from main to second setting via digital input or by means of an internal timer ([StIn],

[StInLH]).

2.2.2.4 –Start time “In”

The time is indicated in Hours, every day at this time the relay automatically set the reference primary

current to main.

2.2.2.5 –Start time “IL”

The time is indicated in Hours, every day at this time the relay automatically set the reference primary

current to second.

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

7

of

37

rs

atTKB

1

Is

I

A

t(I) +••

+

−

=α

2.2.2.4 - Algorithm of the time current curves

The Time Current Curves are generally calculated with the following equation:

(1)

where:

t(I) = Actual trip time delay when the input current equals “I”

I = Maximum of the three input currents.

Is = Set minimum pick-up level

K =

Ts= Set time delay: t(I) = Tswhen

tr = Operation time of the output relay on pick-up (7ms).

The parameters “A” and “a” have different values for the different Time Current Curves.

Curve Name

Curve Identifier

A

B

a

IEC A Inverse

A

0.14

0

0.02

IEC B Very Inverse

B

13.5

0

1

IEC C Extremely Inverse

C

80

0

2

IEEE Moderate Inverse

MI

0.0104

0.0226

0.02

IEEE Short Inverse

SI

0.00342

0.00262

0.02

IEEE Very Inverse

VI

3.88

0.0963

2

IEEE Inverse

I

5.95

0.18

2

IEEE Extremely Inverse

EI

5.67

0.0352

2

The maximum measuring current is “40xIn” for phase elements and “10xOn” for the neutral

element.

1

a110A−

−

10

II

s

=

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

8

of

37

2.2.3 - Time Current Curves IEC (TU1029 Rev.0)

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

9

of

37

2.2.4 - Time Current Curves IEEE (TU1028 Rev.0)

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

10

of

37

3. Functions and Settings (Function)

3.1 - T> (F49) - Thermal Image protection level

FuncEnab

→

Enable

[Disable / Enable]

Options

→

No Param

No Parameters

TripLev

→

Tal

50

%Tb

(50 110)

step

1

%Tb

→

Tst

100

%Tb

(10 100)

step

1

%Tb

Timers

→

No Param

No Parameters

Description of variables

FuncEnab

:

If disable the function is disactivated.

Tal

:

Thermal prealarm temperature.

Tst

:

Reset level.

Trip when

:

The temperature exceeded for time “tI>”.

When the function is tripped

:

Signalization

=

Led “Trip” is illuminated

Last Trip

=

Is recorded

Led reset when

:

Return in normal condition

Warming-up is computed proportionally to the square of the largest phase current “I”.

-Allowed overloading time (See Curve)

The trip time delay “t”of the thermal element, depends on the warming-up time constant

“tw”, on the previous thermal status (Ip/In)2, on the admissible continuous overload (Ib) and, of

course, on the actual load (I)

tw

=

Warming-up time constant

(60-3600) s.

I

=

Largest of the three phase currents

Ip

=

Preheating current: Steady-State Current corresponding to the thermal status

existing at the moment when the current is increased to the overload value “I”

Ib

=

Continuously admissible current

(50-130) %In, step 0.1%In

In

=

Rated primary current of phase C.Ts

n

=

Natural logarithm

Reset takes please when the simulated temperature drops below the programming level [Tst].

An alarm signal is issued when the computed warming exceeds the set percentage “Tal” of the Full

Load temperature “Tb”.

:where

(Ib/In)(I/In) (Ip/In)(I/In)

twt22

22

−

−

= n

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

11

of

37

3.1.2 - Thermal Image Curves (TU0445 Rev.0)

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

12

of

37

3.2. - I> (1F51) - First overcurrent protection level

FuncEnab

→

Enable

[Disable / Enable]

Options

→

TCC

D

[D / A / B / C / MI / VI / I / EI / / SI]

→

BI

Disable

[Disable / Enable]

→

Trg

Enable

[Disable / Enable]

TripLev

→

I>

0.5

In

(0.10 4.00)

step

0.01

In

Timers

→

tI>

2.00

s

(0.05 60.00)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

TCC

:

Time current curves

D

=

Independent Definite Time

A

=

IEC A Inverse

B

=

IEC B Very Inverse

C

=

IEC C Extremely Inverse

MI

=

IEEE Moderate Inverse Curve

VI

=

IEEE Very Inverse Curve

I

=

IEEE Inverse Curve

EI

=

IEEE Extremely Inverse Curve

SI

=

IEEE Short Inverse Curve

BI

:

Operation controlled by Blocking Digital Input

Trg

:

Function operation triggers the oscillographic wave form capture

(see § Oscillographic Recording)

I>

:

Minimum phase current pick-up level (limited to 40 times In)

tI>

:

Trip time delay

Trip when

:

The current trip level is exceeded for time “tI>”.

When the function is tripped

:

Signalization

=

Led “Trip” is illuminated

Last Trip

=

Is recorded

Function reset when

:

The current drop below 95% I>.

Led reset when

:

push-button is pressed

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

13

of

37

3.3 - I>> (2F51) - Second overcurrent protection level

FuncEnab

→

Enable

[Disable / Enable]

Options

→

BI

Disable

[Disable / Enable]

→

2xI

Disable

[Disable / Enable]

→

Trg

Enable

[Disable / Enable]

TripLev

→

I>>

2.00

In

(0.50 40.00)

step

0.01

In

Timers

→

tI>>

1.00

s

(0.05 60.00)

step

0.01

s

→

t2xI

0.10

s

(0.02 9.99)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

BI

:

Operation controlled by Blocking Digital Input

2xI

:

Automatic threshold doubling on inrush

Trg

:

Function operation triggers the oscillographic wave form capture

(see § Oscillographic Recording)

I>>

:

Minimum phase current pick-up level (limited to 40 times In)

tI>>

:

Trip time delay

t2xI

:

Trip time delay

Trip when

:

The current trip level is exceeded for time “tI>>”.

When the function is tripped

:

Signalization

=

Led “Trip” is illuminated

Last Trip

=

Is recorded

Function reset when

:

The current drop below 95% I>>.

Led reset when

:

push-button is pressed

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

14

of

37

3.4 - IH (3F51) - Third overcurrent protection level

FuncEnab

→

Enable

[Disable / Enable]

Options

→

BI

Disable

[Disable / Enable]

→

2xI

Enable

[Disable / Enable]

→

Trg

Enable

[Disable / Enable]

TripLev

→

IH

5.00

In

(0.50 40.00)

step

0.01

In

Timers

→

tIH

0.05

s

(0.05 60.00)

step

0.01

s

→

t2xI

0.10

s

(0.02 9.99)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

BI

:

Operation controlled by Blocking Digital Input

2xI

:

Automatic threshold doubling on inrush

Trg

:

Function operation triggers the oscillographic wave form capture

(see § Oscillographic Recording)

IH

:

Minimum phase current pick-up level (limited to 40 times In)

t2xI

:

Trip time delay

tIH

:

Trip time delay

Trip when

:

The current trip level is exceeded for time “tIH”.

When the function is tripped

:

Signalization

=

Led “Trip” is illuminated

Last Trip

=

Is recorded

Function reset when

:

The current drop below 95% IH.

Led reset when

:

push-button is pressed

3.4.2 –Automatic doubling of Overcurrent thresholds on current inrush

For some of the phase Overcurrent functions (I>>, IH) it is possible to have the set trip level [Is] automatically

doubled when strong inrush current is detected.

If at circuit Breaker closure (i.e. when the input current rises from zero to a minimum measurable value) the

current increases from 0 to 1.5 times the rated value [In] in less than 60ms, the set minimum pick-up level

[Is] is dynamically doubled ([Is]→[2Is]) and keeps this value until the input current drops below 1.25xIn or

the set time [t2xI] has elapsed.

This functionality is very useful to avoid spurious tripping of the instantaneous or short-time delayed

Overcurrent elements that could be experienced at switch-on of reactive loads like Transformer or Capacitors.

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

15

of

37

3.5 - Io> (1F51N) - First Earth Fault protection level

FuncEnab

→

Enable

[Disable / Enable]

Options

→

TCC

D

[D / A / B / C / I / VI / EI / MI / SI]

→

BI

Disable

[Disable / Enable]

→

Trg

Enable

[Disable / Enable]

TripLev

→

Io>

0.10

Ion

(0.01 4)

step

0.01

Ion

Timers

→

tIo>

2.00

s

(0.05 60)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

TCC

:

Time current curves

D

=

Independent Definite Time

A

=

IEC A Inverse

B

=

IEC B Very Inverse

C

=

IEC C Extremely Inverse

MI

=

IEEE Moderate Inverse Curve

VI

=

IEEE Very Inverse Curve

I

=

IEEE Inverse Curve

EI

=

IEEE Extremely Inverse Curve

SI

=

IEEE Short Inverse Curve

BI

:

Operation controlled by Blocking Digital Input

Trg

:

Function operation triggers the oscillographic wave form capture

(see § Oscillographic Recording)

Io>

:

Minimum Zero Sequence Residual Current Pick-up level

tIo>

:

Trip time delay

Trip when

:

The current trip level is exceeded for time “tIo>”.

When the function is tripped

:

Signalization

=

Led “Trip” is illuminated

Last Trip

=

Is recorded

Function reset when

:

The current drop below 95% Io>.

Led reset when

:

push-button is pressed

3.6 - Io>> (2F51N) - Second Earth Fault protection level

FuncEnab

→

Enable

[Disable / Enable]

Options

→

BI

Disable

[Disable / Enable]

→

Trg

Enable

[Disable / Enable]

TripLev

→

Io>>

0.50

Ion

(0.01 9.99)

step

0.01

Ion

Timers

→

tIo>>

1.00

s

(0.05 60)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

BI

:

Operation controlled by Blocking Digital Input

Trg

:

Function operation triggers the oscillographic wave form capture

(see § Oscillographic Recording)

Io>>

:

Minimum Zero Sequence Residual Current Pick-up level

tIo>>

:

Trip time delay

Trip when

:

The current trip level is exceeded for time “tIo>>”.

When the function is tripped

:

Signalization

=

Led “Trip” is illuminated

Last Trip

=

Is recorded

Function reset when

:

The current drop below 95% Io>>.

Led reset when

:

push-button is pressed

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

16

of

37

3.7 - IoH (3F51N) - Third Earth Fault protection level

FuncEnab

→

Enable

[Disable / Enable]

Options

→

BI

Disable

[Disable / Enable]

→

Trg

Enable

[Disable / Enable]

TripLev

→

IoH

2.00

Ion

(0.01 9.99)

step

0.01

Ion

Timers

→

tIoH

0.10

s

(0.05 60)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

BI

:

Operation controlled by Blocking Digital Input

Trg

:

Function operation triggers the oscillographic wave form capture

(see § Oscillographic Recording)

IoH

:

Minimum Zero Sequence Residual Current Pick-up level

tIoH

:

Trip time delay

Trip when

:

The current trip level is exceeded for time “tIoH”.

When the function is tripped

:

Signalization

=

Led “Trip” is illuminated

Last Trip

=

Is recorded

Function reset when

:

The current drop below 95% IoH.

Led reset when

:

Push-button is pressed

3.8 - BF (F51BF) - Breaker Failure

FuncEnab

→

Enable

[Disable / Enable]

Options

→

TrR

Relay1

Relay1 –Relay2 –Relay3 –Relay4

TripLev

→

No Param

No Parameters

Timers

→

tBF

0.2

s

(0.05 0.75)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

TrR

:

Output relay programmed for trip command to the Circuit Breaker

tBF

:

Trip time delay

Operation: If after the time “tBF” from pick-up of the programmed relay “TrR” the current measured still

exceeds 5%In, the output relay associated to the “BF” function is operated (relay another than TrR).

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

17

of

37

3.9 - BC (I2/I1) –Broken Conductor

FuncEnab

→

Enable

[Disable / Enable]

Options

→

Trg

Disable

[Disable / Enable]

TripLev

→

BC>

10.00

%

(10 100)

step

1

%

Timers

→

tBC>

0.20

s

(0.05 60.00)

step

0.01

s

Description of variables

FuncEnab

:

If disable the function is disactivated

BC>

:

Ratio between inverse sequence current and direct sequence current.

tBC>

:

Trip time delay

Operation: Minimum operation level >5%In

The function of Broken Conductor is based on the calculation of the ratio of negative and positive sequence

current, if this value exceeds the set level [BC>] a relay is energized.

When a broken conductor is big experienced, a negative sequence current appears; measuring not only I2

but computing the ratio I2/I1 gives a much more accuracy at the low values.

3.10 –F86 –Lock-out relay

FuncEnab

→

Enable

[Disable / Enable]

Options

→

1I>

Enable

[Disable / Enable]

→

2I>

Enable

[Disable / Enable]

→

IH

Enable

[Disable / Enable]

→

1Io

Enable

[Disable / Enable]

→

2Io

Enable

[Disable / Enable]

→

IoH

Enable

[Disable / Enable]

→

T>

Enable

[Disable / Enable]

→

BC

Enable

[Disable / Enable]

→

IRF

Enable

[Disable / Enable]

TripLev

→

No Param

No Parameters

Timers

→

No Param

No Parameters

Description of variables

FuncEnab

:

If disable the function is disactivated

1I>

:

First overcurrent element

2I>

:

Second overcurrent element

IH

:

Third overcurrent element

1Io

:

First earth fault element

2Io

:

Second earth fault element

IoH

:

Third earth fault element

T>

:

Thermal image element

BC

:

Broken Conductor element

IRF

:

Internal Relay Fault

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

18

of

37

3.11 –S Sel –Setting Selection

Selecting the mode of operation of the change value of rated current.

FuncEnab

→

Disable

[Disable / Enable]

Options

→

Md

HourSE

[HourSE / InputSE]

TripLev

→

No Param

No Parameters

Timers

→

No Param

No Parameters

Description of variables

FuncEnab

:

If disable the function is disactivated

Md

HourSE

=

Change “In” to “InL” setting based on time slot

(For settings see § RatedVal. parameters [StIn] and [StInLH]).

InputSE

=

Change “In” to “InL” setting based on Digital input D2

(see § Digital Inputs)

3.12 - I.R.F. - Internal Relay Failure

FuncEnab

→

No Param

No Parameters

Options

→

Opl

NoTrip

[NoTrip / Trip]

TripLev

→

No Param

No Parameters

Timers

→

No Param

No Parameters

Description of variables

Opl

:

The variable “Opl” can be programmed to trip the output relays same as the other protection

functions (Opl = TRIP), or to only operate the “IRF” signal led without tripping the output

relays (Opl = NoTRIP).

Trip when

:

an internal fault in the relay is detected (see Diagnostics)

When the function is tripped

:

Signalization

=

Led “PWR/I.R.F.” blink

Last Trip

=

Is recorded

Function reset when

:

it returns to normal operation

Led reset when

:

Push-button is pressed

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

19

of

37

3.13 - Osc - Oscillographic Recording

FuncEnab

→

Enable

[Disable / Enable]

Options

→

Trg

Trip

[Disable / Start / Trip / Ext.Inp.]

TripLev

→

No Param

No Parameters

Timers

→

tPre

0.3

s

(0.1 0.5)

step

0.1

s

→

tPost

0.3

s

(0.1 1.5)

step

0.1

s

Description of variables

FuncEnab

:

If disable the function is disactivated

Trg

:

Disab

=

Function Disable (no recording)

Start.

=

Trigger on time start of protection functions

Trip

=

Trigger on trip (time delay end) of protection functions

Ext.Inp.

=

Trigger from the Digital Input D3

tPre

:

Recording time before Trigger

tPost

:

Recording time after Trigger

When the option “Start” or “Trip” is selected:

The oscillographic recording is started respectively by the “Time Start” or by the “Time End” of any of the

functions that have been programmed to Trigger the Wave Form Capture (I>, I>>, IH, Io>, Io>>, IoH, BC).

The “Osc” Function includes the wave Form Capture of the input quantities (IA, IB, IC, Io) and can totally

store a record of 3 seconds.

The number of events recorded depends on the duration of each individual recording (tPre + tPost),

up to a maximum of 10 (0.3 sec).

Any new event beyond the 3 sec capacity of the memory, cancel and overwrites the former records (FIFO

Memory).

3.14 - CBMng –Close Breaker Manage

FuncEnab

→

No Param

No Parameters

Options

→

No Param

No Parameters

TripLev

→

No Param

No Parameters

Timers

→

tcmd

0.10

s

(0.10 5.00)

step

0.1

s

→

tC

0.10

s

(0.10 5.00)

step

0.1

s

Description of variables

tcmd

:

C/B closing output command duration

tC

:

Maximum admissible delay for detection of status signal after C/B operation.

MC30-BC

Doc. N° MO-0365-ING

Copyright 2008

FW

980.09.01.X

Date

15.06.2022

Rev.

1

Pag.

20

of

37

3.15 - Comm –Communication Parameters

FuncEnab

→

No Param

No Parameters

Options

→

LBd

9600

[9600 / 19200 / 38400 / 57600]

→

RBd

9600

[9600 / 19200]

→

Mod

8,n,1

[8,n,1 / 8,o,1 / 8,e,1]

→

RPr

Modbus

[Iec103 / Modbus]

TripLev

→

No Param

No Parameters

Timers

→

No Param

No Parameters

Description of variables

LBd

:

Local Baud Rate (Front panel RS232 communication speed)

RBd

:

Remote Baud Rate

(Rear panel terminal blocks RS485 communication speed)

Mod

:

Remote mode (communication parameters)

Note: Any change of this setting becomes valid at the next power on

RPr

:

Remote Protocol

3.16 - LCD –Display and Buzzer operation

FuncEnab

→

No Param

No Parameters

Options

→

Key

BeepON

[BeepOFF / BeepON]

→

BkL

Auto

[Auto / On]

TripLev

→

No Param

No Parameters

Timers

→

No Param

No Parameters

Description of variables

Key

:

Buzzer “Beep” on operation of Keyboard buttons.

BkL

:

LCD Backlight continuously “ON” or switched-on Automatically on operation of

Keyboard buttons.

Table of contents

Other MICROELETTRICA Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Noctua

Noctua NF-A9 14 PWM Series user manual

Cypress Semiconductor

Cypress Semiconductor CY7C1440AV33 Specification sheet

NTI

NTI DVI-EDID-EMLTR-LC instruction manual

Texas Instruments

Texas Instruments CC2533 Hardware user's guide

NXP Semiconductors

NXP Semiconductors OM13488 user manual

Quanmax

Quanmax QDSP-1100 Series user guide

Digital Equipment

Digital Equipment VAXft owner's manual

NEC

NEC N8103-179 Notes on Use

Toshiba

Toshiba WN4301A-LF-JT user manual

Renesas

Renesas Converter Board R0E436049CFJ10 user manual

Omega Engineering

Omega Engineering USB-4761 user guide

TRENDnet

TRENDnet TEW-621PC - 300Mbps Wireless N PC Card... Specifications